冷变形与再时效处理对2519A-T87铝合金板材力学性能和微观组织的影响

孙大翔1, 2,顾刚1, 2,叶凌英1, 2,张新明1, 2

(1. 中南大学 材料科学与工程学院,湖南 长沙,410083;

2. 中南大学 有色金属材料科学与工程教育部重点实验室,湖南 长沙,410083)

摘要:通过硬度测试、拉伸测试、透射电镜和扫描电镜等分析方法,研究冷变形及再时效对2519A-T87铝合金微观组织与性能的影响。研究结果表明:经过50%冷轧变形以及于100 ℃再时效3 h后,合金的抗拉强度为516 MPa,屈服强度为485 MPa,伸长率为6.5%,综合效果最佳。此时合金受冷变形与再时效的影响,合金内的θ′相开始向平衡相(θ相)转化,与T87相比,合金析出相的长宽比变小,体积分数增加,总体时效强化效果不明显。合金强度的提升主要依赖于加工硬化。

关键词:2519A铝合金;冷变形;力学性能;显微组织

中图分类号:TG113.12 文献标志码:A 文章编号:1672-7207(2014)12-4145-07

Effect of cold deformation and reaging on microstructures and mechanical properties of 2519A-T87 alloy plate

SUN Daxiang1, 2, GU Gang1, 2, YE Lingying1, 2, ZHANG Xinming1, 2

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Key Laboratory of Nonferrous Materials Science and Engineering, Ministry of Education,

Central South University, Changsha 410083, China)

Abstract: The effects of cold deformation and reaging on the microstructures and mechanical properties of 2519A-T87 alloy plate were investigated by hardness test, tensile test, transmission electron microscopy(TEM) and scanning electron microcopy(SEM). The results show that after 50% cold rolling reduction and reaging at 100 ℃ for 3 h, the tensile strength, yield strength and elongation of the alloy plate are 516 MPa, 485 MPa, 6.5%, respectively. Due to the effect of cold deformation and reaging, the alloy with θ′ phase transforms into equilibrium phase(θ). Compared to T87, the aspect ratio of precipitates decreases, and its volume fraction increases. The overall aging strengthening of the alloy is not obvious, therefore, the enhancement of the strength is primarily dependent on work hardening.

Key words: 2519A aluminum alloy; cold deformation; mechanical properties; microstructures

2519铝合金是一种新型的Al-Cu系高强铝合金,于20 世纪80 年代末研制出来,具有良好的抗弹性能、抗应力腐蚀性能及焊接性能,已作为替代7039铝合金和5083 铝合金的新一代装甲板材料。目前,美国已将该合金用作先进的两栖突击车(AAAV)的装甲材料[1-2]。目前的研究表明,2519铝合金一般在形变热处理态(T87)下使用。形变热处理是将形变强化与相变强化相结合,是提高铝合金强度和耐热性的一种重要手段。关于Al-Cu系铝合金的形变热处理有很多报道,早期主要集中研究冷变形及后面的时效对合金组织和性能的影响,一般在固溶淬火后进行5%~20%的冷变形,而后在180 ℃或165 ℃下时效,即T8态[3-7]。此时合金θ′相比T6态时更加弥散、细小,合金的强度和硬度更高。后来为了进一步提高强度,逐渐将冷变形量放大,现已报道的有30%~90%的冷变形量的试验研究[5, 7-8],经过大变形后的合金强度大幅提升,从原来T87态的480 MPa左右提高到580 MPa,但此时合金的伸长率下降较大,一般不超过4%。同时过大的冷变形量使得制备厚板困难,在制备过程中废品率高,使得大变形的制备工艺尚没有实际应用。到目前为止,关于Al-Cu系铝合金的冷变形工艺的研究主要集中在固溶淬火之后,而时效态的冷变形工艺还没有系统性的研究。本文作者主要针对时效态2519A铝合金(T87态),研究较大变形量及之后的再时效工艺对合金的力学性能及其微观组织的影响,探索制备较高强度及较好韧性的2519A铝合金的新途径。

