文章编号:1004-0609(2014)07-1888-07

煤粉炉高铝粉煤灰碱溶脱硅反应动力学

贺实月1, 2,李会泉2,李少鹏2,李勇辉2,解 强1

(1. 中国矿业大学(北京) 化学与环境工程学院,北京 100083;

2. 中国科学院 过程工程研究所 绿色过程与工程重点实验室 湿法冶金清洁技术国家工程实验室,北京 100190)

摘 要:以内蒙古中西部地区某电厂煤粉炉高铝粉煤灰为对象,研究NaOH溶液脱除粉煤灰非晶态SiO2过程中搅拌速度、反应温度、NaOH溶液初始浓度对粉煤灰非晶态SiO2浸出率的影响,通过实验数据与液固多相反应缩芯模型拟合的方法确定动力学规律及动力学方程。结果表明:SiO2的浸出过程分为2个阶段,反应前期为表面反应控制,表观活化能为80.15 kJ/mol;反应后期为固膜扩散控制,表观活化能为29.93 kJ/mol。结合动力学实验结果及扫描电镜(SEM)、能谱(EDS)分析可知,随着反应的进行,固相产物逐渐附着于粉煤灰表面形成固膜导致控制步骤转变。

关键词:高铝粉煤灰;脱硅;浸出;动力学;缩芯模型

中图分类号:X758 文献标志码:A

Kinetics of Desilication Process of Fly Ash with High Aluminum from Pulverized Coal Fired Boiler in Alkali Solution

HE Shi-yue1, 2, LI Hui-quan2, LI Shao-peng2, LI Yong-hui2, XIE Qiang1

(1. School of Chemical and Environmental Engineering,

China University of Mining and Technology Beijing, Beijing 100083, China;

2. National Engineering Laboratory for Hydrometallurgical Cleaner Production Technology,

Key Laboratory of Green Process and Engineering, Institute of Process Engineering,

Chinese Academy of Sciences, Beijing 100190, China)

Abstract: Using high-aluminum fly ash from pulverized coal fired boiler in midwest of Inner Mongolia as an object, the effects of stirring speed, reaction temperature and initial NaOH concentration on the leaching rate of SiO2 in the desilication of fly ash in NaOH solution were studied. The kinetic rules and kinetic equations were confirmed by the experimental data fitting with shrinking core model of liquid-solid multiphase reaction. The results show that there are two stages in the leaching process. Earlier stage is limited by the surface reaction, and the apparent activation energy is 80.15 kJ/mol. Later stage is proven that the internal diffusion on the solid product layer is the rate-controlling step in the leaching process, and the apparent activation energy is 29.93 kJ/mol. The results of the kinetic experiment and SEM, EDS analysis show that solid product attached to the surface of fly ash leads to the rate-controlling step changes with the reaction progress.

Key words: high-aluminum fly ash; desilication; leaching; kinetics; shrinking core model

高铝粉煤灰是近年来出现在我国山西北部及内蒙古中西部地区的一种新型粉煤灰类型,氧化铝含量可达40%~50%,相当于我国中低品位铝土矿中氧化铝的含量,是一种宝贵的含铝二次资源[1-2]。有效利用高铝粉煤灰将会缓解我国铝土矿资源的紧张现状[3]。近年来,从粉煤灰中提取氧化铝已经成为非铝土矿含铝资源生产氧化铝的重要途径[3-4]。

目前,高铝粉煤灰提取氧化铝主要采用烧结法工艺,高铝粉煤灰铝硅比较低(A/S<1.5)且部分铝硅成键以莫来石形式存在,导致该工艺能耗高、产渣量巨大[5]。研究表明[6-7],粉煤灰中SiO2的含量约为40%,其存在开式主要有两种:一部分与氧化铝结合形成莫来石,另一部分以非晶态SiO2形式包裹于莫来石表面。针对高铝粉煤灰中非晶态SiO2反应活性较高的特点,研究者通常采用低碱脱硅的方式脱除非晶态SiO2以降低提铝过程产生的硅酸钙废渣[8]。BAI等[9]、苏双青等[10]和杜淄川等[11]从工艺优化角度对高铝粉煤灰脱硅工艺进行研究。薄春丽等[12]对中煤集团循环流化床粉煤灰进行了动力学研究,证明脱硅过程受固膜扩散控制。内蒙古中西部地区的火力电厂以煤粉炉为主,相比于循环流化床锅炉,由于原料粒径、燃烧温度、脱硫方式等不同,因此,产生的粉煤灰在化学活性、晶相结构、微观形貌等方面差别显著[13]。循环流化床粉煤灰形成温度低(850~900 ℃),主要为少量的晶相石英及非晶相玻璃体,大多为非晶质不定型物质,而煤粉炉粉煤灰形成温度较高(1250~1450 ℃),含有大量晶相莫来石及非晶相玻璃体,多为球形[14-15]。循环流化床粉煤灰与煤粉炉粉煤灰的差异会影响粉煤灰碱溶脱硅反应动力学规律。目前,对煤粉炉粉煤灰脱硅反应动力学等基础性研究较少。

