文章编号:1004-0609(2010)S1-s0309-06

机械合金化与放电等离子烧结制备

Ti-45Al-5.5(Cr, Nb, B, Ta)合金

肖树龙1,于宏宝2,韩杰才3,徐丽娟1,陈玉勇1

(1. 哈尔滨工业大学 材料科学与工程学院,哈尔滨 150001;2. 山西航天机电设备研究所,晋中 030800;

3. 哈尔滨工业大学 航天学院,哈尔滨 150001)

摘 要:采用双步球磨法和放电等离子烧结技术制备细晶Ti-45Al-5.5(Cr, Nb, B, Ta)(摩尔分数,%)合金,利用扫描电子显微镜(SEM)和X射线衍射仪(XRD)等对球磨后的粉末形貌、相组成以及烧结块体的显微组织结构进行观察和分析,研究烧结温度对Ti-45Al-5.5(Cr, Nb, B, Ta)合金显微组织和力学性能的影响。结果表明:双步球磨粉末的颗粒形状较规则,其颗粒尺寸为10~40 μm,内部结构较均匀,主要由TiAl和Ti3Al相组成;放电等离子烧结后的块体主要由主相TiAl、少量的Ti3Al相及Ti2Al和TiB2相组成;当烧结温度为1 000 ℃时,烧结块体主要为等轴晶组织,等轴晶粒平均尺小于500 nm;当烧结温度为1 100 ℃时,烧结块体致密、无孔洞,部分等轴晶粒明显长大;随着烧结温度的升高,Ti-45Al-5.5(Cr, Nb, B, Ta)合金的显微硬度随之增大,抗压强度和抗弯强度却随之降低;压缩断口形貌分析表明:Ti-45Al-5.5(Cr, Nb, B, Ta)合金在1 000 ℃时,属于沿晶断裂,在1 100 ℃时,断口以沿晶断裂为主,存在部分解理断裂。弯曲断口形貌分析表明:Ti-45Al-5.5(Cr, Nb, B, Ta)合金以沿晶断裂为主,存在部分解理断裂。

关键词:TiAl合金;双步球磨;放电等离子烧结;显微组织;力学性能

中图分类号:TG 146.2 文献标志码:A

Preparation of Ti-45Al-5.5(Cr, Nb, B, Ta) alloy by

mechanical milling and spark plasma sintering

XIAO Shu-long1, YU Hong-bao2, HAN Jie-cai3, XU Li-juan1, CHEN Yu-yong1

(1. School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China;

2. Institute of Shanxi Astronauties Electromechanical Device, Jinzhong 030800, China;

3. School of Astronautics, Harbin Institute of Technology, Harbin 150001, China)

Abstract: A fine-grained TiAl alloy with composition of Ti-45Al-5.5(Cr, Nb, B, Ta)(mole fraction, %) was prepared by double mechanical milling (DMM) and spark plasma sintering (SPS). The effects of sintering temperature on the microstructure and mechanical properties of the Ti-45Al-5.5(Cr, Nb, B, Ta) were studied by X-ray diffractometry(XRD), scanning electron microscopy (SEM) and mechanical testing machine. The results show that the morphology of double mechanical milling powder is regular with sizes of 10-40 μm and the internal structure is even. TiAl and Ti3Al are the main phases in the powders, with few phases such as Ti3Al, Ti2Al and TiB2 observed in the SPS bulk samples of Ti-45Al-5.5(Cr, Nb, B, Ta) alloy. For samples sintered at 1 000 ℃, the microstructure of equiaxed crystal grain with sizes less than 500 nm is achieved. For samples sintered at 1 100 ℃, the sizes of few equiaxed crystal grain obviously increases. The SPS bulk samples exhibit better microstructures. The micro-hardness of the SPS bulk samples at 1 000 ℃ is obviously lower than that of the SPS bulk samples at 1 100 ℃. The compression strength and bending strength of the SPS bulk samples at 1 000 ℃ is obviously higher than that of the SPS bulk samples at 1 100 ℃. On the base of analysis of fractographies, it shows that the compression fracture transformation of the SPS Ti-45Al-5.5(Cr, Nb, B, Ta) alloy at 1 000 ℃ is intergranular rupture and that at 1 100 ℃ is intergranular rupture and cleavage fracture. The bending fracture transformation of the SPS Ti-45Al-5.5(Cr, Nb, B, Ta) alloy samples is intergranular rupture and cleavage fracture.

