文章编号:1004-0609(2010)06-1088-07

拉伸与轧制预变形对2519A铝合金组织与力学性能的影响

张新明,刘 玲,贾寓真

(中南大学 材料科学与工程学院,长沙 410083)

摘 要:通过硬度测试、拉伸测试、透射电镜分析以及织构测试等手段,研究拉伸和冷轧两种不同预变形方式对2519A铝合金165 ℃时效后组织与力学性能的影响。结果表明:适当的变形量均使θ′相尺寸细小、密度增加,而变形量过大使θ′相分布变得较不均匀,合金强度提高不大,而塑性降低;6%拉伸预变形和7%冷轧预变形使合金板材峰值时效抗拉强度、屈服强度和伸长率分别为472 MPa、404 MPa、15.6%和472 MPa、417 MPa、9.4%,二者的抗拉强度基本相同,但前者的屈服强度低、塑性高;两种预变形方式下板材织构类型相同,取向密度无明显差别;合金板材屈服强度和伸长率的差别由第二相θ′相的数量、尺寸和分布所确定。

关键词:铝合金;2519A铝合金;拉伸预变形;冷轧预变形;力学性能;显微组织;织构

中图分类号:TG146.21 文献标志码:A

Effects of stretching and rolling pre-deformation on

microstructures and mechanical properties of 2519A aluminum alloy

ZHANG Xin-ming, LIU Ling, JIA Yu-zhen

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The effects of stretching and rolling pre-deformation on the microstructures and mechanical properties of 2519A alloy plate aged at 165 ℃ were investigated by hardness test, tensile test, transmission electron microscopy(TEM) and texture measurement. The results show that for both of the pre-deformation methods, proper pre-deformation leads to the quantity increasing and refinement of θ′ phase. But the inordinate deformation leads to an inhomogeneous distribution of θ′ phase, which decreases the elongation. For the 6% pre-stretching elongation and 7% pre-cold cooling deformation, the tensile strength, yield strength and elongation are 472 MPa, 404 MPa, 15.6% and 472 MPa, 417 MPa, 9.4%, respectively. Both of their tensile strengths are equivalent, but the yield strength of the pre-stretched alloy plate is lower, while the elongation is higher. The texture components and orientation density of the pre-stretched and pre-rolled alloy plates are almost the same, therefore, the yield strength of the alloy plate is determined by the quantity, size and θ ′ phase distribution.

Key words: aluminum alloy; 2519A aluminum alloy; pre-stretching; cold rolling pre-deformation; mechanical properties; microstructure; texture

2519铝合金属Cu和Mg质量比较高Al-Cu-Mg合金,该合金具有良好的力学性能、抗弹性能、抗应力腐蚀性能以及可焊接性能,美国已将其用于先进的两栖装甲突击车(Advanced amphibious assault vehicle,AAAV)[1-2]。2519A合金是我国在美国2519合金基础上通过提高铜含量、降低杂质含量和改变微量元素开发的一种新型装甲材料,具有更为优异的力学性能和抗应力腐蚀性能[3-6]。

形变热处理是提高2×××系铝合金性能的一种重要手段[7]。作为热处理可强化合金,国内对2519以及2519A合金形变热处理研究较多,林启全等[8]和陈险峰等[9]研究形变热处理对2519合金组织与性能的影响,李慧中等[10-11]研究冷轧预变形对2519A合金分别经165 ℃和180 ℃时效后的组织与力学性能的影响,均得到随冷轧变形量的增加,时效后合金中θ′相愈弥散、细小,合金强度和硬度也愈高。黄佩武和刘友良[12]采用冷轧预变形研究2519A合金的形变热处理工艺,也得到相同的结论。

