DOI:10.19476/j.ysxb.1004.0609.2017.12.05

预变形量对2519A-T9I6铝合金力学性能和组织的影响

董 宇1, 2,叶凌英1, 2,孙大翔1, 2,张新明1, 2

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 中南大学 有色金属先进结构材料与制造协同创新中心,长沙 410083)

摘 要:研究预变形量对经T9I6工艺处理的2519A铝合金组织和力学性能的影响。通过显微硬度测试、室温拉伸测试检测合金的室温力学性能,采用透射电镜(TEM)和高分辨透射电镜(HRTEM)分析合金的显微组织。结果表明:当预变形量为15%时,合金的屈服强度和抗拉强度取得最大值,分别为456.1 MPa和501.6 MPa,继续增大预变形量会导致强度下降;而合金的伸长率随着预变形量的增大而逐渐下降。2519A铝合金在T9I6工艺中强化方式主要为形变强化和析出强化;合金的形变强化效果随着预变形量的增大有增大的趋势,但提升幅度逐渐减小。预变形过程中引入的位错能够与合金在预时效阶段析出的GP区相互作用,从而改善位错分布。当预变形量增大时,基体内会发生回复作用导致位错密度减少,且后续时效过程中GP区析出被抑制,对强化相θ′相的形核产生不利影响,减弱析出强化的效果。

关键词:2519A铝合金;断续时效;力学性能;显微组织;预变形

文章编号:1004-0609(2017)-12-2434-09 中图分类号:TG146.21 文献标志码:A

2519铝合金是美国铝业在20世纪80年代研发的一种装甲材料,该合金解决了前两代铝合金装甲板焊接性能弱和抗应力腐蚀性能弱的问题,并且防护性能也得到加强,被应用于水陆两栖装甲车中[1-3]。为适应我国国防科工需求,中南大学张新明课题组[1-4]通过调整2519铝合金的合金成分和改良加工工艺,研制出了2519A铝合金。2519A铝合金为高Cu/Mg比的2XXX系铝合金,同样具备良好的力学性能、焊接性能和抗应力腐蚀性。为未满足服役环境不断增长的需求,如何进一步提高其力学性能,对于2519A铝合金的应用最为关键[4]。

美国铝业在研制2519铝合金时,使用T87工艺(固溶,冷轧7%,165 ℃时效至峰值)作为其热处理工艺[5]。而中国的2519A铝合金使用T87态作为合金的常规使用状态,合金的室温抗拉强度和伸长率分别可达472 MPa和10.8%。采用大变形量变形,可以有效提高2519A铝合金的强度,王会敏等[6]将合金固溶后,直接使用50%的冷轧变形量轧制,之后将合金在165 ℃下时效4 h之后,合金的屈服强度和抗拉强度可以分别提升至496 MPa和538 MPa,但大变形量带来的形变强化牺牲了合金的伸长率。WU等[7]通过DSC的手段研究了2519A铝合金的析出动力学,发现使用T87工艺处理的2519A铝合金,随着预变形量的增大,合金的析出强化能力逐渐降低,θ′相析出的激活能升高,这可能是由于冷轧之后合金内位错分布不均匀导致强化相θ′相的析出不均匀。

为改善2519A铝合金在时效过程中θ′相的析出,本实验中使用多级时效制度。在2XXX系铝合金中,传统多级时效运用较少,且双级时效对2519A铝合金强度的提升较小,因此需要寻求更有效的多级时效技术。断续时效是近20年来研究出的一种新型的多级时效工艺,顾刚等[8]通过将预变形引入断续时效,制订了T9I6工艺。使用T9I6工艺处理2519A铝合金,可以大幅提升其强度和伸长率,同时对合金的韧性及抗腐蚀性能影响较小。本文作者通过改变T9I6工艺中的预变形量,利用硬度测试、室温拉伸性能测试、扫描电镜(SEM)、透射电镜(TEM)以及高分辨透射电镜(HRTEM)比较不同预变形量对2519A铝合金的力学性能和显微组织的影响机理,为继续优化T9I6热处理工艺提供依据。