Key words: TiAl alloy; double mechanical milling; spark plasma sintering (SPS); microstructure; mechanical property

TiAl基合金具有密度低、比强度和比模量高,抗氧化性和抗蠕变性能好以及抗疲劳性能优良等特点,是一种非常有潜力的高温结构材料,在航空航天、军工和民用等领域具有广泛的应用前景[1-6]。然而,TiAl基合金的室温塑性低,制约和阻碍了TiAl基合金的发展和应用[7]。要解决以上问题,其中一个重要途径就是根据材料自身特点,研究和开发出更加行之有效的制备与成形技术[8]。近年来,采用粉末冶金方法制备TiAl基合金已引起了极大关注。采用机械合金化和放电等离子烧结相结合的方法制备TiAl基合金,是近年来发展的一种新技术,由于放电等离子烧结具有非常高的热效率,因而容易得到均匀的、高质量的烧结体[8]。在TiAl基合金的各种添加元素中,Nb可以提高合金的抗氧化性、抗蠕变性能、合金的强度及组织稳定性;Cr可以提高合金的塑性、抗氧化性和断裂韧性;Ta可以提高合金的抗氧化性和抗蠕变性能[9];B可以提高合金的塑性、强度及细化晶粒[10]。由于细化显微组织可以提高材料室温塑性,为了综合改善TiAl基合金的室温力学性能,提高其室温塑性,本文作者采用机械合金化(双步球磨)与等离子烧结(SPS)工艺相结合制备细晶Ti-45Al-5.5(Cr, Nb, B, Ta)(摩尔分数,%)合金,观察双步球磨后粉末的显微组织结构,同时对等离子烧结细晶Ti-45Al-5.5(Cr, Nb, B, Ta)合金的微观结构和力学性能进行研究,分析烧结温度对合金显微组织和力学性能的影响。

1 实验

1.1 实验材料及球磨工艺

实验所用原始粉末如下:Ti粉(纯度为99.9%,平均粒度150 μm),Al粉(纯度为99.9%,平均粒度70 μm),Nb粉(99.8%,平均粒度50 μm),Cr粉(99%,平均粒度50 μm),B粉(99.999%,平均粒度0.6 μm),Ta粉(99.98%,平均粒度50 μm)。采用双步球磨法来制备Ti-45Al-5.5(Cr, Nb, B, Ta)合金粉末,其工艺如下:12 h低速混粉(100 r/min)→6 h高能球磨(一步球磨,300 r/min)→粉末(700 ℃, 2 h)真空热处理→6 h高能球磨(二步球磨,300 r/min)。球磨过程在高纯氩气环境下进行(氧含量低于5.0×105),球料质量比6:1。球磨机为PM100型行星式球磨机,磨球为不锈钢球,一步球磨加入0.63%(质量分数)硬脂酸作为过程控制剂,二步球磨不加入过程控制剂。球磨过程在室温下进行,对应室温下连续球磨30 min,停机冷却30 min。

1.2 烧结工艺

实验用放电等离子烧结设备型号为Dr. SinterSPS-1050,放电等离子烧结工艺如下:初始状态采用高纯度氩气清洗炉体3次,按100 ℃/min升温至300 ℃保温10 min,再以100 ℃/min升温至θ -100 ℃(θ为最终温度),然后以50 ℃/min升温1 min之后采用25 ℃/min升温2 min至温度θ,随后在该温度下保温(5 min)后随炉冷却。对应加压:在500 ℃手动加压至最终温度,外加轴向压力均为50 MPa,系统真空度为2 Pa。粉末烧结温度分别为1 000和1 100 ℃。烧结块体直径为30 mm,厚度为6~7 mm。

