文章编号:1004-0609(2008)S1-0407-05

粉煤灰提铝渣中二氧化硅在高浓度碱液中的溶解行为

吴 艳,翟玉春,牟文宁,孙 扬

(东北大学 材料冶金学院,沈阳 110004)

摘 要:粉煤灰酸法提取氧化铝后渣中二氧化硅含量接近85%,是制备硅酸钠水玻璃的优质原料。提出了在常压下用高浓度碱液浸出粉煤灰提铝渣中二氧化硅的工艺;研究了二氧化硅在浓碱体系中的浸出行为。实验结果表明,在温度为110 ℃、碱浓度为50%、液固比为2.2?1、时间为60 min条件下反应最佳,碱浸渣的XRD分析表明,对酸渣进行二次碱浸后,渣中SiO2浸出完全,主要物相为钠硅渣和碳酸盐。

关键词:粉煤灰;渣;浸出;浓碱;硅酸钠;二氧化硅

中图分类号:TQ 110.3 文献标识码:A

Dissolving behavior of SiO2 in residue of fly ash detached Al2O3 in highly concentrated alkali solution

WU Yan, ZHAI Yu-chun, MU Wen-ning, SUN Yang

(School of Materials and Metallurgy, Northeastern University, Shenyang 110004, China)

Abstract: The concentration of SiO2 in the residue of fly ash detached Al2O3 was 85%. It is the excellent material to prepare Na2SiO3. A new method of leaching SiO2 from the residue was studied in atmosphere and highly concentrated alkali solution. The optimum conditions are: reaction temperature 110 ℃, alkali concentration 50%, ratio of liquid to ore 2.2?1 and reaction time 60 min. The XRD was used to analyze the residue after alkali leaching. The result shows that SiO2 is leached completely and the main phases are Na-Al silicate slime and carbonate.

Key words: fly ash; residue; leaching; highly concentrated alkali solution; Na2SiO3; SiO2

粉煤灰提取氧化铝是其精细化利用的一个重要研究方向。随着酸法从粉煤灰中提取氧化铝工艺的日渐成熟,酸法提铝后渣的处理已经成为目前酸法工艺工业化推广的重要问题。粉煤灰酸法制备硫酸铝后,剩余废渣含量接近粉煤灰原料的60%,其中二氧化硅含量高达85%。若直接配制水泥,不仅经济效益差,产品附加值低[1-6],而且由于产量大,当地无法全部利用,因而不能实现粉煤灰的完全精细化综合利用。

粉煤灰提铝后渣中二氧化硅含量较高,氧化铝含量低,可以制成硅酸钠[7-8],再加工制备SiO2产品。目前,国内钠水玻璃生产方法可分为干法与湿法。干法存在能耗高、原料消耗高、成本高等缺点;湿法能耗仅为干法的1/6~1/3,但要求原料中的二氧化硅具有较高的活性[9]。为此,本实验在湿法工艺的基础上进行改进,利用高浓介质沸点上升原理,在常压下利用高温、高浓介质来增强反应动力,处理普通湿法难分解的含硅矿物,提高其浸出率。为保证浸出过程中浸出剂浓度高,又不使浸出剂过量较多而造成浪费,本工艺采用低液固比条件下反应,因而具有更大的工业化价值。通过实验考察了反应温度、初始NaOH浓度、液固比和反应时间对SiO2浸出率的影响,并结合XRD衍射谱分析了原料和反应剩余物的物相成分。

1 实验

1.1 原料

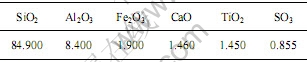

实验所用原料粉煤灰来自山西大唐电厂,经过浓硫酸浸出后得到酸浸废渣(简称酸渣,以FAS表示),其主要化学成分见表1。可以看出,SiO2含量达到84.900%,Al2O3含量仅为8.400%,其中还有Fe2O3、CaO及TiO2等杂质。

表1 酸浸废渣的化学成分

Table 1 Composition of FAS (mass fraction, %)

