DOI:10.19476/j.ysxb.1004.0609.2019.04.06

放电等离子烧结石墨烯铝材料的组织与性能

申 超1,朱德智1,罗铭强2,陈文泗2,李 辉2,王春雨3

(1. 华南理工大学 广东省金属新材料制备与成形重点实验室,广州 510640;

2. 广东兴发铝业(江西)有限公司,宜春 336000;

3. 哈尔滨工业大学(威海) 材料科学与工程学院,威海 264200)

摘 要:针对石墨烯与铝的界面润湿性差、不易均匀分散等问题,利用超声和机械搅拌方法分散粉体,并采用放电等离子烧结工艺制备成型石墨烯铝材料。借助扫描电镜(SEM)、透射电镜(TEM)、电子万能试验机、导电率测量仪、激光导热仪等设备对石墨烯铝材料的微观组织力学性能和物理性能进行研究,重点探讨镀镍石墨烯的加入对纯铝的力学性能和物理性能的影响。结果表明:采用超声分散和机械搅拌相结合的方法可使镀镍石墨烯均匀分散在纯铝中;随着镀镍石墨烯的含量从0%增加到0.87%(质量分数),石墨烯铝材料的抗拉强度、硬度、导电率和热导率均显著提升;当镀镍石墨烯含量为0.87%时,石墨烯铝材料的抗拉强度达到194MPa,硬度52HB,相对于纯铝放电等离子烧结试样分别提高了168%和23%;石墨烯铝材料的导电率达到48.5%IACS,热导率为193.4W/(K·m)。石墨烯表面镀镍处理有利于石墨烯与铝二者的界面结合,提升其强度和硬度,但界面处过多的镍会降低石墨烯铝材料的导电率。

关键词:石墨烯;放电等离子烧结;微观组织;性能

文章编号:1004-0609(2019)-04-0709-08 中图分类号:TB333 文献标志码:A

随着现代工业的发展,传统的导电导热材料如铜、铝及其合金已经逐渐不能满足航空、航天、轨道交通、电力电子等领域的需要,其对高强、高韧、高导的先进材料或新型复合材料的需求日益强烈。石墨烯是一种二维结构材料,具有非常优异的力学与物理性能,如拉伸强度高达130 GPa,电子迁移率超过15000 cm2/(V·s),导热系数高达5300 W/(m·K),作为增强相材料来制备高强、高导金属基复合材料将极具应用前景[1-5]。

石墨烯铝材料又称为石墨烯/铝复合材料、石墨烯强化铝合金或铝基烯合金,因其具有较高的强度和韧性以及较高的导电率和热导率等性能特点成为了近年来的研究热点[6-8]。邹高鹏等[9]用超声和电化学相结合的方法制备出微纳石墨烯片,然后采用粉末冶金的方法制备出了含0.2%石墨烯的铝合金复合材料;结果发现,复合材料的抗蠕变性能显著提高,保载阶段平均蠕变度降低了45%。BASTWROS等[10]采用半固态烧结的方法制备出了含1%石墨烯的铝基复合材料,结果发现,球磨时间达到90 min时,复合材料抗弯强度比6061铝合金的提高了43%。YAN等[11]采用热等静压的方法制备出含0.5%石墨烯的铝基复合材料,其抗拉强度比纯铝的提高了25%,屈服强度提高了50%,且其伸长率和纯铝的基本相当。尽管石墨烯铝材料表现出较高的性能和非常好的应用前景,但目前关于石墨烯铝材料的研究仍然存在着一些问题,需要深入研究,如石墨烯和铝润湿性差,界面结合强度较低;固态法制备成型过程中粉体难分散均匀;液态法制备过程中石墨烯易与铝合金发生界面反应[12-15]。另外,石墨烯对铝合金物理性能的影响及其相关机理尚不明晰。