本文作者以内蒙古中西部地区煤粉炉高铝粉煤灰为研究对象,研究NaOH溶液脱除粉煤灰非晶态SiO2过程中搅拌速度、反应温度、NaOH溶液初始浓度影响粉煤灰中SiO2浸出率的规律,通过实验数据与液固多相反应缩芯模型拟合的方法确定动力学规律及动力学方程,并进一步采用扫描电镜、能谱等分析手段验证所得结论。通过浸出动力学研究,为工程设计与放大提供基础数据[16]。

1 实验

1.1 试样及药剂

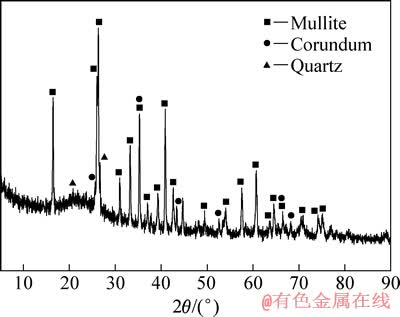

实验所用高铝粉煤灰来自内蒙古某电厂,其主要化学组成列于表1,X射线衍射(XRD)谱见图1。由图1可知,高铝粉煤灰主要物相为莫来石、刚玉、无定形SiO2及少量石英。

实验采用分析纯NaOH,购自西陇化工股份有限公司,纯度≥96%。

表1 高铝粉煤灰的化学组成

Table 1 Composition of high-aluminum fly ash (mass fraction, %)

图1 高铝粉煤灰的XRD谱

Fig. 1 XRD pattern of high-aluminum fly ash sample

1.2 实验方法

将盛有定量NaOH溶液的三口圆底烧瓶置于恒温油浴中,打开搅拌及冷凝回流装置。待溶液升至设定温度后,按一定的液固比(NaOH溶液体积与粉煤灰的质量比,mL/g)加入粉煤灰,定时取样,经过滤、洗涤、烘干后,分别表征液相和固相样品。通过测定液相中硅元素浓度,计算SiO2浸出率(XB):

(1)

(1)

式中:cB为固液分离后液相中硅元素浓度,g/L;VB为固液分离后液相体积,L;wB为原始粉煤灰中SiO2的质量分数,%;m为加入粉煤灰的总质量,g。

1.3 分析表征

采用美国Perkin-Elmer公司生产的Optimal 5300DV型电感耦合等离子体-原子发射光谱仪(ICP-OES)测定液相元素浓度;采用荷兰PANalytical公司生产的X’Pert PROMPD型X射线衍射仪(XRD,Cu Kα辐射,40 kV,40 mA)分析固相样品物相组成;采用荷兰PANalytical公司AXIOS型X射线荧光光谱仪(XRF)测定固体样品元素组成;采用FEI电子光学公司生产的FEIMLA250型矿物解离分析仪(MLA)所带Quanta 250环境扫描电镜分析固体形貌。

2 表观动力学模型选择

液-固非均相催化反应最常见的反应模型为收缩未反应芯模型[16-19],简称为“缩芯模型”。缩芯模型又分为粒径不变缩芯模型和颗粒缩小缩芯模型。粒径不变缩芯模型的特点是有固相产物层生成,反应过程中颗粒粒径不变,在碱性浸出反应中该类模型较为常见[20],且固相原料多为球形颗粒[21],如图2所示,有固态产物层的浸出反应由以下步骤组成:

1) 液相中的浸出剂A通过矿粒(半径为r0)外面的液膜扩散到颗粒外表面,即反应物外扩散过程,浓度由cA减小到cAS;

2) 浸出剂由矿粒外面通过固相产物层或惰性残留层扩散到收缩未反应芯(半径为r)的界面,即反应物内扩散过程,浓度由cAS减小到cAC;

