文章编号:1004-0609(2012)1-0296-08

氧化锌贫矿提锌渣中铅和银的氯盐一步浸出

张亚莉1, 2,于先进2,李小斌1

(1. 中南大学 冶金科学与工程学院,长沙 410083;2. 山东理工大学 化学工程学院,淄博 255081)

摘 要:运用X射线衍射、扫描电镜和X射线能谱等分析手段,对山东某地深度氧化锌贫矿提锌后渣进行工艺矿物学特征分析可知,矿物中金属赋存状态复杂,属难选矿物。开发出氯盐一步法浸出铅和银的新工艺,考察反应温度、NaCl浓度、添加剂用量、液固比、HCl加入量和浸出时间对浸出过程的影响。结果表明:加入添加剂对铅的浸出率没有影响,但可以显著提高银的浸出率。条件试验研究得出最佳工艺条件如下:浸出温度90 ℃、NaCl浓度390 g/L、添加剂用量15 mL、液固比(质量比)7:1、HCl加入量3 mL、浸出时间3 h。在此最佳工艺条件下,铅的浸出率达到95%左右,银的浸出率达到90%左右。

关键词:氧化锌贫矿;铅;银;提锌渣;氯盐;浸出

中图分类号:TF803 文献标志码:A

Leaching of silver and lead by chloride simultaneously from residue after zinc extraction of low-grade zinc oxide ores

ZHANG Ya-li1, 2, YU Xian-jin2, LI Xiao-bin1

(1. School of Metallurgical Science and Engineering, Central South University, Changsha 410083, China;

2. College of Chemical Engineering, Shandong University of Technology, Zibo 255081, China)

Abstract: According to the mineral analysis of the residue after zinc extraction of low-grade zinc oxide by XRD, SEM and EDS, the occurring state of metals is complicated and difficult to be treated by mineral process. A novel process of treating the residue by chloride leaching was developed. The effects of experimental conditions, i.e., reaction temperature, NaCl concentration, liquid-solid ratio, HCl amount and immersion time, on the leaching process were investigated. The results show that the additive does not affect the leaching rate of Pb, while it can increase the leaching rate of Ag significantly. The best technology conditions are obtained as follows: leaching temperature 90 ℃, NaCl concentration 390 g/L, additive amount 15 mL, liquid-solid ratio (mass ratio) 7:1, HCl amount 3 mL and immersion time 3 h. Under the optimal conditions the leaching rates of Pb and Ag can reach about 95% and 90%, respectively.

Key words: low-grade zinc oxide ore; Pb; Ag; residue after zinc extraction; chloride; leaching

目前,国内相继发现了深度氧化锌贫矿,其中,锌含量在10%左右,锌主要存在于硅酸盐中,其次分布在氧化物中。赋存于硅酸盐中的锌以固溶体形式存在于橄榄石中,赋存于氧化物中的锌主要以锌铁尖晶石存在,粒度一般为8~40 μm,常呈微粒包裹状态嵌布于橄榄石中,不具备选矿回收价值[1-3]。矿中除含 锌以外,还含有一定数量的铅和银。铅含量为7.5%左右,银含量为300~400 g/t,均达到综合利用的一般工业要求。深度氧化锌矿的矿相组成复杂,采用选矿方法无法将有价金属富集,冶炼方法也很难将锌、铅和银进行有效提取。随着高品位资源的日渐贫乏[4-5]和金属价格的不断上升,氧化锌贫矿的开发利用引起国内外广大冶金工作者的关注和重视[6-10]。近年来,人们对含铅和银氧化锌贫矿的综合利用进行了大量的研究,研究主要集中在以下几个方面:1)贫矿经选矿使有价金属富集,然后进入冶炼系统得到相应产品。?NAL等[11]采用选矿法处理锌品位为10.17%、铅品 位为10.98%、银含量为57 g/t的贫矿,浮选过程中加入硫化钠和浮选剂,得到铅品位为65.42%的精矿。该方法虽然富集了部分铅和银,但不能回收锌。且加入大量硫化钠使氧化矿硫化,以利于选矿。尾矿中仍含有大量铅和银。铅占34.58%的回收率,这部分难以利用。RASHCHI等[12]经两段选矿,首先用羟基硫亚胺处理矿物,选矿后经低pH浸出,洗去溶于水的物质,再经过第二次选矿,得到铅品位为41.32%的富矿。该方法主要针对铅的富集,但选矿指标并不太好,并且中间有湿法处理步骤。选矿方法主要针对硫化矿,对于结构复杂的氧化矿,效果并不好,富集困难,回收率低,不能有效回收氧化矿中的有价金属。2)贫矿直接进入冶炼系统。冶炼方法主要有火法和湿法。火法主要采用回转窑挥发法[13]。内蒙古赤峰松山区安凯有限公司、温州冶炼厂等采用回转窑挥发处理,即向铅和银渣中加入石灰和焦炭配料,进入回转窑挥发,布袋收尘,尾气脱硫工艺回收有价金属,铅和锌的回收率为80%~90%,但银的回收率只有35%。该方法侧重于锌和铅回收,缺点是设备庞大,耗能高,不能综合回收有价金属,且对环境有害。要用到昂贵的焦 炭,耐火材料消耗大。富含铅和银的氧化锌贫矿的湿法处理有碱法[14-16]或酸法[17]浸出锌,之后用盐浸出回收铅。碱法回收锌采用拜耳法生产氧化铝的方法生产氧化锌,该法处理低品位氧化锌矿流程长、成本高。酸法浸出锌存在以下问题:1)浸出过程中产生大量硅胶,溶液过滤困难;2)浸出液含锌品位低,溶液平衡不易控制。对于浸锌后含铅渣再用盐浸出回收 铅[18-19]。湿法主要针对锌和铅的回收,而单独处理每一种金属,关于湿法处理回收银的报道甚少。