本文针对石墨烯与铝合金材料界面润湿性差且难分散均匀等问题,采用石墨烯表面镀镍处理,通过超声分散和机械搅拌相结合的工艺将镀镍石墨烯和铝粉混合均匀,获得石墨烯均匀分散的石墨烯铝材料预制体,并采用放电等离子烧结(SPS)工艺制备成型石墨 烯铝材料。通过对石墨烯铝材料的微观组织、力学性能和物理性能测试分析,总结石墨烯铝材料的力学性能和物理性能随石墨烯含量的变化规律。

1 实验

1.1 实验材料

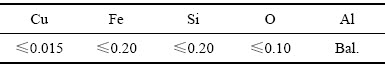

本实验使用河南省远洋粉体科技股份有限公司生产的微细球形铝粉作为基体材料,铝粉粒度1~2 μm,纯度≥99.75%,主要成分及含量见表1。所用石墨烯为表面镀镍处理之后的改性石墨烯。镀镍石墨烯是由石墨烯微粉化学镀镍得到,是将表面活化之后的石墨烯和镀镍溶液混合超声,并高温水浴加热反应一段时间得到。并由硫碳分析法测得镀镍石墨烯中C含量为31.46%。图1所示为原料铝粉和改性石墨烯的SEM像。其中,图1(a)所示为纯铝粉,呈球形,分散均匀;图1(b)所示为改性石墨烯,呈片状,表面的白点为镍。

表1 纯铝粉的主要成分

Table 1 Main components of pure aluminum powder (mass fraction, %)

图1 原料铝粉和改性石墨烯的SEM像

Fig. 1 SEM images of aluminum powders (a) and Ni-graphene (b)

1.2 实验方法

本实验中石墨烯铝材料采用放电等离子烧结(SPS)工艺制备成型,共分为5组试样(石墨烯质量分数分别为0%、0.26%、0.52%、0.87%、2.10%;分别对应为图2中试样1、2、3、4和5)。首先将表面镀镍处理后的石墨烯在无水乙醇中超声分散1h,然后加入纯铝粉进行机械搅拌6h,分散均匀之后将浆料过滤、烘干,得到石墨烯均匀分散的石墨烯铝预混粉体。将不同质量配比的石墨烯铝预混粉体装进直径60 mm的石墨模具,在真空环境下,施加30~50 MPa的压力,在540℃的烧结温度下进行放电等离子烧结,制备出d 60 mm×16 mm的石墨烯铝材料,如图2所示。

图2 石墨烯铝材料试样照片

Fig. 2 Photo of aluminum/graphene composites

采用QUANTA FEG250型扫描电子显微镜观察石墨烯铝材料粉体和试样中的石墨烯形貌特征及拉伸断口形貌。采用FEI TECNAL G2 S-TWIN F20型透射电子显微镜观察石墨烯铝材料中石墨烯和铝基体的界面特征,加速电压200 kV。使用HB-3000型布氏硬度计测量试样硬度,压头选用直径5 mm的淬火钢球,载荷2500 N,保压时间30 s。室温拉伸性能测试在岛津AG-X 100 kN型万能材料试验机上完成,加载速率为0.3 mm/min。导电率使用德国SIGMATEST2.069型便携式导电率测量仪进行测量,热导率使用NETZSCHLFA-447型激光导热仪进行测量。