1.3 测试方法

采用Philips X-Pert 型X射线衍射(XRD),Hitachi S4000型扫描电子显微镜(SEM)对球磨后的粉末形貌和相组成以及烧结块体的显微组织结构进行分析。

采用阿基米德法精确测量试样密度,测量前将试样用超声波清洗20 min,然后采用烘干箱烘干,每个试样测量5次。硬度采用HVS-1000型显微硬度计上进行测量,试样采用直线型等距离5点,间距为0.5 mm,测定5次的平均值,外加载荷1 N,保压时间为15 s。

采用INSTRON型实验机进行压缩性能测试,压缩试样尺寸为d 3 mm×4.5 mm,加载速率为0.5 mm/min,每种材料测试3个试样取其平均值。抗弯强度采用INSTRON 型实验机上通过三点弯曲法测定,试样尺寸为3 mm×4 mm×20 mm,跨距为16 mm,加载速率为0.5 mm/min,抗弯强度采用式(1)计算:

(1)

(1)

式中:σ为合金的抗弯强度, MPa;F为断裂载荷, N;L为试样跨距, mm;b为试样的宽度, mm;h为试样的高度, mm。采用Hitachi S4000型扫描电子显微镜(SEM) 对试样的压缩断口和弯曲断口进行观察分析。

2 结果与分析

2.1 双步球磨混合粉末的形貌及相组成

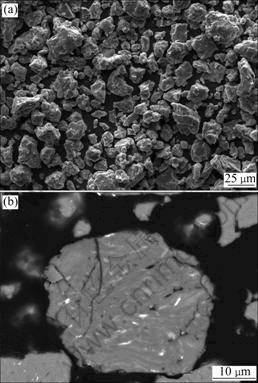

图1所示为Ti-45Al-5.5(Cr, Nb, B, Ta)混合粉末经过双步球磨后的SEM形貌及内部结构。从图1中可以看出,经过双步球磨后,粉末颗粒形状变得较为规则,粉末颗粒等轴化,其颗粒尺寸在10~40 μm之间,内部结构均匀,片层复合结构已经形成。

图1 双步球磨Ti-45Al-5.5(Cr, Nb, B, Ta)合金粉末及其内部结构的SEM像

Fig.1 SEM images of double mechanical milling Ti-45Al- 5.5(Cr, Nb, B, Ta) powders (a) and internal structure (b)

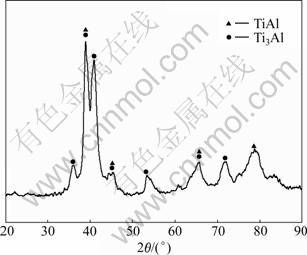

图2所示为双步球磨Ti-45Al-5.5(Cr, Nb, B, Ta)粉末的XRD谱,粉末主要由TiAl和Ti3Al相组成。由图2可以看出,TiAl峰和Ti3Al变得非常宽,这说明粉末的晶粒尺寸已到纳米级。双步球磨法(一步球磨+热处理+二步球磨)可以实现多体系球磨,一步球磨实现粉末部分固溶,缩短Ti/Al片层的层间距,增大粉末晶格畸变,热处理过程可以形成部分硬脆相;二步球磨加剧粉末球磨过程及粉末的细化,在二步球磨过程中断裂占主导地位,变形及冷焊几率减弱,粉末颗粒、内部结构不断细化,最终形成主要由TiAl和Ti3Al组成的纳米晶合金粉末。

图2 双步球磨后Ti-45Al-5.5(Cr, Nb, B, Ta)粉末的XRD谱

Fig.2 XRD patterns of Ti-45Al-5.5(Cr, Nb, B, Ta) powders after double mechanical milling