拉伸预变形对铝合金时效强化的影响在Al-Cu- Mg-Ag和Al-Cu-Li等合金中有见报道[13-17]。而对2519合金拉伸预变形的研究,DYMEK等[18]对比研究单一的拉伸预变形和冷轧+拉伸组合变形对2519合金抗应力腐蚀性能的影响,发现采用先冷轧再拉伸变形,合金抗应力腐蚀性能比要比单一的拉伸变形好,认为其原因可能是复杂的变形方式能得到更均匀的位错组态,但并没有给出具体的组织说明。美国2519合金专利[19]进行至少6%的拉伸预变形可使合金强度较大提高,并指出冷轧预变形可以得到同样的效果,没有区别二者。本文作者研究拉伸预变形和轧制预变形对2519A铝合金板时效后组织和性能的影响规律,比较了它们的差别,在纳米析出相层次上分析了差别的原因,为探求2×××合金有利的形变热处理工艺提供依据。

1 实验

1.1 材料和处理工艺

实验材料为自行研制的6 mm厚2519A铝合金热轧板,合金主要名义成分如表1所列。

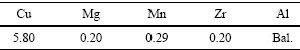

表1 2519A铝合金化学成分

Table 1 Chemical composition of 2519A aluminum alloy (mass fraction, %)

将板材热轧至2 mm,在533 ℃固溶、水淬后,分别进行2%、6%、10%的拉伸变形和7%、10%、25%的冷轧变形,然后在165 ℃进行时效。

1.2 实验方法

用HV-10B硬度计测试硬度(测5点取平均值)。常温拉伸性能在 CSS44100 电子拉伸机上测试(每个状态测2个样取平均值)。TEM分析用TecnaiG220 型透射电镜上观察,薄膜试样采用电解双喷减薄,电解液为30%硝酸和70%甲醇混合液,采用液氮冷却,双喷温度为-20 ℃以下,电压15 V。织构测试在Bruker D8 Discovery上进行,试样为矩形,以预拉伸和预轧制方向为长向,用水磨砂纸磨至中心层后用NaOH溶液浸泡3~5 min,消除表面残余应力。

2 结果与分析

2.1 时效硬化曲线

图1所示为合金拉伸预变形和冷轧预变形后在165 ℃时效的硬度曲线。由图1可看出,在时效初期,合金主要由GP区强化,硬度升高较快,并随变形量的增加,上升速率减缓;随时效的进行,GP区逐渐向θ′相转化,曲线趋于平缓,直到达到峰值。由图1(a)可看出,拉伸预变形2%的合金峰值硬度较低,为140HV;当变形量增大到6%后,合金峰值硬度有较大提高,继续增大变形量,合金峰值硬度又降低,但变化不大,分别为155HV和151HV;合金峰时效时间随变形量增加而逐渐缩短,分别为16、11和8 h。由图1(b)可看出,随冷轧变形量从7%到25%增加,合金峰值硬度先下降后增加,分别为155HV、153HV和156HV,变化也较小。合金峰值时效时间也是随变形量增加而降低,分别为17、16和12 h。

图1 165 ℃时合金的时效硬化曲线

Fig.1 Isothermal age-hardening curves of alloys at 165 ℃: (a) Pre-stretching; (b) Pre-cold rolling plate

2.2 常温拉伸力学性能

对淬火后进行不同拉伸和冷轧预变形的合金板材在 165 ℃经峰值时效处理后进行室温拉伸性能检测,并与时效前的合金进行对比,其结果如表2所列。

表2 合金的力学性能

Table 2 Mechanical properties of experimented alloy plates

由表2可看出,时效后板材抗拉强度和屈服强度显著提高,且屈服强度提高的幅度要高于抗拉强度的。冷轧预拉伸变形从2%到6%时,板材的抗拉强度和屈服强度均提高很大,但继续增大预变形量至10%时,抗拉强度变化不大。冷轧预变形7%时,板材时效前抗拉强度最低,峰值时效后抗拉强度则最高。当冷轧预变形为10%时,同样板材的强度变化不大。这说明两种变形方式下,至某一预变形量时,时效强化作用并没有随变形量的增加而明显提高。综合考虑强度和塑性,拉伸预变形和冷轧预变形较合适的变形量分别为6%和7%。