为此,本文作者依据该矿的自身特点,提出了低温预处理、水浸提锌,水洗液返锌净化系统,水洗渣再用氯盐一步同时浸出铅和银的新型工艺。该工艺特点是低温预处理常温水浸出锌、工艺简单、设备投资少、无有害气体排出、成本低,实现了锌选择性浸出与矿物中有价金属铅和银的分离富集,元素铅和银得到富集并全部留在渣中。然后,对水浸渣采用氯盐一步法浸出铅和银,再根据其物理性质将浸出液中铅和银分离,实现氧化锌贫矿的综合开发利用。该方法采用全湿法处理工艺,同时回收低品位矿中的铅和银,流程短,操作简单,回收率高。在能源价格日益上涨和环保要求日渐严格的情况下,其工业应用前景广阔。国内外关于同时处理含铅和银的氧化锌贫矿及铅和银的同时浸出回收的报道很少。为此,本文作者介绍了提锌渣中铅和银的一步浸出工艺。

1 实验

1.1 原料性能

实验原料取自山东某地氧化锌矿,经水浸提锌 后,渣中水的质量分数为50%左右,原料经真空烘干后荧光光谱测得渣中各元素含量见表1。由表1可知,样品中主要可回收的金属元素为铅和银。经过预处理水浸提锌后渣中铅和银得到富集,远远高于综合利用的工业要求。实验所用盐酸和NaCl为化学纯,实验用水为去离子水。

