DOI:10.19476/j.ysxb.1004.0609.2019.07.08

放电等离子烧结制备Ti-22Al-25Nb合金及致密化机理

贾建波1,杨 越1,孙 威1,仲晓晓1,徐 岩1, 2,顾勇飞1,骆俊廷1

(1. 燕山大学 先进锻压成形技术与科学教育部重点实验室,秦皇岛 066004;

2. 燕山大学 国家冷轧板带装备及工艺工程技术研究中心,秦皇岛 066004)

摘 要:以Ti-22Al-25Nb(摩尔分数,%)预合金粉末为实验初始原料,采用放电等离子烧结工艺(SPS)方法,在温度为950~1200 ℃,保温时间为10~20 min,压力为35~80 MPa的条件下制备晶粒小、组织致密的粉末冶金Ti-22Al-25Nb合金。研究烧结温度、烧结压力和保温时间对预合金粉末致密化过程的影响,分析粉末的烧结致密化机理,揭示烧结温度、烧结压力和保温时间对Ti-22Al-25Nb烧结合金的相对密度、相组成、显微组织以及力学性能的影响规律,明确烧结合金的室温断裂机制。结果表明:经950 ℃、80 MPa、10 min烧结的Ti-22Al-25Nb合金相对密度达到99.43%,具有更优异的综合力学性能,其室温伸长率、屈服强度和抗拉强度分别达到9.38%、933.57 MPa和990.01 MPa。

关键词:Ti-22Al-25Nb合金;放电等离子烧结;致密化;力学性能

文章编号:1004-0609(2019)-07-1399-09 中图分类号:TG146.2 文献标志码:A

Ti2AlNb基合金具有密度低,高温强度、比强度、断裂韧性、蠕变抗力和抗氧化性高等突出优势,成为替代镍基高温合金最理想的轻质高温结构材料,是新一代可在600~800 ℃温度范围内长期服役的航空航天发动机制备材料首选之一[1-3]。第二代有序正交O相合金—Ti-22Al-25Nb(摩尔分数,%)合金,已成为国内外学者的研究热点[4-6]。粉末冶金工艺涉及无压烧结、热压烧结和热等静压烧结等工艺,因烧结时间一般较长,容易造成烧结合金的显微组织粗大,晶界容易形成杂质相[7]。放电等离子烧结工艺(Spark plasma sintering,SPS),也称等离子活化烧结,是近年来兴起的一种能实现材料快速致密,致密度高的新型烧结工艺。与传统烧结工艺相比,SPS具有升温速度快、烧结时间短、烧结气氛可控等优点,易于获得致密度高,成份均匀、晶粒细小和力学性能好的烧结材料。采用SPS制备粉末冶金块体材料成为国内外学者研究的热点[8-12]。SPS烧结过程中,烧结温度、烧结压力和保温时间等烧结因素对烧结合金的SPS致密化过程及机理有重要影响。而目前关于粉末冶金制备Ti-22Al- 25Nb合金的SPS致密化过程和机理还缺乏系统研究。曹帅[7]采用SPS技术烧结高能球磨制备的Al-Ni-Ce非晶合金粉末,主要从粉末的初始形貌以及孔洞的变化对合金的致密化过程进行了研究,忽略了烧结因素对其致密化程度的影响。杨鑫[13]研究了SPS过程中烧结温度和压力对TiAl基合金显微组织、力学性能和致密化机理的影响,但未将保温时间因素考虑其中。张朝晖等[14]通过放电等离子烧结技术制备了新型的TiB-TiB2陶瓷复合材料,测试了复合材料的微观组织和力学性能,揭示了复合材料的放电等离子烧结致密化机理。胡美俊等[15]采用放电等离子烧结(SPS)方法制备了Ti3SiC2/Al基复合材料,研究了烧结温度和时间对复合材料组织及性能的影响,未针对烧结压力对材料组织及性能的影响进行相关研究。因此,本文以Ti-22Al-25Nb预合金粉末为研究对象,设计系列烧结实验,考察了各个烧结阶段和不同烧结条件下的合金的相对密度的演变规律,分析了烧结温度、烧结压力和保温时间对烧结合金的相对密度、显微组织和力学性能的影响,揭示合金的断裂机制。

1 实验

1.1 实验材料

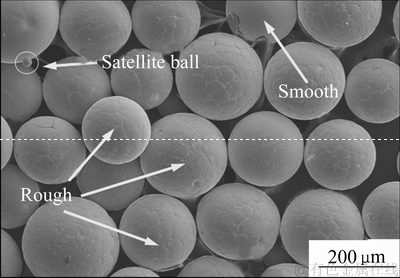

图1所示为气雾化法制备Ti-22Al-25Nb(摩尔分数,%)预合金粉末表面形貌的SEM像。粉末的形貌特征主要包括两种:一种为粒度粗大表面粗糙的粉末,另一种为表面光洁度好的较小粉末颗粒,如图1所示。大部分粉末呈球形或近球形。极少数粉末表面凹凸不平,大颗粒附带小颗粒,出现卫星球现象。造成这种现象的主要原因可能是雾化冷却过程中粉末的冷却速度不同导致的。粒度小的粉末比粒度大的粉末凝固时间短,粒径较大的粉末还未来得及凝固,细小的粉末就开始黏附在粒径较大的粉末表面,形成卫星球现象[16]。