1 实验

1.1 材料和处理工艺

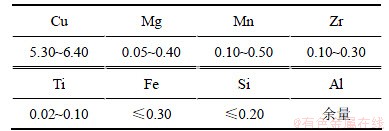

经过熔铸、均匀化、热轧、固溶、冷变形和时效处理,制备2519A-T87板材。铝合金板材其化学成分如表1所示。

表1 2519A铝合金的化学成分(质量分数)

Table 1 Chemical composition of 2519 aluminum alloy %

将上述板材在d 420轧机冷轧,变形量控制为35%和50%,即轧制到22 mm和17 mm。在距表层2 mm和7 mm处取样,分别在80,100和120 ℃进行时效。

1.2 实验方法

用HV-10B硬度计测试样品硬度,载荷为30 N,每个试样至少测量5个点,取平均值作为最终硬度值。拉伸实验选取板材同一截面上的3片拉伸试样(每片厚度4.5 mm),在CSS-44100万能材料力学拉伸机上进行试验,3次实验结果取平均值作为最终的实验结果。

时效析出物的观察在Tecnai G220型透射电镜下进行,从基体的<001>方向观察;样品先用机械方法减薄至 0.1 mm 的薄片,在 MIT-Ⅱ型双喷电解仪上用HNO3(30%)+CH3OH(70%)(体积比)溶液双喷减薄,采用液氮冷却,双喷温度为-25~-30 ℃,电压为 15~ 20 V,电流为50~80 mA。

2 结果与分析

2.1 时效硬化曲线

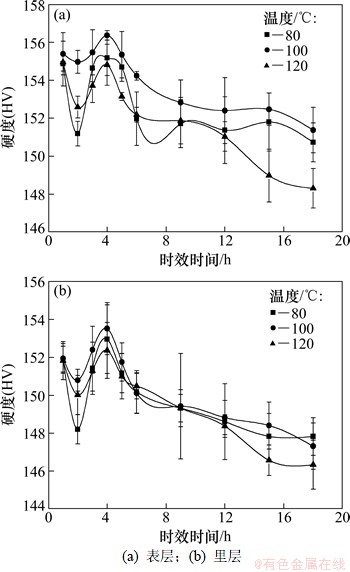

图1所示为35%冷轧变形后时效曲线。从图1可以发现时效过程中合金表层与里层具有相同的变化规律。35%冷变形合金的表层硬度(HV)为154。时效刚开始后合金硬度稍微下降,然后其值有小幅度提高,在4 h达到峰值,之后合金的硬度开始逐渐下降。于100 ℃时合金硬度峰值最高,80 ℃时次之,120 ℃时最小。峰值时效时表层的硬度(HV)为156.5,里层的硬度为153.5,有2%左右的差距。

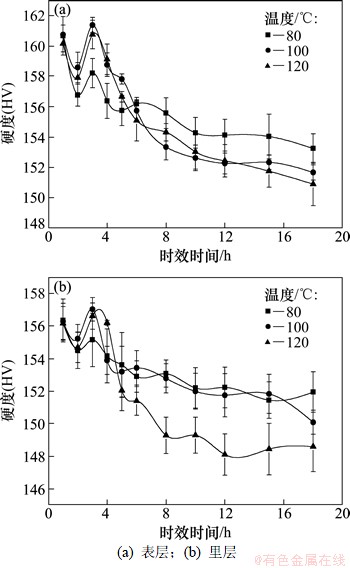

图2所示为50%冷轧变形后时效曲线。从图2可见:50%冷变形合金的再时效变化规律与35%冷轧变形合金相似;时效开始后合金硬度值小幅下降然后开始上升,在3 h达到峰值,然后合金的硬度开始下降。峰值时硬度由大到小对应的温度顺序为100 ℃,120 ℃和80 ℃;峰值时效时表层的硬度为161.5,里层的硬度为157,两者间有2.8%的相对误差。