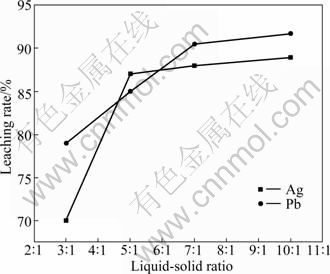

采用X射线衍射技术对原矿的物相组成进行分析,结果如图1所示。

XRD结果表明,提锌渣中铅以硫酸铅为主,含硅矿物以石英为主,硫酸钙的衍射峰也很明显。由于渣中银含量较低(651 g/t),很难看到明显的衍射峰。

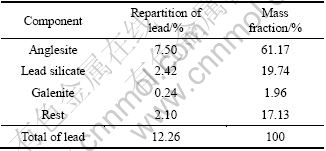

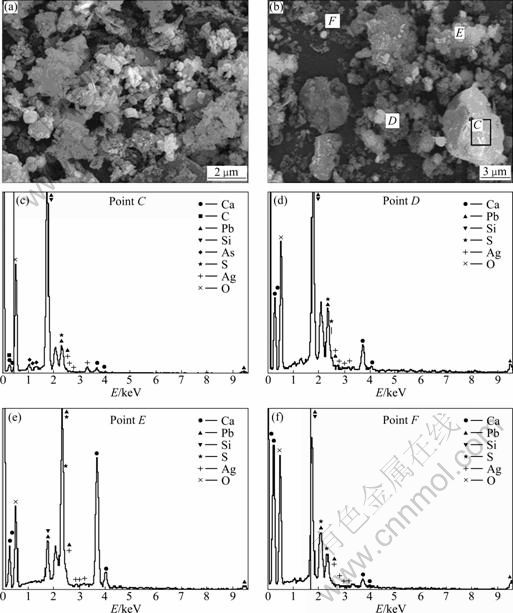

为确定渣中铅和银的赋存状态,进行化学物相分析、X射线能谱(EDS)和扫描电镜(SEM)分析,结果见表2~3和图2。

由表2可知,样品中银含量达到651g/t,其赋存形式较多,主要集中于硅酸铅中,达到51.62%,其次是单质银,以自然银的形式存在于渣中,品位达到177 g/t,另外,还有少量铁酸盐中的银以及其他矿物中银。由表1和表3可知,铅的质量分数达到12.26%,主要以硫酸铅和硅酸盐形式存在,其中硫酸铅含量最高,占61.17%,其次是硅酸铅矿,还有其他形式的铅包括氧化铅等。在此基础上,通过镜下鉴定和扫描电镜分析,对铅和银的赋存状态进行了进一步确定。由图2可知,样品中各元素粒度微细、分散程度高、杂质与铅和银共生、银以分散状态被其包裹、与样品中的主要脉石矿石的镶嵌关系复杂、可选性能差,属于难处理矿物。

表1 氧化锌矿提锌后渣的化学成分

Table 1 Chemical compositions of residue after zinc extraction of low-grade zinc oxide

图1 提锌渣的XRD谱

Fig. 1 XRD pattern of residue after zinc extraction

表2 银的物相组成

Table 2 Mineral phase constitutes of silver

表3 铅的物相组成

Table 3 Mineral phase constitutes of lead

1.2 实验方法

将深度氧化锌贫矿经浸出提锌以后的渣过滤,反复水洗至溶液pH值接近7,将滤饼置于瓷皿中,在真空干燥箱中控温80 ℃,干燥1 h。干燥箱型号为DEF- 6021,控温范围为10~200 ℃。到达干燥实验预定的时间后取出,冷却至室温。分析冷却后渣铅和银含量和进行浸出实验。

浸出实验在油浴锅中进行,油浴锅采用自动控温装置,控温精度为±1 ℃,配置可变速式磁力搅拌器,浸出温度根据实验要求而定。首先将准确称量的提锌渣按一定的液固比和水混合调浆放入250 mL的烧杯中,当油浴锅温度达到实验温度时,搅拌速度调为中速。在装有浆液的烧杯中滴加HCl调节pH至设定值,加入称量好的NaCl、添加剂和几粒搅拌磁子。将烧杯上方用薄膜覆盖防止水分蒸发。将烧杯置于油浴锅中开始反应。1 min后开始计时,在预定时间内完成实验。实验完毕后,取出烧杯进行热过滤分离,用热水反复洗涤滤饼,滤饼烘干后取样分析铅和银含量。热浸出液用流动水冷却至产生足够沉淀后过滤,用室温蒸馏水反复洗涤滤饼,滤饼烘干备用。分别考察NaCl用量、反应温度、浸出时间、液固比、添加剂用量和酸度6个因素对铅和银浸出率的影响。

使用日本理学3070e型X荧光光谱仪对浸出渣中的化学组成进行检测;使用荷兰帕纳克公司制造的PW2040-60型X射线衍射仪进行XRD物相分析。浸出液中的铅采用EDTA络合滴定法检测,银采用GGX-900塞曼原子吸收分光光度计进行检测。

按照式(1)计算提锌渣中铅和银的浸出率:

×100% (1)

×100% (1)

