DOI:10.19476/j.ysxb.1004.0609.2019.06.08

纯热暴露下Ta-W涂层/钛合金体系稳定性

彭小敏1,董丽君1,孙小刚1,吴安如1,夏长清2

(1. 湖南工程学院 机械工程学院,湘潭 411101;

2. 中南大学 材料科学与工程学院,长沙 410083)

摘 要:采用电弧离子镀(AIP)在Ti-6.48Al-0.99Mo-0.91Fe (质量分数,%) 钛合金表面制备Ta-10W (质量分数,%)涂层。通过真空热处理试验、X射线衍射分析(XRD)、扫描电镜(SEM)与能谱(EDS)分析、透射电镜(TEM)分析、电子探针分析(EPMA)等方法,研究纯热暴露下Ta-W涂层/钛合金体系的相组成、显微组织形貌、元素分布、界面行为等,评估了体系热稳定性能。结果表明:纯热暴露过程中,Ta-W涂层相组成无明显变化,均由多晶α-Ta(W)组成,其平均晶粒尺寸由沉积态的46 nm小幅增至750 ℃时的49 nm和950 ℃时的51 nm,涂层表现出良好的相稳定性;由于元素Ta、Ti在Ta-Ti体系中扩散系数的差异及难熔金属元素Ta、W良好的稳定性,Ta-W涂层/钛合金体系呈现出良好的界面及元素稳定性:涂层中元素Ta、W始终维持在接近沉积态含量水平,无快速扩散、固溶于基体而失效的行为,体系仅在界面形成互扩散层,无空洞、裂纹缺陷和金属间化合物的形成;由于元素互扩散的加剧及涂层元素在α-Ti、β-Ti中的固溶度差异,钛合金基体同素异晶转变温度(ATT)对体系界面和元素稳定性影响明显;纯热暴露过程中,Ta-W涂层有效厚度保持稳定、无明显变化。基于Fick定律,获得550、750和950 ℃时互扩散层厚度与时间的关系式。

关键词:Ta-W涂层;钛合金;纯热暴露;热稳定性;真空热处理

文章编号:1004-0609(2019)-06-1198-12 中图分类号:TB43 文献标志码:A

钛合金材料因密度小、熔点高、比强度高、中低温性能稳定、耐蚀性好并具有良好的生物相容性,被广泛应用于航空、航天、兵器、汽车、化工、医疗等领域[1-3]。高温钛合金以其优异的比强度和良好的高温性能及抗蠕变性能,被认为是有望替代钢铁及镍基高温合金的理想候选材料,是极具应用前景的轻型高温结构材料之一[4]。随着航空航天发动机推重比的不断提高、零部件减重以减少运行成本、武器装备减重以提高其机动性能和攻击精度、汽车减重以提高其燃油效率减少CO2排放量等应用需求的出现,钛合金在上述领域应用的迫切性日益提高[5]。而在上述领域中,钛合金将暴露于烧蚀气氛,如燃气轮机叶片、枪炮身管、发动机排气阀等零部件。此类零件往往遭受高温高压、且含H2S、CO、O2、H2、H2O、N2及残留固体颗粒的侵蚀性气体的腐蚀、冲刷及热震冲击。钛合金高温下的耐烧蚀、耐磨损性能不佳,限制了其在上述领域的应用[3-6]。