2.1 放电等离子烧结块体的微观结构及相组成分析

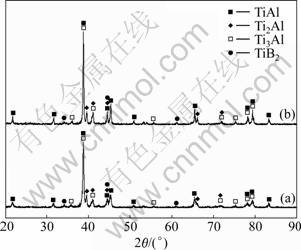

图3所示为Ti-45Al-5.5(Cr, Nb, B, Ta)粉末等离子烧结块体的XRD谱。由图3可看出,等离子烧结块体主要由主相TiAl和少量的Ti3Al相及Ti2Al和TiB2相组成。目前,有关于Ti2Al相形成研究者有两种观点[11]:一种观点认为蠕变变形过程中位错聚集造成Ti2Al相形成;另一种观点认为Ti2Al相在晶界出形核产生,本研究关于Ti2Al相的形成机理将在后续工作中进行研究。另外,许多研究者已经对Ti-Al系添加B元素形成硼化物机制进行大量的研究,有关TiB2相的

图3 Ti-45Al-5.5(Cr, Nb, B, Ta)不同温度SPS烧结块体的XRD谱

Fig.3 XRD patterns of Ti-45Al-5.5(Cr, Nb, B, Ta) bulk samples prepared by SPS at different temperatures: (a) 1 000 ℃; (b) 1 100 ℃

形成可以通过相平衡热力学计算,即反应的吉布斯自由能变化公式:

式中: 为标准态吉布斯自由能;cp为定压比热容;νB化学反应中的化学计量数;T为热力学的温度。

为标准态吉布斯自由能;cp为定压比热容;νB化学反应中的化学计量数;T为热力学的温度。

根据Ti-B和Al-B二元相图,形成硼化物主要为TiB、TiB2、Ti3B4、α-AlB12、β-AlB12, AlB10、AlB2。研究者认为β-AlB12和AlB10通常分别以Al2B48C2和AlB24C4的形式存在,因此主要考虑TiB、TiB2、Ti3B4、α-AlB12、AlB2的形成。Cr、Nb、Ta元素与B元素较低的扩散率和较低的体积分数,因此认为其间不发生反应。WANG等[12]计算温度在298~2 000 K之间形成硼化物的相吉布斯能,得出Ti(s)+B(s)→TiB2(s)反应形成吉布斯自由能最低,因此易形成TiB2。

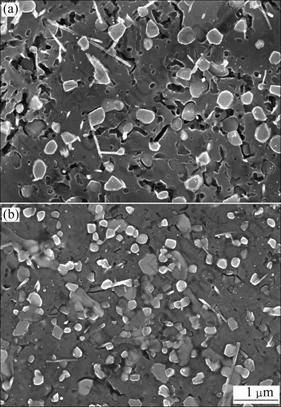

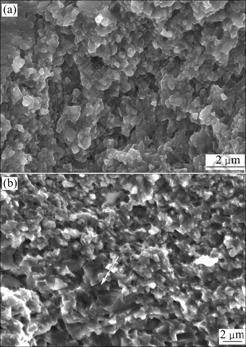

烧结温度为1 000 ℃时,烧结块体的密度为4.174 g/cm3;当烧结温度上升为1 100 ℃时,烧结块体的密度为4.1748 g/cm3;随着烧结温度的继续升高,烧结块体的密度也随之增加。图4所示为Ti-45Al-5.5(Cr, Nb, B, Ta)不同温度SPS烧结块体的SEM像。从图4中可以看出,双步球磨Ti-45Al-5.5(Cr, Nb, B, Ta)粉末经过1 000 ℃ SPS烧结获得的主要为等轴晶组织,晶粒平均尺寸小于500 nm,粉末颗粒扩散不完全,存在原始颗粒边界,并在颗粒间存在大量孔隙,材料没有达到完全致密化。等轴晶粒平均尺;烧结温度为1 100 ℃时,烧结块体致密、无孔洞,部分等轴晶粒明显 长大。

