Cr和Yb复合添加对2519A铝合金组织和力学性能的影响

李玉乾,叶凌英,张新明,孙大翔

(中南大学 材料科学与工程学院,湖南 长沙,410083)

摘要:采用力学性能测试、金相﹑扫描电镜及透射电镜等手段研究复合添加Cr和Yb元素对2519A合金显微组织及力学性能的影响。研究结果表明:添加稀土元素Yb,能细化合金的时效强化相,提高合金力学性能。未溶于基体的Yb元素与Cu和Al元素主要形成AlCuYb金属间化合物,并沿晶界分布。复合添加Cr和Yb元素,与单独添加Yb元素的合金相比,Cr元素的加入改变了稀土元素的分布状态,合金在结晶过程中沿晶界形成的富稀土相明显减少,使更多的Yb元素固溶到基体中,从而更有效地细化合金的时效强化相,提高合金的力学性能,使合金室温抗拉强度由490.5MPa提高至508.9MPa。

关键词:2519A铝合金;铬;镱;显微组织;力学性能

中图分类号:TG146 文献标志码:A 文章编号:1672-7207(2014)07-2182-05

Effects of Cr and Yb additions on microstructures and mechanical properties of 2519A aluminum alloy

LI Yuqian, YE Lingying, ZHANG Xinming, SUN Daxiang

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The effects of composite additions of Cr and Yb on microstructures and mechanical properties of 2519A aluminum alloy were investigated by tensile test, optical microscopy, scanning electron microcopy and transmission electron microscopy. The results show that aging precipitates can be refined with appropriate addition of Yb, which increases the mechanical properties of the alloy. The AlCuYb phase is formed at the grain boundary of as-cast with Yb addition. Compared with the 2519A alloy with Yb only, the distribution of Yb element is changed in the 2519A alloy with both Yb and Cr. The coarse rare earth-rich phase along the grain boundaries decreases while the solubility of Yb increases in the alloy with Yb and Cr. Aging precipitates can be better refined with appropriate additions of Cr and Yb, which increases the mechanical properties of the alloy from 490.5 MPa to 508.9 MPa.

Key words: 2519 aluminum alloy; Cr; Yb; microstructure; mechanical properties

2519铝合金是一种新型装甲铝合金,其力学性能优良,并有良好的抗应力腐蚀性能和焊接性能[1-4]。在铝合金中添加少量稀土元素往往可以起到变质、净化和微合金化的作用[5-6]。文献[7-10]研究了不同稀土元素对2519A铝合金组织和性能的影响,结果表明稀土元素改善了合金的组织,细化了合金的主要强化相,提高了合金的力学性能。但稀土加入合金之后,形成尺寸较大的AlCuRE相,并沿晶界富集。这些富稀土相熔点较高,在后续的加工过程中难以消除,限制了合金性能的进一步提高。据文献[11-13]报道:在Al-Zn-Mg-Cu超高强铝合金中复合添加稀土元素RE和过渡族元素Zr和Cr形成含有Cr,RE和Zr多元弥散相均匀分布于基体。这些多元弥散相抑制了合金的再结晶,也改善了稀土元素在合金中的分布状态,使更多的稀土元素固溶到基体中。本文作者通过在2519A中复合添加Cr和Yb元素以期改造合金晶界处尺寸较大的富稀土相,使稀土在2519A合金中的分布更均匀,更有效促进合金强化的析出,从而提高合金性能。

1 实验

实验合金的化学成分(质量分数)如表1所列。采用工业纯铝、工业纯Cu和工业纯Mg为原料,合金元素Mn,Zr,Cr和Yb以中间合金形式加入,熔炼在电阻石墨坩锅炉中进行,熔炼度为780 ℃,采用NaCl和KCl精炼,将合金于740 ℃浇入预热至250 ℃的铁模中,铸锭长×宽×厚为120 mm×100 mm×25mm。铸锭经520 ℃,24 h均匀化处理,铣面后加热至430 ℃,保温2 h热轧至2.4 mm。合金的形变热处理工艺为533 ℃,2 h固溶,水淬(水温15 ℃),冷变形13%,然后进行峰时效,时效时间均为12 h。

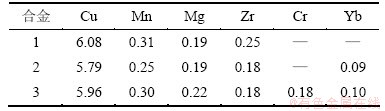

表1 实验合金的化学成分(质量分数)