式中:ηMe为金属Me的浸出率,%;mR为浸出铅和银后的干渣质量,g;m0为提锌渣干质量,g; 和

和 分别为浸出铅和银后干渣和提锌干渣中金属含量(质量分数),%。

分别为浸出铅和银后干渣和提锌干渣中金属含量(质量分数),%。

2 结果与讨论

2.1 NaCl浓度对铅和银浸出效果的影响

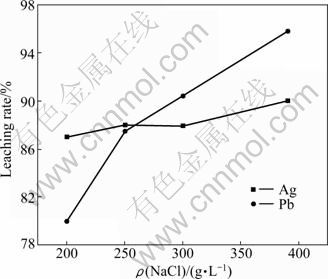

称取10 g渣,固定反应温度为90 ℃,浸出时间为3 h,添加剂用量为15 mL,液固比为7:1,HCl加入量为3 mL,考察NaCl浓度对铅和银浸出率(以渣计,以下同)的影响,结果如图3所示。

图2 提锌渣的SEM像和EDS谱

Fig. 2 SEM images ((a), (b)) and EDS patterns ((c)-(f)) of residue after zinc extraction

由图3可见,当NaCl浓度为200 g/L时,银的浸出率达到87%,随NaCl浓度的增加,银的浸出率在87%到89%之间变化,变化不大;但NaCl浓度对铅的浸出率影响较大,随NaCl浓度的增加,铅的浸出率明显增加。当NaCl浓度为390 g/L时,铅的浸出率增至96%。说明浓度升高增加了固液接触面积和反应的扩散速度,使浸出率提高。兼顾铅和银的浸出率均达到最大值,选择NaCl浓度为390 g/L。提锌渣中铅主要以硫酸铅的形式存在,与银硅钙等元素互相镶嵌。在氯盐作用下铅和银发生如下反应[20]:

(2)

(2)

Pb2++iCl-= (i=1~5) (3)

(i=1~5) (3)

Ag-e=Ag+ (4)

Ag++iCl-= (5)

(5)

在整个浸出过程中,铅和银的浸出互相促进,随浸出的进行,被包裹的银暴露出来,有利于浸出的进行。NaCl浓度的影响主要体现在被浸物质的初始浓度,如果被浸物质在渣中含量高,则浸出剂浓度与被浸物浓度的比值小,从反应动力学角度考虑,其浸出速率较慢,所以,开始时银的浸出率高于铅的浸出率。从铅和银的整体浸出来说,根据质量作用定律,提高反应物浓度有利于反应更快地达到平衡状态,从而提高反应的速率;根据化学平衡规律,提高反应物的浓度有利于提高化学平衡向右移动。

图3 NaCl浓度对铅和银浸出率的影响

Fig. 3 Effect of NaCl concentration on leaching rates of Pb and Ag

2.2 添加剂A的用量对铅和银浸出效果的影响

称取10 g渣,在固定反应温度为90 ℃、NaCl浓度为390 g/L、HCl加入量为3 mL、浸出时间为3 h和液固比为7:1的条件下,考察添加剂用量对铅和银浸出率的影响,结果如图4所示。

图4 添加剂A用量对铅和银浸出率的影响

Fig. 4 Effect of amount of additive A on leaching rates of Pb and Ag

从图4可知,在没有加入添加剂A时,铅的浸出率已达到92%,并且随A加入量的增多,其浸出率没有明显变化;但A加入量对银的浸出率影响很大。当A加入量为0时,银的浸出率为80%,随A加入量的增加,银的浸出率明显增加。当A加入量为15 mL,银的浸出率达到90.23%,这与铅和银的赋存状态和浸出特点有关。从其物相组成可知,铅主要为氧化物和含氧酸盐的结构,几乎没有单质存在,其浸出过程是与Cl-形成配合物的过程,无氧化数的变化;而银的浸出过程,除了Ag+与Cl-形成配合物的过程外,还伴随单质银的氧化数的变化。随添加剂A加入量的增多,单质银被不断改性,然后与Cl-形成配合物。因此,添加剂A的用量对银的浸出具有明显影响。

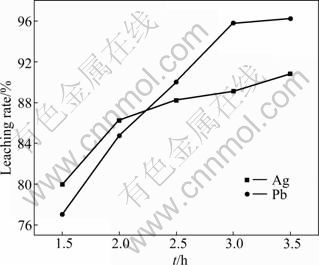

2.3 液固比对铅和银浸出效果的影响

由于氯盐一步浸出铅和银的技术路线为全湿法过程,液固比决定着物料流量,影响设备投资,也会影响工业应用后的技术经济指标,液固比越低,单位产品的物料流量就越小。

称取10 g渣,在固定反应温度为90 ℃、NaCl浓度为390 g/L、添加剂用量为15 mL、浸出时间为3 h和HCl加入量为3 mL的条件下,考察液固比对铅和银浸出率的影响,结果如图5所示。