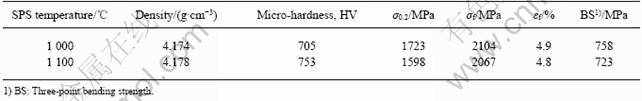

表1所列为Ti-45Al-5.5(Cr, Nb, B, Ta)合金不同烧结温度下的力学性能。从表1中可以看出,当烧结温度从1 000 ℃上升到1 100 ℃时,合金的显微硬度从705HV增加到753HV,屈服强度(σ0.2)从1 723 MPa降低为 1 598 MPa,断裂强度(σf)从2 104 MPa降低至 2 067 MPa,同时,三点抗弯强度(BS)从758 MPa降低为723 MPa,压缩率(εf)从4.9%降低到4.8%。烧结温度从1 000 ℃提高到1 100 ℃,部分晶粒尺寸随之增加,屈服强度强度随之降低,这与Hall-Petch关系相符合,反映出晶粒尺寸对强度的影响。

图4 Ti-45Al-5.5(Cr, Nb, B, Ta) 块体经不同温度SPS烧结后的SEM像

Fig.4 SEM images of Ti-45Al-5.5(Cr, Nb, B, Ta) bulk samples prepared by SPS at different temperatures: (a) 1 000 ℃; (b) 1 100 ℃

图5所示为Ti-45Al-5.5(Cr, Nb, B, Ta)合金压缩断口的SEM像。从图5可以看出,1 000 ℃时合金属于沿晶断裂,合金1 100 ℃以沿晶断裂为主,存在部分解理断裂,解理面如图中箭头所指。

图6所示为Ti-45Al-5.5(Cr, Nb, B, Ta)合金弯曲断口的SEM像。由图6可看出,Ti-45Al-5.5(Cr, Nb, B, Ta)合金以沿晶断裂为主,存在部分解理断裂,解理面如图中箭头所指。

表1 不同温度等离子烧结Ti-45Al-5.5(Cr, Nb, B, Ta)合金的力学性能

Table 1 Mechanical properties of bulk Ti-45Al-5.5(Cr, Nb, B, Ta) samples prepared by SPS at different temperatures

图5 SPS烧结Ti-45Al-5.5(Cr, Nb, B, Ta)合金压缩断口的SEM像

Fig.5 SEM images of fractures of compressed Ti-45Al-5.5(Cr, Nb, B, Ta) prepared by SPS; (a) 1 000 ℃; (b) 1 100 ℃

图6 SPS烧结Ti-45Al-5.5(Cr,Nb,B,Ta)合金弯曲断口的SEM像

Fig.6 SEM images of fracture of Ti-45Al-5.5(Cr, Nb, B, Ta) bending samples prepared by SPS: (a) 1 000 ℃; (b) 1 100 ℃

3 结论

1) 双步球磨粉末的颗粒形状较规则,内部结构均匀,主要由TiAl和Ti3Al相组成。放电等离子烧结后的块体主要由主相TiAl、少量的Ti3Al相及Ti2Al和TiB2相组成。

2) 烧结温度为1 000 ℃时,烧结块体获得的主要是等轴晶组织;烧结温度为1 100 ℃时,烧结块体致密、无孔洞,部分等轴晶粒明显长大;随着烧结温度的升高,Ti-45Al-5.5(Cr, Nb, B, Ta)合金的显微硬度随之增加,抗压强度和抗弯强度却随之降低。

3) 经1 000 ℃烧结的Ti-45Al-5.5(Cr, Nb, B, Ta)合金压缩时属于沿晶断裂,经1 100 ℃烧结的合金以沿晶断裂为主存在部分解理断裂。两种烧结温度的合金弯曲时以沿晶断裂为主,存在部分解理断裂。

REFERENCES

[1] FOROUZANMELU N, KARIMZADEH F, ENAYATI M H. Study on solid-state reactions of nanocrystalline TiAl synthesized by mechanical alloying [J]. Journal of Alloys and Compounds, 2009, 471(1/2): 93-97.