提高钛合金的使用温度远不能满足其工程需求,开发、制备钛合金用高温防护涂层被认为是改善钛合金性能的经济而有效的方法[3-4]。目前电镀Cr涂层体系已应用于钢基体枪炮身管及其他高温压力容器表面,以起到防烧蚀、冲刷作用[7-9]。电镀Cr层在沉积后或使用初期容易产生裂纹,可为侵蚀性气氛到达基体提供捷径,这导致烧蚀性气氛容易进入镀层而侵蚀基体[10]。同时,电镀Cr产生的六价Cr是一种公认的强致癌性环境污染物[11]。因此,物理气相沉积(PVD)制备Ta、W、Ta-W、Ta-Cr、氧化物和碳化物等环境友好型高温涂层体系被认为是替代电镀Cr层理想的耐烧蚀材料[3, 12-13]。Ta涂层由于具有理想的物理、化学及力学性能[12, 14],如高熔点、低热导率、优异的抗化学腐蚀能力、良好的塑性(BCC结构α-Ta)等,而得到广泛关注。文献[12-13]报道:在钢基体炮管内表面制备纯Ta层,经实弹测试(Firing test)发现涂层表现出优异的耐烧蚀性能。由于BCC结构α-Ta(硬度为8~12 GPa)较四方结构(Tetragonal) β-Ta(硬度为18~20 GPa)具备更优的抗热震性能[11, 15],目前绝大部分研究都集中在沉积参数对α-Ta及β-Ta相含量(β-Ta→α-Ta转变机制)的影响上[12-13, 15-19]。钨(W)可对Ta起到固溶强化作用,改善纯Ta涂层的力学性能,Ta-W合金涂层的耐烧蚀、冲刷性能相比纯Ta涂层的有望得到进一步提高[20-22]。根据相图[23],Ta、W和Ti间无脆性金属间化合物形成,从理论上分析Ta-W涂层适合钛及其合金的高温烧蚀防护。

由于电弧离子镀(AIP)在沉积过程中存在连续或周期性离子轰击(Bombardment),有望改善溅射沉积方法制备纯Ta涂层存在的某些问题,如高α-Ta含量涂层的获得、厚涂层残余应力、柱状晶结构等问题[3, 24]。

烧蚀性气氛往往由高温高压侵蚀性气体和残留固体颗粒等成分组成,如火炮发射过程中,火炮身管表面温度可达到1000 ℃,压力可达到100 MPa[5, 16]。因此,Ta-W涂层若作为耐烧蚀防护涂层除具备较好的防侵蚀、抗热震性能外,涂层/基体体系在高温下的稳定性也显得尤为重要,目前尚未见关于该体系热稳定性研究的报道。

综上,工程领域对钛合金在高温领域应用的迫切性日益增加,Ta基涂层理论上非常适合其高温烧蚀防护的应用,目前仅有纯Ta涂层应用于Fe基材料表面高温烧蚀防护的研究,而关于Ta基涂层/钛基基体体系高温相关问题的研究较少。本文利用电弧离子镀在某高温钛合金表面制备了Ta-W涂层,研究了Ta-W涂层/钛合金体系经不同参数真空热处理(纯热暴露)后的相组成、显微组织形貌、界面反应、元素分布等问题,评估了纯热暴露下体系的热稳定性能,为Ta-W涂层在钛合金表面高温防护的应用提供理论指导。

1 实验

1.1 材料及涂层制备

选择由宝钛集团研制的某α+β型高温钛合金挤压棒材作为试验基材(名义成分Ti-6.48Al-0.99Mo-0.91Fe,质量分数,%),试样加工成尺寸为d 35 mm×10 mm的圆片。基体试样先在500号砂纸上磨光,去除氧化物,然后依次在碱液、蒸馏水中清洗,最后在丙酮溶液中超声清洗,干燥后置于沉积设备。

采用电弧离子镀(AIP)技术在合金基体表面沉积Ta-10W(名义成分,质量分数,%)涂层,Ta-W靶材直径为100 mm。沉积工艺参数为:先抽真空为5×10-3 Pa,沉积前进行预溅射,轰击偏压700 V,时间为5~10 min,涂层沉积时,加工作偏压150 V,工作电流450 A,沉积时间60 min。

1.2 真空热处理

将沉积好Ta-W涂层的试样置于真空炉中,抽真空至1.33×10-3 Pa,升温至指定温度,并保温相应的时间,升温速率小于8 ℃/min。真空热处理参数如下:温度为550~1050 ℃,保温时间为3~50 h,冷却方式为空冷至室温。

1.3 检测分析

采用Rigaku D/Max 2500型X射线衍射仪对真空热处理前后涂层相组成进行分析,试验使用Cu 靶Kα射线,波长0.154 056 nm,加速电压36 kV,电流30 mA,扫描速率4 (°)/min,步宽0.02°;采用JEM-2100F场发射高分辨率透射电镜对热处理前后涂层微观形貌进行观察,利用电子衍射确定涂层相组成,操作电压为200 kV。涂层平面透射试样由平行于样品表面方向减薄至30 μm后,冲成d 3 mm圆片,再进行离子减薄 (Gatan model 691,5 kV电压,6°入射角);采用Sirion200场发射扫描电镜(SEM)观察真空热处理前后试样微观形貌,使用其自带的GENESIS60E能谱仪(EDS)或JAX-8230电子探针仪(操作电压15 kV)分析试样元素分布情况。