1 实验

1.1 样品

本实验中所用合金样品为工业生产的2519A铝合金板材,其化学成分如表1所列。热处理过程如图1所示,工艺制度如下:固溶淬火→预时效→预变形→断续时效→再时效。固溶处理在箱式空气电阻炉中进行,固溶温度为535 ℃,固溶时间2 h以保证充分固溶,之后在室温的水中进行淬火并且保证转移时间不超过15 s。预时效过程在101A-3型恒温干燥箱中进行,时效温度为165 ℃,时效时间80 min。预变形过程使用冷轧作为变形方式,样品分为4组,分别使用7%、15%、22%和30%的预变形量。预变形完成之后,立即将试样放入时效炉中进行65 ℃下保温5 d的断续时效,最后随炉升温至165 ℃并保温至合金达到峰时效状态。

表1 2519A铝合金的化学成分

Table 1 Chemical compositions of 2519A (mass fraction, %)

图1 T9I6断续时效工艺示意图

Fig. 1 General schematic representation of T9I6 interrupted ageing treatment

1.2 试验方法

硬度测试依据国标GB/T 4340.1—2009进行,所有样品在测试硬度前均进行预磨、终磨和抛光。在华银200HVS-5型数显小负荷维氏硬度测量仪上进行测试,每个试样的硬度平均值至少从7个压痕上取得。实验中加载负荷为30 N,持续时间为15 s。读出菱形压痕对角线的尺寸并在屏幕上直接读出试样的硬度值。

室温拉伸试样依据国标GB/T 228.1—2010规定进行加工制作,试样从轧制板材上沿轧制方向切取,试样平行区标距长度为30 mm,平行区宽度为10 mm,厚度为2 mm,在CRIMS拉伸机上进行室温拉伸实验,拉伸速率控制在2 mm/min,选取3个拉伸数据的平均值作为实验有效结果。

透射电镜(TEM)分析在TECNAI G2型透射电镜下进行,加速电压为200 kV。高分辨透射电镜(HRTEM)在FEI Titan3 80-300型球差电镜下进行,加速电压为300 kV。制取样品时,先切取1 mm左右的薄片,在金相研磨机上机械减薄至80~100 μm,用冲片器冲出直径3 mm的圆片,放入MTP-1A电解双喷仪上用电解双喷液(30%HNO3+70%CH3OH,体积分数)减薄。实验过程中使用液氮冷却,保证温度在-25 ℃左右,实验电压为10~20 V,电流为80~100 mA。实验得到的图片使用Image Pro Plus软件进行统计分析。

2 结果与分析

2.1 时效硬度曲线

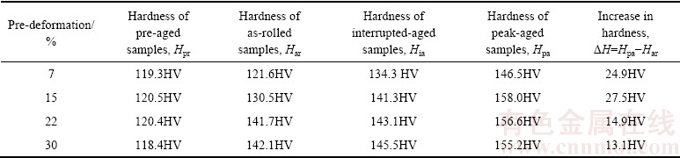

图2所示为不同预变形量铝合金在T9I6工艺的再时效阶段165 ℃下的时效硬化曲线,表2所列为合金在T9I6工艺各阶段的平均硬度值。从表2中看出,所有样品在完成预时效之后的硬度值都接近。不同样品经历的预变形量从7%增加到30%时,不同样品的硬度值从121.6HV增加到142.1HV,形变强化的效果随着预变形量的增大而增大,提升幅度减弱。断续时效阶段,不同样品的硬度有少量的提升,但随着预变形量增大,提升的数值降低显著。从图2中看出,随着预变形量的增大,合金到达峰时效的时间有一定的提前。当合金预变形量为15%时,峰值硬度最高,为158.0HV。若继续增大预变形量,合金的峰值硬度逐渐减小。断续时效过程中基体内生成了细小、弥散的GP区,对位错起到了钉扎作用,会阻碍再时效过程基体的回复过程[9-10]。因此表2中的ΔH可以在一定程度上表示预变形之后的时效过程中沉淀强化的效果,ΔH的值在15%的预变形量时取得最大,继续增大预变形量会导致ΔH的值急剧下降。