3) 浸出剂与矿粒在半径为r的界面上进行反应,即表面化学反应控制过程;

4) 生成的可溶性反应产物通过固相产物层或惰性残留层扩散到颗粒外表面,及产物内扩散过程,浓度由cEC减小到cFS;

5) 可溶性反应产物由颗粒外表面通过液膜扩散到液相主体,即产物外扩散过程,浓度由cFS减小到cF。

反应动力学方程通常由浸出过程速率控制步骤确定。因此,当单位时间内浸出矿物的量取决于浸出剂通过液膜层的扩散速度,速率方程可表示为

kt=XB (2)

当浸出过程中固态产物层对浸出剂的扩散阻力远大于外扩散,同时化学反应速度很快,即反应受固膜扩散控制,此时速率方程可表示为

图2 有固态产物层的缩芯反应模型示意图

Fig. 2 Schematic diagram of shrinking-core model with solid product layer

kt=1-2/3XB-(1-XB)2/3 (3)

当浸出过程中浸出剂通过液膜扩散层及固膜的扩散阻力很小,以致反应受化学反应控制时,速率方程可表示为

kt=1-(1-XB)1/3 (4)

式中:k是速率常数;t为反应时间。

为研究煤粉炉高铝粉煤灰碱溶脱硅反应动力学,本文作者从以上3种模型着手进行数据拟合,最终确定动力学方程。动力学方程表示反应温度和反应物系中各组分的浓度与反应速率之间的定量关系,反应温度和反应物浓度是影响动力学方程的重要参数。另外,通过搅拌速度的研究可确定外扩散的影响。因此,选择搅拌速度、反应温度和NaOH溶液初始浓度3个因素来研究煤粉炉高铝粉煤灰碱溶脱硅反应动力学。

3 结果与讨论

3.1 搅拌速度的影响

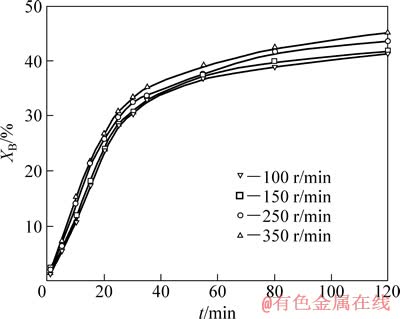

搅拌速度对SiO2浸出率的影响较大时,表明反应受液膜扩散控制。因此,在反应温度为95 ℃、液固比为3:1、NaOH溶液浓度为20%条件下,考察搅拌速度对SiO2浸出率的影响,其结果如图3所示。由图3可以看出,不同搅拌速度对SiO2浸出率影响不大,这说明液膜扩散不是浸出反应的控制步骤。为了减小外扩散影响,本研究选择在搅拌速度为350 r/min条件下进行。

3.2 反应温度的影响

图3 不同搅拌速度时SiO2浸出率与浸出时间的关系

Fig. 3 Relationship between leaching rate of SiO2 and leaching time at different stirring speeds