图1 2519A-T87冷轧变形35%后时效曲线

Fig. 1 Aging curves of 2519A-T87 with 35% cold rolling

图2 2519A-T87冷轧变形50%后时效曲线

Fig. 2 Aging curves of 2519A-T87 with 50% cold rolling

冷变形样品在时效过程中,时效强化和回复软化2种现象同时发生的,而且2种现象都是随着温度的升高而加强的。35%变形量的样品在80 ℃下的样品峰值硬度大于120 ℃下的峰值硬度,这主要是由于位错密度较低的条件下,时效析出强化过程小于回复软化的过程。50%变形量的合金样品在120 ℃下的峰值硬度高于80 ℃下峰值硬度,应是在增大变形量后,样品组织中产生更多的位错,时效后会有更多的析出相析出及长大,此时时效强化过程大于回复软化过程,因此,120 ℃时的样品硬度大于80 ℃时的样品。

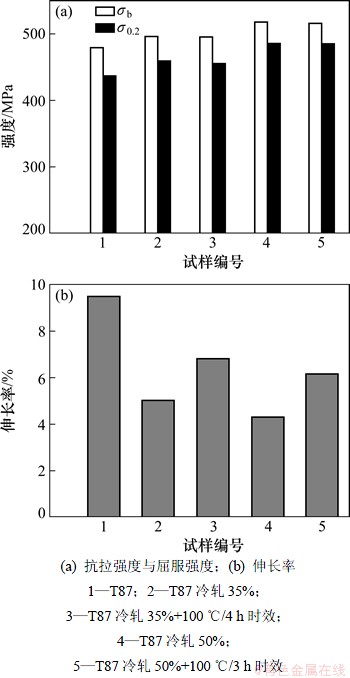

2.2 拉伸力学性能

由时效实验可知:所制备的合金板材性能较为均匀,表面和内侧的差距不大,所以拉伸试验选择板材同一截面上的3片拉伸试样,结果取平均值以表征板材的拉伸力学性能。图3所示为5种状态合金的抗拉强度和屈服强度以及伸长率的变化。经过冷轧大变形及时效处理,合金的强度与T87态相比都得到了较大的提高。从图3可以看出:随着变形量的增加,合金强度提升明显。35%变形量时抗拉强度与屈服强度分别为500 MPa和475 MPa;50%变形量时抗拉强度与屈服强度分别为518 MPa和485 MPa。但是2种状态的伸长率都较低,只有3%~4%。而冷轧后进行再时效处理的合金,其强度变化较小,但伸长率得到了比较明显的提高。50%冷轧变形后接着于100 ℃时效3 h,合金的抗拉强度与屈服强度分别为516 MPa和485 MPa,伸长率达到6.5%,综合效果最佳。