图2 不同预变形量合金再时效阶段的时效强化曲线

Fig. 2 Hardness curves of re-ageing stage for alloys under different pre-deformation

表2 不同预变形量合金在T9I6工艺不同阶段的平均维氏硬度值

Table 2 Average Vickers hardness of alloys under different pre-deformations at different stages in T9I6 treatment

2.2 室温拉伸性能

不同预变形量的2519A铝合金的室温拉伸性能如表3所示,所有拉伸试样都取自T9I6工艺的峰时效状态样品。从表中可以看出,屈服强度和抗拉强度在预变形量为15%时达到最大值456.1 MPa和511.6 MPa,继续增大预变形量,屈服强度和抗拉强度逐渐减小。合金的伸长率随着预变形量的增大而减小。

表3 不同预变形量合金的室温拉伸性能

Table 3 Tensile properties of alloys under different pre- deformations

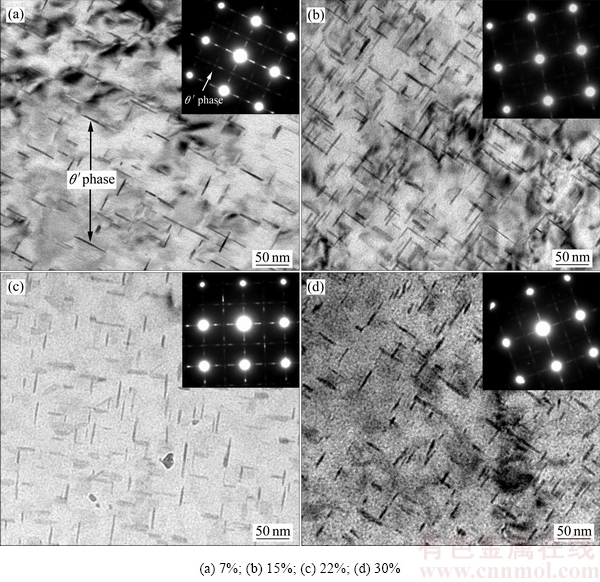

2.3 透射电镜观察

在Tecnai G2 20型透射电镜下对不同预变形量的2519A铝合金在T9I6峰时效状态进行观察,典型的TEM像如图3所示。入射电子束平行于[100]晶带轴,观察到针状析出相,结合衍射斑点可知为θ′相[11]。从图3中看出,预变形量为7%时,θ′相的密度较小但其平均尺寸较大。随着预变形量增大,θ′相的平均尺寸逐渐减小。预变形15%样品中θ′相的密度较高且分布较为均匀。若继续增大预变形量到22%和30%,θ′相密度逐渐减小且θ′相出现沿位错集中分布的趋势。使用Image Pro Plus软件对不同预变形量合金的θ′相面积分数进行统计,为保证统计规律准确,每个样品都从至少5张TEM像上统计,结果如图4所示。图4中各饼状图中空白部分为Al基体的面积,随着预变形量增大,θ′相所占的总面积分数减小,且尺寸大于40 nm的θ′相所占比例不断减小。预变形量为15%时,样品中的θ′相所占的面积分数较大,此时尺寸为20~30 nm的θ′相所占比例最大。

图5所示为不同预变形量样品的位错集中的区域。在图5中并未观察到明显的位错线,这是由于预变形过程中位错与GP区相互作用发生高度缠结而转变为较短的位错线[12]。当预变形量为7%时,未发现大量位错缠结集中的区域,仅观察到如图5(a)所示的少量位错缠结。预变形量进一步增大之后,由于位错滑移时的交割作用,这种位错缠结会进一步增多。从图5(b)中可以明显看出位错缠结已经形成胞状组织,胞壁之间相互平行,尚未包围低位错密度区域。而预变形量增加到22%时,从图5(c)中观察到胞状组织将低位错密度区域包围,且在晶粒内所占区域进一步增大。当预变形量达到30%时,从图5(d)可以发现胞状组织的胞壁变薄,但出现更清晰的条纹衬度。位错胞,但胞壁内的位错密度明显减小,这是由于时效过程中发生了回复。由于预时效的80min内生成的GP区的数量有限,当预变形量达到30%时,GP区无法有效阻碍大量位错的运动。低密度位错区域的部分位错运动到位错胞内,异号位错相互抵消,使得晶粒内的能量得以释放。回复会导致合金的位错密度减小,降低形变强化的效果。