2 结果与分析

2.1 显微组织特征

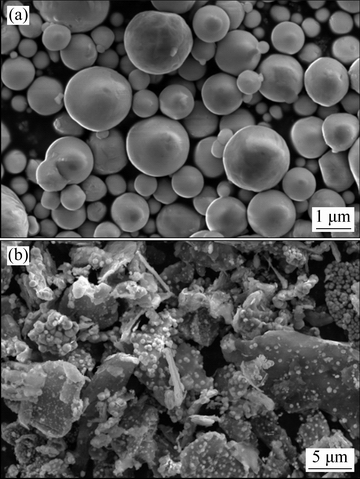

图3所示为表面镀镍石墨烯铝材料粉体扫描电镜照片。从图3可以看出,与铝粉混合之后的石墨烯还保留着二维片状结构,片层厚度和混合之前的石墨烯(见图1)相比有所减薄。推测石墨烯的减薄是由于石墨烯在无水乙醇中超声震荡,在外力的作用下,片层之间的范德华力遭到破坏,石墨烯层数减小;在随后的机械搅拌过程中,铝颗粒对石墨烯产生撞击、剪切等作用,再次破坏了石墨烯片层之间的范德华力,使石墨烯片较为均匀地分散在铝粉中,但是目前还没有直接证据证明该分析结果。同时,实验中所用的石墨烯进行了表面镀镍处理,改善了石墨烯和铝粉的相容性,并且提高了石墨烯的密度,使石墨烯和铝粉密度差减小,利于石墨烯在铝粉当中的均匀分散。

图3 石墨烯铝材料粉体SEM像

Fig. 3 SEM image of aluminum/graphene composites powder

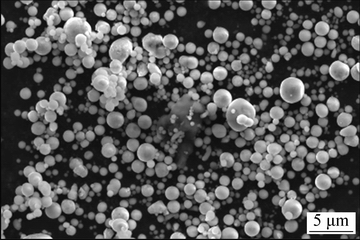

图4所示为典型的石墨烯铝材料的SEM像。其中黑色区域为石墨烯,由图4(b)可知白色区域为镍扩散区。可见试样中石墨烯仍保持二维片状结构,在制备过程中没有被破坏。镀镍石墨烯片在铝基体中分布均匀,未发现有明显的团聚现象。另外,由于本文中采用的烧结温度较低,致密化程度不够,所制备的石墨烯铝材料中存在一定的孔隙率。