图3 5种状态合金样品的力学性能

Fig. 3 Mechanical properties of 5 samples with different states

2.3 透射电子显微分析

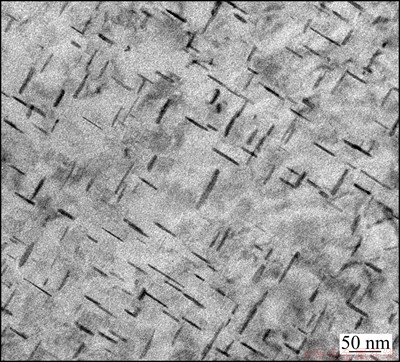

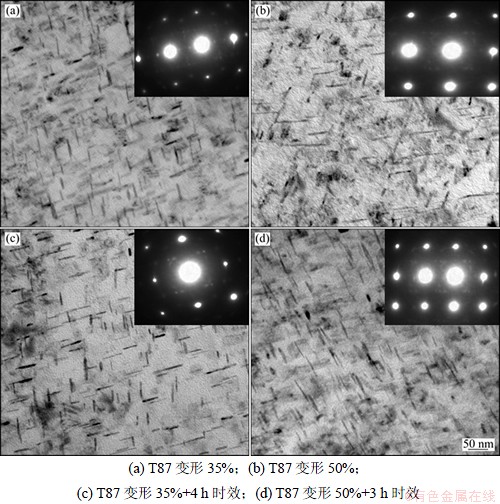

图4所示为典型的T87态2519A合金<100>方向TEM像。θ′ 析出相细小,但分布并不十分均匀。图5所示为经过冷轧变形及再时效后合金的TEM像。从图5可以看出:合金经过剧烈的冷变形后,微观组织发生了明显的变化。从图5(a)和(b)可以看出:随着冷轧变形量由35%增加到50%,合金的析出相的分布不均匀性提高,而且部分析出相发生粗化,使得各析出相间的形貌差别也很大。从衍射斑点可以看出,其析出相为θ′ 和θ相共存的状态。经过再时效处理后,图5(c)和(d)中合金析出相的分布比冷轧态更加密集,但是析出相发生粗化的现象也十分显著,析出相的尺寸变得不均匀。从衍射斑点照片辨识,此时的析出相以θ相为主。

2.4 拉伸断口扫描分析

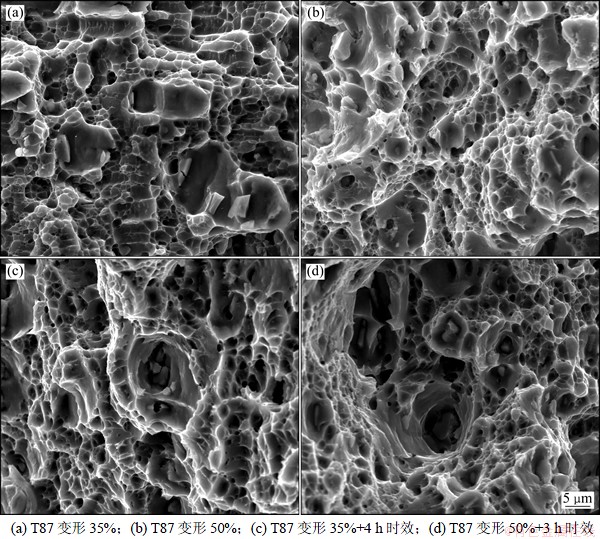

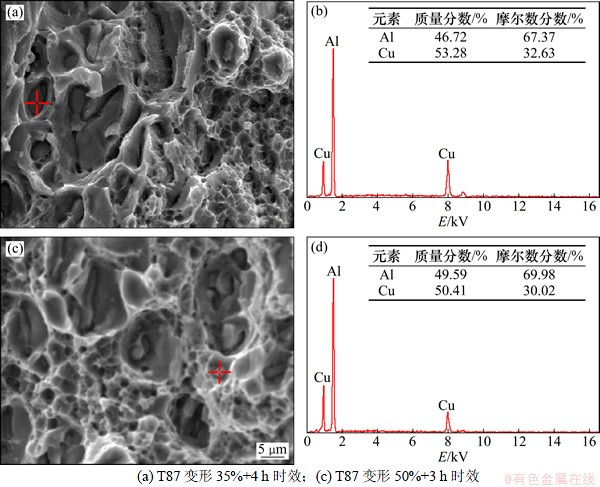

图6所示为4种状态合金断口的SEM像。从图6(a)和6(b)可以看出:T87冷变形后的合金,断口的韧窝大小不一,但是韧窝都比较浅,说明此时脆性断裂的程度较大,沿晶脆性断裂的程度增加,合金塑性较差。经过再时效处理后(图6(c)和6(d)),合金断口也出现了许多大小不同的韧窝,其中部分韧窝粗大且较深,说明此时的沿晶断裂的程度较少,延性韧窝形貌明显,显示出韧性断裂特征,以韧性断裂为主。韧窝深处有微米级小颗粒存在(图7),通过能谱测试分析,主要组成元素为Al和Cu,物质的量的比约为2:1,证明为平衡相θ相。