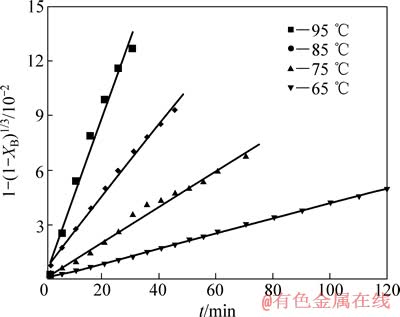

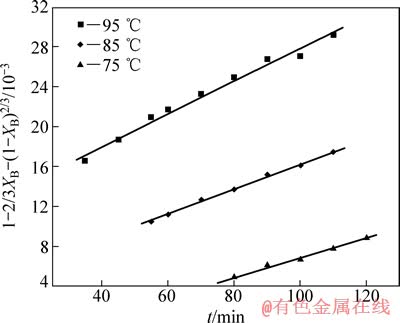

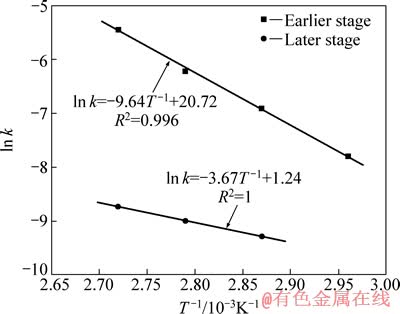

在液固比为3:1,NaOH溶液浓度为20%,搅拌速度为350 r/min条件下,考察反应温度对SiO2浸出率的影响,结果如图4所示。反应温度对SiO2浸出率的影响显著,SiO2浸出率随着温度升高及反应时间延长而升高。在不同反应温度下,反应前期缩芯模型1-(1-XB)1/3与浸出时间同样呈良好的线性关系,表明前期反应受表面反应控制,结果如图5所示。反应后期缩芯模型1-2/3XB-(1-XB)2/3与浸出时间呈良好的线性关系,表明后期反应受固膜扩散控制,其结果如图6所示。将前期及后期缩芯模型分别与浸出时间之间的关系进行线性回归,所得直线斜率即为不同温度下的 k 值。根据Arrhenius 方程lnk=lnA-E/(RT),将lnk对1/T作图,结果如图7所示,前期及后期均呈现良好的线性关系。由直线斜率可求得在实验条件下,浸出反应前期表观活化能 E=80.15 kJ/mol,后期表观活化能E=29.93 kJ/mol。

图4 不同反应温度时SiO2浸出率与浸出时间的关系

Fig. 4 Relationship between leaching rate of SiO2 and leaching time at different reaction temperatures

图5 不同反应温度时反应前期动力学方程式与浸出时间的关系

Fig. 5 Relationship between kinetic equation at earlier stage and leaching time at different reaction temperatures

图6 不同反应温度时反应后期动力学方程式与浸出时间的关系

Fig. 6 Relationship between kinetic equation at later stage and leaching time at different reaction temperatures

图7 lnk与T-1的关系

Fig. 7 Relationship between lnk and T-1

3.3 NaOH溶液初始浓度的影响

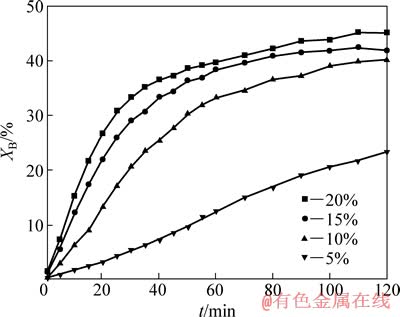

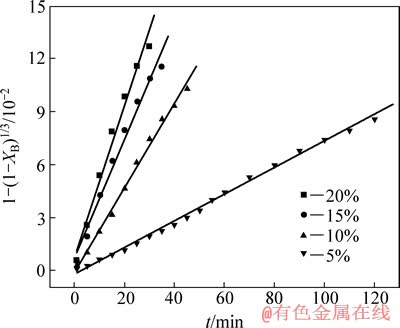

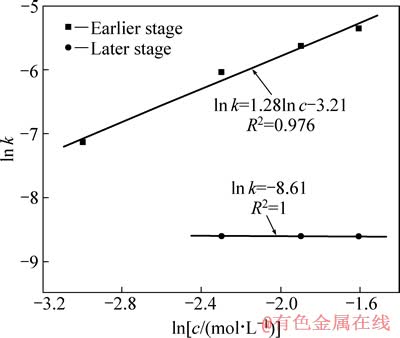

在液固比3:1,反应温度95 ℃、搅拌速度350 r/min条件下,考察NaOH溶液初始浓度(c)对SiO2浸出率的影响,结果如图8所示。SiO2浸出率随NaOH溶液浓度升高及反应时间延长而提高,随着NaOH溶液浓度的增大,其对SiO2浸出率的影响差距逐渐减小。在不同NaOH溶液浓度下,反应前期缩芯模型1-(1-XB)1/3与浸出时间同样呈良好的线性关系,表明前期反应受表面反应控制,结果如图9所示。反应后期缩芯模型1-2/3XB-(1-XB)2/3与浸出时间呈良好的线性关系,表明后期反应受固膜扩散控制,其结果如图10所示。将前期及后期缩芯模型分别与浸出时间之间的关系进行线性回归,所得直线斜率即为不同初始NaOH溶液浓度下的 k 值。将ln k对ln c作图,其结果如图11所示,前期及后期均呈现良好的线性关系。由直线斜率可求得反应前期表观反应级数为1.28,反应后期表观反应级数为0,此时NaOH溶液浓度不是影响反应速率的主要因素。

图8 不同NaOH溶液浓度时SiO2浸出率与浸出时间的关系

Fig. 8 Relationship between leaching rate of SiO2 and leaching time under various NaOH concentrations