峰值时效态下,6%预拉伸变形板材的抗拉强度与7%预冷轧变形板材的相同,但屈服强度略低,而当变形量增至10%时,预冷轧变形板材的抗拉强度和屈服强度均略低于拉伸变形合金的。两种变形方式下,板材峰时效后的伸长率均随变形量增加而逐渐降低,但拉伸预变形板材的塑性要明显优于冷轧预变形的。经6%和10%拉伸预变形后,板材峰值时效后伸长率分别为15.6%和11.7%,而7%和10%冷轧预变形板材峰值时效后,伸长率分别为9.4%和7.6%。

2.3 透射电子显微分析

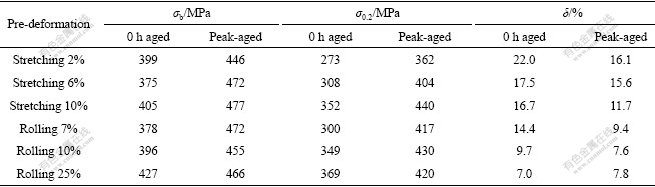

图2所示为拉伸预变形合金经165 ℃峰时效后晶内和晶界处TEM像。由图2可看出,从2%到6%拉伸预变形,晶内第二相θ′相细化较明显,晶界沉淀相也由连续链条状变为不连续状,且尺寸明显减小;当拉伸预变形量增至10%时,θ′第二相尺寸变化不大。与拉伸2%预变形相比,6%和10%预变形量板材晶内第二相尺寸和分布变得较不均匀,有些部位θ′相尺寸较大、密度较高(见图2(b)和(c)中的A区),而有些部位,θ′相则比较细小稀疏(如图2(b)和(c)中的B区)。

图2 拉伸预变形合金165 ℃时效后的TEM像

Fig.2 TEM images of stretched alloy plate aged at 165 ℃: (a), (d) 2%; (b), (e) 6%; (c), (f) 10%

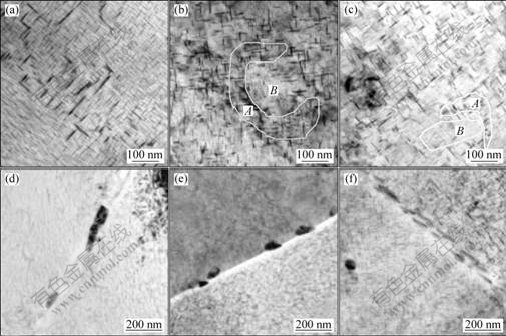

图3所示为冷轧预变形合金165 ℃峰时效后晶内和晶界处TEM像。由图3可看出,晶内第二相θ′相的分布也不均匀(见图3(a)和(b)中的A区和B区),变形量从10%增至25%时,晶内第二相略有粗化,而晶界第二相则明显长大。

图3 冷轧预变形合金经165 ℃时效后的TEM像

Fig.3 TEM images of cold-rolled alloy plate aged at 165 ℃: (a), (c) 10%; (b), (d) 25%