图4 2519A-T87合金的TEM明场像

Fig. 4 TEM bright-field images of 2519A-T87 alloys

图5 4种状态合金的TEM明场像

Fig. 5 TEM bright-field images of 4 specimens with different states

图6 4种状态合金拉伸断口的SEM像

Fig. 6 SEM images of tensile fracture of 4 specimens with different states

图7 冷变形再时效态合金拉伸断口SEM像和微米级颗粒能谱

Fig. 7 SEM images and energy spectrum of micro grains from tensile fracture of specimens with cold deformation and reaging

3 讨论

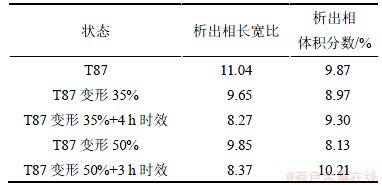

2519A铝合金是典型的Cu与Mg的高比Al-Cu系合金,其典型的时效析出过程为:α过饱和固溶体→G.P区→θ″ 相→θ′ 相(正方结构)→θ(CuAl2)相(体心立方结构)。在此过程中,G.P区、θ″ 相、θ′ 相与Al基体共格或者半共格,可以使合金的强度提高。而稳定相θ(CuAl2)与基体不共格,会使合金的强度降低。2519A合金T87态工艺是合金经过固溶淬火后,先进行15%的冷变形,然后于165 ℃时效12 h,此时合金的析出相是以半共格的θ′相为主。合金在冷变形过程中,不仅仅发生了晶粒的细化,合金内的析出相形貌和分布也发生了明显的变化。在Al-Cu合金强变形过程中,由材料内部产生的高密度位错,使析出相发生变形断裂以及低温回溶现象已有很多报道[9-10]。在本试验中,合金在冷变形过程中,也发生了析出相回溶现象。随着变形量的增加,析出相体积分数逐渐减少。用ImageJ软件分别计算合金不同状态下的透射照片的析出相尺寸和析出相体积分数,取平均值,见表2。计算结果表明:经过35%的冷轧变形后,合金的析出相体积分数从9.87%减少到8.97%,再继续增大到50%变形量的情况下,析出相体积分数继续减少到8.13%,说明在冷变形过程中,合金中的部分析出相发生了回溶。关于回溶的机理目前主要有2种观点,比较主流的观点认为在变形过程中,析出相被破碎成纳米级细小颗粒,表面能显著增加而变得不稳定,导致它们溶入基体,形成过饱和固溶体[9-12];还有认为析出相被破碎后并没有回溶于基体形成过饱和固溶体,而是在晶界上形成一层薄层[13]。试验中,35%和50%的冷变形2种情况下,再时效后,合金析出相的体积分数都有一定的增加,所以认为在冷变形过程中,析出相发生了一定的回溶,而且随着变形量的增大,析出相发生回溶的数量越多。

同时也发现在冷变形过程中,合金析出相的尺寸也发生了变化。已有研究学者用CuAl2相的宽度或者长宽比来表征析出相的析出状态[14-15],平衡相θ相为体心正方结构,与基体不共格,在透射照片中表现为宽度较大,长宽比很小,一般在3左右;而亚稳相θ′ 相为正方结构,在照片中表现为比较细长,长宽比较大,一般在10以上,通过分析得出相长宽比,可以判断析出相的状态及其强化作用效果。从表2可以看出:随着冷变形量的增加,析出相的长宽比下降明显。T87状态下,其长宽比为11左右,35%冷变形后下降到9.65%,说明此时合金析出相发生粗化,亚稳相θ′ 相开始向稳定相θ相转化。由于在冷变形过程中,变形所做的功转化成热能、相界面能、位错能、应变能等多种形式,使试样的温度升高,试样中得析出相θ′相产生部分的回溶,并且还有一部分析出相开始向与基体非共格的θ相转变。因为θ相与基体之间的界面能较高,θ相的临界形核功ΔG较大,冷变形过程中外力对试样所做得功转化为应变能和位错能恰好可以补偿一部分ΔG,因而导致试样中析出相θ′相开始粗化,向θ相转变。综上所述,在2519A-T87合金中,析出相θ′相在冷变形过程中发生了2种变化,较细小或者较不稳定的θ′相在冷变形过程中,被破碎成纳米级的细小颗粒,回溶于基体中;较粗大或者较稳定的θ′相在冷变形过程中,转变成与基体非共格的θ相。冷变形后的再时效析出过程中,合金的析出相明显发生粗化。35%和50%变形量下的合金再时效样品,析出相的长宽比减小,说明θ′ 相更进一步粗化,向稳定相转变。Murayama等[16]指出:由强变形诱导析出相回溶后形成的过饱和固溶体再时效时,不遵守常规的过饱和固溶体时效析出顺序,平衡相容易超越先驱相率先析出。回溶析出相再时效过程中,析出相的体积分数也明显增加,同时析出相的长宽比也逐渐减少,说明再时效的析出相以平衡相θ相为主,使得合金在时效过程中强度得不到提升,还会随着时间的延长,强度逐渐下降。在统计析出相长宽比过程中,再时效后长宽比小于6的析出相所占比例显著提高也证明了这一结论。