1.2 实验方法

实验在不锈钢材质的反应容器中进行。首先配制高浓度NaOH溶液,在控温系统下预热到实验温度;再称取定量的粉煤灰酸渣倒入NaOH浓液中,以100 r/min的速度搅拌,反应一定时间;反应完毕后,降温至80 ℃并加入5倍酸渣质量的水,搅拌溶出30 min;固液分离后得到硅酸钠溶液和滤饼,将滤饼清洗3次。

使用日本理学D/max-RB X射线衍射仪测定固体物相成分,用德国斯派特X射线荧光光谱仪分析粉末样品中的元素含量。用EDTA直接滴定法分析溶液中铝的含量[10],用氟硅酸钾容量法分析溶液中硅的含量[11]。

2 结果与讨论

2.1 原料分析

图1所示为粉煤灰及其酸渣的XRD物相分析图。其中图1(a)为粉煤灰的XRD谱,图1(b)为酸渣的XRD谱。由图1可见,粉煤灰酸法提取氧化铝后的渣中以α-SiO2相为主,粉煤灰和酸渣的XRD谱中在20?~25?区域都出现了较宽的特征衍射峰,表明玻璃相的存在。原灰中的宽峰没有酸渣中的宽峰明显,是由于酸渣中不仅含有玻璃相,而且在反应过程中分离出无定形SiO2而强化了宽峰。因此,酸渣中的主要成分SiO2的存在形态有3种:一是以玻璃相的形式存在;二是以无定形存在;三是以α-SiO2晶相存在[1]。在这3种存在形态中,以无定形态存在的SiO2活性最高,其次为玻璃相,再次为α-SiO2。

图1 粉煤灰及酸浸废渣的X射线衍射谱

Fig.1 XRD patterns of fly ash and FAS: (a) Fly ash; (b) FAS

2.2 SiO2的浓碱浸出行为

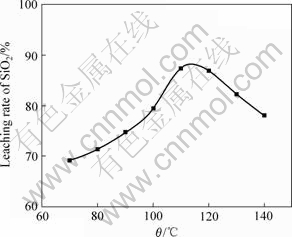

2.2.1 碱浸反应温度对SiO2提取率的影响

图2所示为反应温度对酸渣中SiO2提取率的影响。随着反应温度的升高,SiO2提取率明显增大;当温度升高到110 ℃以上时,再增加温度,提取率明显降低。在反应的开始阶段,反应剧烈,有沸腾现象。这主要是因为渣中存在部分活性SiO2,在高浓度碱液的作用下,迅速反应,体系温度骤升,超过沸点,产生沸腾现象。随着反应温度的提高,非活性SiO2也逐渐与浓碱液反应,温度增高,反应活化能增大,进而增大了SiO2浸出率。当反应温度高于110 ℃时,由于反应初期沸腾时间较长,失水过多,造成反应体系粘度增大,流动性差,扩散速度减慢,浸出过程受扩散速度影响而呈下降趋势[12]。另外,由于水分蒸发过快,容器底部的物料出现结痂现象,使浸出率降低。

图2 温度对SiO2提取率的影响

Fig.2 Effect of temperature on leaching rate of SiO2 (Concentration of NaOH: 50%; Mass ratio of alkali to ore: 2.2?1.0; Time: 60 min)

从图2可以看出,温度过高或过低对SiO2的浸出都是不利的。提铝渣中SiO2与NaOH的反应使NaOH浓度降低。一方面是由于NaOH的消耗引起的,另一方面是由于反应过程中有水的生成。但反应过程中同时存在水分的蒸发,进而维持了NaOH的浓度。实验结果表明,控制反应温度在110 ℃时,SiO2的浸出率较高,此温度恰好能维持溶液的水分平衡,既保持了NaOH的浓度,又使溶液不因水分的蒸发而降低其流动性。