图3 不同预变形量2519A铝合金的峰时效状态TEM像

Fig. 3 TEM images of peak-aged 2519A aluminium alloys under different pre-deformations

图4 不同预变形量2519A铝合金析出相面积分数统计图

Fig. 4 Area fraction of precipitate phase of 2519A aluminum alloy under different pre-deformations

图5 不同预变形量2519A铝合金中位错及析出相的TEM像

Fig. 5 TEM images of dislocations and precipitates in 2519A aluminium alloys under different pre-deformations

2519A铝合金在165 ℃时效的析出序列为:过饱和固溶体→GP区→θ″相→θ′相→θ相[13]。其中,GP区和θ″相与Al基体共格,θ′相和θ相与Al基体半共格。GP区的尺寸达到临界值时会生成θ″相,而θ″相为了释放弹性应变能会迅速转变为θ′相。断续时效过程中由于温度较低,溶质原子扩散速率较慢,且预变形后基体内因淬火形成的空位被位错吸收,GP区的形核速率要远低于预时效阶段[14]。当合金在65 ℃下保温较长时间之后,溶质原子在附近偏聚,基体内能够形成细小、密集、均匀的GP区。当合金进入再时效阶段,温度重新升至165 ℃,基体内θ′相开始析出。θ′相会优先在基体内的两种地方形核,分别为GP区和位错[14]。

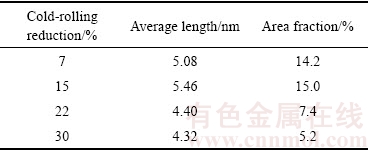

图6(a)所示为15%预变形量的样品在断续时效之后的HRTEM像,从图中观察到厚度约为几个原子层的GP区,与Al基体的共格关系比较明显,GP区的衍射为Al基体斑点周围的“芒线”[15]。而图6(b)中基本上观察不到明显的GP区的衬度,仅发现部分不规则条纹状的衬度,可能是韧形位错。为了比较预变形量对不同样品基体内GP区形貌的影响,使用高倍数TEM观察不同预变形量合金断续时效完成时的样品,典型的TEM像如图7所示。不同预变形量下,GP区的分布都较为均匀,表4所示为不同样品断续时效之后GP区平均尺寸和面积分数的统计情况,每组样品的结果从至少5张TEM图片上统计。预变形量从7%增加到15%时,GP区的尺寸和密度较大,且变化不明显。继续增大预变形量,GP区的尺寸和密度都明显减小。

图6 不同预变形量2519A铝合金断续时效完成阶段HRTEM像

Fig. 6 HRTEM images of 2519A alloys after interrupted ageing under different pre-deformations

图7 2519A-T9I6铝合金在断续时效完成阶段的TEM像

Fig. 7 TEM images of 2519A alloys after interrupted ageing under different pre-deformations

表4 不同预变形量2519A铝合金断续时效后GP区分布情况

Table 4 Distribution of GP zones in 2519A aluminium alloys after interrupted ageing under different pre-deformations

研究表明[16],2519A铝合金峰时效状态的强化相为θ′相,流变应力方程可以表示为:

(1)

(1)

式中: 为固有的晶格应力,测定值约为28 MPa;

为固有的晶格应力,测定值约为28 MPa; 为固溶体的强度,取决于Cu原子的浓度,在本研究中由于样品都取自同一板材,不同样品间

为固溶体的强度,取决于Cu原子的浓度,在本研究中由于样品都取自同一板材,不同样品间 的差别可以忽略不计;

的差别可以忽略不计; 为形变强化带来的强度提升;