2 结果与讨论

2.1 Ta-W涂层相组成稳定性

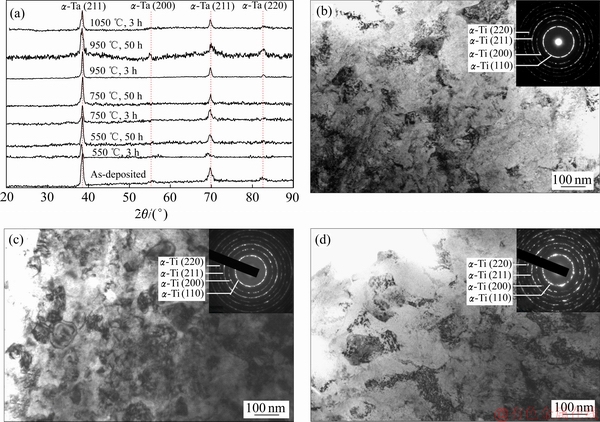

彭小敏等[3]表明:沉积态Ta-W涂层表面光滑、无剥落、与基体结合紧密、无裂纹和空洞出现,结合力满足工程需求。图1所示为沉积态及不同参数真空热处理后Ta-W涂层XRD谱及显微组织形貌。由图1(a)可知,沉积态Ta-W涂层由纯α-Ta (JCPDS-04-0788, a=0.3306 nm)组成,并具有(110)面择优取向;由相图[23]可知,涂层中Ta、W以α-Ta(W)固溶体形式存在,W固溶于α-Ta使其衍射峰轻微(约0.16%)向高角度偏移。真空热处理时间为3 h时,随着温度从550 ℃提高至1050 ℃,Ta-W涂层热处理后其相组成相比沉积态无明显变化,仍由α-Ta(W)相组成。当真空热处理时间延长至50 h时,随着温度从550 ℃提高至1050 ℃,Ta-W涂层仍由α-Ta(W)相组成。上述分析可知:在550~1050 ℃温度区间,无论是随着纯热暴露温度的提高还是时间的延长,Ta-W涂层相组成均无明显变化,涂层呈现良好的相组成稳定性。α-Ta因具有良好的塑性、合适的硬度(8~12 GPa)及较低的电阻率(15~80 μΩ·cm),更适合应用于高温烧蚀对热震性能要求较高的工况环境[11-12, 15]。图1(b)~(d)所示为不同参数真空热处理前后涂层TEM明场像及选区衍射斑点。由图1(b)~(d)插图可知:沉积态及经750 ℃和950 ℃真空热处理3 h后Ta-W涂层选区衍射斑点主要由α-Ta (110)、(200)、(211)及(220)衍射环组成,说明涂层热处理前后均由多晶α-Ta组成,与XRD结果吻合。由图1(b)~(d)涂层显微组织形貌可知:沉积态及经750 ℃和950 ℃真空热处理3 h后涂层中α-Ta晶粒取向随机,且热处理前后形貌无明显变化。由晶粒尺寸分布统计可知:沉积态Ta-W涂层晶粒大小分布在20~100 nm之间,平均尺寸约为46 nm;经750 ℃和950 ℃真空热处理3 h后涂层平均晶粒尺寸分别增至49 nm和51 nm。随着真空热处理温度的提高,Ta-W涂层元素扩散加剧并重新分布,涂层组成相平均晶粒尺寸小幅增加。在其他电弧离子镀涂层体系真空热处理[25]、纳米晶材料高温煅烧过程中[26],纳米晶粒的长大现象也十分常见。但由于高熔点难熔金属元素Ta、W良好的稳定性,如高温下扩散缓慢[27],导致Ta-W涂层在热处理过程中通过元素扩散使晶体长大的过程变得更加困难,进而呈现出良好的相稳定性。电弧离子镀Ta-W涂层由于纳米晶粒带来的细晶强化及添加W后的固溶强化效果,导致涂层硬度明显提高,进而有望提高涂层耐高压、高速、含固体残余颗粒气体的机械冲蚀性能[3]。真空热处理过程中,由于Ta-W涂层的平均晶粒尺寸增加幅度小,可认为由于晶粒尺寸的变化对涂层硬度等性能的影响有限。

