Trans. Nonferrous Met. Soc. China 22(2012) 2960-2964

Microstructure and mechanical properties of Ti-45Al-5.5(Cr,Nb,B,Ta) alloy sintered at different SPS temperatures

XIAO Shu-long1,2, XU Li-juan1, YU Hong-bao3, TIAN Jing1, CHEN Yu-yong1,2

1. School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China;

2. National Key Laboratory for Precision Hot Processing of Metals, Harbin Institute of Technology, Harbin 150001, China;

3. School of Materials Science and Engineering, Northwestern Polytechnical University, Xi’an 710072, China

Received 9 July 2012; accepted 9 October 2012

Abstract: TiAl alloy bulk samples with the composition of Ti-45Al-5.5(Cr,Nb,B,Ta) (mole fraction, %) were prepared by high energy mechanical milling and spark plasma sintering (SPS) and then heat treatment. The microstructure and mechanical properties after heat treatment of TiAl alloy prepared by SPS at different temperatures were studied. The results showed that the morphology of high energy mechanically milled powder was irregular and the average grain size was about decades micrometers. X-ray diffraction analysis showed that the mechanically milled powder was composed of two phases of TiAl and Ti3Al. The main phase of TiAl and few phases of Ti3Al and TiB2 were observed in the SPS bulk samples of Ti-45Al-5.5(Cr,Nb,B,Ta) alloy. For samples sintered at 900 °C and 1000 °C, the microstructure was duplex structure with some fine equiaxed gamma grains and thin needly TiB2 phases. With the SPS temperature increasing from 900 °C to 1000 °C, the micro-hardness was changed little, the compression strength increased from 1812 MPa to 2275 MPa and the compression ratio increased from 22.66% to 25.59%. The fractography results showed that the compression fracture transform of the SPS Ti-45Al-5.5(Cr,Nb,B,Ta) alloy was rgranular rupture.

Key words: TiAl alloy; powder metallurgy; spark plasma sintering (SPS); heat treatment

1 Introduction

TiAl alloys are attractive engineering materials in the field of aerospace due to their properties of low density, high specific strength and high strength at elevated temperatures [1-3]. However, the practical engine applications of TiAl alloys are limited due to their poor room temperature ductility and formability.

Powder metallurgy (PM) is a favorable process for synthesizing ultrafine grained TiAl alloys and forming near-net shaped components of TiAl alloys, which could overcome the above problems. Spark plasma sintering (SPS) is attractive among multiple PM processes [4,5]. Through SPS the higher heat efficiency could be gained so that the good quality sintered bulks could be prepared through compacting and sintering powder [6,7]. There is an ascending interest in the investigation of preparing TiAl alloys by spark plasma sintering (SPS) due to its specific characters [8-10].

In addition, the application of gamma TiAl alloys requires specific properties in different fields, for example, in aerospace fields excellent properties including fatigue, toughness, creep, etc were needed. Alloying is a primary means to obtain the TiAl alloys with required properties [11].

In this work, TiAl based alloy with alloying elements of Nb, Cr, B and Ta was synthesized by the PM process that combined mechanical milling and SPS.

2 Experimental

The mechanically alloyed TiAl based alloy powder was produced by ball milling a mixture of powders of Ti (99.9% purity, <150 μm), Al (99.9% purity, <70 μm), Cr (99% purity, average particle size of 50 μm), Nb (99.8% purity, average particle size of 50 μm), B (99.999% purity, average particle size of 0.6μm) and Ta (99.98% purity, average particle size of 50μm). The powders were fully mixed with composition of Ti-45Al-5.5(Cr,Nb,B, Ta) (mole fraction, %).

The PM100 high energy planetary ball mill was used for milling TiAl based alloy powder. The mechanical milling was done with a stainless steel vial and 75 stainless steel balls with diameter of 12.5 mm in high purity argon atmosphere, and 100 g of TiAl based alloy powder mixture by adding 0.63% stearic acid as a process control agent in one vial. The rotation speed of disc was 100-300 r/min, and that of vial was 200-600 r/min. The mass ratio of ball to powder was 6:1. At first the powders were milled with a low rotation speed of 100 r/min to mix the powders thoroughly, and then the powders were mechanically milled under high purity argon atmosphere with a rotation speed of 300 r/min for 6 h.