Table 1 Chemical compositions of experimental alloys %

硬度测试在HV-10B维氏硬度计上进行,负荷为30 N。常温拉伸实验在CSS-44100万能材料力学拉伸机上进行,拉伸速度为2 mm/min。在XJP-6A型金相显微镜下观察金相组织,在D/max2500转型X线衍射仪上进行物相分Sirion200扫描电镜上进行拉伸试样的表面形貌观察与能谱分析。在Tecnai G220型透射电镜上进行TEM分析,加速电压为200 kV,薄膜试样采用电解双喷减薄,电解液为30%(体积分数)硝酸和70%甲醇混合液,在-15 ℃和15 V条件下制备。

2 结果与分析

2.1 Cr和Yb对合金力学性能的影响

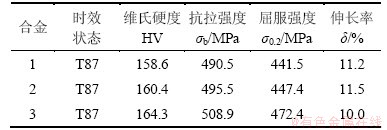

添加不同元素的合金的力学性能见表2。由表2可知:与合金1相比,合金3的抗拉强度最高,抗拉强度由492.5 MPa提高到508.9 MPa。合金2的抗拉强度则略微提高,其峰时效后的抗拉强度为495.5 MPa。而3组合金的硬度和伸长率变化均不明显。

表2 合金的力学性能

Table 2 Mechanical properties of studied alloys

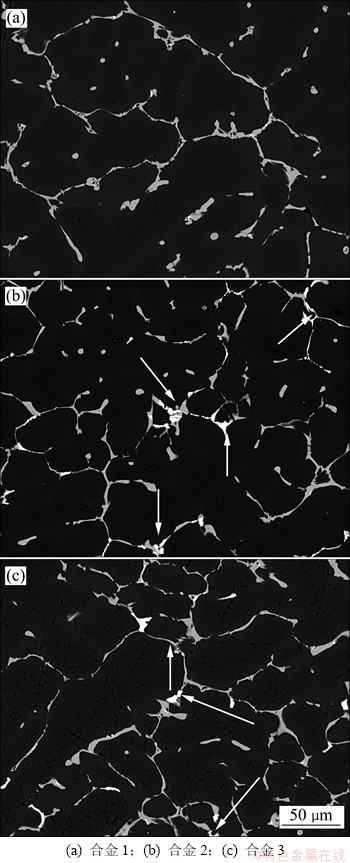

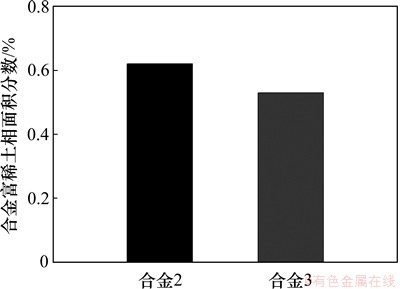

2.2 合金的铸态组织

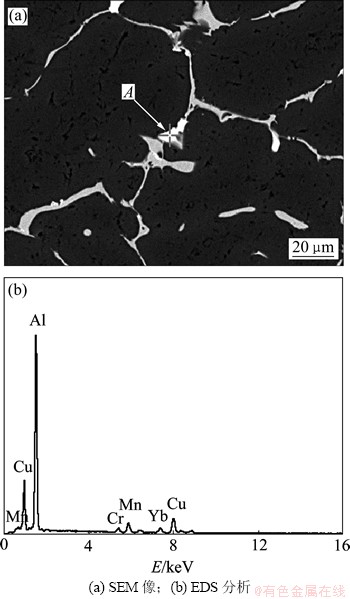

图1所示为合金铸态的SEM像。由图1可知:在未添加合金元素的合金1中,其铸态合金的非平衡共晶相呈灰色,且沿晶界呈网状或层片状分布,为典型的共晶Al2Cu组织,并含有少量的杂质相Al7Cu2Fe。而在添加了Yb元素的合金2与合金3中发现了亮白的沿晶界分布的富稀土相,其能谱分析见图2(b)和图3(b)。且合金3中沿晶界分布的富稀土相明显比合金2(如图1(b)和(c)中箭头所示)的少,利用Image-Pro-Pius软件统计了合金2和合金3的900 μm×900 μm区域内稀土相所占面积分数,合金2和合金3中稀土相的面积分数分别为0.62%和0.53%,结果见图4。由图4可知:Cr元素的加入,改变了合金中富稀土相的尺寸与分布,使更多的稀土元素固溶到基体中。