2.2 Ta-W涂层/钛合金体系界面稳定性

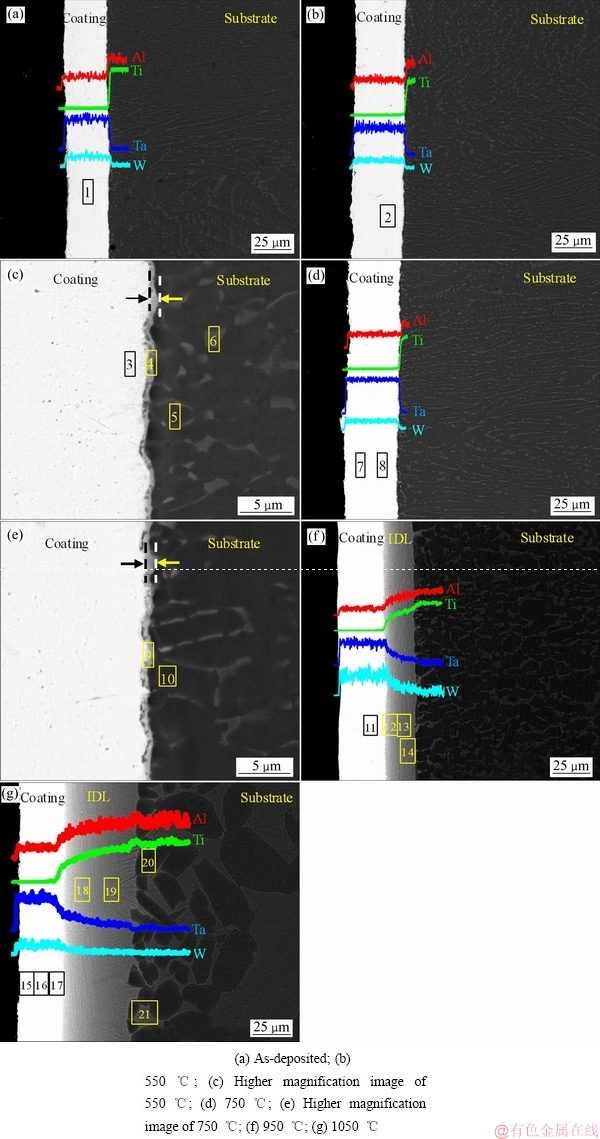

图2所示为沉积态及经不同温度真空热处理3 h后Ta-W涂层/钛合金体系截面BSE形貌及元素分布。相比沉积态,Ta-W涂层/钛合金体系经550 ℃和750 ℃真空热处理3 h后,其截面显微组织形貌及元素分布并无明显变化,如图2(a)~(e)所示。当真空热处理温度为550 ℃时,涂层/基体间开始发生元素互扩散并形成薄层互扩散层(如图2(c)箭头所示),当温度升高至750 ℃时,由于元素互扩散程度加剧,其界面互扩散层厚度相比550 ℃时有所增加,但并不明显(如图2(e) 箭头所示)。当真空热处理温度升高至950 ℃或1050 ℃时,由于涂层与基体间元素互扩散进一步加剧等原因,涂层/基体界面互扩散层厚度明显增加。

图1 沉积态及不同参数真空热处理后Ta-W涂层XRD谱及显微组织形貌

Fig. 1 XRD spectrum(a) and TEM images and SAD patterns of Ta-W coating as-deposited(b), after vacuum heat treatment at 750 ℃ for 3 h (c) and at 950 ℃ for 3 h(d)

图2 沉积态及不同温度真空热处理3 h后Ta-W涂层/钛合金体系截面显微组织形貌及元素分布

Fig. 2 BSE images and element distribution of Ta-W coating/titanium alloy with and without vacuum heat treatment at different temperatures for 3 h (IDL—Interdiffusion layer; numbers are EPMA positions in Table 1)