图4 石墨烯铝材料的SEM像

Fig. 4 SEM images of aluminum/graphene composites

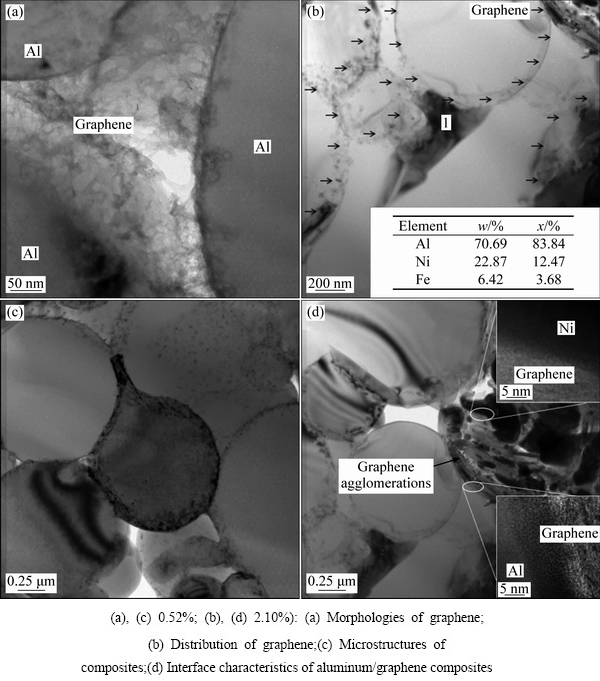

图5所示为石墨烯铝材料中石墨烯的形貌、分布及石墨烯-铝界面的TEM像。从图5(a)中可以看出,透射电镜下的石墨烯呈半透明状,包覆在铝基体表面。这与颗粒或者碳纳米管增强铝基复合材料的TEM特征不同,这些弥散分布的二维石墨烯片层和复合材料接触面积较大,可改善界面传载效果。从图5(b)可以看出,改性石墨烯主要分布于界面处,可阻碍复合材料发生变形,提高复合材料的强度。图5(b)中1处颜色较深区域主要含Al和Ni元素,为镍和铝扩散结合区域,其中少量Fe元素为原料及混粉过程中的杂质元素,可见石墨烯表面镀镍,金属镍与铝的相容性较好,促进了镀镍石墨烯在铝基体中的分散结合。但是,本文中的石墨烯也存在部分团聚现象,如图5(d)所示。对比图5(c)和(d)可知,石墨烯含量的增加会导致粉体团聚、孔隙率提高。石墨烯-铝的界面HRTEM分析(见图5(d)中插图)表明,石墨烯和铝镍之间形成了扩散结合层,而不是简单的机械结合,这样的界面结合大大提高了石墨烯和铝基体之间的界面结合强度,提升材料的性能。此外,在透射电镜观察中并未发现该试验制备的石墨烯铝材料中存在Al4C3。

2.2 石墨烯铝材料的力学性能

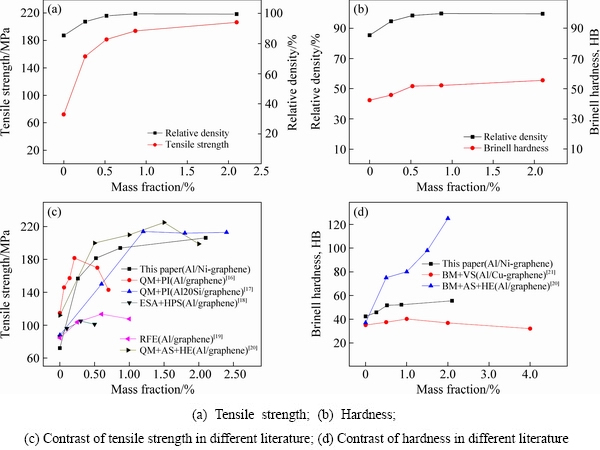

图6(a)给出了石墨烯铝材料的抗拉强度随石墨烯含量和材料致密度变化关系曲线。从图6(a)中可以看出,石墨烯的加入大幅度提高了纯铝基体的强度。当石墨烯的质量分数达到0.87%时,石墨烯铝材料的抗拉强度达到194MPa,较纯铝提高168%。随着石墨烯含量的进一步增加,石墨烯铝材料的抗拉强度缓慢提升。石墨烯铝材料的硬度随石墨烯含量和材料致密度变化关系曲线如图6(b)所示。从图6(b)中可以看出,石墨烯的加入也提高了纯铝的硬度。当镀镍石墨烯的含量达到0.87%时,石墨烯铝材料的硬度达到52HB,较纯铝提高23%。