图1 雾化Ti-22Al-25Nb预合金粉末表面形貌

Fig. 1 Surface morphology of gas atomized Ti-22Al-25Nb prealloyed powders

1.2 实验方法

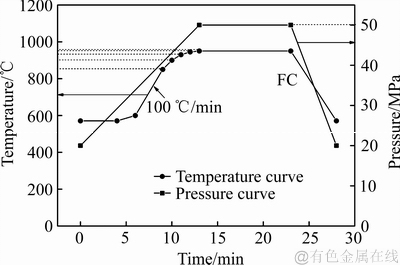

烧结实验在日本Sinter Land公司生产的SPS-3.20MK-IV型放电等离子烧结炉中进行,取称量好的预合金粉末装入直径为20mm的高强石墨模具,采用压片机预压粉末。SPS烧结实验升温速率为100 ℃/min,烧结温度分别为950、1000、1050、1100和1200 ℃,烧结压力分别为35、50和80 MPa,保温时间为10 min和20 min。图2所示为950 ℃、50 MPa、10 min的烧结工艺路线。对于直径为20 mm烧结模具,950 ℃、50 MPa、10 min烧结条件下的升温路线分为3个区间,烧结温度为571~600 ℃,升温时间为2 min;烧结温度为600~850 ℃,以100 ℃/min的恒定升温速率加热,升温时间为3 min;烧结温度850~950 ℃区间内放慢升温速率,防止温度过冲,升温时间为4 min。待烧结温度升至预设烧结温度后,保温10 min。烧结

结束后,烧结材料随炉冷却。烧结过程中,缓慢加压至所需压力50 MPa,待保温时间结束后,将压力归零。采用阿基米德排水法测量烧结块体合金的密度。烧结合金的物相检测在日本理学生产的D/MAX-2500/PC型X射线衍射仪上完成。主要测量参数为:衍射仪为Cu靶Kα,工作时电流电压为100 mA、40 kV,扫描范围为20°~80°,扫描速率为1 (°)/min。实验所用的Axio Scope A1光学显微镜和Sigma 500电子显微镜用于观察并拍摄粉末、烧结合金微观组织和室温拉伸断口形貌。采用电火花线切割方法,将烧结后的合金切割成尺寸为1.2 mm×2 mm×8.5 mm的拉伸尺寸。室温拉伸实验在空气中进行,设备为Inspekt Table-100KN电子万能材料试验机,拉伸速率为0.13 mm/min。

图2 950 ℃、50 MPa、10 min条件下烧结工艺路线

Fig. 2 Sintering process at (950 ℃, 50 MPa, 10 min)

2 放电等离子烧结Ti-22Al-25Nb合金致密化过程

2.1 烧结温度和烧结压力对Ti-22Al-25Nb烧结合金的致密化影响

在SPS过程中,由于高频放电作用,粉末颗粒之间产生等离子体,等离子体在脉冲直流电流作用下击穿粉末颗粒氧化层,净化和活化粉末颗粒表面,使得粉末颗粒之间通过蒸发与凝固、扩散等形式在接触区域形成烧结颈,并在轴向压力、温度场和电压场的综合作用下,粉末发生塑性变形,进而快速消除颗粒之间存在的孔洞,实现快速烧结致密。本节结合实验结果,研究Ti-22Al-25Nb预合金粉末在SPS过程中的致密化过程,分析不同烧结参数对致密化的影响规律,为烧结工艺提供合理理论依据与实验指导。