1050 ℃时互扩散层厚度增加至950 ℃时的两倍左右,但此时元素沿截面分布的变化仅体现在随着互扩散层厚度的增加,元素Ta、W、Ti、Al在扩散层均匀、连续分布的距离明显增加,如图2(f)、(g)所示。经550~1050 ℃真空热处理3 h后,Ta-W涂层/钛合金体系涂层与基体始终结合紧密,未发现由于元素剧烈互扩散或热震等原因所导致的空洞、裂纹等缺陷,热处理前后体系主要元素Ta、W、Ti、Al在涂层和基体中的线分布规律无明显变化,且其在互扩散层中始终呈均匀、连续分布,无元素分布突变现象,界面无金属间化合物的形成。由上述分析可知:经550~ 1050 ℃真空热处理3 h后,Ta-W涂层/钛合金体系存在元素互扩散,仅在涂层/基体界面形成互扩散层,无金属间化合物的形成,涂层与基体结合紧密,无空洞、裂纹等缺陷形成,体系界面呈现良好的稳定性。

为进一步研究Ta-W涂层/钛合金体系界面稳定性,分别在550、750和950 ℃延长热处理时间至50 h,其截面BSE形貌及元素分布如图3所示。由图3(a)、(b)可知:在550 ℃时,随着热处理时间从3 h延长至50 h,Ta-W涂层/钛合金体系截面显微组织形貌及元素分布并无明显变化;当温度升高至750 ℃,随着热处理时间的延长,涂层与基体元素互扩散时间增加,互扩散层厚度有所增加,如图3(c)、(d)所示;当温度升高至950 ℃时,随着时间的延长,元素扩散行程明显增加,互扩散层厚度明显增加外,在互扩散层与基体间可能形成Ta、W含量相对较高的β-Ti稳定层(如图3(e)箭头所示)。在550~950 ℃时,延长真空热处理时间至50 h,Ta-W涂层/钛合金体系涂层与基体依然结合紧密,无空洞、裂纹等缺陷形成,热处理前后体系主要元素Ta、W、Ti、Al元素沿截面分布规律相比3 h时无明显变化。由此可知:温度高于750 ℃时,随着真空热处理时间的延长,Ta-W涂层/钛合金体系中仅呈现互扩散层厚度增加现象,热处理前后体系主要元素Ta、W、Ti、Al元素沿截面分布规律与3 h时相比无明显变化,体系长时间热处理过程中呈现良好的界面稳定性。

上述分析可知:Ta-W涂层/钛合金体系在较低温度(550 ℃)纯热暴露时,涂层与基体界面处形成薄层互扩散层,随着时间的延长,互扩散层厚度无明显变化;当升至较高温度时(750 ℃),随着时间的延长互扩散层厚度有所增加;当升至高温时(950 ℃、1050 ℃),互扩散层厚度明显增加,且随时间的延长,其层厚度增加明显。根据Ti–Ta及Ti–W二元相图,元素Ta、W 在β-Ti 中固溶度均为约100%(摩尔分数),而在α-Ti中固溶度分别为约0.5%、0.2%(摩尔分数)[23]。因此,当纯热暴露温度高于钛合金基体的同素异晶转变温度(Allotropic transformation temperature,ATT)时,如在950 ℃和1050 ℃时,以下因素将导致Ta-W涂层/钛合金体系互扩散层厚度明显增加:1) 温度升高导致元素互扩散行为加剧,如扩散系数的增加等;2) 钛合金基体发生α-Ti→β-Ti转变,此时涂层元素Ta、W在β-Ti基体中固溶度明显增加,在涂层与基体间形成有利于涂层元素向基体方向扩散的动力学条件,加速其扩散。由于Ta、W属β-Ti稳定元素,随着热暴露时间的增加,在互扩散层/基体间可形成β-Ti稳定层(如图3(e)所示)。纯热暴露过程中,Ta-W涂层/钛合金界面行为可归纳为:界面仅形成元素互扩散层,无空洞、裂纹等缺陷形成;温度低于钛合金基体ATT时,互扩散层厚度变化不明显,体系呈现良好的界面稳定性;温度高于钛合金基体ATT时,互扩散层厚度变化明显,并可在互扩散层/基体间形成β-Ti稳定层;涂层有效元素始终保持较高、稳定含量,体系亦呈现较好的界面稳定性。

