Trans. Nonferrous Met. Soc. China 22(2012) 1086-1091

Microstructure and mechanical properties of TiAl-based alloy prepared by double mechanical milling and spark plasma sintering

XIAO Shu-long1,2, XU Li-juan1,2, CHEN Yu-yong1,2, YU Hong-bao3

1. School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China;

2. National Key Laboratory for Precision Hot Processing of Metals,

Harbin Institute of Technology, Harbin 150001, China;

3. School of Materials Science and Engineering, Northwestern Polytechnical University, Xi’an 710072, China

Received 29 September 2011; accepted 16 January 2012

Abstract: A fine-grained TiAl alloy with a composition of Ti-45Al-2Cr-2Nb-1B-0.5Ta-0.225Y (mole fraction, %) was prepared by double mechanical milling(DMM) and spark plasma sintering(SPS). The relationship among sintering temperature, microstructure and mechanical properties was studied. The results show that the morphology of double mechanical milled powder is regular with size in the range of 20-40 μm and mainly composed of TiAl and Ti3Al phases. The main phase TiAl and few phases Ti3Al, Ti2Al and TiB2 were observed in the SPSed alloys. For samples sintered at 900℃, the equiaxed crystal grain microstructure is achieved with size in the range of 100-200 nm. With increasing the SPS temperature from 900℃ to 1000℃, the size of equiaxed crystal grain obviously increases, the microhardness decreases from HV658 to HV616, and the bending strength decreases from 781 MPa to 652 MPa. In the meantime, the compression fracture strength also decreases from 2769 MPa to 2669 MPa, and the strain to fracture in compression increases from 11.69% to 17.76%. On the base of analysis of fractographies, it shows that the compression fracture transform of the SPSed alloys is intergranular rupture.

Key words: TiAl-based alloys; mechanical alloying; spark plasma sintering; microstructure; mechanical properties

1 Introduction

TiAl-based alloys have been considered attractive candidate materials to replace nickel-based superalloys, titanium alloys and other high temperature alloys for aerospace structural and engine applications due to their low density, high specific strength and relatively good properties at an elevated temperature and high creep resistance at temperatures up to 900℃ [1]. However, their low room temperature ductility and elevated temperature formability limit the alloys being widely used. In attempts to improve ductility, recent researches have focused on the production of ultrafine grained TiAl based alloys [2,3]. Grain refinement through boron addition has been investigated in a range of cast TiAl-based alloys and the local boron concentration in the solidification during casting has effect on the grain size [4]. Ultrafine grained intermetallic/ceramic composites have been prepared by mechanical alloying and subsequent powder consolidation [5].

Powder metallurgy (PM) is a favourable process for synthesizing ultrafine grained and nanostructure TiAl- based alloys [6]. PM has the advantages of ensuring high microstructure and compositional homogeneity, and allows the use of nanostructure or ultrafine structured powders and nanopowders produced using various processes such as high energy mechanical milling and rapid solidification [7,8]. TiAl-based alloys were prepared by high-energy ball-milling and hot-pressing sintering [9]. The microstructures and deformation properties of Ti-46Al-(Cr,Nb,W,B) alloy consolidated by pseudo-HIP technology were investigated [10].

SPS is found to compact powders satisfactorily through the simultaneous application of direct current pulses of high intensity and uniaxial pressure. Assisted by the applied pressure, such an electric current induces a temperature elevation within the sample by Joule’s effect, at least in metallic materials, thus leading to powder sintering [11]. Ti-47.5Al-2.5V-1.0Cr alloys from the prealloyed powder were prepared by spark plasma sintering [12]. LI et al [13] investigated the effect of SPS temperature on the microstructure of the TiAl-based alloys fabricated by the mechanical milling and SPS. SPS technique has already been successfully used by several groups of researchers in synthesizing bulk TiAl-based alloys with some of them being nanostructured or ultrafine structured. In most of these studies, pre-alloyed TiAl-based powders produced by atomisation or by mechanical alloying were used [14,15]. Alloying elements, such as Mo, Nb, B and Y, have been added to TiAl-based alloys in order to improve the mechanical properties and oxidation resistance [16]. In previous studies, YU et al [17] fabricated fine-grained Ti-45Al-2Cr-2Nb-1B alloys by low temperature high-energy ball-milling and hot isostatic pressing. In the present work, Ti-45Al-2Cr-2Nb-1B-0.5Ta-0.225Y (mole fraction, %) alloy is prepared by high energy double mechanical milling and SPS. The aim of this study is to determine the effect of SPS temperature on the microstructure and mechanical properties of the TiAl-based alloy with ultrafine grained microstructures.