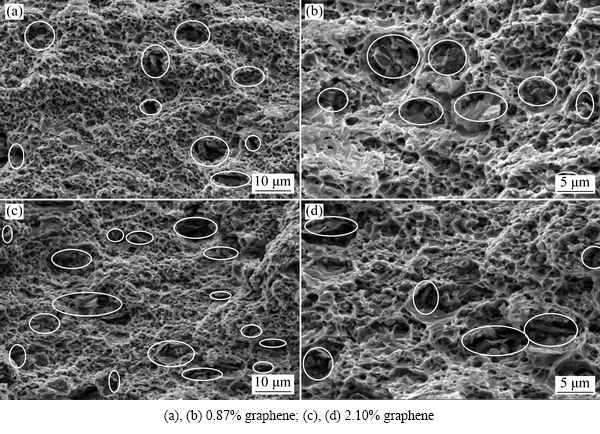

与以往的研究结果相似,本文中少量石墨烯的加入就实现了纯铝合金的抗拉强和和硬度的大幅度增加,随着石墨烯含量的继续增加,材料的性能并没有得到更大改善。图7所示为不同石墨烯含量石墨烯铝材料典型拉伸断口的SEM像。从图7中可以看出,石墨烯保持片状结构嵌入铝基体内,复合材料断裂之后石墨烯仍保持片状结构,可见通过超声和机械搅拌相结合的方法可以均匀分散镀镍石墨烯,并且不破坏石墨烯的二维层状结构。分析认为:石墨烯本身强度较高,抗拉强度可达到130 GPa,远高于铝基体的,石墨烯表面的镍和铝形成扩散结合层,增强了石墨烯和铝基体的结合强度,而石墨烯和铝之间良好的界面结合可以有效传递载荷。因此,在石墨烯铝材料中均匀分散的石墨烯可以大幅提升材料的抗拉强度和硬度。图6(c)与图6(d)所示为本试验制得的石墨烯铝材料强度、硬度和部分文献中的石墨烯铝材料强度、硬度对比,结果可知,与压力浸渗方法制备出石墨烯增强Al20Si复合材料(强度值为214MPa)及热挤压后的石墨烯增强铝基复合材料(抗拉强度为225 MPa,硬度值为135HB)[20]相比,本文中的石墨烯铝材料的抗拉强度和硬度值还有较大的提升空间。

图5 石墨烯铝材料中石墨烯的形貌及石墨烯-铝界面TEM像

Fig. 5 Morphologies of graphene and TEM images of graphene-aluminum inter face of aluminum/graphene composites (Content of graphene

2.3 石墨烯铝材料的物理性能

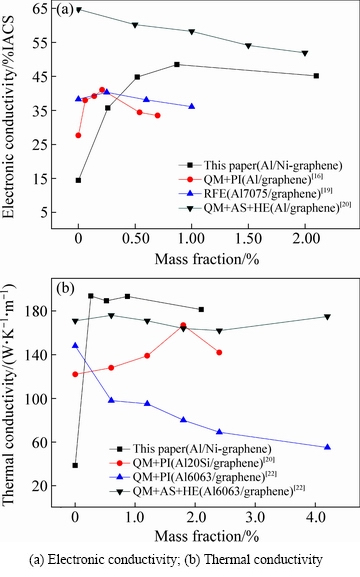

图8(a)所示为石墨烯铝材料的导电率随镀镍石墨烯含量变化曲线。从图8(a)可以看出,添加少量石墨烯即可显著改善石墨烯铝材料的导电性能,当石墨烯含量达到0.87%时,石墨烯铝材料的导电率达到峰值48.5%IACS,当石墨烯的含量高于0.87%时,石墨烯铝材料的导电性能逐渐降低。研究表明,石墨烯是目前已知的室温导电率最高的材料;对于铝基复合材料,导电率的影响因素有增强相的种类和含量,基体本身的晶粒尺寸和晶体缺陷等。总的来说,石墨烯铝材料的导电率是由以下因素综合作用:石墨烯的导电率高于基体铝的,有利于石墨烯铝材料导电率的提升,这是石墨烯含量较低时影响石墨烯铝材料导电率增加的主要因素;石墨烯的加入阻碍烧结过程中复合材料的晶粒长大,晶粒细化增加界面对电子的散射,降低材料的导电率;石墨烯含量增大,易造成石墨烯团聚,团聚的多层石墨烯会降低石墨烯铝材料的导电率,这是石墨烯含量较高时石墨烯铝材料导电率有所降低的主要原因;复合材料内部的微孔等组织缺陷也会降低材料的导电率。和其他文献中制备的石墨烯铝材料相比,本实验中制备的石墨烯铝材料导电性能没有到达预期效果。分析认为镍的导电性能较差,石墨烯铝材料中界面存在较多的镍降低了材料的导电性能。

图6 石墨烯铝材料的力学性能随石墨烯含量变化关系

Fig. 6 Change of mechanical properties with graphene content of aluminum graphene

图7 石墨烯铝材料的拉伸试样断口SEM像

Fig. 7 Fracture SEM images of aluminum/graphene composites

图8 石墨烯铝材料的物理性能随石墨烯含量变化关系

Fig. 8 Change of physical properties with graphene content

图8(b)所示为石墨烯铝材料的热导率随石墨烯含量的变化曲线。可见,仅加入0.26%石墨烯的石墨烯铝材料导热性能相对纯铝就大幅增加,热导率可达到193.7 W/(m·K);当石墨烯含量大于0.87%时,石墨烯铝材料的导热性能又稍有降低。分析认为:由于增强