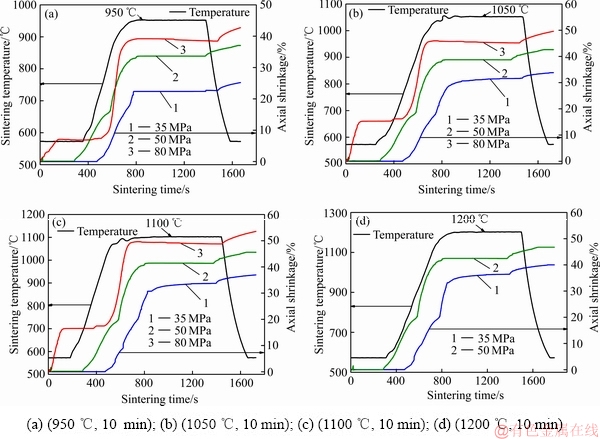

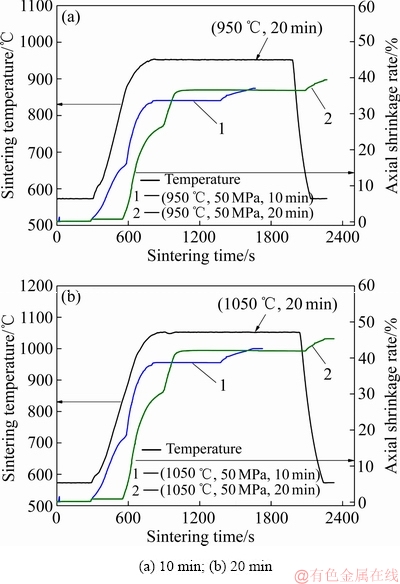

图3所示为不同烧结条件下烧结合金的烧结温度和轴向收缩率随烧结时间的变化曲线,其中35 MPa、50 MPa烧结压力的SPS实验加压方式是升温到预设烧结温度后缓慢加压至预设烧结压力值,80 MPa烧结压力的SPS实验加压方式是在预设烧结温度前已加载至预设烧结压力值。由图3可以发现,烧结温度一定时,烧结合金的轴向收缩率随烧结压力的提高而增大;当烧结压力一定时,烧结合金的轴向收缩率随烧结温度的升高而增加。SPS制备Ti-22Al-25Nb块体合金的烧结过程主要分为初期、中期和末期3个阶段。由图3(a)可知,当t<360 s时,即在SPS初期,烧结温度低于600 ℃,粉末轴向收缩率偏低,首次出现停滞平台。SPS初期,图3中1、2曲线初始表现出轴向收缩率接近零且平行于烧结时间轴的平台阶段,且随着预设烧结压力的降低平台滞留时间越长。这是因为在烧结前粉末经压片机进行冷压,且此时温度较低(低于600 ℃),未达到合金粉末的脆韧转变温度,此阶段压力远低于预设烧结压力,粉末未发生明显颗粒重排现象。而与950 ℃、35 MPa、10 min和950 ℃、50 MPa、10 min烧结条件有所不同,在80 MPa烧结压力下,0~200 s内,轴向收缩率(图3(a)中曲线3)随着烧结时间的增加而迅速提高至7.06%。这是由于在烧结前已将烧结压力调至所需预设压力80 MPa,该压力使合金粉末颗粒发生充分重排,孔隙度大大降低,导致烧结材料轴向收缩率急剧增加。当360 s<t<800 s时,即在SPS中期,烧结温度迅速升高,烧结合金轴向收缩率随烧结时间的增加而发生快速增加。这是因为烧结中期电流较大,形成较多等离子体,预合金粉末在温度为600~900 ℃时,达到脆韧转变温度,粉末颗粒之间形成“烧结颈”[17]。当施加的轴向烧结压力大于烧结材料的屈服强度将发生塑性流动,因此该阶段烧结合金快速致密化方式以热塑性变形为主。在烧结末期,t>800 s,即保温阶段,轴向收缩率随烧结时间的增加而几乎不变再次出现停滞现象。造成这种停滞现象原因可能为:在保温保压阶段,电流数值基本不变,放电现象减弱,此时烧结材料内部形成通路,主要以纯电阻加热为主,在预设烧结压力的作用下烧结合金不再发生塑性变形。因此,在该停滞平台内轴向收缩率几乎保持不变,且滞留时间较长。SPS烧结完毕后,烧结合金的轴向收缩率发生了近似线性增长(见图3)。这是因为烧结完毕后,关闭电流,烧结模具和烧结合金的温度迅速下降,烧结合金由于热胀冷缩导致轴向收缩率提高。此外,从图中3还可以发现,在非冷却阶段,提高烧结压力,轴向收缩率达到峰值的时间缩短,即提高烧结压力有助于提高预合金粉末的致密化烧结效率。

图3 不同烧结条件下烧结合金的烧结温度以及轴向收缩率随烧结时间的变化

Fig. 3 Change of sintering temperature and axial shrinkage with sintering time under different sintering conditions