2 Experimental

The powders of Ti(99.9%), Al(99.9%), Cr(99%), Nb(99.8%), B(99.999%), Ta(99.98%) and Y(99.9%) were used as the starting materials. The mean particle sizes of Ti and Al were less than 150 μm and 70 μm, respectively, Cr, Nb, Ta and Y powders 50 μm, and B powders 0.6 μm. Before milling, the powders were well mixed as Ti-45Al-2Cr-2Nb- 1B-0.5Ta-0.225Y(%) composition. The high energy double mechanical milling(DMM) was carried out in a planetary ball mill under high purity argon atmosphere. The DMM was done with a stainless steel vial containing 100 g of powder mixture, 0.63% (mass fraction) of stearic acid added as a process control agent. Milling conditions are given in Table 1. The milling process consisted of first milling the powders with a low rotation speed of 100 r/min to thoroughly mixing the powders, and subsequent high energy mechanical milling the powder mixture for 6 h with a high rotation speed of 300 r/min (MA1), after 2 h vacuum heat treatment at 700℃ and then 6 h with a high rotation speed of 300 r/min (MA2). To minimize sticking of powders on vial, ball interrupted milling was carried out, and the milling machine was stopped for 30 min after every 30 min of milling.

Dr.Sinter SPS-1050 furnace was employed to sinter and consolidate the alloying powders under a uniaxial pressure of 50 MPa at 900℃ and 1000℃, respectively. The powder compact was heated through generating spark plasma in the furnace first to a temperature equal to t-100℃ at a rate of 100℃/min, where t is the designated sintering temperature (900℃ and 1000℃). It was then heated to t-50℃ at a rate of 50℃/min, followed by heating to the designated sintering temperature at a rate of 25℃/min. The furnace was held for 5 min at the sintering temperature and then the sample was cooled with the furnace. The sintered samples were cylindrical disks with a diameter of 30 mm and thickness of 6-7 mm.

Table 1 Milling conditions used in mechanical alloying of TiAl-based powder fixture

An electric discharge machining(EDM) cutter was used to produce the metallography samples and the specimens for compression. The density of the cut samples was measured using the Archimedes technique. The microstructures of the powder particles and bulk SPSed samples were characterized using X-ray diffractometry(XRD) (Philips X-Pert system with Cu Kα radiation) and scanning electron microscopy(SEM) (Hitachi S-4700 SEM equipped with an energy dispersive spectrometer). The compression tests were performed using an INSTRON mechanical testing machine with cylindrical specimen dimensions of 3 mm×4.5 mm, and rectangular three-point bending test specimens with dimensions of 3 mm×4 mm×20 mm. The cross-head speed for both types of tests was 0.5 mm/min. The Vickers micro-hardness tests were performed using a load of 0.98 N(100 g) and loading time of 15 s.

3 Results and discussion

3.1 Micrograph and phase composition of mechanical alloying powders

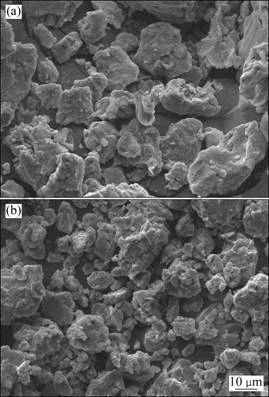

Morphological images of Ti-45Al-2Cr-2Nb-1B- 0.5Ta-0.225Y powder particles at different stages of double mechanical milling are shown in Fig. 1. After high energy mechanical milling for 6 h with rotation speed of 300 r/min, the power particles exhibit an irregular shape due to the plastic deformation and the brittle fracture as a result of rolling and compacting during milling. The average particle size at this stage is 20-80 μm (Fig. 1(a)). After 2 h vacuum heat treatment at 700℃ and then milling for 6 h with a high rotation speed of 300 r/min, powder particle size decreases as a result of fracturing of powder particles over the cold welding process and the powder particles show a regular shape. The average particle size at this stage is 20-40 μm (Fig. 1(b)).