图1 合金铸态的SEM像

Fig. 1 SEM images of as-cast microstructures

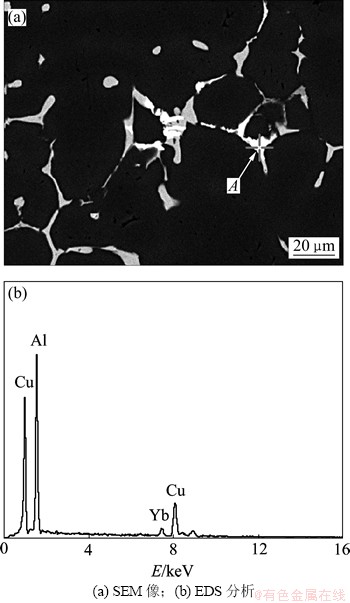

由图2和图3可知:在单独添加Yb元素的合金2中,其晶界处的富稀土相主要由Al,Cu和Yb元素组成,而在复合添加了Yb和Cr元素的合金3中其晶界处的富稀土相除了Al,Cu和Yb元素外还含有Cr和Mn元素,这可能形成了新的富稀土相。

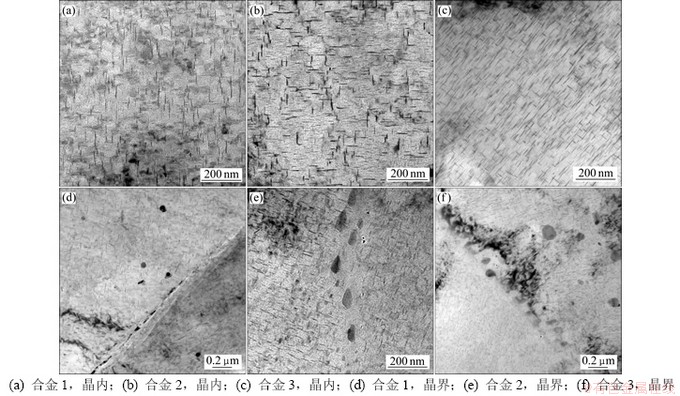

2.3 Cr和Yb元素对合金时效态组织的影响

不同成分合金在峰时效状态下的显微组织如图5所示。由图5可知:合金3复合添加Cr和Yb元素的合金3析出相最为致密。在晶界上,未添加任何元素的合金1晶界析出相细小且不连续,而合金2晶界析出相变得粗大,合金3晶界析出相比合金2数量要少,而且尺寸更细小。

图2 合金2中A点能谱分析

Fig. 2 SEM image and EDS spectrum of particle A of alloy 2

图3 合金3中A点能谱分析

Fig. 3 SEM image and EDS spectrum of particle A of alloy 3

图4 合金2与合金3中稀土相面积分数

Fig. 4 Area fraction of rare earth-rich phase in alloy 2 and alloy 3

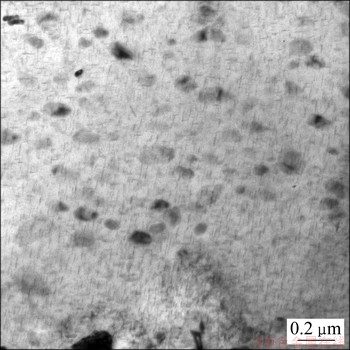

图6所示为合金3在峰时效状态下TEM像。由图6可以看到:复合添加Cr和Yb元素之后,合金基体中析出一些弥散相,这些弥散相可以抑制合金的再结晶,可以提高合金力学性能[14]。

图5 合金在峰时效态下的TEM相

Fig. 5 TEM images of studied alloys under peak-aging

图6 合金3在峰时效状态下TEM像

Fig. 6 TEM image under peak-aging of alloy 3

3 讨论

由以上结果可以看出:Cr和Yb复合添加之后对2519A铝合金时效态组织和性能有较明显的影响。2519A铝合金是典型的热处理可强化铝合金,时效强化相为θ′相,θ′相的尺寸、密度及形貌直接决定了2519A铝合金的力学性能。2519铝合金沉淀相析出序列如下[15]:SSSS GP(Ⅰ)区

GP(Ⅰ)区 G.P(Ⅱ)区(θ″相)