表2 合金析出相尺寸与体积分数统计

Table 2 Statistical results of precipitates size and volume fraction

形变热处理后合金抗拉强度主要由以下几部分组成:

σ=σ0+σε+σθ′ (1)

式中:σ0为合金基体的强度;σε为合金变形后加工硬化导致的强度增加量。σθ′为第二相析出导致的强度增加量。随着冷变形的增加,σε也逐渐升高,使得合金的强度提高。从时效曲线分析,第二相析出对合金强度的提高不明显,随着时间的延长,强度明显下降,所以在短时再时效中σθ′所起到的强化作用十分有限。所以,合金最终强度的提升主要是由冷变形所引起的加工硬化所致。

在100 ℃下再时效后,合金的塑性有一定的提高,这主要是低温回复的作用。在此过程中,合金中的缺陷运动和部分位错运动和重新组合,部分由冷变形而造成的亚稳态组织消除,而合金的微观结构基本上不改变,此时合金的塑性得到恢复。随着再时效的时间延长,合金中的位错运动组合和对消,使得合金的硬度开始逐渐下降。

4 结论

1) 2519A铝合金T87态经过冷轧大变形后,合金的强度大幅提升。在冷变形50%再接着于100 ℃时效3 h,合金的抗拉强度达到518 MPa,屈服强度为485 MPa,伸长率为6.5%,综合效果最佳。

2) 合金的强度提升主要由冷变形引起的加工硬化所致。在冷变形及之后的再时效过程中,合金的析出相θ′同时发生了回溶及粗化2种现象,析出相长宽比减少,逐渐生成稳定相θ相,使得合金的时效强化效果不佳。

参考文献:

[1] James J, Fisher J. Aluminum alloy 2519 in military vehicles[J]. Advanced Materials and Processes, 2002, 160(9): 43-46.

[2] Hamilton B C, Saxena A. Transient crack growth behavior in aluminum alloys C415-T8 and 2519-T87[J]. Engineering Fracture Mechanics, 1999, 62(1): 1-22.

[3] 李慧中, 张新明, 陈明安, 等. 热处理制度对2519A合金的晶间腐蚀性能的影响[J]. 材料热处理学报, 2005, 26(1): 20-23.

LI Huizhong, ZHANG Xinming, CHEN Mingan, et al. Effect of heat treatment on intergranular corrosion of 2519 aluminum alloy[J]. Transactions of Materials and Heat Treatment, 2005, 26(1): 20-23.

[4] 陈险锋, 彭大署, 张辉, 等. 热处理制度对2519铝合金板材力学性能和应力腐蚀敏感性的影响[J]. 中国有色金属学报, 2003, 13(4): 934-938.

CHEN Xianfeng, PENG Dashu, ZHANG Hui, et al. Influence of heat treatment on mechanical properties and stress corrosion sensitivity of 2519 aluminum alloy plate[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(4): 934-938.