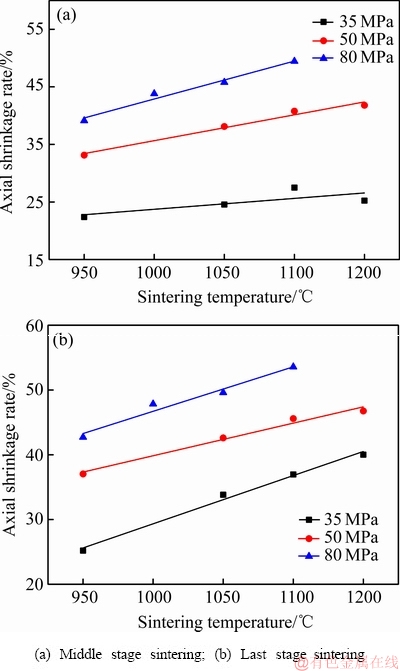

在SPS中期和冷却阶段,烧结合金轴向收缩率随温度变化关系如图4所示。由图4(a)可以观察到,随着烧结压力提高,烧结合金的轴向收缩率显著提高。如烧结温度为1100 ℃时,烧结时间为800 s时,烧结压力为35 MPa、50 MPa、80 MPa的最大轴向收缩率分别为27.49%、40.78%和49.44%。保持烧结压力不变,Ti-22Al-25Nb烧结合金的轴向收缩率随着烧结温度的升高而增加。如烧结压力为50 MPa时,烧结时间为800 s时,烧结温度分别为950 ℃、1050 ℃、1100 ℃和1200 ℃的轴向收缩率分别为33.14%、38.11%、40.78%和41.8%。由于在SPS中期,烧结合金的致密化过程主要以塑性流动为主,预设烧结压力越大、烧结温度越高烧结合金发生的塑性变形程度越大,烧结合金的轴向收缩率就越大。烧结结束后,冷却阶段的轴向收缩率也随烧结温度和烧结压力的提高呈线性增加,且数值较烧结中期略有增加。

图4 不同烧结阶段下烧结合金的轴向收缩速率随烧结温度的关系

Fig. 4 Relationship between axial shrinkage rate and sintering temperature of sintered alloy prepared by SPS at different sintering stages

2.2 保温时间对Ti-22Al-25Nb烧结合金的致密化影响

延长保温时间可以提高烧结合金扩散的均匀性,促进合金致密。图5所示为SPS过程中不同烧结参数下烧结合金的轴向收缩率与烧结时间的变化。从图5(a)和(b)中可看出,烧结温度和压力不变,保温时间从10 min增加至20 min,烧结合金的轴向收缩率略有增加,最大轴向收缩率分别增加了2.38%和2.7%。说明保温时间在10~20 min内,其对烧结合金致密化影响较小,原因可能是烧结合金在保温阶段已不再发生塑性变形,温度与电流处于稳定状态,仅进行原子之间扩散。

图5 不同保温时间下SPS制备Ti-22Al-25Nb烧结合金的烧结温度以及轴向收缩率随烧结时间的变化

Fig. 5 Changes of sintering temperature and axial shrinkage with time of sintered Ti-22Al-25Nb alloy at different holding time

3 SPS制备Ti-22Al-25Nb合金的显微组织与力学性能

3.1 烧结温度、烧结压力和保温时间对Ti-22Al-25Nb烧结合金相对密度和物相的影响

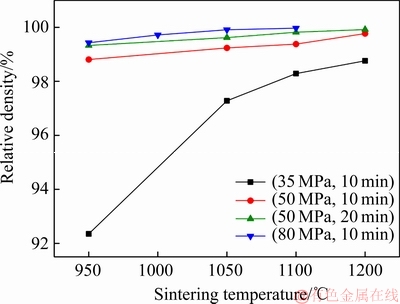

将锻态的Ti-22Al-25Nb合金的密度(5.3 g/cm3)作为理论密度,测量并计算不同烧结条件下获得的烧结合金的相对密度,其相对密度与烧结温度的关系如图6所示。从图6中可以看出,950 ℃、35 MPa、10 min条件下获得的合金相对密度仅为92.35%。提高烧结温度至1050 ℃时,其相对密度有所提高,为97.28%,相对密度仍较低。这是由于在950 ℃条件下,烧结温度较低,粉末的塑性变形抗力较大,塑性变形不充分,粉末之间扩散作用不明显,导致950 ℃烧结合金内部未闭合孔洞多、致密度不高。由图6还可发现,不同烧结压力下获得烧结合金的相对密度变化曲线具有相同的趋势,皆随着烧结温度的提高,烧结合金的相对密度呈增大的趋势,且相对密度的增长速率逐渐降低,当烧结温度大于1050 ℃时,Ti-22Al-25Nb合金的相对密度的增长曲线趋于平缓,意味着此时烧结合金的相对密度已接近致密状态。在烧结温度为1050 ℃,保温时间为10 min和20 min,烧结压力为35~80 MPa条件下,获得烧结Ti-22Al-25Nb合金的相对密度分别为97.28%、99.24%、99.62%和99.91%。保持烧结压力50 MPa和温度不变,延长保温时间至20 min时,合金的相对密度明显高于保温时间为10 min烧结合金的相对密度。当烧结温度为950~ 1100 ℃、保温时间为10 min、烧结压力为80 MPa时,合金的相对密度较同等条件、压力为50 MPa烧结合金的略有增加,测得实际烧结合金相对密度分别为99.43%、99.72%、99.91%、99.97%,接近理论密度,认为达到完全致密。因此,合理提高烧结压力和烧结温度和烧结时间,有利于烧结合金内各种元素的充分扩散和获得更充分的塑性变形,达到更高的致密化效果。