在变形量均为10%的拉伸和冷轧预变形合金中(见图2(c)、(f)和图3(a)、(c)),可观察到预拉伸10%的板材中晶内和晶界上第二相尺寸均明显减小。

2.4 织构分析

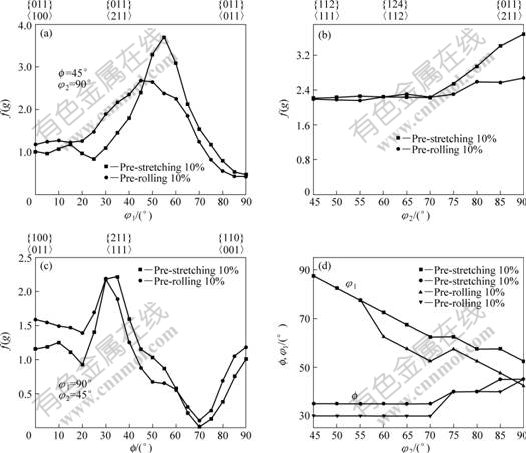

为进一步分析两预变形方式对合金板材力学性能影响的差异,对预拉伸和预冷轧10%的合金板材进行织构分析。图4所示为板材固溶淬火后分别预拉伸和预冷轧10%后的取向线分析。由图4可见,织构总体均较弱,其组分均主要为{011}á211?Br织构和{112}á111?Cu织构,但拉伸预变形板材Br织构比轧制变形板材织构略强。

图4 预拉伸和预冷轧10%合金板材的取向线分析

Fig.4 Orientation density along α-fiber, β-fiber and τ-fiber for 10% pre-stretched and pre-rolled alloy plates: (f, φ1, φ2 are three Euler angles of orientation space): (a) α-fiber; (b) β-fiber; (c) τ-fiber; (d) Positions in Euler space of β-fiber

3 讨论

时效硬化曲线均表明一定的拉伸预变形和冷轧预变形均抑制了合金GP区的析出,减缓时效初期GP区的硬化作用。这是因为形成GP区必须依靠空位和原子迁移,时效前预变形引入的大量位错使空位逸入位错而消失的可能性增加[20],因此预变形后参与形成GP区的空位数目减少了,原子的迁移也因空位数目的减少而变得更困难,从而使GP区析出减少。在时效第二阶段,即θ′相强化阶段,两预变形方式下,一定变形量范围内,增大变形量使θ′相析出密度增加、尺寸变细小,板材强度提高。变形量继续增加时,板材的强度不仅没有进一步提高,冷轧预变形板材还出现了下降。这可能是由于变形量的加大使合金基体中位错数量过多,从而造成大量位错缠结在一起,最终形成胞状位错组织,胞壁处的位错密度高,胞内的位错密度则很小。这样,θ′相沿位错胞壁处形核较多,并容易长大粗化,而在胞内的析出则很少,造成θ′相组织分布的不均匀(见图2(b)、(c)和图3(a)、(b))。新相形核时体系自由能变化为[21]

一方面,时效时溶质原子容易在位错附近富集,使基体过饱和度和自由能增加,从而提高了θ′相的形核动力ΔGv。另一方面,位错作为一种线缺陷与基体之间的畸变提供了θ′相形核所需的应变能,使θ′相形核长大的应变能增量ΔGε减少,θ′相在此形核所需增加的新表面能ΔGs较没有为错的情况下减少,总的相变驱动力ΔG提高。因此,与低位错密度的胞内相比,θ′相易优先在胞壁处形核长大。同样的现象在Al-Cu-Li合金中也存在[22],如表2所列。这种不均匀分布的θ′相虽提高了合金屈服强度,但降低了塑性,拉伸变形合金抗拉强度不仅没有提高,而且冷轧变形合金还出现了下降。

合金时效前后抗拉强度的变化,也说明了变形量增加对第二相强化作用的增强是有限的。形变热处理后合金抗拉强度σ主要由以下几部分组成:

式中:σo为合金基体的强度;σε为合金预变形后加工硬化导致的强度增加量;σθ′为第二相析出导致的强度增加量。当拉伸预变形从2%增加到6%时,合金人工时效前强度不但不增加,反而有所下降,显示GP区数量减少的效果,而人工时效后,6%变形合金强度较2%变形合金提高较大。变形量继续增大,合金时效后抗拉强度变化不大,但屈服强度提高较大,说明第二相θ′相主要作用是阻碍为错的运动。当冷轧预变形从7%增加到10%时,合金人工时效前可能由于空位浓度变化不明显,GP区影响强度的效果不大,强度的提高由于θ″强化相所致。随拉伸或轧制变形量的进一步增加,未人工时效的合金强度提高幅度较大,但人工峰时效合金的强度增加不明显,表明第二相θ′的状态没出现根本性的变化。