为形变强化带来的强度提升; 是θ′相的第二相强化带来的强度提升;

是θ′相的第二相强化带来的强度提升; 是铝合金的内应力,在充分人工时效的合金中可以忽略不计。因此, 2519A铝合金强度的提升主要由形变引入的位错和θ′相共同作用。θ′相是以{100}为惯析面的盘状析出强化相,σθ′可以表示为[16]

是铝合金的内应力,在充分人工时效的合金中可以忽略不计。因此, 2519A铝合金强度的提升主要由形变引入的位错和θ′相共同作用。θ′相是以{100}为惯析面的盘状析出强化相,σθ′可以表示为[16]

(2)

(2)

式中:M、G、b和r0分别代表泰勒因子、基体剪切模量、基体位错矢量和位错绕过强化相时的内半径;r、h和fv分别为θ′相的长度,半厚度和体积分数。式(2)表明,θ′相平均尺寸越小且体积分数越大时,强化效果越明显。若要θ′相分布细小弥散,需要再时效开始阶段,基体内有足够多的θ′相的高能形核点,前文已经指出,形核点由位错和GP区提供。因此形核点数量越多, 的数值就会越大。而

的数值就会越大。而 的值可以由泰勒方程表示[16]:

的值可以由泰勒方程表示[16]:

(3)

(3)

式中: 表示位错连结强度,为0.28;

表示位错连结强度,为0.28; 表示剪切模量;

表示剪切模量; 是位错密度。从式(3)可以看出,当合金基体内位错密度增大时,

是位错密度。从式(3)可以看出,当合金基体内位错密度增大时, 的值增大。

的值增大。

T9I6工艺中引入预变形,一方面为合金引入形变强化,提高了合金的强度;另一方面为强化相θ′相的析出提供形核点,改善θ′相的分布。研究指出,预变形结束时,合金内的GP区受位错诱导会发生回溶。通常情况下,只有当合金的温度在固溶温度以上时,析出相才会回溶。当合金在预变形过程中,部分区域位错较为集中,析出相破碎而与基体间产生浓度梯度,因此析出相在室温下也会发生部分回溶。回溶后的GP区在位错缠结部位发生偏聚,可以强化位错之间结合的强度。当预变形量为7%时,合金内位错密度较小,形变强化的效果较弱。而当预变形量大于22%时,合金内引入大量的位错,此时位错缠结增多,增强了形变强化,但位错密度增大使得更多GP区回溶,同时晶格畸变增大也会抑制后续的GP区析出[17]。形变强化对强度的提升不足以弥补析出强化的减弱,因此当预变形量从15%增加到22%时,合金强度减弱。当预变形量进一步增大到30%时,由于预时效过程中生成的GP区有限,部分GP区回溶之后,剩余的GP区不能阻碍位错的运动,后续时效过程中,合金内会发生强烈的回复作用。因此,合金的形变强化效果也会减弱,合金的强度增幅减小。

3 结论

1) 当预变形量为15%时,合金有最大的抗拉强度和屈服强度,分别为511.7 MPa和456.4 MPa。伸长率随着预变形量的增大而减小。2519A铝合金在T9I6工艺中的强化主要由形变强化和析出强化共同作用。

2) 形变强化主要来自于位错密度的升高,合金的位错密度随着预变形量的增大而不断增大。当预变形量从7%增大到22%时,位错密度增大速率较快。继续增大预变形量,由于基体内GP区数量有限,部分位错会发生强烈的回复作用,使得位错密度增长速率降低。

3) 析出强化主要来自于再时效过程中θ′相的析出。预变形量为15%时,合金内θ′相的体积分数最大且平均尺寸较小,析出强化效果最好。继续增大预变形量,位错密度增大会抑制GP区的形核。再时效过程中由于θ′相的形核点GP区严重减少,θ′相的体积分数急剧减少,析出强化效果减弱。

REFERENCES

[1] 顾 刚, 叶凌英, 蒋海春, 孙大翔, 张 盼, 张新明. T9I6形变热处理工艺对2519A铝合金组织、力学性能及抗弹性能的影响[J]. 中国有色金属学报, 2014, 24(7): 2295-2300.