Fig. 1 SEM images of Ti-45Al-2Cr-2Nb-1B-0.5Ta-0.225Y powder particles at different stages of double mechanical milling: (a) MA1; (b) MA2

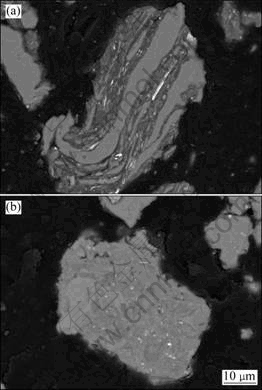

The SEM examination of cross-sections of the powder particles was used for studied microstructure of the powder particles at different milling stages (Fig. 2). At the stage of MA1, the starting materials became the layered composite structure. In the structure, the bright phase is α-Ti phase and the dark phase is Al phase. From Fig. 2(a), the Ti phase strip could be found. The section rich in elements of Nb and Ta appear (the white section in Fig. 2(a)) due to difficulty of Nb and Ta solution into Ti phase or Al phase. After heat treatment and following milling for 6 h the layered structure is refined and then disappears, and the structure exhibits homogeneous structure (Fig. 2(b)).

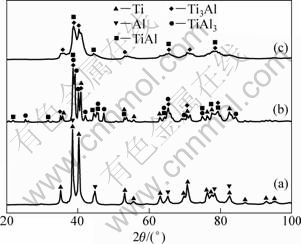

The XRD patterns of Ti-45Al-2Cr-2Nb-1B- 0.5Ta-0.225Y powder mixture at different milling stages are shown in Fig. 3. The powder after milling for 6 h shows peaks of Ti and Al, and peak width of Ti increases due to decrease in crystallite size caused by mechanical alloying during milling (Fig. 3(a)).

After heat treatment on the base of MA1, the XRD peak intensity of Ti decreases and the peak of Al disappears due to lattice strain and chemical reaction between Ti and Al. The TiAl, Ti3Al and TiAl3 phases appear owing to the reaction between Ti and Al (Fig. 3(b)), that is to say after heat treatment, Ti, TiAl, Ti3Al and TiAl3 are the all phases in the powders. During the continued milling (MA2), the XRD peaks of Ti and TiAl3 are not found, the TiAl and Ti3Al are the main phases in the milled powder particles and the width of peaks increases (Fig. 3(c)). The reason causing the result is the interdiffusion and reaction between the phases. Based on the broadening of the XRD peaks and the Schererr’s equation, the grain sizes of the phases decrease [17].

Fig. 2 SEM images of cross-sections of Ti-45Al-2Cr-2Nb- 1B-0.5Ta-0.225Y powder particles at different stages of double mechanical milling: (a) MA1; (b) MA2

Fig. 3 XRD patterns for Ti-45Al-2Cr-2Nb-1B-0.5Ta- 0.225Y powders at different stages of double mechanical milling: (a) MA1; (b) MA1+heat treatment (700℃, 2 h); (c) MA2

3.2 Microstructure and phase composition of SPSed Ti-45Al-2Cr-2Nb-1B-0.5Ta-0.225Y alloy

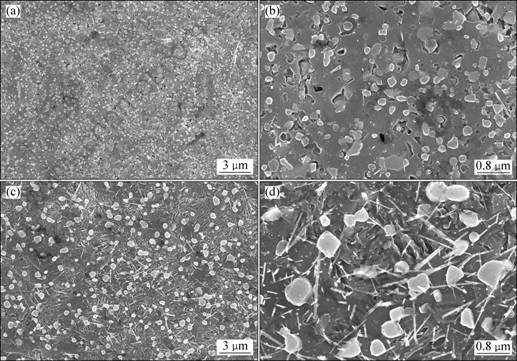

Figure 4 shows the SEM images of the bulk samples prepared by SPSed Ti-45Al-2Cr-2Nb-1B-0.5Ta- 0.225Y powders at different temperatures, which clearly shows the effect of SPS temperature on the microstructure of the sintered samples. From Fig. 4(a) and Fig. 4(b), it could be found that the samples with the SPS temperature of 900℃ exhibit the equiaxed structure and the grain size is 100-200 nm. The sample exhibits compact structure with a few pores. As the SPS temperature increases from 900℃ to 1000℃ (Fig. 4(c) and Fig. 4(d)), the microstructure remains to be equiaxed structure, but the grain size increases to 200-500 nm, and the TiB2 phase with a diameter of about 50 nm appears. The compact structure without visible pore was obtained due to diffusion in the fine powders at the high SPS temperature.