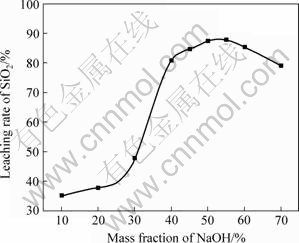

2.2.2 NaOH浓度对SiO2提取率的影响

NaOH浓度(质量分数)对SiO2提取率的影响见图3。当NaOH浓度较小时,提取率较低,随着NaOH浓度的增加,提取率不断增高;当浓度从30%增大到40%时,浸出率大幅度提高;当NaOH浓度大于60%时,由于水含量较少,浆液粘度高,容易在容器壁和容器底部结痂,结痂后反应物不再有流动性,扩散困难,导致反应速率降低,因而浸出率不再增加。

图3 NaOH浓度对SiO2提取率的影响

Fig.3 Effect of mass fraction of NaOH on leaching rate of SiO2 (Temperature: 110 ℃; Mass ratio of alkali to ore: 2.2?1.0; Time: 60 min)

另外,当NaOH浓度大于60%时,由于矿浆中溶解的Na2SiO3容易达到过饱和,因而加速了溶液中铝和硅离子反应生成钠硅渣沉淀的反应[13],而钠硅渣也会在反应物表面形成保护层而抑制SiO2的浸出。因此,NaOH浓度选取50%为宜。

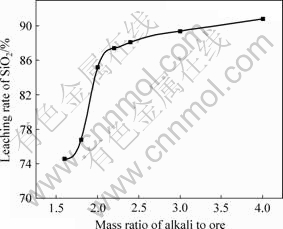

2.2.3 液固比对SiO2提取率的影响

为保证在较低的液固比(质量比)条件下NaOH也是足量的,在本因素实验中NaOH浓度为60%,则当液固比大于1.9?1.0时,NaOH相对过量。图4所示为液固比与SiO2提取率的关系。当液固比小于2?1时,随液固比的增大,浸出率提高很快;当液固比大于2?1时,浸出率随液固比的增加提高缓慢。在NaOH溶液浓度一定的条件下,较低的液固比可以减少碱耗,降低成本。但是,在液固比较低的情况下,矿浆粘度 大,不利于反应的传质过程,从而浸出率降低。增大液固比可以提高矿浆的流动性,提高传质速度,进而提高反应速度。但对本体系而言,由于碱的浓度很高,在较低的液固比下即可得到较高的浸出率。所以,综合经济因素,选取液固比为2.2?1.0。

图4 固液比对SiO2提取率的影响

Fig.4 Effect of mass ratio of alkali to ore on leaching rate of SiO2 (Temperature: 110 ℃; Concentration of NaOH: 50%; Time: 60 min)

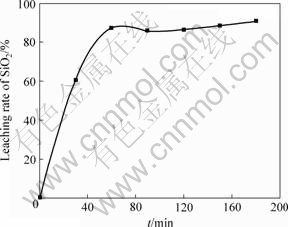

2.2.4 反应时间对SiO2提取率的影响

反应时间与SiO2提取率的关系见图5。在反应进行到30 min以前,浸出率随时间增加很快;在反应进行到30~60 min的阶段,浸出率增加速度减慢,当反应进行到60 min以后,浸出率的增加更为缓慢;在实验过程中亦可观察到在矿物和浓碱混合初期,反应非常剧烈,浆液鼓泡,呈沸腾状态,体积增大,反应体系温度升高5~7 ℃,反应30 min后体系趋于平静。这是因为酸渣中含有部分活性氧化硅,酸渣中的玻璃体也在酸浸提铝的过程中形成了大量的孔洞和表面缺陷,而热的浓NaOH溶液具有很强的反应能 力,与暴露在外面的活性SiO2接触后立即反应,因而出现沸腾现象。反应60 min后,溶液中的SiO2和AlO3达到一定浓度,生成钠硅渣沉淀,不仅使溶液中SiO2浓度降低,而且在反应物表面形成保护层而抑制反应的进行,因而浸出率随反应时间的延长不会有明显的变化。因此,反应时间以60 min为宜。