GU Gang, YE Ling-ying, JIANG Hai-chun, SUN Da-xiang, ZHANG Pan, ZHANG Xin-ming. Effects of T9I6 thermo- mechanical process on microstructure, mechanical properties and ballistic resistance of 2519A aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(7): 2295-2300.

[2] 郑玉林, 暨 波, 叶凌英, 张新明. 稀土镱对2519A铝合金抗晶间腐蚀性能的影响[J]. 中南大学学报(自然科学版), 2013, 44(12): 4806-4810.

ZHEN Yu-lin, JI Bo, YE Ling-ying, ZHANG Xin-ming. Influence of Yb addition on intergranular corrosion resistance of aluminum alloy 2519A[J]. Journal of Central South University (Science and Technology), 2013, 44(12): 4806-4810.

[3] 贵星卉, 叶凌英, 孙大翔, 顾 刚, 蒋海春, 张新明. 断续时效对2519A铝合金抗应力腐蚀性能的影响[J]. 中国有色金属学报, 2014, 24(12): 2995-3001.

GUI Xing-hui, YE Ling-ying, SUN Da-xiang, GU Gang, JIANG Hai-chun, ZHANG Xin-ming. Effect of interrupted aging on stress corrosion resistance of 2519A aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(12): 2995-3001.

[4] 张新明, 刘 玲, 贾寓真. 拉伸与轧制预变形对2519A铝合金组织与力学性能的影响[J]. 中国有色金属学报, 2010, 20(6): 1088-1094.

ZHANG Xin-ming, LIU Ling, JIA Yu-zhen. Effects of stretching and rolling pre-deformation on microstructures and mechanical properties of 2519A aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(6): 1088-1094.

[5] 林启权, 张 辉, 彭大暑. 形变热处理对2519铝合金性能的影响[J]. 矿冶工程, 2004, 24(1): 92-94.

LIN Qi-quan, ZHANG Hui, PENG Da-shu. Effect of thermomechanical treatment on properties of 2519 aluminum alloy[J]. Mining & Metallurgical Engineering, 2004, 24(1): 92-94.

[6] 王会敏, 夏长清, 吴柳融, 周 飞. 时效温度对大冷变形2519A铝合金组织与性能的影响[J]. 材料热处理学报, 2011,32(6): 83-86.

WANG Hui-min, XIA Chang-qing, WU Liu-Rong, ZHOU Fei. Effect of aging temperature on microstructure and mechanical properties of cold-heavy deformed 2519A aluminum alloy[J]. Transactions of Materials & Heat Treatment, 2011, 32(6): 83-86.

[7] WU Yi-ping, YE Ling-ying, JIA Yu-zhen, LIU Ling, ZHANG Xin-ming. Precipitation kinetics of 2519A aluminum alloy based on aging curves and DSC analysis[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(10): 3076-3083.

[8] 顾 刚, 叶凌英, 张新明, 蒋海春, 孙大翔, 张 盼. 断续时效对2519A铝合金组织和力学性能的影响[J]. 中国有色金属学报, 2013, 23(8): 2098-2103.

GU Gang, YE Ling-ying, ZHANG Xin-ming, JAING Hai-chun, SUN Da-xiang, ZHANG Pan. Effects of interrupted ageing on microstructure and mechanical properties of 2519A aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(8): 2098-2103.

[9] ZLATEVA G, MARTINOVA Z. Microstructure of metals and alloys—an atlas of transmission electron microscopy images[M]. New York: CRC Press, 2008: 93-96.

[10] HUMPHREYS F J, HATHERLY M. Recrystallization and related annealing phenomena[M]. Oxford: Elsevier, 2004: 207-213.

[11] QI Hao, LIU Xiao-yan, LIANG Shun-xing, ZHANG Xi-liang, CUI Hao-xuan, ZHENG Li-yun, GAO Fei, CHEN Huai-qi. Mechanical properties and corrosion resistance of Al-Cu-Mg-Ag heat-resistant alloy modified by interrupted aging[J]. Journal of Alloys & Compounds, 2016, 657(2): 318-324.