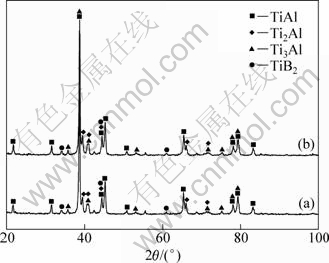

Figure 5 shows the XRD patterns of the bulk samples prepared by SPSed Ti-45Al-2Cr-2Nb-1B- 0.5Ta-0.225Y powders at different SPS temperatures of 900℃ and 1000℃. The clear diffraction peaks suggest that the sintered specimens are the formation of TiAl as the major phase, Ti3Al and Ti2Al as the minor phases and with a minor amount of TiB2 phase. The reason is that interdiffusion and reaction of the milled powders had happened during SPS. The intensities of peaks of the phases show that with increasing SPS temperature, peak intensity of TiAl phase decreases and intensities of peaks of Ti3Al and TiB2 phases increase, which indicates that the contents of Ti3Al and TiB2 phases increase.

The density of the sample prepared by SPS at 900℃ is 4.167 g/cm3, showing that the sample is not fully densified (pores shown in Fig. 4(b)). When the temperature increases from 900℃ to 1000℃, the density of the sample reaches 4.176 g/cm3 and the sample exhibits almost fully densified structure.

3.3 Mechanical properties of SPSed Ti-45Al-2Cr- 2Nb-1B-0.5Ta-0.225Y alloy

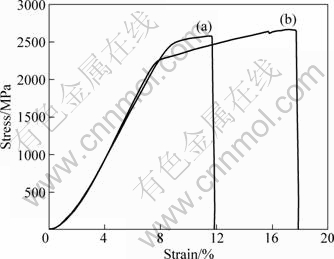

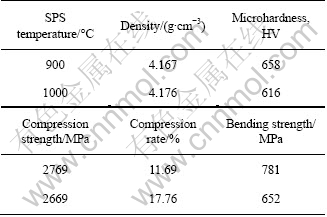

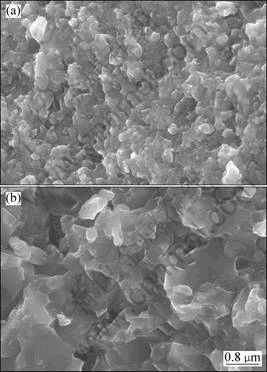

Figure 6 shows the compress stress—strain curves of the bulk samples produced by SPSed Ti-45Al-2Cr-2Nb-1B-0.5Ta-0.225Y alloy powders at different temperatures. The samples exhibit plastic deformation and work hardening before fracture. The typical mechanical properties of the bulk TiAl samples produced by SPS of double mechanical milled Ti-45Al-2Cr-2Nb-1B-0.5Ta-0.225Y powders at different temperatures are shown in Table 2. The results show that two kinds of samples obtained at different SPS temperatures exhibit the excellent mechanical properties. With the SPS temperature increasing from 900℃ to 1000℃, the bending strength and micro-hardness decrease, and the compression strength decreases from 2769 MPa to 2669 MPa due to the increase in grain sizes of TiAl, which suggests the strength change follows the Hall-Petch relationship. Figure 7 shows the fracture morphologies of compression test specimens from the Ti-45Al-2Cr-2Nb-1B-0.5Ta-0.225Y bulk samples at different temperatures. The transform of fracture of both kinds of samples is likely to be intergranular fracture.