2.3 Ta-W涂层/钛合金体系元素稳定性

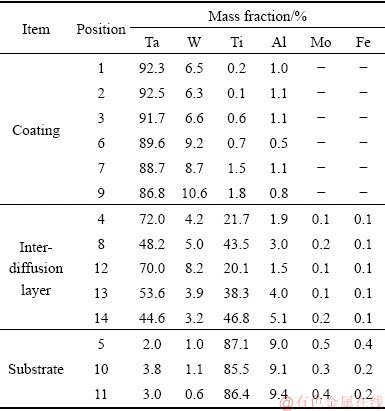

PENG等[28]表明:当真空热处理温度高于钛合金基体ATT时,NiCrAlY涂层/钛合金体系中涂层元素快速 (≤3 h)扩散并固溶于基体而消耗,导致涂层可能完全失效。鉴于此,研究了Ta-W涂层/钛合金体系不同参数真空热处理后元素沿截面分布情况(如图1和2中插图及表1和2)。由图2(a)、(b)、(d)、(f)、(g)及图3(a)、(c)、(e)元素截面线分布规律并结合表1~2结果可知:在真空热处理过程中,涂层组成元素Ta、W向钛合金基体方向扩散,基体主要元素Ti、Al向涂层方向扩散;在550~1050 ℃温度区间,热处理时间为3 h或50 h时,Ta、W元素在涂层区域保持较高、稳定含量,在基体区域保持较低含量;基体主要元素Ti、Al在涂层中含量低;即使温度高于钛合金基体ATT时(如950 ℃、1050 ℃),未发现涂层元素快速扩散、固溶于基体而失效的现象。上述结果表明:在550~1050 ℃纯热暴露下,Ta-W涂层/钛合金体系元素稳定性良好,有利于Ta-W涂层在钛合金表面的高温、长时间应用。

图3 不同温度50 h真空热处理后Ta-W涂层/钛合金体系显微组织形貌及元素分布

Fig. 3 SEM images and element distribution of Ta-W coating/titanium alloy after vacuum heat treatment at different temperatures for 50 h (Numbers are EPMA positions in Table 2)

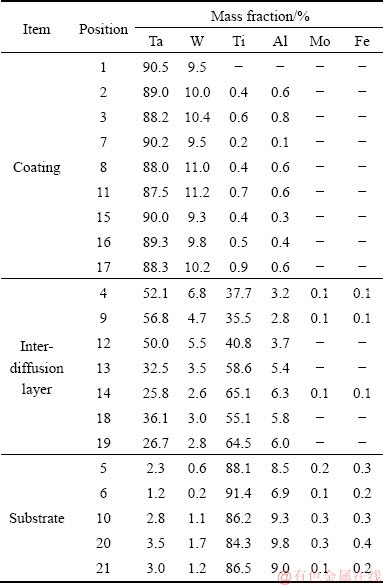

表1~2所列为Ta-W涂层/钛合金体系热处理后涂层、互扩散层及基体不同位置元素点分布情况。由表1~2可知:在550~1050 ℃真空热处理3~50 h后,体系涂层区域Ta元素含量始终维持在90.0%(质量分数)左右,W元素含量从3 h热处理后的10.0%小幅度降至50 h的6.0%以上。由于W元素向基体方向扩散而在涂层近界面区域轻微富集,涂层中元素Ti、Al含量始终维持在较低水平(低于2.0%),如图2中点1~3、7、8、11、15~17位置及图3中点1~3、6、7、9位置的Ta、W、Ti、Al元素含量。体系互扩散层中元素Ta始终维持在相对较高含量(热处理3 h 后Ta含量高于25.0%,热处理50 h后Ta含量高于44.0%),元素Al含量始终维持在钛合金基体名义Al含量(6.48%)以下,如图2中点4、9、12~14、18、19位置及图3中点4、8、12~14位置元素含量。随着元素Ta、W向基体方向扩散并固溶,体系近界面基体区域形成相对富Ta、W区域(3~50 h,Ta含量皆为3.0%左右,W含量均低于2.0%),随着Al元素向涂层方向扩散,Al元素在近界面基体区域轻微富集(3~50 h,Al含量均高于8.0%),如图2中点5、6、10、20、21位置及图3中点5、10、11位置元素含量。由上述分析可知:纯热暴露下,Ta-W涂层/钛合金体系涂层与基体间虽存在元素互扩散现象,但涂层区域Ta、W元素含量始终保持较高、稳定含量,元素Ti、Al在涂层中始终维持较低含量,即使温度高于钛合金基体ATT时,未发现涂层元素快速扩散、固溶于基体而失效的现象,体系呈现良好的元素稳定性。