图6 不同烧结参数条件下烧结合金的相对密度变化

Fig. 6 Change of relative density of sintered alloy under different sintering parameters

3.2 烧结温度、烧结压力和保温时间对Ti-22Al-25Nb烧结合金微观组织和力学性能的影响

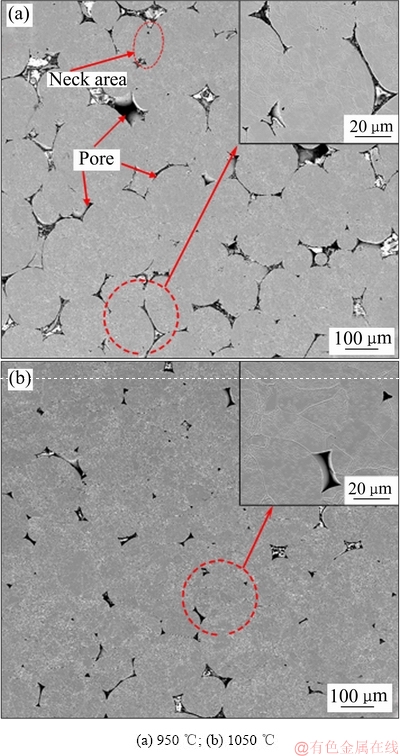

图7所示为不同烧结温度获得的烧结合金的SEM像。由图7(a)看出,950 ℃烧结合金出现大量未闭合孔洞,孔洞面积较大,大部分孔洞形状呈颈状分布,也有少量的三角形孔洞。粒径大于200 μm的粉末颗粒之间紧密粘结,且在粗大颗粒周围团聚着小颗粒(粒径<50 μm)形成明显的烧结颈。部分粒径小于150 μm的颗粒扩散不完全,仅发生一定程度的塑性变形,由球状粉末变为椭圆形或扁形粉末。这表明在950 ℃烧结,瞬时高温只能使部分颗粒熔化形成烧结颈,颗粒之间孔洞未完全闭合,致密度低。由图7(b)可发现,当烧结温度提高至1050 ℃时,颗粒之间孔洞数量明显下降,部分孔洞由颈状变成三角形。小颗粒塑性变形程度增大,大颗粒之间烧结颈面积进一步扩大,发生了明显的塑性变形,球状颗粒的界面依然很清晰,致密化程度提高。这是因为烧结温度的提高降低了粉末的塑性变形抗力,在外加压力的作用下,粉末颗粒更易发生塑性变形充填孔隙,孔洞逐渐收缩,由起初的颈状向三叉节点的三角形转变,导致烧结过程中的粉末颗粒的边界能逐渐减小,三角形孔洞的边界逐渐直化,最终烧结材料内仅留下极少量微孔接近完全致密。此外,结合图6的烧结合金的相对密度曲线变化图可以看出,在950~1050 ℃温度范围,合金的相对密度上升速率最快,表明此阶段随着温度的提高,合金粉末的变形抗力下降,塑性变形更容易进行,更易填充孔洞,从而提高合金的组织致密度。当烧结温度高于1050 ℃时,随着温度的提高,合金的相对密度的增长速度逐渐下降[18]。

图7 35 MPa、10 min下不同烧结温度的烧结合金的SEM像

Fig. 7 SEM images of spark sintered alloy at 35 MPa and 10 min

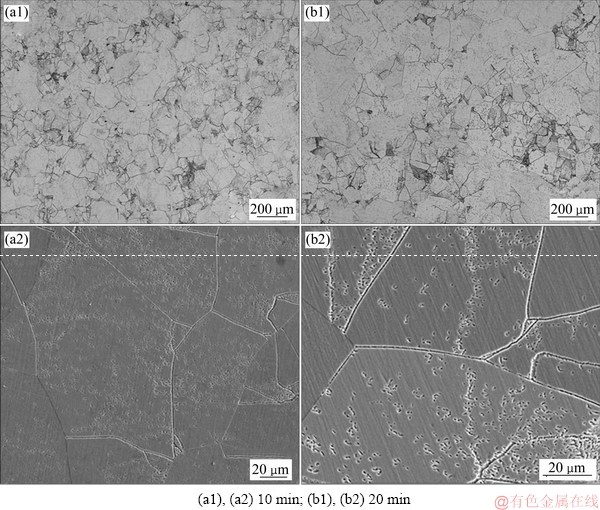

图8所示为1050 ℃、50 MPa不同保温时间下获得的烧结合金的OM和SEM像。对比图7和8可以看出,提高烧结压力至50 MPa,烧结合金的致密化程度提高。当烧结压力为35 MPa(见图7(b)),孔隙较多,组织致密性差。当烧结压力提高至50 MPa,合金致密化更充分,烧结合金无明显孔洞,未见粉末的边界轮廓出现(见图8(a1)和(a2))。只在部分晶界处存在很小的微孔,孔洞大小为1~2 μm,烧结合金的平均晶粒尺寸为41.79 μm。决定合金组织形貌的主要因素是烧结温度,与烧结压力关系不大。烧结压力的提高,主要加快合金致密化速度,缩短烧结时间。当保温时间从10 min延长至20 min时,组织致密度无明显变化,但与保温时间为10 min获得的合金的组织相比,保温时间为20 min的合金晶粒发生长大,故保温时间不宜过长。但保温时间不足时,容易使合金组织不致密,内部孔洞较多,合金的相对密度较低,保温时间10 min为适宜的烧结参数。