图5 液固比对铅和银浸出率的影响

Fig. 5 Effect of liquid-solid ratio on leaching rates of Pb and Ag

由图5可知,当液固比为3:1时,银的浸出率为70%,当液固比增加到5:1时,银的浸出率达到87%,以后随液固比的增加,银浸出率变化缓慢;对于铅,当液固比增加到7:1时,浸出率达到最大值,以后变化缓慢。为考察铅和银同时浸出的效果,实验选择液固比为7:1。配料液固比的改变,实质是改变反应的初始液相量,即氯盐的量,增加液固比,参与反应的液相增多,溶液溶解铅和银的能力增强。当浸出率达到一定程度时,再增加液固比,对浸出不再有影响。

2.4 HCl用量对铅和银浸出效果的影响

称取10 g渣,在固定反应温度为90 ℃、NaCl浓度为390 g/L、添加剂用量为15 mL、浸出时间为3 h和液固比为7:1的条件下,考察HCl加入量对铅和银浸出效果的影响,结果如图6所示。

图6 HCl用量对铅和银浸出率的影响

Fig. 6 Effect of HCl amount on leaching rates of Pb and Ag

从图6可知,HCl加入量对铅浸出率影响不大,加入HCl与否,铅浸出率几乎没有变化;但是HCl的加入对银浸出率的影响较大。当HCl加入量为0.2 mL时,银的浸出率只有60%;而当HCl加入量为3 mL时,银的浸出率达到90%。增加HCl用量之所以可以增加银的浸出率,一方面是因为提锌渣中成分复杂,其中含有铁矿物,加入HCl可以降低溶液pH值,溶解Fe3+,释放出被包裹的银;另一方面,溶解后的Fe3+又可以氧化渣中的单质银,银的氧化浸出概率加大。

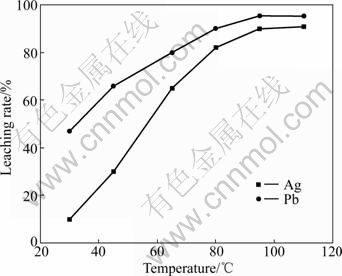

2.5 温度对铅和银浸出效果的影响

温度对铅和银浸出效果的影响很大。根据反应动力学可知,高温有利于反应速率的提高,反应能在较短时间内达到平衡。称取10 g渣,在固定浸出时间3 h、NaCl浓度为390 g/L、添加剂用量为15 mL、液固比为7:1及HCl加入量为3 mL的条件下,考察反应温度对铅和银浸出效果的影响,结果如图7所示。

由图7可见,随温度的增加,铅和银浸出率均增加。银的浸出率随温度变化尤其明显。在90 ℃时,铅和银的浸出率均达到最大值,温度增高时,浸出率均趋于平缓,故选择90 ℃为最佳温度。铅和银的浸出反应为固相与液相的多相反应,提高温度可以促进反应的动力学行为,缩短反应时间,但是温度较高时也存在许多竞争反应,如杂质离子的浸出;而当温度较低时,会影响反应物的活性,减慢反应物分子向生成物分子之间的扩散,反应进行较慢。如果延长反应时间,有可能达到预期效果,但是会增加成本,所以选择合适的温度很重要。

图7 温度对铅和银浸出率影响

Fig. 7 Effect of temperature on leaching rates of Pb and Ag

2.6 浸出时间对铅和银浸出效果的影响

称取10 g渣,在固定反应温度为90 ℃、NaCl浓度为390 g/L、添加剂用量为15 mL、液固比为7:1和HCl加入量为3 mL的条件下,考察浸出时间对铅和银浸出率的影响,结果如图8所示。

由图8可知,随着浸出时间的延长,铅和银的浸出率均增加。但是铅和银浸出率的变化规律明显不同。在开始一段时间,银的浸出率增加很快,在时间为 2 h以后,其浸出率变化平缓;而铅的浸出率则是缓慢增加,且2.2 h前铅的浸出率小于银的浸出率,在3 h时达到最大值,之后趋于不变。这是因为在反应的开始阶段,银和添加剂进行反应,变成游离的Ag+,迅速与Cl-反应,因此,银的浸出率首先达到最大值。