The milled TiAl based alloy powder was sintered under pressure of 50 MPa at 900 and 1000 °C by DR. Sinter 1050 SPS furnace. The holding time at the sintering temperature was 5 min. The size of the sintered samples was d30 mm×(5-6) mm. The sintered samples were heat treated at 1360 °C for 0.5 h. The Vickers hardness was measured by a HV-5 Vickers tester with a load of 49 N for 30 s. Circular specimens with size of d3 mm×5 mm were machined from the sintered samples. The Instron 5500 testing machine was used for compressive tests, and the strain rate was 0.5 mm/s.

3 Results and discussion

3.1 Microstructure and phase composition

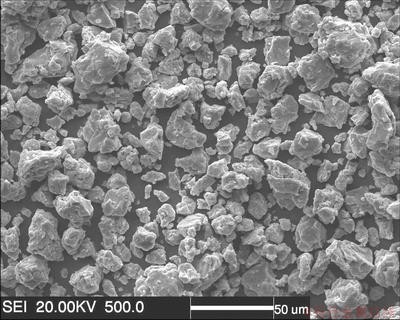

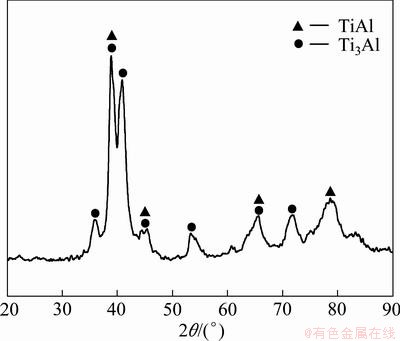

Figure 1 shows the SEM image of the high energy mechanically milled Ti-45Al-5.5(Cr,Nb,B,Ta) powder. The grains show unequal shape and the size of grains ranges from several micrometer to scores of micrometers. Figure 2 shows the XRD pattern of the high energy mechanically milled Ti-45Al-5.5(Cr,Nb,B,Ta) powder. From the XRD pattern, it can be found that the Ti3Al and TiAl are the major phases, which shows that after 0.5 h high energy mechanical milling the powders have almost reacted each other. In addition, the intensity of peaks of XRD pattern indicates that the amount of Ti3Al phase is more than that of TiAl phase. Both the peaks of two phases are broader and exhibit shoulders, which indicate the trend of transiting of Ti3Al and TiAl phases to amorphous and decreasing of grain size.

Fig. 1 SEM image of high energy mechanically milled Ti-45Al-5.5(Cr,Nb,B,Ta) powder

Fig. 2 XRD pattern of Ti-45Al-5.5(Cr, Nb, B, Ta) powder after high energy mechanical milling