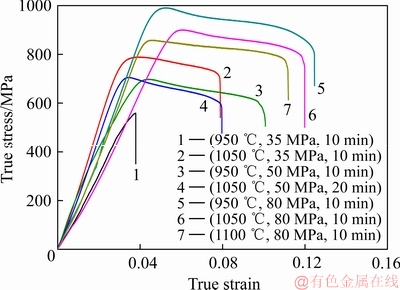

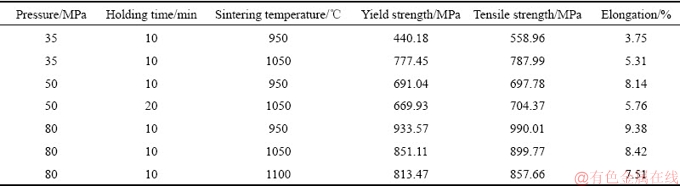

室温下Ti-22Al-25Nb烧结合金的真实应力-应变曲线如图9所示。表1所列为烧结合金的室温拉伸性能。由表1可知,在较低的烧结温度和烧结压力条件下烧结,得到的合金的致密度较低,粉末之间界面结合力较弱,合金的强度和塑性较差。随着烧结温度或烧结压力的提高合金的强度和塑性得到改善。结合图9和表1可以发现,在950 ℃、80 MPa、10 min条下烧结时,Ti-22Al-25Nb合金具有最优的室温拉伸性能,室温伸长率、屈服强度和抗拉强度分别为9.38%、933.57 MPa和990.01 MPa,力学性能显著高于其他条件下的力学性能。图10所示为不同烧结条件下制备Ti-22Al-25Nb合金的室温拉伸件断口形貌SEM像。

图8 烧结温度为1050 ℃、烧结压力为50 MPa下不同保温时间烧结合金的OM像和SEM像

Fig. 8 OM((a1), (b1)) and SEM((a2), (b2)) images of spark sintered alloy holding for different time at sinter 1050 ℃ and 50 MPa

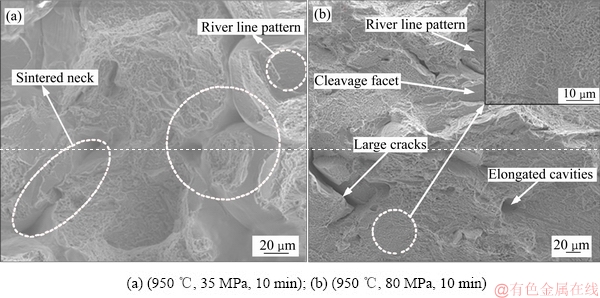

从图10(a)可以明显发现,在35 MPa、10 min条件下,950 ℃烧结合金的断口处仍可观察到球状粉末颗粒,且粉末颗粒之间的孔洞也十分明显。而当压力提高至80 MPa,在950 ℃、80 MPa、10 min获得的烧结合金室温下拉伸断口形貌孔洞完全消失,呈现河流状花样、解理面以及大量的韧窝存在,断裂机制为脆性断裂与韧性断裂的混合断裂方式。

图9 不同烧结参数下Ti-22Al-25Nb烧结合金室温真实应力-应变曲线

Fig. 9 True stress-strain curves of sintered Ti-22Al-25Nb alloy under different sintering parameters

4 结论

1) SPS致密化过程中,烧结初期,仅发生粉末颗粒重排,致密度低。烧结中期,粉末颗粒之间形成烧结颈,以粉末的塑性流动为主。烧结末期,以纯电阻加热为主,致密度进一步提高。通过轴向收缩率的变化,发现提高烧结温度、烧结压力的升高和保温时间可以提高粉末的致密化程度。1100 ℃、80 MPa、10 min条件制备合金的致密化程度最高,轴向收缩率为53.57%。

2) 950 ℃、35 MPa、10 min烧结合金的相对密度最低,仅为92.35%。提高温度、压力和保温时间,相对密度也会相应得到提高。80 MPa、10 min时,烧结温度950、1000、1050和1100 ℃获得烧结合金的相对密度为99.43%、99.72%、99.91%和99.97%。