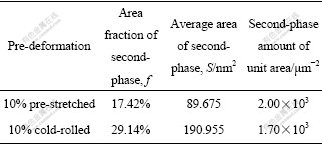

两预变形方式下的织构类型是相同的,而变形量一致时,冷轧变形合金第二相更易长大(见图2(c)和3(a))。采用ImageJ图像分析软件对图2(c)和图3(a)第二相进行统计分析,结果如表3所列。

表3 10%拉伸和冷轧变形合金峰时效后的第二相分布

Table 3 Second phase distribution of 10% pre-stretched and pre-cold rolled alloy plates after peak aging

10%预拉伸和预冷轧变形板材单位面积内,第二相数量相差不大,但轧制变形板材第二相总面积分数高40%多,且第二相粒子的平均面积也明显较大,表明轧制变形易使第二相长大,第二相粒子较粗大。在预冷轧7%时,第二相还没有发生长大,相比预拉伸6%板材没有表现出较低的屈服强度,而预冷轧10%比预拉伸10%较低的屈服强度则是由第二相的长大所致。

第二相粒子阻碍位错运动有两种机制[23]:

对于尺寸较小的第二相粒子,位错主要以切过第二相粒子的方式运动,随着粒子尺寸的增大,位错切过粒子所需的临界切应力逐渐增大;对于尺寸较大第二相粒子,位错主要以绕过第二相粒子的方式运动,随着粒子尺寸的增大,位错绕过粒子所需的临界切应力则逐渐减小。因此,存在一个第二相粒子强化的最佳粒子半径。预冷轧7%和预拉伸6%时,第二相粒子尺寸较小,位错切过第二相粒子而使合金板材屈服强度提高。而预冷轧和预拉伸10%时,第二相粒子较大,位错主要以绕过第二相粒子的方式运动,由表3和式(4)得到其临界切应力的增量分别为

预拉伸10%:Δτr=0.441k;

预轧制10%:Δτr=0.391k;

其中 ,为常数;

,为常数;

。

。

由此可见,预轧制10%合金板材中第二相粒子导致位错运动的临界切应力增量要小于预拉伸10%合金板材,从而表现出较低的屈服强度。此外,较小的均匀分布的第二相也是导致预拉伸变形合金塑性较高的原因。

4 结论

1) 淬火后适当的拉伸和冷轧预变形均量使时效后θ′相分布细小均匀、强化效果好,但进一步增大变形量,θ′相尺寸和分布变得不均匀,合金板材强度变化不大,塑性降低。拉伸预变形6%和冷轧预变形7%时,2519A合金板材峰时效抗拉强度、屈服强度、塑性分别为472 MPa、404 MPa、15.6%和472 MPa、417 MPa、9.4%,二者抗拉强度基本相同,但前者比后者屈服强度低、塑性高。

2) 10%拉伸和冷轧两预变形下板材织构类型和抗拉强度基本不变,合金板材屈服强度由第二相θ′的数量和尺寸所确定。

REFERENCES

[1] JAMES J, FISHER J. Aluminum alloy 2519 in military vehicles[J]. Advanced Materials and Processes, 2002, 160(9): 43-46.

[2] HAMILTON B C, SAXENA A. Transient crack growth behavior in aluminum alloys C415-T87[J]. Engineering Fracture Mechanics, 1999, 62(1): 1-22.

[3] 李慧中, 张新明, 陈明安, 龚敏如, 周卓平. Zr含量对2519铝合金组织与力学性能的影响[J]. 金属热处理, 2004, 29(11): 11-14.

LI Hui-zhong, ZHANG Xin-ming, CHEN Ming-an, GONG Min-ru, ZHOU Zhuo-ping. Effect of Zr content on microstructures and mechanical properties of 2519 aluminum alloy[J]. Heat Treatment of Metals, 2004, 29(11): 11-14.