在上述实验条件下,选择浸出时间为3 h的浸出渣,利用XRF分析其化学成分,结果见表4。

由表1和表4数据对比可知,铅和银基本上被全部浸出。

图8 浸出时间对铅和银浸出率的影响

Fig. 8 Effect of immersion time on leaching rates of Pb and Ag

表4 铅和银浸出渣的化学成分

Table 4 Chemical compositions of leaching slag containing Pb and Ag

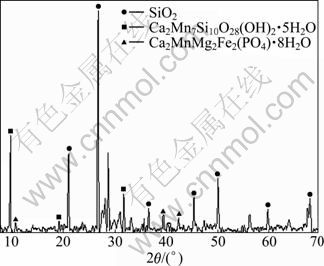

3 浸出后渣物相分析

对提锌渣经氯盐一步浸出后的残渣进行X射线衍射分析,结果如图9所示。结果表明,提锌渣经氯盐处理后,残渣中二氧化硅特征峰很明显,还有一些复杂的硅酸盐和复盐的特征峰,这些特征峰均不含铅和银。说明铅和银已经进入溶液,残渣中几乎不存在铅和银,这与XRF化学成分定量分析结果一致。根据化学成分分析和XRD谱分析可知,其他金属杂质则以复盐或硅酸盐形式留在渣中。

图9 浸出渣的XRD谱

Fig. 9 XRD pattern of residue after chloride leaching

4 结论

1) 由低温预处理水浸提锌渣的化学物相及EDS和SEM分析可知,铅和银的赋存状态较复杂,均含有多种形态,属于较难选矿物。

2) 浸出过程中,NaCl浓度、添加剂用量、液固比、酸度和浸出时间对铅和银的浸出率均有影响。由于银含量低,在较低NaCl浓度的范围即达到较高浸出率;铅则随NaCl浓度的增加而增大。HCl的加入和添加剂的使用对铅的浸出率无明显影响,但可以大大提高银的浸出率;同时,液固比的增加和时间的延长均有利于浸出过程。

3) 采用氯盐可同时浸出铅和银。在反应温度为90 ℃、NaCl浓度为390 g/L、添加剂用量为15 mL、液固比为7:1、HCl加入量为3 mL和浸出时间为3 h的最佳浸出条件下,铅的浸出率达到95%左右,银的浸出率达到90%左右。该方法能有效处理复杂赋存状态的铅银渣,为氧化锌贫矿的综合利用找到了新途径。

REFERENCES

[1] 刘 丽, 丰章发, 刘 林. 某银锌铅矿石可选性试验研究[J]. 矿冶工程, 2009, 7(3): 25-29.

LIU Li, FENG Zhang-fa, LIU Lin. Research test of beneficiation practicability of silver-lead-zinc ore[J]. Mining and Metallurgical Engineering, 2009, 7(3): 25-29.

[2] CUI Ji-rang, ZHANG Li-feng. Metallurgical recovery of metals from electronic waste[J]. Journal of Hazardous Materials, 2008, 158: 228-256.

[3] 王新丽, 杨树生, 庞艳春. 云南金顶铅锌矿床成矿物质来源及有机成矿作用[J]. 地球科学与环境学报, 2009, 31(4): 376-382.

WANG Xin-li, YANG Shu-sheng, PANG Yan-chun. Ore sources and organic mineralization in the Jinding lead-zinc deposit of Yunnan province[J]. Journal of Earth Sciences and Environment, 2009, 31(4): 376-382.

[4] 彭容秋. 铅锌冶金学[M]. 北京: 科学出版社, 2003: 114-118.

PENG Rong-qiu. Metallurgy of lead-zinc[M]. Beijing: Science Press, 2003: 114-118.

[5] 蒋继穆. 我国铅锌冶炼现状与持续发展[J]. 中国有色金属学报, 2004, 14(S1): 52-62.

JIANG Ji-mu. Status and sustainable development of lead and zinc smelting industry in China[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(S1): 52-62.

[6] 李黎婷. 利用铅银渣综合提取锌铅银的试验研究[J]. 矿产综合利用, 2010(3): 15-20.

LI Li-ting. Experimental research on comprehensive recovery of lead, zinc and silver from a lead-silver residue[J]. Multipurpose Utilization of Mineral Resources, 2010(3): 15-20.