3) 950 ℃、80 MPa、10 min条件下,获得的Ti-22Al-25Nb烧结合金的相对密度为99.43%,平均晶粒尺寸仅为9.39 μm,室温屈服强度、抗拉强度和伸长率分别为933.57 MPa、990.01 MPa和9.38%,展现出最优的综合力学性能,室温断裂机制为脆性断裂与韧性断裂的混合断裂方式。

表1 室温下Ti-22Al-25Nb合金的拉伸性能

Table 1 Tensile properties of Ti-22Al-25Nb alloys at room temperature

图10 不同烧结参数下SPS烧结 Ti-22Al-25Nb合金室温拉伸断口形貌

Fig. 10 Room-temperature tensile fractographs of sparking plasma sintered Ti-22Al-25Nb alloy under different sintering parameters

REFERENCES

[1] KUMPFERT J. Intermetallic alloys based on orthorhombic titanium aluminide[J]. Adv Eng Mater, 2001, 3: 851-864.

[2] LEYENS C, PETERS M. Titanium and titanium alloys[M]// Titanium and Titanium Alloys-Fundamentals and Applications. DLR-German Aerospace Center, 2003: 1-513.

[3] LI D Q, BOEHLERT C J. Processing effects on the grain-boundary character distribution of the orthorhombic phase in Ti-Al-Nb alloys[J]. Metallurgical & Materials Transactions A, 2005, 36(10): 2569-2584.

[4] SIM K H, WANG G F, SON R C, CHOE S L. Influence of mechanical alloying on the microstructure and mechanical properties of powder metallurgy Ti2AlNb-based alloy[J]. Powder Technology, 2017, 317: 133-141.

[5] 王远鑫. 反应烧结Ti-22Al-25Nb合金组织特征与高温成 形/扩散连接[D]. 哈尔滨: 哈尔滨工业大学, 2017.

WANG Yuan-xin. Microstructure characteristics and high temperature forming/diffusion bonding of Ti-22Al-25Nb alloy synthesized via reactive sintering[D]. Harbin: Harbin Institute of Technology, 2017.

[6] 马长语. TC4/Ti22Al25Nb激光焊接工艺与组织性能研究[D]. 青岛: 山东大学, 2017.

MA Chang-yu. Research on laser welding process and origanization performance of TC4/Ti22Al25Nb[D]. Qingdao: Shandong University, 2017.

[7] 曹 帅. 粉末冶金制备大块Al基非晶合金及其力学性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2010.

CAO Shuai. Preparation and properties of a Al-based bulk amorphous alloy by powder metallurgy[D]. Harbin: Harbin Institute of Technology, 2010.

[8] 王 葛, 王兴华, 王海舰, 李 强. Fe73.5Cu1Nb3Si13.5B9非晶合金粉体的SPS烧结特性研究[J]. 燕山大学学报, 2014(6): 491-496.

WANG Ge, WANG Xing-hua, WANG Hai-jian, LI Qiang. Research on sintering characteristics of Fe73.5Cu1Nb3Si13.5B9 amorphous alloys prepared by spark plasma sintering[J]. Journal of Yanshan University, 2014(6): 491-496.

[9] 李洪波, 王依敬, 顾勇飞, 韩金成. H13钢表面喷涂Cr3C2-NiCr和Ni60A涂层的结合强度及耐磨性研究[J]. 燕山大学学报, 2017, 41(6): 496-502.

LI Hong-bo, WANG Yi-jing, GU Yong-fei, HAN Jin-cheng. Bonding strength and wear resistance of Cr3C2-NiCr and Ni60A thermal spray coatings on H13 steel surface[J]. Journal of Yanshan University, 2017, 41(6): 496-502.

[10] 王海涛, 陈宏超, 王 鹏, 向建勇, 陈灿坤, 柳忠元, 温福昇. 放电等离子烧结制备高强度奥氏体不锈钢[J]. 燕山大学学报, 2013, 37(1): 34-38.

WANG Hai-tao, CHEN Hong-chao, WANG Peng, XIANG Jian-yong, CHEN Can-kun, LIU Zhong-yuan, WEN Fu-sheng. High strength austenitic stainless steel prepared by spark plasma sintering[J]. Journal of Yanshan University, 2013, 37(1): 34-38.

[11] 王艳辉, 成晓哲, 臧建兵. 金刚石、碳化硅复合热传导材料的发展[J]. 燕山大学学报, 2015, 39(5): 390-402.

WANG Yan-hui, CHENG Xiao-zhe, ZANG Jian-bing. Development of diamond and SiC composited heat sink materials[J]. Journal of Yanshan University, 2015, 39(5): 390-402.

[12] 李洪波, 韩金成, 顾勇飞, 石晓轩. T10钢表面HVOF喷涂WC-10Co-4Cr涂层的耐磨性研究[J]. 燕山大学学报, 2016, 40(1): 22-28.

LI Hong-bo, HAN Jin-cheng, GU Yong-fei, SHI Xiao-xuan. Abrasive resistance of WC-10Co-4Cr coating on deposited T10 steel surface by HVOF[J]. Journal of Yanshan University, 2016, 40(1): 22-28.