[2] COURET A, MOLENAT G, GALY J, THOMAS M. Microstructures and mechanical properties of TiAl alloys consolidated by spark plasma sintering [J]. Intermetallics, 2008, 16(9): 1134-1141.

[3] BHATTACHARYA P, BELLON P, AVERBACK R S, HALES S J. Nanocrystalline TiAl powders synthesized by high-energy ball milling: Effects of milling parameters on yield and contamination [J]. Journal of Alloys and Compounds, 2004, 368(1/2): 187-196.

[4] MOON K II, LEE K S. A study of the microstructure of nanocrystalline Al-Ti alloys synthesized by ball milling in a hydrogen atmosphere and hot extrusion [J]. Journal of Alloys and Compounds, 1999, 291(1/2): 312-321.

[5] LI Z W, GAO W, ZHANG D L, CAI Z H. High temperature oxidation behaviour of a TiAl-Al2O3 intermetallic matrix composite [J]. Corrosion Science, 2004, 46(8): 1997-2007.

[6] WU Y, HWANG S K. Microstructural refinement and improvement of mechanical properties and oxidation resistance in EPM TiAl-based intermetallics with yttrium addition [J]. Acta Materialia, 2002, 50(6): 1479-1493.

[7] 李东辉, 吴玉程, 李 云, 龚 明, 郑玉春. 机械球磨与不同温度烧结下的TiAl合金研究[J]. 合肥工业大学学报, 2006, 29(8): 969-975.

LI Dong-hui, WU Yu-cheng, LI Yun, GONG Ming, ZHENG Yu-chun. Investigation of TiAl-based alloys prepared by the mechanical milling method and sintered at different temperatures [J]. Journal of Hefei University of Technology, 2006, 29(8): 969-975.

[8] 路 新, 何新波, 李世琼, 曲选辉. 放电等离子烧结TiAl基合金的显微组织及力学性能[J]. 北京科技大学学报, 2008, 30(3): 254-257.

LU Xin, HE Xin-bo, LI Shi-qiong, QU Xuan-hui. Microstructures and mechanical properties of TiAl-based alloys by spark plasma sintering [J]. Journal of University of Science and Technology, 2008, 30(3): 254-257.

[9] 李书江, 王艳丽, 林均品, 林 志, 陈国良. 微量C, B对高铌TiAl合金显微组织与力学性能的影响[J]. 稀有金属材料与工程, 2004, 33(2): 144-148.

LI Shu-jiang, WANG Yan-li, LIN Jun-pin, LIN Zhi, CHEN Guo-liang. Influence of C and B elements on structures and mechanical properties for high Nb containing TiAl alloy [J]. Rare Metal Materials and Engineering, 2004, 33(2): 144-148.

[10] 史耀君, 杜宇雷, 陈 光. 高铌钛铝基合金研究进展[J]. 稀有金属, 2007, 31(6): 834-839.

SHI Yao-jun, DU Yu-lei, CHEN Guang. Progress in research on high niobium containing TiAl-based alloy [J]. Rare Metals, 2007, 31(6): 834-839.

[11] YANG S J, NAM S W. Investigation of α2/γ phase transformation mechanism under the interaction of dislocation with lamellar interface in primary creep of lamellar TiAl alloys [J]. Materials Science and Engineering A, 2002, 329/331: 898-905.

[12] WANG Y H, LIN J P, HE Y H, WANG Y L, CHEN G L. Microstructural characteristics of Ti-45Al-8.5Nb/TiB2 composites by powder metallurgy [J]. Journal of Alloys and Compounds, 2009, 468(1/2): 505-511.

(编辑 李艳红)

肖树龙; 电话: 0451-86418802; E-mail: xiaoshulong@hit.edu.cn