体石墨烯的导热性能强于基体铝的,少量石墨烯的加入即可大幅提高石墨烯铝材料的热导率。随着石墨烯片层厚度的增加,声子散射发生改变,当石墨烯达到一定厚度时,石墨烯的导热性甚至会降低到石墨的程度,因此,随着石墨烯含量的增加,石墨烯团聚严重片层厚度增加,石墨烯铝材料的热导率又会逐渐降低。相对其他工艺和材料成分的石墨烯铝材料,本文中石墨烯片层分散均匀,界面结合良好,导致石墨烯铝材料的热导率较高。

3 结论

1) 表面镀镍处理的石墨烯易于分散且与纯铝基体界面结合良好;超声和机械搅拌方法可以有效分散石墨烯和纯铝粉体,获得混合均匀的石墨烯铝预混粉体。

2) 放电等离子烧结工艺可以有效制备成型石墨烯铝材料,其低温、快速烧结成形工艺特点使得石墨烯二维片层结构不被破坏,同时避免了Al4C3等界面产物的生成。

3) 少量石墨烯的加入可大幅提升石墨烯铝材料的抗拉强度,当石墨烯含量为0.87%时,石墨烯铝材料的抗拉强度达到194 MPa,硬度达到52HB,相对于纯铝粉末烧结试样的分别提高168%和23%。

4) 石墨烯铝材料具有高的导电率和热导率。0.87%的石墨烯铝材料的导电率可达到48.5%IACS,热导率达到193.4W/(K·m),但界面处过多的金属镍会降低石墨烯铝材料的导电率。

REFERENCES

[1] NOVOSELOV K S, GEIM A K, MOROZOV S V, JIANG D, ZHANG Y, DUBONOS S V, GRIGORIEVA I V, FIRSOY A A. Electric field effect in atomically thin carbon films[J]. Science, 2004, 306(5696): 666-9.

[2] 李多生, 吴文政, QIN Qing-hua, 周贤良, 左敦稳, 鲁世强, 郜友彬. 石墨烯/Al复合材料的微观结构及力学性能[J]. 中国有色金属学报, 2015(6): 1498-1504.

LI Duo-sheng, WU Wen-zheng, Qin Qing-hua, ZHOU Xian-liang, ZUO Dun-wen, LU Shi-qiang, GAO You-bin. Microstructure and mechanical properties of graphene/Al composites[J]. The Chinese Journal of Nonferrous Metals, 2015(6): 1498-1504.

[3] MEYER J C, GEIM A K, KATSNELSON M I, NOVOSELOV K S, BOOTH T J, ROTH S. The structure of suspended graphene sheets[J]. Nature, 2007, 446: 60-63.

[4] 潘利科, 韩建民, 张颖骁, 杨智勇, 李志强, 李卫京. 高含量SiCp/A356复合材料衍生材料的组织与性能[J]. 中国有色金属学报, 2016, 26(10): 2078-2085.

PAN Li-ke, HAN Jian-min, ZHANG Ying-xiao, YANG Zhi-yong, LI Zhi-qiang, LI Wei-jing. Microstructure and properties of derived material for high content SiCp/A356 composites[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(10): 2078-2085.

[5] GEIM A K, NOVOSELOV K S. The rise of graphene[J]. Nature Materials, 2007, 6: 183-191.

[6] PAWAR P B, UTPAT A A. Development of aluminium based silicon carbide particulate metal matrix composite for spur gear[J]. Procedia Materials Science, 2014, 6: 1150-1156.

[7] 齐天娇, 俞泽民, 许志鹏, 段雪峰, 杨 笛, 李 旺. 石墨烯增强铝基复合材料制备及力学性能研究[J]. 哈尔滨理工大学学报, 2015, 20(3): 61-65.