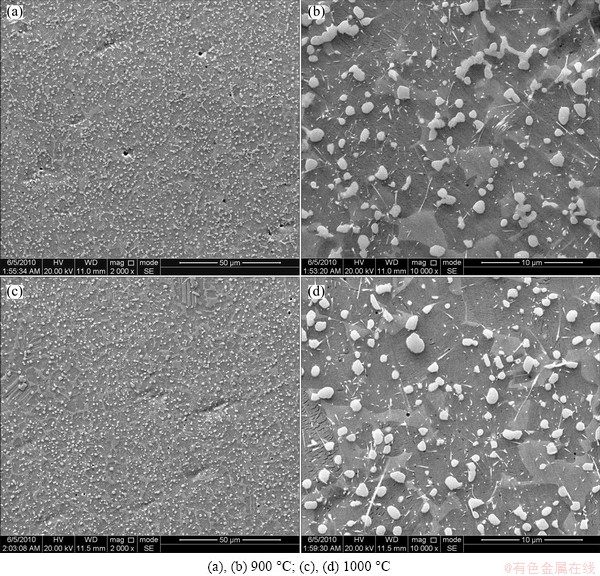

Figure 3 shows the SEM images of the bulk samples sintered and consolidated by SPS of Ti-45Al-5.5(Cr,Nb, B,Ta) powder at different temperatures after heat treatment at 1360 °C for 0.5 h. After heat treatment the microstructure is not the equiaxed near gamma grain with some TiB2 phases as the microstructure without heat treatment as referred in Ref. [8], but the duplex structure with some fine equiaxed gamma grains and thin needle TiB2 phases. From Fig. 3, it can also be found that the character of duplex structure is obvious in the microstructure of bulk samples SPSed at 1000 °C than that at 900 °C, but the grain size changed a little. The samples SPSed at both the temperatures exhibit compact structure with few pores.

At both the SPS temperature of 900 °C and 1000 °C the full lamellar is not found, which suggests that the Tα (α transition temperature) of this kind of TiAl alloy may be higher than the heat treatment temperature of 1360°, h otherg TiAl based alloy powdern, or the holding time is not enough.

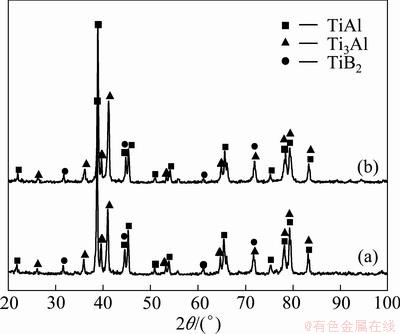

Figure 4 shows the XRD patterns of the heat treated bulk samples prepared by SPS of Ti-45Al-5.5(Cr,Nb,B, Ta) powder at SPS temperatures of 900 °C and 1000 °C. The clear diffraction peaks suggest that the sintered samples are both composed of TiAl and Ti3Al as the major phase, with a minor amount of TiB2 phase. The reason is that during the process of SPS and heat treatment the milled powder reacted completely.

XIAO et al [8] indicated that with the SPS temperature increasing the peak intensity of TiAl phase decreased, and that of Ti3Al and TiB2 phases increased in the sintered bulk TiAl alloy sample before heat treatment. From Fig. 4 it could be found that after heat treatment more TiAl phases transferred to Ti3Al phases. Due to heat treatment at temperature of α+γ phase area, more α2/γ lamellar columns appeared, so that the microstructure of TiAl alloy prepared at higher SPS temperature is with much character of duplex structure, which is similar to the results from microstructure observation.

Fig. 3 SEM images of Ti-45Al-5.5(Cr,Nb,B,Ta) alloy sintered at different temperatures

Fig. 4 XRD patterns of Ti-45Al-5.5(Cr,Nb,B,Ta) alloy sintered at 900 °C (a) and 1000 °C (b)

3.2 Mechanical properties

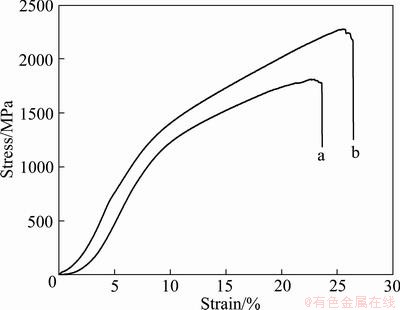

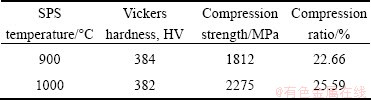

Figure 5 shows the compression stress—strain curves of the SPSed bulk Ti-45Al-5.5(Cr,Nb,B,Ta) alloy samples after heat treatment. The typical mechanical properties of the SPSed bulk TiAl samples after heat treatment are shown in Table 1. The results show that the two kinds of samples exhibited excellent mechanical properties. With the SPS temperature increasing from 900 °C to 1000 °C the micro-hardness changed little, but the compression strength increased from 1812 MPa to 2275 MPa and the compression ratio increased from 22.66% to 25.59%. The reasons are that higher sintering temperature leads to less pore, and after heat treatment the sample sintered at 1000 °C with more duplex structure has better mechanical properties than the sample sintered at 900 °C with more gamma structure.