[5] 李慧中, 梁萧鹏, 陈明安, 等. 冷轧变形量对2519铝合金组织与力学性能的影响[J]. 材料热处理学报, 2008, 29(2): 86-89.

LI Huizhong, LIANG Xiaopeng, CHEN Mingan, et al. Effect of cold rolling reduction on microstructure and mechanical property of 2519 aluminum alloy[J]. Transactions of Materials and Heat Treatment, 2008, 29(2): 86-89.

[6] 张新明, 刘玲, 贾寓真. 拉伸与轧制预变形对2519A铝合金组织与力学性能的影响[J]. 中国有色金属学报, 2010, 20(6): 1088-1094.

ZHANG Xinming, LIU Ling, JIA Yuzhen. Effects of stretching and rolling pre-deformation on microstructures and mechanical properties of 2519A aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(6): 1088-1094.

[7] 李慧中, 张新明, 陈明安, 等. 预变形对2519铝合金组织与力学性能的影响[J]. 中国有色金属学报, 2004, 14(12): 1990-1994.

LI Huizhong, ZHANG Xinming, CHEN Mingan, et al. Effect of pre-deformation on microstructures and mechanical properties of 2519 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(12): 1990-1994.

[8] ZHANG Xinming, GAO Zhiguo, ZHAO Yisheng. Effects of shart aging on thickening anisotropy of θ′ precipitate and mechanical properties of severe cold-rolled 2519A aluminum alloy plate[J]. Journal of Materials Science, 2009, 45(5): 1401-1405.

[9] Nourbakhsh S, Nutting J. The high strain deformation of an aluminium-4% copper alloy in supersaturated and aged conditions[J]. Acta Metallurgica, 1980, 28(3): 357-365.

[10] Kang S B, Lim C Y. Microstructure evolution and hardening behavior of 2024 aluminum alloy processed by severe plastic deformation[J]. Materials Science Forum, 2002, 396/397/398/399/400/401/402(2): 1163-1168.

[11] Li B Q, Wawner F E. Dislocation interaction with semicoherent precipitater (Ω Phase) in deformed Al-Cu-Mg-Ag alloy[J]. Acta Mater, 1998, 46(15): 5483-5490.

[12] Ohashi K, Fujite T, Oh-Ishi K, et al. Microstructure control of a precipitate-hardenable Al-Ag alloy using severe plastic deformation[J]. Materials Science Forum, 2003, 426/427/428/429/430/431/432(3): 2637-2642.

[13] Fatay D, Bastarash E, Nyilsa K, et al. X-ray diffraction study on the microstructure of Al-Mg-Sc-Zr alloy deformed by high-pressure torsion[J]. Materials Research and Advanced Techniques, 2003, 94(7): 842-847.

[14] GAO Zhiguo, ZHANG Xinming, CHEN Mingan. Investigation on θ’ precipitate thicking in 2519A-T87 aluminum alloy plate impacted[J]. Journal of Alloy and Compounds, 2009, 476(1/2): 1-3.

[15] GAO Zhiguo, ZHANG Xinming, CHEN Mingan. Influence of strain rate on the precipitate microstructure in impacted aluminum alloy[J]. Scripta Materialia, 2008, 59(9): 983-986.

[16] Murayama M, Horita Z, Hono K. Microstructure of two-phase Al-1.7at%Cu Alloy deformed by equel-channel angular pressing[J]. Acta Mater, 2001, 49(1): 21-29.

(编辑 陈爱华)

收稿日期:2014-03-10;修回日期:2014-06-23

基金项目(Foundation item):国家重点基础研究发展规划(973计划)项目(2012CB619500)(Project (2012CB619500) supported by the National Basic Research Development Program of China (973 Program))

通信作者:孙大翔(1984-),男,黑龙江哈尔滨人,博士研究生,从事高强铝合金性能研究,电话:0731-88830265;E-mail:eagle19840831@sina.com