Fig. 4 SEM images of Ti-45Al-2Cr-2Nb-1B-0.5Ta-0.225Y alloys sintered at different temperatures: (a), (b) 900℃; (c), (d) 1000℃

Fig. 5 XRD patterns of Ti-45Al-2Cr-2Nb-1B-0.5Ta-0.225Y alloy sintered at different temperatures: (a) 900℃; (b) 1000℃

Fig. 6 Compress stress—strain curves of Ti-45Al-2Cr-2Nb- 1B-0.5Ta-0.225Y alloy samples sintered at different temperatures: (a) 900℃; (b) 1000℃

Table 2 Properties of Ti-45Al-2Cr-2Nb-1B-0.5Ta-0.225Y alloy samples sintered at different temperatures

Fig. 7 Fracture morphologies of compression test samples from Ti-45Al-2Cr-2Nb-1B-0.5Ta-0.225Y alloy samples sintered at different temperatures: (a) 900℃; (b) 1000℃

4 Conclusions

1) The morphology of double mechanical milled Ti-45Al-2Cr-2Nb-1B-0.5Ta-0.225Y(mole fraction, %) powders is regular with size in the range of 20-40 μm, and the structure exhibits homogeneous structure. The TiAl and Ti3Al phases are observed in the double mechanical milled powders.

2) The sintered Ti-45Al-2Cr-2Nb-1B-0.5Ta- 0.225Y sample exhibits an equiaxed grain microstructure and grain size increases from 100-200 nm to 200-500 nm with the SPS temperature increasing from 900℃ to 1000℃. TiAl, Ti3Al, Ti2Al and TiB2 phases are observed in Ti-45Al-2Cr-2Nb-1B- 0.5Ta-0.225Y bulk samples.

3) Ti-45Al-2Cr-2Nb-1B-0.5Ta-0.225Y alloy shows a substantial amount of plastic deformation and work hardening before fracture. With the SPS temperature increasing from 900℃ to 1000℃, the bending strength, micro-hardness, and the compression strength decrease. The compression fracture mode of SPSed Ti-45Al-2Cr-2Nb-1B-0.5Ta-0.225Y alloy is likely to be intergranular fracture.

References

[1] ZHANG X J, LI Q, ZHAO S Y, GAO C X, WANG L, ZHANG J. Improvement in the oxidation resistance of a γ-TiAl-based alloy by sol-gel derived Al2O3 film [J]. Applied Surface Science, 2008, 255: 1860-1864.

[2] Gosslar D, Gunther R, Hecht U, Hartig C, Bormann R. Grain refinement of TiAl-based alloys: The role of TiB2 crystallography and growth [J]. Acta Materialia, 2010, 58: 6744-6751.

[3] Hecht U, Witusiewicz V, Drevermann A, Zollinger J. Grain refinement by low boron additions in niobium-rich TiAl-based alloys [J]. Intermetallics, 2008, 16: 969-978.

[4] Hu D. Effect of composition on grain refinement in TiAl-based alloy [J]. Intermetallics, 2001, 9: 1037-1042.

[5] Fanta G, Bohn R, Dahms M, Klassen T, Bormann R. The effect of ultrafine grained microstructures on the hot-workability of intermetallic/ceramic composites based on gamma-TiAl [J]. Intermetallics, 2001, 9: 45-49.

[6] Gerling R, Bartels A, Clemens H, Kestler H, Schimansky F P. Structural characterization and tensile properties of a high niobium containing gamma TiAl sheet obtained by powder metallurgical processing [J]. Intermetallics, 2004, 12: 275-280.

[7] Forouzanmehr N, Karimzadeh F, Enayati M H. Synthesis and characterization of TiAl/α-Al2O3 nanocomposite by mechanical alloying [J]. Journal of Alloys and Compounds, 2009, 478: 257-259.

[8] Chen Y Y, Yu H B, Zhang D L, Chai L H. Effect of spark plasma sintering temperature on microstructure and mechanical properties of an ultrafine grained TiAl intermetallic alloy [J]. Materials Science and Engineering A, 2009, 525: 166-173.

[9] WANG T G, SHAO G Q, DUAN X L, SHI H L, SUN P, LI Y. Preparation of TiAl-based alloys by high-energy ball-milling and hot-pressing sintering [J]. Materials for Mechanical Engineering, 2008, 30(3): 32-34.