[4] LI Hui-zhong, ZHANG Xin-ming, CHEN Ming-an, LIU Ying, ZHOU Zhuo-ping. Effect of Cu on microstructure and mechanical properties of 2519 aluminum alloy[J]. Trans Nonferrous Met Soc China, 2005, 15(5): 1026-1030.

[5] 李慧中, 周古昕, 张新明, 陈明安, 梁霄鹏, 高 慧. Mn含量对2519铝合金的组织与力学性能的影响[J]. 航空材料学报, 2007, 27(1): 1-5.

LI Hui-zhong, ZHOU Gu-xin, ZHANG Xin-ming, CHEN Ming-an, LIANG Xiao-peng, GAO Hui. Effect of Mn on microstructures and mechanical properties of 2519 aluminum alloy[J]. Journal of Aeronautical Materials, 2007, 27(1): 1-5.

[6] LI Hui-zhong, ZHANG Xin-ming, CHEN Ming-an, LI Yan-fang, HANG Xiao-peng. Effect of pre-deformation on the stress corrosion cracking susceptibility of aluminum alloy 2519[J]. Rare Metals, 2007, 26(4): 385-390.

[7] SUGAMATA M, KANEKO J. Effect of thermomechanical treatment on mechanical properties of 2024 aluminum alloy[J]. Light Metals, 1983, 33 (7): 407-414.

[8] 林启全, 张 辉, 彭大署.形变热处理对2519铝合金性能的影响[J]. 矿冶工程, 2004, 24(1): 92-99.

LIN Qi-quan, ZHANG Hui, PENG Da-shu. Effect of thermomechanical treatment on properties of 2519 aluminum alloy[J]. Mining and Metal Urgigal Engineering, 2004, 24(1): 92-99.

[9] 陈险峰, 彭大暑, 张 辉, 林启权, 林高用. 热处理制度对2519铝合金板材力学性能和应力腐蚀敏感性的影响[J]. 中国有色金属学报, 2003, 13(4): 934-938.

CHEN Xian-feng, PENG Da-shu, ZHANG Hui, LIN Qi-quan, LIN Gao-yong. Influence of heat treatment on mechanical properties and stress corrosion sensitivity of 2519 aluminum alloy plate[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(4): 934-938.

[10] 李慧中, 梁霄鹏, 陈明安, 张新明. 冷轧变形量对2519铝合金组织与力学性能的影响[J]. 材料热处理学报, 2008, 29(2):86-89.

LI Hui-zhong, LIANG Xiao-peng, ChEN Ming-an, ZHANG Xin-ming. Effect of cold rolling reduction on microstructure and mechanical property of 2519 aluminum alloy[J]. Transactions of Materials and Heat Treatment, 2008, 29(2): 86-89.

[11] 李慧中, 张新明, 陈明安, 周卓平, 龚敏如. 预变形对2519铝合金组织与力学性能的影响[J]. 中国有色金属学报, 2004, 14(12): 1990-1994.

LI Hui-zhong, ZHANG Xin-ming, CHEN Ming-an, ZHOU Zhou-ping, GONG Min-ru. Effect of Pre-deformation on microstructures and mechanical properties of 2519 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(12): 1990-1994.

[12] 黄佩武, 刘友良. 180 ℃形变热处理对2519A铝合金性能的影响[J]. 湖南冶金, 2006, 134(4): 12-15.

HUANG Pei-wu, LIU You-liang. Influence of 180℃ strain heat treatment on properties of the 2519 aluminum alloy[J]. Hunan Metallurgy, 2006, 134(4): 12-15.

[13] GABLE B M, ZHU A W, CSONTOS A A, STARKE JR E A. The role of plastic deformation on the competitive microstructure evolution and mechanical properties of a novel Al-Li-Cu-X alloy[J]. Journal of Light Metals, 2001, 9(1): 1-14.