QI Tian-jiao, YU Ze-min, XU Zhi-peng, DUAN Xue-feng, YANG Di, LI Wang. Preparation and mechanical properties of graphene reinforced aluminum matrix composites[J]. Journal of Harbin University of Science and Technology, 2015, 20(3): 61-65.

[8] WILLIAMS J C, STARKE E A. Progress in structural materials for aerospace systems[J]. Acta Materialia, 2003, 51(19): 5775-5799.

[9] 邹高鹏, 贺显聪, 孙滨洲, 朱建斌, 白苏南, 许永祥, 张 慧, 杨少锋. 微纳石墨烯片增强铝合金的力学性能及其机理[J]. 中国有色金属学报, 2017, 27(11): 2228-2235.

ZOU Gao-peng, HE Xian-cong, SUN Bin-zhou, ZHU Jian-bin, BAI Su-nan, XU Yong-xiang, ZHANG Hui, YANG Shao-feng. Mechanical properties and mechanism of aluminum alloy reinforced by micro nano graphene sheets[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(11): 2228-2235.

[10] BASTWROS M, KIM G Y, ZHU C, ZHANG K, WANG S R, TANG X D, WANG X W. Effect of ball milling on graphene reinforced Al6061 composite fabricated by semi-solid sintering[J]. Composites: Part B, 2014, 60: 111-118.

[11] YAN S J, DAI S L, ZHANG X Y, YANG C, HONG Q H, CHEN J Z, LIN Z M. Investigating aluminum alloy reinforced by graphene nanoflakes[J]. Materials Science and Engineering A, 2014, 612: 440-444.

[12] WANG J Y, LI Z Q, FAN G L, PAN H H, CHEN Z X, ZHANG D. Reinforcement with graphene nanosheets in aluminum matrix composites[J]. Scripta Materialia, 2012, 66(8): 594-597.

[13] LI J L, XIONG Y C, WANG X D, YAN S J, YANG C, HE W W, CHEN J Z, WANG S Q, ZHANG X Y, DAI S L. Microstructure and tensile properties of bulk nanostructured aluminum/graphene composites prepared via cryomilling[J]. Materials Science & Engineering A, 2015, 626: 400-405.

[14] RASHAD M, PAN S F, YU Z W, ASIF M, LIN H, PAN R. Investigation on microstructural, mechanical and electrochemical properties of aluminum composites reinforced with graphene nanoplatelets[J]. Progress in Natural Science: Materials International, 2015, 25: 460-470.

[15] SHIN S E, CHOI H J, SHIN J H, BAE D H. Strengthening behavior of few-layered graphene/aluminum composites[J]. Carbon, 2015, 82: 143-151.

[16] 邹君玉. 石墨烯/纯铝复合材料的制备及其性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2015.

ZOU Jun-yu. The preparation and properties of graphene reinforced pure aluminum composites[D]. Harbin: Harbin Institute of Technology, 2015.

[17] 罗 昊. 石墨烯微片增强铝基复合材料组织与性能的研究[D]. 哈尔滨: 哈尔滨工业大学, 2015.

LUO Hao. Research on the microstructure and properties of graphene nanoplatelets reinforced aluminum matrix composites[D]. Harbin: Harbin Institute of Technology, 2015.

[18] 高 鑫. 石墨烯增强铝基复合材料的制备及力学性能研究[D]. 哈尔滨: 哈尔滨理工大学, 2015.

GAO Xin. Preparation and mechanical properties of graphene reinforced aluminum matrix composites[D]. Harbin: Harbin University of Science and Technology, 2015.

[19] 赵 鹏. 石墨烯增强铝基复合材料组织及性能研究[D]. 南昌: 南昌航空大学, 2017.

ZHAO Peng. Study on microstructure and properties of the aluminum matrix composites reinforced with the graphene[D]. Nanchang: Nanchang Hangkong University, 2017.