图5 反应时间对SiO2浸出率的影响

Fig.5 Effect of reaction time on leaching rate of SiO2 (Temperature: 110 ℃; Concentration of NaOH: 50%; Mass ratio of alkali to ore: 2.2?1.0)

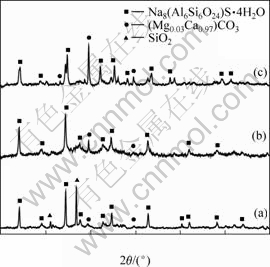

2.3 碱浸渣的成分分析

为使碱浸反应充分进行,观察酸渣在碱浸反应过程中的反应情况,对酸渣进行三次反复碱浸,使其中的SiO2充分反应,渣中物相表示为反应产物和不能反应物质。碱浸渣的XRD分析谱见图6。在本体系中,由于所采用原料为粉煤灰提铝后的产物,经过浓碱反应后的渣为二次反应渣,因而反应产物比较复杂。从图6可明显看出有钠硅渣类晶体物质,其化学式均可表示为:Na8(Al6Si6O24)X?yH2O[14]。在浓碱反应过程中,一方面Al2O3和SiO2在浓碱作用下溶解进入溶液,另一方面进入溶液中的铝和硅又与溶液中的钠和硫等元素反应生成沉淀。这与时间因素中增加反应时间浸出率增大不明显的结果是相吻合的。此外,在碱浸渣中还有镁和钙等碳酸盐沉淀。

图6 碱浸渣的X射线衍射谱

Fig.6 XRD patterns of residue of alkali leaching: (a) Leaching once; (b) Leaching twice; (c) Leaching three times

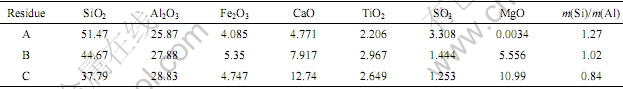

从图6还可以看出,一次碱浸反应后渣中还存在明显的SiO2晶相,但二次碱浸渣中的SiO2相消失,说明碱浸两次后酸渣中的α-SiO2反应比较完 全。此外,碳酸钙和碳酸镁的峰型更加明显,三次碱浸反应后,钠硅渣类物质部分衍射峰发生了偏移,碳酸钙和碳酸镁的化合物峰较强烈。这是由于随碱浸反应次数的增加,渣中物质的含量发生变化,引起衍射峰的强度变化。由碱浸后渣的成分分析(见表2)可见,随着碱浸次数的增加,渣中SiO2含量降低,Al2O3含量升高,硅铝比降低。一次碱浸不能进行到底的主要原因为:反应时间不充分;反应进行到一定程度后,由于NaOH消耗而达不到浸出所需浓度;由于反应体系中液固比较低,反应进行到一定程度后产物不能及时脱离反应物表面,形成产物包覆在反应物表面,从而增大了NaOH向反应物扩散的难度。

表2 碱浸后渣的化学成分

Table 2 Compositions of residue leached by alkali (mass fraction, %)

3 结论

1) 提出了常压下利用高浓度碱液提取粉煤灰酸法提铝渣中SiO2的工艺,研究了酸渣中二氧化硅在浓碱体系中的浸出行为。

2) 在温度为110 ℃、碱浓度为50%、液固比为2.2?1.0、反应为60 min的条件下反应最佳。反应过程中生成的钠硅渣类沉淀包覆在反应物表面,不利于反应的进行,从而严重影响SiO2的浸出。增加碱浸反应次数可以达到SiO2充分浸出的目的,碱浸产物中的主要物质为钠硅渣和碳酸盐相。

REFERENCES

[1] 王福元, 吴正严. 粉煤灰综合利用[M]. 2版. 北京: 中国电力出版社, 2004: 545.

WANG Fu-yuan, WU Zheng-yan. Fly ash utilization handbook[M]. 2nd ed. Beijing: China Electric Power Press, 2004: 545.

[2] SEIDEL A, SLUSZNV A, SHELEF G, ZIM MELS Y. Variation in fly ash properties with milling and acid leaching[J]. Fuel, 2005, 84(1): 89-96.