图9 不同NaOH溶液浓度时反应前期动力学方程式与浸出时间的关系

Fig. 9 Relationship between kinetic equation at earlier stage and leaching time at different NaOH concentrations

图10 不同NaOH溶液浓度时反应后期动力学方程式与浸出时间的关系

Fig. 10 Relationship between kinetic equation and leaching time under different NaOH concentrations at later stage

图11 ln k 与ln c的关系

Fig. 11 Relationship between ln k and ln c

从以上分析可以看出,不同实验影响因素下所得实验数据反应前期均符合表面反应控制,后期均符合固膜扩散控制。因此,所用粉煤灰碱溶脱硅反应前期动力学方程为

1-(1-XB)1/3=9.967×105exp[-80150/(RT)]·t (5)

反应后期动力学方程为

1-2/3XB-(1-XB)2/3=3.46exp[-29930/(RT)] ·t (6)

4 浸出机理分析

高铝粉煤灰碱溶脱硅过程可能发生的反应包括

Al2O3(s)+2NaOH(aq)=2NaAlO2(aq)+H2O(l) (7)

Al6Si2O13(s)+10NaOH(aq)=6NaAlO2(aq)+2Na2SiO3(aq)+5H2O(l) (8)

SiO2(非晶态)+2NaOH=Na2SiO3+H2O (9)

同时,发生以下副反应:

2NaAlO2(aq)+2Na2SiO3(aq)+4H2O(aq)=NaO·Al2O3·2SiO2·2H2O(s)+4NaOH(aq) (10)

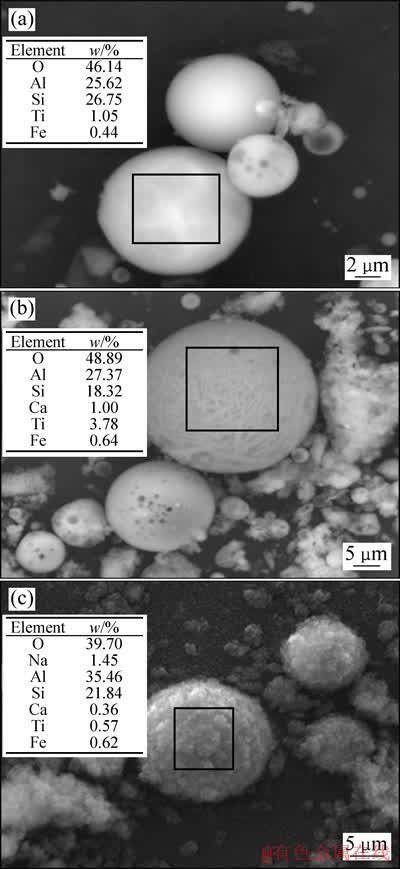

根据反应动力学分析结果,高铝粉煤灰与NaOH溶液的反应前期符合表面反应控制,后期符合固膜扩散控制。为进一步证明上述结论,在反应温度95 ℃、NaOH溶液浓度20%的条件下,将反应不同时间后的渣相进行XRD及SEM和EDS分析,其结果分别如图12和13所示。

图12 不同反应时间所得渣相的XRD谱

Fig. 12 XRD patterns of treated fly ash at different reaction times

图13 粉煤灰、25 min碱溶渣、2 h碱溶渣的SEM像和EDS分析结果

Fig. 13 SEM images and EDS analysis results of fly ash (a), fly ash treated by alkali solution for 25 min (b) and 2 h (c)

由图12可以看出,25 min时,XRD谱与原料粉煤灰XRD谱(图1)相比,并无其他特征峰出现,表明没有新相生成或生成量很小,不足以改变反应的控制步骤。2 h时,在2θ为12.45°、21.52°和28.14 °处出现沸石特征衍射峰,表明此时已生成沸石相。

图13所示为粉煤灰、25 min碱溶渣、2 h碱溶渣的SEM像和EDS分析结果。由图13(a)可知,粉煤灰原料为表面光滑的球形。25 min时,部分非晶态SiO2反应进入液相导致表面非晶态SiO2减少,此时球形表面呈现网状结构。由能谱分析结果可以看出,颗粒表面无Na元素,表明表面没有生成沸石或生成量很少,即没有形成固膜。2 h时,球形表面被较多颗粒所附着,同时结合能谱分析表明,该颗粒为含钠相,结合XRD可知其为沸石,从而证明了固膜的存在。