G.P(Ⅱ)区(θ″相)  θ′相

θ′相 θ(Al2Cu)相。由文献[8]可知:在一定范围内稀土Yb能够促进θ′相的析出,这是由于Yb的原子半径为0.182 nm远大于Al原子的半径(0.143 nm),因此,固溶于基体中的Yb会引起晶格较大的正畸变。而在晶格畸变区,淬火保留的空位密度较高,稀土原子最可能在时效初期与淬火空位优先结合,形成稀土-空位团簇,用RE+V表示。而θ′相是一种盘状相,与基体半共格,容易依托缺陷而形核,这些团簇和位错为θ′相提供了形核位置。另一方面Yb原子引起的晶格畸变能为为 θ′相的形核提供储能。因此,促进了θ′相的析出(见图5(b)和(c)),提高了合金的力学性能。

θ(Al2Cu)相。由文献[8]可知:在一定范围内稀土Yb能够促进θ′相的析出,这是由于Yb的原子半径为0.182 nm远大于Al原子的半径(0.143 nm),因此,固溶于基体中的Yb会引起晶格较大的正畸变。而在晶格畸变区,淬火保留的空位密度较高,稀土原子最可能在时效初期与淬火空位优先结合,形成稀土-空位团簇,用RE+V表示。而θ′相是一种盘状相,与基体半共格,容易依托缺陷而形核,这些团簇和位错为θ′相提供了形核位置。另一方面Yb原子引起的晶格畸变能为为 θ′相的形核提供储能。因此,促进了θ′相的析出(见图5(b)和(c)),提高了合金的力学性能。

一般来说,稀土在铝合金中主要以3种形式存在:固溶在基体α(Al)中,含量为0.03%~0.07%(质量分数);偏聚在相界、晶界和枝晶界;固溶在化合物中或以化合物的形式存在。当稀土含量较低时(小于0.1%)稀土主要以前2种形式分布;当稀土元素质量分数大于0.3%时,后一种存在形式开始主导[16-17]。由图1可以看出:合金2与合金3所析出的亮白的稀土化合物多沿晶间或枝晶间析出。但是,相比于单加Yb元素的合金,复合添加Cr和Yb元素后所析出的稀土化合物明显减少,见图2与图3。这是由于Cr元素的加入形成了不同的稀土化合物,改变了稀土在合金中的存在形式,使稀土Yb更多的固溶到基体中去,从而更好的促进θ′相的析出(见图5(c)),使合金3的力学性能优于合金2的力学性能。此外,合金3在热处理过程中析出一些弥散相(见图6),这些弥散相可以抑制合金再结晶,对合金性能有一定提升作用。

4 结论

(1) 相比于单独添加Yb元素,合金中复合添加Cr和Yb元素后,合金再结晶过程中沿晶界析出的稀土化合物数量明显减少,Cr元素的加入使Yb更多的固溶到基体中。

(2) 与单独添加Yb元素相比,复合添加Cr和Yb能够更有效促进时效强化相θ′相的析出,使合金抗拉强度从490.5 MPa提高至508.9 MPa。

参考文献:

[1] Carter H B, Saxena A. Transient crack growth behavior in aluminum alloy C415-T8 and 2519-T87[J]. Engineering Fracture Mechanics, 1999, 62(1): 1-22.

[2] Kramer L S, Blair T P, Blough S D, et al. Stress-corrosion cracking susceptibility of various product forms of aluminum alloy 25 19[J]. Journal of Materials Engineering and Performance, 2002, 11(6): 645-650.

[3] Dymek S, Dollar M. TEM investigation of age-hardenable Al 2519 alloy subjected to stress corrosion cracking tests[J]. Materials Chemistry and Physics, 2003, 81(2/3): 286-288.

[4] Fisher J Jr, Karmer L S, Pickens J R. Aluminum alloy 2519 in military vehicles[J]. Advance materials and Processes, 2002, 160(9): 43-46.

[5] 杜挺. 稀土元素在金属材料中的一些物理化学作用[J]. 金属学报, 1997, 33(1): 69-77.

DU Ting. Physical-chemistry effect of lear earth elements on metallic material[J]. Acta Mctallurgica Sinica, 1997, 33(1): 69-77.

[6] Ferro R, Saccone A, Borzone G. Rare earth metal in light alloy[J]. Journal of Rare Earths, 1997, 5(1): 45-50.