[3] 黄少文. 粉煤灰酸法提铝渣制备硅酸盐水泥的研究[J]. 粉煤灰综合利用, 2002(2): 40-41.

HUANG Shao-wen. Study on preparing Portland cement from the residue of fly ash detached Al2O3[J]. Fly Ash Comprehensive Utilization, 2002(2): 40-41.

[4] PARK H C, PARK Y J. Synthesis of alumina from high purity alum derived from coal fly ash[J]. Materials Science and Engineering A, 2004, A367: 166-170.

[5] 李来时, 翟玉春, 秦晋国, 吴 艳. 以粉煤灰为原料制备高纯氧化铝[J]. 化工学报, 2006, 57(9): 2189-2193.

LI Lai-shi, ZHAI Yu-chun, QIN Jin-guo, WU Yan.Extracting high-purity alumina from fly ash[J]. Journal of Chemical Industry and Engineering, 2006, 57(9): 2189-2193.

[6] MATJIE R H, BUNT J R, van HEERDEN. Extraction of alumina from coal fly ash generated from a selected low rank bituminous South African coal[J]. Minerals Engineering, 2005, 18(3): 299-310.

[7] 李来时. 粉煤灰高附加值综合利用—提取氧化铝[D]. 沈阳: 东北大学, 2007.

LI Lai-shi. High added value utilization of coal fly ash—Extracting alumina from it[D]. Shenyang: Northeastern University, 2007.

[8] 王文静, 韩作振, 程建光, 房建国. 酸法提取粉煤灰中氧化铝的条件选择[J]. 能源环境保护, 2003, 17(4): 17-19, 47.

WANG Wen-jing, HAN Zuo-zhen, CHENG Jian-guang, FANG Jian-guo. The withdrawing of oxidize the aluminum from the fly ash[J]. Energy Environment Protection, 2003, 17(4): 17-19, 47.

[9] 詹 勤. 钠水玻璃的生产及其应用[J]. 化学工业与工程技术, 1995, 16(2): 52-56.

ZHAN Qin. The production and application of sodium soluble glass[J]. Journal of Chemical Industry and Engineering, 1995, 16(2): 52-56.

[10] 常发现. 轻金属冶金分析[M]. 北京: 冶金工业出版社, 1990: 43-62.

CHANG Fa-xian. Metallurgy of light metals analysis[M]. Beijing: Metallurgical Industry Press, 1990: 43-62.

[11] 杜利成. 容量分析法测定硅酸钠[J]. 四川轻化工学院学报, 2001, 14(1): 21-23.

DU Li-cheng. Volumetry analysis natrium silicate[J]. Journal of Sichuan Institute of Light Industry and Chemical Technology, 2001, 14(1): 21-23.

[12] 杨重愚. 氧化铝生产工艺学[M]. 北京: 冶金工业出版社, 1982: 85.

YANG Chong-yu. The technology of alumina production[M]. Beijing: Metallurgical Industry Press, 1982: 85.

[13] 刘桂华, 李小斌, 彭志宏. 浓碱高苛性比铝酸钠溶液中水合铝硅酸钠形成的动力学研究[J]. 高等学校化学学报, 1999, 20(8): 1262-1265.

LIU Gui-hua, LI Xiao-bin, PENG Zhi-hong. The kinetics of formation of sodium aluminosilicate hydrate in strong caustic solutions[J]. Chemical Journal of Chinese Universities, 1999, 20(8): 1262-1265.

[14] 李小斌. 铝酸钠溶液铝硅分离的机理研究[D]. 沈阳: 东北大学, 2000.

LI Xiao-bin. Study on technology and mechanism of separating silica and alumina in aluminate solution[D]. Shenyang: Northeastern University, 2000.

基金项目:国家重点基础研究发展计划资助项目(2007CB613603)

通讯作者:翟玉春,教授;电话:024-83687731;E-mail: wuy@smm.neu.edu.cn

(编辑 陈卫萍)