Fig. 5 Compression stress—strain curves of Ti-45Al- 5.5(Cr,Nb,B,Ta) alloy sintered at temperatures of 900 °C (a) and 1000 °C (b)

Table 1 Properties of Ti-45Al-5.5(Cr, Nb, B, Ta) alloy sintered at different temperatures

Compared with the compression properties of TiAl alloy before heat treatment, the compression strength of bulk TiAl alloy prepared by SPS at 900 °C and 1000 °C decreases and the compression ratio increases. It is because after sintering at higher temperature and heat treatment the grain size increases, which leads to the compression strength decrease based on the Hall-Petch relationship between the strength and grain size.

The TiAl alloy samples sintered at 1000 °C exhibited better compression properties than that sintered at 900 °C. After sintering at 1000 °C, the grain size increased, which led to the decrease of properties. But the density of the alloy increased and the interparticle atomic bonding increased. The effect of density and bonding increasing was more significant than the effect of grain size coarsening, which is the cause of the better compression properties of the sample sintered at 1000 °C than that at 900 °C.

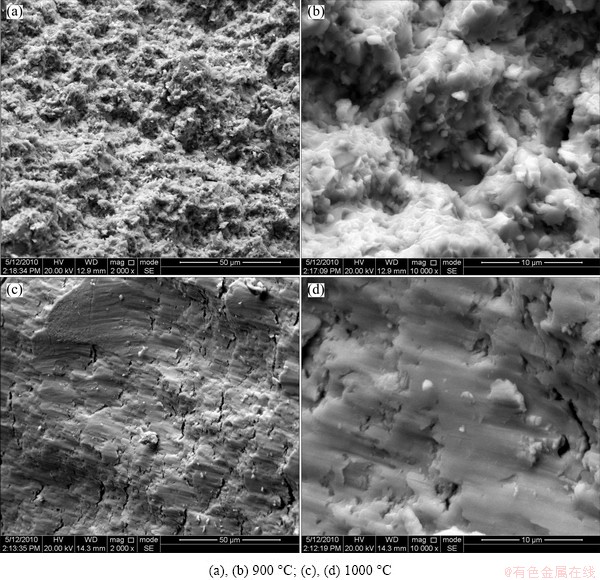

Figure 6 shows the fracture morphologies of the compression test samples of sintered Ti-45Al- 5.5(Cr,Nb,B,Ta) after heat treatment. From Fig. 6, it is clearly showed that the plasticity of the alloy sintered at 1000 °C is better than that at 900 °C. The fracture of both kinds of samples is likely to be intergranular fracture.

Fig. 6 Fracture morphologies of compression test samples from Ti-45Al-5.5(Cr,Nb,B,Ta) alloy sintered at different temperatures

4 Conclusions

1) The morphology of high energy mechanically milled Ti-45Al-5.5(Cr,Nb,B,Ta) powder was irregular with size range of decades micrometers, and the only two phases of TiAl and Ti3Al phase were observed.

2) After heat treatment at 1360 °C for 0.5 h the sintered Ti-45Al-5.5(Cr,Nb,B,Ta) bulk samples exhibited duplex structure with some fine equiaxed gamma grains and thin needle TiB2 phases, and the grain sizes increased with the SPS temperature increasing from 900 °C to 1000 °C. TiAl, Ti3Al and TiB2 phases were observed in the SPS Ti-45Al-5.5(Cr,Nb,B,Ta) bulk samples.

3) With the SPS temperature increasing from 900 °C to 1000 °C, the micro-hardness changed hardly, the compression strength increased from 1812 MPa to 2275 MPa, and the compression ratio increased from 22.66% to 25.59%. The compression fracture mode of the samples was likely to be intergranular fracture.

References

[1] WU X. Review of alloy and process development of TiAl alloys [J]. Intermetallics, 2006, 14: 1114-1122.

[2] CLEMENS H, KESTLER H. Processing and applications of intermetallic γ-TiAl based alloys [J]. Adv Eng Mater, 2000, 2: 551-570.