[14] 周昌荣, 刘心宇, 潘清林. 预变形对含钪Al-Cu-Li合金组织与性能的影响[J]. 稀有金属, 2005, 29(6): 837-840.

ZHOU Chang-rong, LIU Xin-yu, PAN Qing-lin. Effect of pretension on microstructure and tensile property of Al-Cu-Li alloy containing scandium[J]. Chinese Journal of Rare Metals, 2005, 29(6): 837-840.

[15] 朱朝明, 潘清林, 王新宇, 梁文杰, 何运斌, 刘元裴. 含钪Al-Cu-Li-Zr合金的热处理[J]. 轻合金加工技术, 2005, 33(12): 41-44.

ZHU Chao-ming, PAN Qing-lin, WANG Xin-yu, LIANG Wen-jie, HE Yun-bin, LIU Yuan-fei. Heat treatment of Al-Cu-Li-Zr alloy containing Sc[J]. Light Alloy Fabrication Technology, 2005, 33(12): 41-44.

[16] 刘延斌, 刘志义, 余日成, 夏卿坤, 李云涛. 预拉伸对Al-Cu-Mg-Ag合金室温性能的影响[J]. 金属热处理, 2007, 32(4): 64-67.

LIU Yan-bing, LIU Zhi-yi, YU Ri-cheng, XIA Qin-kun, LI Yun-tao. Effects of prestretching on mechanical properties of Al-Cu-Mg-Ag alloy at room temperature[J]. Heat Treatment of Metals, 2007, 32(4): 64-67.

[17] 肖代红, 王键农, 丁冬雁. 预拉伸处理对Al-5.3Cu-0.8Mg- 0.3Ag合金性能和时效过程影响[J]. 热加工工艺, 2004, 4: 1-2.

XIAO Dai-hong, WANG Jian-nong, DING Dong-yan. Effect of the prestretching treatment on the properties and precipitation of Al-Cu-Mg-Ag alloy[J]. Hot Working Technology, 2004, 4: 1-2.

[18] DYMEK S, DOLLAR M. TEM investigation of age-hardenable Al 2519 alloy subjected to stress corrosion cracking tests[J]. Materials Chemistry and Physics, 2003, 81: 286-288.

[19] ROBERT E, SANDERS J R, JOCELYN I. High strength weldable aluminum base alloy product and method of making same[P]. US 4610733. 1986-09-09.

[20] 《有色金属及其热处理》编写组. 有色金属及其热处理[M]. 北京: 国防工业出版社, 1993.

《Non-Ferrous Metals and Their Heat Treatment》writing group[M]. Beijing: National Defence Industrial Press, 1993.

[21] 李松瑞, 周善初. 金属热处理[M]. 长沙:中南大学出版社, 2003: 112-122.

LI Song-rui, ZHOU Shan-chu. Heat treatment of metals[M]. Changsha: Central South University Press, 2003: 112-122.

[22] 周昌荣, 潘清林, 王新宇, 梁文杰, 尹志明. 含钪Al-Cu-Li合金的形变时效研究[J]. 金属热处理, 2004, 29(10): 1-4.

ZHOU Chang-rong, PAN Qing-lin, WANG Xin-yu, LIANG Wen-jie, YIN Zhi-min. Study of deformation -aging of Al-Cu-Li alloy containing Sc[J]. Heat Treatment of Metals, 2004, 29(10): 1-4.

[23] 何肇基. 金属的力学性质[M]. 北京:冶金工业出版社, 1982: 193-196.

HE Zhao-ji. Mechanical properties of metals[M]. Beijing: Metallurgical Industrial Press, 1982: 193-196.

(编辑 李艳红)

基金项目:国家重点基础研究发展计划资助项目(2005CB623706)

收稿日期:2009-05-04;修订日期:2010-01-10

通信作者:张新明,教授,博士;电话:0731-88830265;E-mail:xmzhang@mail.csu.edu.cn