[7] 李玉梅,李 洁,陈启元,丁红青. 超声波辐射对低品位氧化锌矿氨浸行为的影响[J]. 中国有色金属学报, 2009,19(5): 960-966.

LI Yu-mei, LI Jie, CHEN Qi-yuan, DING Hong-qing. Influence of ultrasonic irradiation on ammonia leaching of zinc from low-grade oxide zinc ore[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(5): 960-966.

[8] SIEGMUND A H J. Primary lead production—A survey of existing and refineries[C]//Proceedings of Lead-zinc 2000. Warrendale: Minerals, Metals and Materials Society, 2000: 55- 116.

[9] LECLERC N, MEUX E, LECUIRE J M. Hydrometallurgical extraction of zinc from zinc ferrites[J]. Hydrometallurgy, 2003, 70: 175-183.

[10] RUSEN A, SUNKAR A S, TOPKAYA Y A. Zinc and lead extraction from contour leach residues by using hydro- metallurgical method [J]. Hydrometallurgy, 2008, 93: 45-50.

[11] ?NAL G, BULUT G, G?L A, KANGAL O, PEREK K T, ARSLAN F. Flotation of alada oxide lead-zinc ores[J]. Minerals Engineering, 2005, 18: 279-282.

[12] RASHCHI F, DASHTI A, YAZDI M, ABDIZADEH H. Anglesite flotation: A study for lead recovery from zinc leach residue[J]. Minerals Engineering, 2005, 18: 205-212.

[13] 谢大元. 锌挥发窑渣选银试验研究[D]. 长沙: 中南大学冶金科学与工程学院, 2004: 12-15.

XIE Da-yuan. Experimental study on recovering silver from zinc volatilizing kiln slag[D]. Changsha: School of Metallurgical Science and Engineering, Central South University, 2004: 12-15.

[14] HUA Y, YAN Z. Application of microwave irradiation to quick leach of zinc silicate ore[J]. Minerals Engineering, 2002, 15: 451-456.

[15] 赵中伟, 龙 双, 陈爱良, 霍广生, 贾希俊, 李洪桂, 阎海泉. 难选高硅型氧化锌矿机械活化减法浸出研究[J]. 中南大学学报: 自然科学版, 2010, 41: 1246-1251.

ZHAO Zhong-wei, LONG Shuang, CHEN Ai-liang, HUO Guang-sheng, JIA Xi-jun, LI Hong-gui, YAN Hai-quan. Alkali leaching of refractory high silica zinc oxide ore by mechanical activation[J]. Journal of Central South University: Science and Technology, 2010, 41: 1246-1251.

[16] FENG Lin-yong, YANG Xian-wan, SHEN Qing-feng, XU Ming-li, JIN Bing-jie. Palletizing and alkaline of powdery low grade zinc oxide ores[J]. Hydrometallurgy, 2007, 89: 305-310.

[17] 李存兄, 魏 旭, 樊 刚, 杨秀丽, 徐红胜, 邓志敢, 李旻廷, 李兴彬. 高硅氧化锌矿加压酸浸处理[J]. 中国有色金属学报, 2009, 19(9): 1678-1683.

LI Cun-xiong, WEI Xu, FAN Gang, YANG Xiu-li, XU Hong-sheng, DENG Zhi-gan, LI Min-ting, LI Xing-bin. Pressure acid leaching high silicone zinc oxide ore[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(9): 1678-1683.

[18] IKENOBU S. Method for processing siliceous zinc ores[C]// Proceedings of Lead-zinc 2000. Warrendale: Minerals, Metals and Materials Society, 2000: 427-435.

[19] TURAN M D, ALTUNDOGAN H S, TUMEN F. Recovery of zinc and lead from zinc plant residue[J]. Hydrometallurgy, 2004, 75: 169-176.

[20] LIU Wei-feng, YANG Tian-zu, XIA Xing. Behavior of silver and lead in selective chlorination leaching process of gold- antimony alloy[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(2): 322-329.

(编辑 陈卫萍)

基金项目:山东省自然科学基金资助项目(ZR2010EL006)

收稿日期:2010-08-01;修订日期:2011-04-16

通信作者:于先进,教授,博士;电话:0533-2781681; E-mail: xjy@sdut.edu.cn