[3] DING X F, ZHANG L Q, LIN J P, HE J P, YIN J, CHEN G L. Microstructure control and mechanical properties of directionally solidified TiAl-Nb alloys [J]. Transactions of Nonferrous Metals Society of China, 2012, 22(4): 747-753.

[4] GERLING R, CLEMENS H, SCHIMANSKY F P. Powder metallurgical processing of intermetallic gamma titanium aluminides [J]. Adv Eng Mater, 2004, 6: 23-38.

[5] THOMAS M, RAVIART JL, POPOFF F. Cast and PM processing development in gamma titanium aluminides [J]. Intermetallics, 2005, 13: 944-951.

[6] FENG H B, ZHOU Y, JIA D C. Principle and application of spark plasma sintering technology [J]. Mater Sci Technol, 2003, 11(3): 327-331.

[7] PENG T T, FU Z Y, ZHANG D M. Spark plasma sintering technique [J]. Maters Rev, 2002, 16(2): 31-33.

[8] XIAO S L, XU L J, CHEN Y Y, YU H B. Microstructure and mechanical properties of TiAl-based alloy prepared by double mechanical milling and spark plasma sintering [J]. Transactions of Nonferrous Metals Society of China, 2012, 22(5): 1086-1091.

[9] WANG Y H, LIN J P, HE Y H, WANG Y L, CHEN G L. Fabrication and SPS microstructures of Ti-45Al-8.5Nb-(W,B,Y) alloying powders [J]. Intermetallics, 2008, 16: 215-224.

[10] LI H Z, ZENG M, LIANG X P, LI Z, LIU Y. Flow behavior and processing map of PM Ti-47Al-2Cr-0.2Mo alloy [J]. Transactions of Nonferrous Metals Society of China, 2012, 22(4): 754-760.

[11] CHENG T T, WILLIS M R, JONES I P. Effects of major alloying additions on the microstructure and mechanical properties of γ-TiAl [J]. Intermetallics, 1999, 7: 89-99.

不同SPS烧结温度Ti-45Al-5.5(Cr, Nb, B, Ta)合金的显微组织及力学性能

肖树龙1,2, 徐丽娟1, 于宏宝3, 田 竟1, 陈玉勇1,2

1. 哈尔滨工业大学 材料科学与工程学院,哈尔滨 150001;

2. 哈尔滨工业大学 金属精密热加工国家级重点实验室,哈尔滨 150001;

3. 西北工业大学 材料科学与工程学院,西安 710072

摘 要:采用高能球磨和放电等离子烧结(SPS)技术,制备成分为Ti-45Al-5.5(Cr, Nb, B, Ta)的TiAl合金块体,随后对TiAl合金进行热处理。研究在不同SPS烧结温度下制备的TiAl合金经过热处理后的显微组织和力学性能。结果表明:高能球磨后的合金粉末形状不规则,粉末颗粒尺寸大约为几十微米。XRD分析表明,机械球磨后的粉末由TiAl和Ti3Al两相组成;烧结后的Ti-45Al-5.5 (Cr, Nb, B, Ta)合金块体主要是TiAl相,以及少量的Ti3Al和TiB2相。当烧结温度为900 °C和1000 °C时,合金的显微组织为双相结构,并伴随有一些细小的等轴γ晶粒和细小的针状TiB2相。当烧结温度从900 °C上升到1000 °C时,Ti-45Al-5.5(Cr, Nb, B, Ta)合金的显微硬度变化不大,抗压强度从1812 MPa提高到2275 MPa,压缩率从22.66%增加到25.59%,合金的断裂方式为穿晶断裂。

关键词:TiAl合金;粉末冶金;放电等离子烧结;热处理

(Edited by YUAN Sai-qian)

Foundation item: Project (51001040) supported by the National Natural Science Foundation of China; Project (HITQNJS.2009.022) supported by Development Program for Outstanding Young Teachers in Harbin Institute of Technology; Project (2012RFQXG109) supported by the Youth Science and Technology Innovation Talents

Corresponding author: XIAO Shu-long; Tel/Fax: +86-451-86418802; E-mail: xiaoshulong@hit.edu.cn

DOI: 10.1016/S1003-6326(11)61556-2