[10] Zhang Wei, Liu Yong, Liu Bin, Li Hui-zhong, Tang Bei. Deformability and microstructure transformation of PM TiAl alloy prepared by pseudo-HIP technology [J]. Transactions of Nonferrous Metals Society of China, 2010, 20: 547-552.

[11] FOROUZANMELU N, KARIMZADEH F, ENAYATI M H. Study on solid-state reactions of nanocrystalline TiAl synthesized by mechanical alloying [J]. Journal of Alloys and Compounds, 2009, 471(1-2): 93-97.

[12] LU Xin, HE Xin-bo, LI Shi-qiong, QU Xuan-hui. Microstructures and mechanical properties of TiAl-based alloys by spark plasma sintering [J]. Journal of University of Science and Technology Beijing, 2008, 30(3): 254-257. (in Chinese)

[13] LI Dong-hui, WU Yu-cheng, LI Yun, GONG Ming, ZHENG Yu-chun. Investigation of TiAl-based alloys prepared by the mechanical milling method and sintered at different temperatures [J]. Journal of Hefei University of Technology, 2006, 29(8): 969-975.

[14] Lu X, He X B, Zhang B, Qu X H, Zhang L, Guo Z X, Tian J J. High-temperature oxidation behavior of TiAl-based alloys fabricated by spark plasma sintering [J]. Journal of Alloys and Compounds, 2009, 478: 220–225.

[15] Couret A, Molenat G, Galy J, Thomas M. Microstructure and mechanical properties of TiAl alloys consolidated by spark plasma sintering [J]. Intermetallics, 2008, 16: 1134-1141.

[16] ZHAO L L, LI G Y, ZHANG L Q, LIN J P, SONG X P, YE F, CHEN G L. Influence of Y addition on the long time oxidation behaviors of high Nb containing TiAl alloys at 900℃ [J]. Intermetallics, 2010, 18: 1586-1596.

[17] YU Hong-bao, CHEN Yu-yong, ZHANG De-liang, CHEN Yan-fei. Study on fabrication of fine-grained γ-TiAl by hot isostatic pressing method and its formability [J]. Rare Metal Materials and Engineering, 2008, 37(10): 1824-1827. (in Chinese)

双步球磨和放电等离子烧结TiAl基合金的

显微组织和力学性能

肖树龙1,2,徐丽娟1,2,陈玉勇1,2,于宏宝3

1. 哈尔滨工业大学 材料科学与工程学院,哈尔滨 150001;

2. 哈尔滨工业大学 金属精密热加工国家级重点实验室,哈尔滨 150001;

3. 西北工业大学 材料科学与工程学院,西安 710072

摘 要:采用双步球磨法和放电等离子烧结技术制备细晶Ti-45Al-2Cr-2Nb-1B-0.5Ta-0.225Y(摩尔分数,%)合金,并研究烧结温度、显微组织和力学性能之间的关系。结果表明:双步球磨粉末的颗粒形状较规则,其颗粒尺寸为20~40 μm,主要由TiAl和Ti3Al相组成。放电等离子烧结后的块体由主相TiAl、少量的Ti3Al相及Ti2Al和TiB2相组成。当烧结温度为900℃时,烧结块体获得的主要组织是等轴晶组织,等轴晶粒尺寸大多数在100~200 nm的范围内,合金的压缩断裂强度为2769 MPa,压缩率为11.69%,抗弯强度为781 MPa;当烧结温度为1000℃时,等轴晶粒明显长大,TiB2相明显增多,合金的压缩断裂强度为2669 MPa,压缩率为17.76%,抗弯强度为652 MPa。随着烧结温度的升高,合金的维氏硬度由658降低到616。压缩断口形貌分析表明,合金的断裂方式为沿晶断裂。

关键词:TiAl基合金;机械合金化;放电等离子烧结;显微组织结构;力学性能

(Edited by YANG Hua)

Foundation item: Project (51001040) supported by the National Natural Science Foundation of China; Project (HITQNJS.2009.022) supported by Development Program for Outstanding Young Teachers in Harbin Institute of Technology, China

Corresponding author: XIAO Shu-long; Tel/Fax: +86-451-86418802; E-mail: xiaoshulong@hit.edu.cn

DOI: 10.1016/S1003-6326(11)61287-9