由以上分析得出,反应前期粉煤灰主要进行脱硅反应,没有产生固膜。随着反应的进行,反应不断生成新相附着于粉煤灰表面,形成固膜,从而使反应后期受固膜扩散控制,这与动力学的研究结果相符。

5 结论

1) 煤粉炉高铝粉煤灰碱溶脱硅反应过程中,搅拌速度对SiO2浸出率的影响较小,反应温度、NaOH溶液浓度对SiO2浸出率的影响显著。

2) 煤粉炉高铝粉煤灰脱硅反应符合有固态产物层的缩芯模型,反应分为两个阶段进行,前期反应符合表面反应控制,表观活化能为80.15 kJ/mol,后期反应符合固膜扩散控制,表观活化能为29.93 kJ/mol。

3) 确定了煤粉炉高铝粉煤灰碱溶脱硅反应动力学方程,反应前期动力学方程为

1-(1-XB)1/3= 9.967×105exp[-80150/(RT)]·t

反应后期动力学方程为

1-2/3XB-(1-XB)2/3=3.46exp[-29930/(RT)]·t。

REFERENCES

[1] 中国人民共和国国家发展与改革委员. 关于进一步加强高铝粉煤灰资源开发利用的指导意见[EB/OL]. [2011]. http://www. Nmgjxw.gov.cn/cms/tzgl/20110318/4308.html.

The national development and reform commission. Guidance of develop and use high aluminum fly ash[EB/OL]. [2011]. http://www.nmgjxw.gov.cn//cms/tzgl/20110318/4308.html.

[2] CAO Da-zuo, SELIC E, HERBELL J. Utilization of fly ash from coal-fired power plants in China[J]. Journal of Zhejiang University, Sciences, 2008, A9: 681-687.

[3] WU Cheng-you, YU Hong-fa, ZHANG Hui-fang. Extraction of aluminum by pressure acid-leaching method from coal fly ash[J]. Transaction of Nonferrous Society of China, 2012, 22(9): 2282-2288.

[4] 张晓云, 张 毅, 陈 刚, 孙俊民, 张占军. 非铝土矿含铝资源生产氧化铝的方法[J]. 轻金属, 2012(11): 21-25.

ZHANG Xiao-yun, ZHANG Yi, CHEN Gang, SUN Jun-min, ZHANG Zhan-jun. Alumina production methods from non-bauxite aluminium resources[J]. Light Metal, 2012(11): 21-25.

[5] 邬国栋, 叶亚平, 钱维兰, 孙月华, 马凤云, 王雅男. 低温碱溶粉煤灰中硅和铝的溶出规律研究[J]. 环境科学研究, 2006, 19(1): 53-56.

WU Guo-dong, YE Ya-ping, QIAN Wei-lan, SUN Yue-hua, MA Feng-yun, WANG Ya-nan. Research on the rules of leaching silicon and aluminum from fly ash in alkaline solution at low temperature[J]. Research of Environmental Sciences, 2006, 19(1): 53-56.

[6] BROWN P, JONES T,  K. The internal microstructure and fibrous mineralogy of fly ash from coal-burning power stations[J]. Environmental Pollution, 2011, 159: 3324-3333.

K. The internal microstructure and fibrous mineralogy of fly ash from coal-burning power stations[J]. Environmental Pollution, 2011, 159: 3324-3333.

[7] 陈江峰, 邵龙义. 高铝粉煤灰特性及其在合成莫来石和堇青石中的应用[M]. 北京: 地质出版社, 2009: 21-66.

CHEN Jiang-feng, SHAO Long-yi. Characterisation of high aluminum fly ash and utilization in synthetic mullite and cordierite[M]. Beijing: Geological Publishing House, 2009: 21-66.

[8] HERRY J, TOWLER M R, STANTON. Characterisation of the glass fraction of a selection of European coal fly ash[J]. Journal of Chemical Technology and Biotechnology, 2004, 79(5): 540-546.

[9] BAI Guang-hui, TENG Wei, WANG Xiang-gang. ZHANG Hui, XU Peng. Processing and kinetics studies on the alumina enrichment of coal fly ash by fractionating silicon dioxide as nano particles[J]. Fuel Processing Technology, 2010, 91: 175-184.