[20] 吴 昊. 粉末冶金法制备铝基复合材料及其性能表征[D]. 合肥: 合肥工业大学, 2013.

WU Hao. Preparation and characterization of aluminum matrix composites by powder metallurgy[D]. Hefei: Hefei University of Technology, 2013.

[21] 赵晓东. 铝碳基复合材料的合成工艺研究[D]. 青岛: 青岛科技大学, 2015.

ZHAO Xiao-dong. Preparation of carbon aluminum matrix composites[D]. Qingdao: Qingdao University of Science and Technology, 2015.

[22] 谢一鸣. 石墨烯纳米片/6063A1复合材料微观组织及性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2016.

XIE Yi-ming. Research on the microstructure and properties of graphene nanoplatelets reinforced 6063 aluminum alloy matrix composites[D]. Harbin: Harbin University of Science and Technology, 2016.

Microstructure and properties of graphene/aluminum composites prepared via spark plasma sintering

SHEN Chao1, ZHU De-zhi1, LUO Ming-qiang2, CHEN Wen-si2, LI Hui2, WANG Chun-yu3

(1. Guangdong Key Laboratory for Advanced Metallic Materials Processing,

South China University of Technology, Guangzhou 510640, China;

2. Guangdong Xingfa Aluminum (Jiangxi) Co., Ltd., Yichun 336000, China;

3. School of Materials Science and Engineering, Harbin Institute of Technology at Weihai, Weihai 264200, China)

Abstract: In order to solve the problem of poor interfacial wettability and difficult to disperse uniformly of graphene and aluminum, the ultrasonic and mechanical stirring were used to disperse powder, and the spark plasma sintering was employed for the fabrication of the aluminum/graphene composites. In order to investigate the influence of Ni-graphene content on the microstructure and properties of aluminum/graphene composites, the microstructure and properties were characterized and determined by scanning electron microscopy(SEM), transmission electron microscopy (TEM), electronic universal testing machine, conductivity measuring instrument, and thermal conductivity tester. The results show that ultrasonic dispersion and mechanical agitation can make Ni-graphene uniformly disperse in pure aluminum matrix. With the content of Ni-graphene increases from 0% to 0.87%, all of the tensile strength, hardness, electrical conductivity and thermal conductivity of aluminum/graphene composites are significantly improved. The tensile strength of the composites reinforced with 0.87% Ni-graphene can reach 194 MPa, and the hardness is 52 HB, which are increased by 168% and 23% compared with those of the pure aluminum prepared via spark plasma sintering, respectively. The conductivity of the composites can reach 48.5%IACS and the thermal conductivity is 193.4 W/(K·m). The Ni-graphene is beneficial for the interface bonding between graphene and aluminum alloy, so, the strength and hardness of the composites can be enhanced. However, too much nickel at the interface will reduce the conductivity of aluminum/graphene composites.

Key words: graphene; spark plasma sintering; microstructures; property

Foundation item: Project(2017(No.83)) supported by the Green Manufacturing System of Ministry of Industry and Information Technology, China; Project(2016A010103006) supported by Guangdong Science and Technology Program, China; Project(20171ACH80012) supported by Key Research and Development Plan of Jiangxi Province, China; Project(2016AG101761) supported by Scientific and Technological Innovation in Foshan, China

Received date: 2018-04-09; Accepted date: 2018-06-11

Corresponding author: ZHU De-zhi; Tel: +86-20-87113267; E-mail: mezhudz@scut.edu.cn

(编辑 龙怀中)

基金项目:工信部绿色制造系统集成项目(2017(83));广东省科技计划项目(2016A010103006);江西省重点研发计划项目(20171ACH80012);佛山市科技创新项目(2016AG101761)

收稿日期:2018-04-09;修订日期:2018-06-11

通信作者:朱德智,副教授,博士;电话:020-87113267;E-mail:mezhudz@scut.edu.cn