[12] 马 征. 冷变形及时效对2219铝合金组织性能的影响规律[D]. 哈尔滨: 哈尔滨工业大学, 2014: 34-35.

MA Zheng. Influence of cold deformation and aging on microstructure and properties of aluminum alloy 2219[D]. Harbin: Harbin Institute of Technology, 2014: 34-35.

[13] HETNARSKI R B. Encyclopedia of thermal stresses[M]. Dordrecht: Springer, 2014: 3027-3041.

[14] 李慧中, 梁霄鹏, 陈明安, 张新明. 冷轧变形量对2519铝合金组织与力学性能的影响[J]. 材料热处理学报, 2008, 29(2): 86-89.

LI Hui-zhong, LIANG Xiao-peng, CHEN Ming-an, ZHANG Xin-ming. Effect of cold rolling reduction on microstructure and mechanical property of 2519 aluminum alloy[J]. Transactions of Materials & Heat Treatment, 2008, 29(2): 86-89.

[15] TEIXEIRA J D C, CRAM D G, BOURGEOIS L, BASTOW T J, HILL A J, HUTCHINSON C R. On the strengthening response of aluminum alloys containing shear-resistant plate-shaped precipitates[J]. Acta Materialia, 2008, 56(20): 6109-6122.

[16] CHEN Y, WEYLAND M, HUTCHINSON C R. The effect of interrupted aging on the yield strength and uniform elongation of precipitation-hardened Al alloys[J]. Acta Materialia, 2013, 61(15): 5877-5894.

[17] GAZIZOV M, KAIBYSHEV R. Effect of pre-straining on the aging behavior and mechanical properties of an Al-Cu-Mg-Ag alloy[J]. Materials Science and Engineering A, 2015, 625(14): 119-130.

Effects of pre-deformation on microstructure and mechanical properties of 2519A-T9I6 aluminum alloy

DONG Yu1, 2, YE Ling-ying1, 2, SUN Da-xiang1, 2, ZHANG Xin-ming1, 2

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Key Laboratory of Nonferrous Materials Science and Engineering, Ministry of Education, Central South University, Changsha 410083, China)

Abstract: The effects of pre-deformation on microstructure and mechanical properties of T9I6 interrupted-aged 2519A aluminum alloy were investigated by transmission electron microscopy (TEM), high resolution transmission electron microscopy (HRTEM), hardness tests and tensile tests. The results show that when the pre-deformation rate is 15%, both the yield strength and tensile strength of the alloy get their highest values, 456.1 MPa and 501.6 MPa, respectively. Further increasing the pre-deformation rate will decrease the strength. While the elongation decreases with increasing the pre-deformation rate. The mechanical properties of 2519A alunimiun in T9I6 treatment are contributed mainly by strain hardening and age hardening. The effect of strain hardening tends to increase with increasing the pre-deformation rate, but the rate of increase gradually reduces. The dislocation introduced by strain can interact with GP zones formed during pre-ageing and improve the distribution of dislocation. If the pre-deformation rate is too large, the occurring of recovery can decrease the density of dislocations. Also, the formation of GP zones in the following process will be inhibited, which can adversely affect the nucleation of θ′ precipitates and reduce the effect of age hardening.

Key words: 2519A aluminum alloy; T9I6 thermo-mechanical treatment; mechanical property; microstructure; pre-deformation

Foundation item: Project(2016YFB0300901) supported by the National Key Research and Development Program of China

Received date: 2016-09-27; Accepted date: 2017-03-16

Corresponding author: YE Ling-ying; Tel: +86-13607435545; E-mail: 30575421@qq.com

(编辑 龙怀中)

基金项目:国家重点研发计划资助项目(2016YFB0300901)

收稿日期:2016-09-27;修订日期:2017-03-16

通信作者:叶凌英,副教授,博士;电话:13607435545;E-mail: 30575421@qq.com