[7] 李慧中, 张新明, 陈明安, 等. 钇对2519铝合金铸态组织的影响[J]. 中南大学学报(自然科学版), 2005, 36(4): 545-549.

LI Huizhong, ZHANG Xinming, CHEN Mingan, et al. Effect of yttrium on as-cast microstructure of 2519 aluminum alloy[J]. Journal of Central South University (Science and Technology), 2005, 36(4): 545-549.

[8] WANG Wentao, ZHANG Xinming, GAO Zhiguo, et al. Influences of Ce addition on the microstructures and mechanical properties of 2519A aluminum alloy plate[J]. Journal of Alloys and Compounds, 2010, 491: 366-371.

[9] ZHANG Xinming, WANG Wentao, CHEN Mingan, et al. Effects of Yb addition on microstructures and mechanical properties of 2519A aluminum alloy plate[J]. Transaction of Nonferrous Metals Society of China, 2010, 20(5): 727-731.

[10] 张新明, 王文韬, 刘波, 等. Nd对2519铝合金组织与耐热性能的影响[J]. 中国有色金属学报, 2009, 19(1): 15-20.

ZHANG Xinming, WANG Wentao, LIU Bo, et al. Effect of Nd addition on microstructures and heat-resisting properties of 2519 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(1): 15-20.

[11] CHEN Kanghua, FANG Huachan. Effect of of Yb, Cr and Zr additions on recrystallization and corrosion resistance of AI-Zn-Mg-Cu alloy[J]. Materials Science and Engineering A, 2008, 497: 426-431.

[12] 陈康华, 方华婵, 陈祥. 复合添加Zr、Cr和Pr对A1-Zn-Mg-Cu合金组织和性能的影响[J]. 中国有色金属学报, 2010, 20(2): 195-201.

CHEN Kanghua, FANG Huachan, CHEN Xiang. Effects of Zr, Cr and Pr additions on microstructure and properties of AI-Zn-Mg-Cu alloys[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(2): 195-201.

[13] 张茁, 陈康华, 方华婵. 微量Cr和Nb对Al-Zn-Mg-Cu-Zr合金力学性能和应力腐蚀性能的影响[J]. 中国有色金属学报, 2008, 18(2): 985-990.

ZHANG Zhuo, CHEN Kanghua, FANG Huachan. Effects of trace Cr and Nb additions on mechanical properties and stress corroded cracking of Al-Zn-Mg-Cu-Zr aluminium alloy[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(2): 985-990.

[14] 方华婵, 陈康华, 张茁, 等. Cr、Yb合金化对AI-Zn-Mg-Cu-Zr合金组织和断裂特征的影响[J]. 稀有金属材料与工程, 2009, 38(11): 1960-1963.

FANG Huachan, CHEN Kanghua, ZHANG Zhuo, et al. Influence of Cr and Yb alloying on the microstructures and fracture characteristics of Al-Zn-Mg-Cu-Zr alloy[J]. Rare Metal Material and Engineering, 2009, 38(11): 1960-1963.

[15] Takeda T, MaedaY, Yoshida A, et al. Discontinuity of G.P.(I)zone and θ′-phase in an Al-Cu alloy[J]. Scripta Materialia, 1999, 41(6): 643-649.

[16] 王武, 舒光翼, 何德坪. 稀土元素在Al-Mg合金中的分布及对结晶组织的影响[J]. 中国稀土学报, 1990, 8(3): 252-256.

WANG Wu, SHU Guanyi, HE Deping. The distribution of rare earth metal in Al-Mg alloy and its effect on grain structure[J]. Journal of the Chinese Rare Earths Society, 1990, 8(3): 252-256.

[17] 杨军军, 聂祚仁, 金头男, 等. 稀土铒在Al-Zn-Mg合金中的存在形式与细化机理[J]. 中国有色金属学报, 2004, 14(4): 620-626.

YANG Junjun, NIE Zuoren, JIN Tounan, et al. Form and refinement mechanism of element Er in Al-Zn-Mg alloy[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(4): 620-626.

(编辑 杨幼平)

收稿日期:2013-07-06;修回日期:2013-10-18

基金项目:国家重点基础研究发展计划(“973”计划)项目 (2012CB619500)

通信作者:叶凌英(1981-),男,吉林九台人,讲师,从事高性能铝、镁合金材料研究;电话:0731-88830265;E-mail: lingyingye@csu.edu.cn