[10] 苏双青, 马鸿文, 邹 丹, 李 歌. 高铝粉煤灰碱溶法制备氢氧化铝的研究[J]. 岩石矿物学杂志, 2011, 20(6): 981-986.

SU Shuang-qing, MA Hong-wen, ZOU Dan, LI Ge. The preparation of aluminum hydroxide from high-alumina fly ash based on alkali dissolution method[J]. Acta Petrologica et Mineralogical, 2011, 20(6): 981-986.

[11] 杜淄川, 李会泉, 包炜军, 李少鹏, 蔡卫权. 高铝粉煤灰碱溶脱硅过程反应机理[J]. 过程工程学报, 2011, 11(3): 442-447.

DU Zhi-chuan, LI Hui-quan, BAO Wei-jun, LI Shao-peng, CAI Wei-quan. Research on reaction mechanism of desilication process of high aluminum fly ash by alkali solution[J]. The Chinese Journal of Process Engineering, 2011, 11(3): 442-447.

[12] 薄春丽, 马淑花, 郑诗礼, 解 华. 高铝粉煤灰在碱介质中脱硅反应动力学研究[J]. 中国稀土学报, 2012, 30(s): 154-157.

BO Chun-li, MA Shu-hua, ZHENG Shi-li, XIE Hua. Research on kinetics of desilication process of high aluminum fly ash in alkaline medium[J]. Journal of Chinese Society Rare Earths, 2012, 30(s): 154-157.

[13] 李军旗, 宫 敏, 金会心, 蒲 锐. 不同燃烧方式粉煤灰性质研究[J]. 粉煤灰, 2010(5): 10-13.

LI Jun-qi, GONG Min, JIN Hui-xin, PU Rui. Research on pulverized coal ash charater with different combustion way[J]. Coal Ash, 2010(5): 10-13.

[14] 盛广宏. 循环流化床锅炉粉煤灰的特点及其在水泥工业中的应用[J]. 水泥工程, 2009(5): 79-81.

SHENG Guang-hong. Character of the circulating fluidized bed boiler fly ash and the application in cement industry[J]. Cement Engineering, 2009(5): 79-81.

[15] 邵靖邦, 邵绪新, 王祖讷, 李 浩. 沸腾炉粉煤灰的特性研究[J]. 中国环境科学, 1997, 17(5): 454-457.

SHAO Jing-bang, SHAO Xu-xin, WANG Zu-ne, LI Hao. Charater of coal fly ash from fluidized bed furnace[J]. China Environmental Science, 1997, 17(5): 454-457.

[16] 刘挥彬, 杜 浩, 刘 彪, 王少娜, 郑诗礼, 张 懿. KOH亚熔盐中钒渣的溶出行为[J]. 中国有色金属学报, 2013, 23(4): 1129-1139.

LIU Hui-bin, DU Hao, LIU Biao, WANG Shao-na, ZHENG Shi-li, ZHANG Yi. Dissolution behavior of vanadium slag in KOH sub-molten salt[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(4): 1129-1139.

[17] TKACOVO K, BALAZ P. Selective leaching of zinc from mechanically activated complex Cu-Pb-Zn concentrate[J]. Hydrometallurgy, 1993, 33(3): 291-300.

[18] EKINCI Z, COLAK S, CAKICI A. Technical note leaching kinetics of sphalerite with pyrite in chloride saturated water[J]. Minerals Engineering, 1998, 11(3): 279-283.

[19] BREED A W, HANSFORD G S. Studies on the mechanism and kinetics of bioleaching[J]. Minerals Engineering, 1999, 12(4): 383-392.

[20] 赵由才, 张承龙, 蒋家超. 碱介质湿法冶金技术[M]. 北京: 冶金工业出版社,1999: 14-16.

ZHAO You-cai, ZHANG Cheng-long, JIANG Jia-chao. Hydrometallurgy technology in alkaline medium[M]. Beijing: Metallurgical Industry Press, 1999: 14-16.

[21] SCHILM J, HERRMANN M, MICHAEL G. Kinetic study of the corrosion of silicon nitride material in acid[J]. Journal of the European Ceramic Society, 2003, 23(4): 577-584.

(编辑 李艳红)

基金项目:国家“十二五”科技支撑计划项目(2012BAF03B01);国家自然科学基金资助项目(51304184)

收稿日期:2013-09-09;修订日期:2014-01-14

通信作者:李会泉,研究员,博士;电话:010-82544830;E-mail:hqli@home.ipe.ac.cn