[13] 杨 鑫. 放电等离子烧结制备钛铝基合金及致密化机理研究[D]. 长沙: 中南大学, 2012.

YANG Xin. Study on preparation and consolidation mechanism of TiAl-based alloy prepared by spark plasma sintering[D]. Changsha: Central South University, 2012.

[14] 张朝晖, 罗 杰, 黄橙骋, 王富耻, 李树奎. TiB-TiB2陶瓷复合材料的放电等离子烧结致密化[J]. 北京理工大学学报, 2010, 30(4): 492-495.

ZHANG Zhao-hui, LUO Jie, HUANG Cheng-cheng, WANG Fu-chi, LI Shu-kui. Densification of TiB-TiB2 ceramic composites by spark plasma sintering[J]. Journal of Beijing Institute of Technology, 2010, 30(4): 492-495.

[15] 胡美俊, 刘文扬, 张建波, 陈婷婷, 柳瑞清. SPS制备致密Ti3SiC2/Al复合材料的组织及性能研究[J]. 有色金属工程, 2018, 8(2): 31-38.

HU Mei-jun, LIU Wen-yang, ZHANG Jian-bo, CHEN Ting-ting, LIU Rui-qing. Microstructure and properties of dense Ti3SiC2/Al composites prepared by SPS[J]. Non-ferrous Metal Engineering, 2018, 8(2): 31-38.

[16] 李 鑫, 王永祥. 气雾化工艺参数对金属粉末粒度影响的研究[J]. 江西有色金属, 2002, 16(3): 27-29.

LI Xin, WANG Yong-xiang. Study on the effect of atomization parameters on the granularity of metal powder[J]. Jiangxi Nonferrous Metals, 2002, 16(3): 27-29.

[17] 陈小安, 尚福军, 宋顺成. 放电等离子体烧结W粉数值模拟[J]. 粉末冶金技术, 2010, 28(4): 256-261.

CHEN Xiao-an, SHANG Fu-jun, SONG Shun-cheng. Numerical simulation for spark plasma sintering of W powder[J] . Powder Metallurgy Technology, 2010, 28(4): 256-261.

[18] LIU Xin-wang, ZHANG Zhao-long, SUN Rui, LIU Fu-chu, FAN Zi-tian, NIU Hong-zhi. Microstructure and mechanical properties of beta TiAl alloys elaborated by spark plasma sintering[J]. Intermetallics, 2014, 55(31): 177-183.

Preparation and densification mechanism of Ti-22Al-25Nb alloy prepared by spark plasma sintering

JIA Jian-bo1, YANG Yue1, SUN Wei1, ZHONG Xiao-xiao1, XU Yan1, 2, GU Yong-fei1, LUO Jun-ting1

(1. Education Ministry Key Laboratory of Advanced Forging and Stamping Technology and Science, Yanshan University, Qinhuangdao 066004;

2. National Engineering Research Center for Equipment and Technology of C.S.R, Yanshan University, Qinhuangdao 066004, China)

Abstract: Ti-22Al-25Nb (mole fraction, %) pre-alloyed powders were used as the experimental starting materials. A powdery metallurgy Ti-22Al-25Nb alloy with fine grain size and dense microstructure was prepared using the spark plasma sintering process (SPS) method at the temperature of 950-1200 ℃, holding time of 10-20 min and pressure of 35-80 MPa. The effects of sintering temperature, sintering pressure and holding time on the densification of pre-alloyed powders were studied. The sintering densification mechanism was analyzed. The influences of sintering temperature, sintering pressure and holding time on the relative density, phase composition, microstructure and mechanical properties of the sintered Ti-22Al-25Nb alloy were revealed. In addition, the room temperature fracture mechanism of the sintered alloy was clarified. The results show that the relative density of the Ti-22Al-25Nb sintered alloy at (950 ℃, 80 MPa, 10 min) reaches 99.43%, and it has better comprehensive mechanical properties. The room temperature elongation, yield strength and tensile strength reach 9.38%, 933.57 MPa and 990.01 MPa, respectively.

Key words: Ti-22Al-25Nb alloy; spark plasma sintering; densification; mechanical property

Foundation item: Project(E2016203157) supported by the Natural Science Foundation of Hebei Province, China; Project(51875502) supported by the National Natural Science Foundation of China

Received date: 2018-06-12; Accepted date: 2019-04-06

Corresponding author: XU Yan; Tel: +86-335-8387503; E-mail: xuyan_916@ysu.edu.cn

(编辑 李艳红)

基金项目:河北省自然科学基金资助项目(E2016203157);国家自然科学基金资助项目(51875502)

收稿日期:2018-06-12;修订日期:2019-04-06

通信作者:徐 岩,副教授,博士;电话:0335-8387503;E-mail:xuyan_916@ysu.edu.cn