表1 Ta-W涂层/钛合金体系元素分析结果(位置参考图2)

Table 1 Element contents of Ta-W coating/titanium alloy system (positions shown in Fig. 2)

表2 Ta-W涂层/钛合金体系元素分析结果(位置参考图3)

Table 2 Element contents of Ta-W coating/titanium alloy system (positions shown in Fig. 3)

对于Ta-Ti体系,富Ti侧的元素互扩散系数比富Ta侧的大3个数量级,Ti原子的内扩散系数(Intrinsic diffusion coefficient)要比Ta原子的大[29],而对于Ta-W体系,Ta原子的内扩散系数要比W原子的稍大[27]。因此,纯热暴露过程中涂层Ta原子在富Ti基体侧扩散要比Ti在富Ta涂层侧扩散快的多,同时Ta原子的扩散比W原子稍快。Ta-W涂层/钛合金体系经不同参数纯热暴露处理后,由于涂层主要组成元素Ta在富Ti基体中扩散系数比基体主要组成元素Ti在富Ta涂层中的扩散系数大,形成以涂层/基体原始界面为起点、向基体方向增厚且相对富Ta的互扩散层。由于相对较低的扩散系数及互扩散层的阻挡作用,基体组成元素Ti、Al虽然向涂层方向扩散,但在涂层中的含量始终维持较低水平。尽管如此,由于高熔点难熔金属元素Ta、W高稳定性特点,如高的扩散激活能(20%~80% W(摩尔分数)时,Ta-W体系扩散激活能Q≈544.28 kJ/mol)[27]、高温下极低的扩散系数(1000 ℃,10% Ta(摩尔分数)时,D≈6×10-11 cm2/s)[29]等,导致涂层中Ta、W元素含量始终维持在接近沉积态含量水平,涂层保持完整、有效,体系呈现出良好的元素稳定性。

根据相图可知:Ta-W涂层/钛合金体系Ta、W、Ti、Al等4种主要组成元素中,Ta-Al二元系最有可能形成金属间化合物,且形成金属间化合物种类多,如TaAl3、TaAl2、TaAl、Ta2Al等,而Ta、W和Ti间无脆性金属间化合物的形成[23, 30]。由表1~2元素含量可知:经不同参数纯热暴露处理后,Ta-W涂层/钛合金体系互扩散层中元素Al含量始终维持在6.48%以下,低于Ta-Al二元相图[23, 30]中形成金属间化合的最低Al含量要求(8.0%)。因此,纯热暴露过程中Ta-W涂层/钛合金体系仅在界面形成互扩散层,且由于不存在形成Ta-Al金属间化合物的动力学条件(Al含量小于8.0%),而在互扩散层中无Ta-Al金属间化合物的形成,这对涂层与基体间的结合及体系的稳定非常有利。

2.4 Ta-W涂层及互扩散层厚度变化

在不同参数纯热暴露处理过程中,Ta-W涂层/钛合金体系表现出良好的元素稳定性,涂层中元素Ta、W含量始终维持在接近沉积态含量水平。若定义试样表面到涂层元素Ta、W含量突变位置的距离为Ta-W涂层的厚度,则由图2~3可获得经不同参数纯热暴露处理后Ta-W涂层的厚度值,其结果如图4(a)所示。由图4(a)可知: Ta-W涂层经不同参数纯热暴露处理后,其厚度维持在32~35 μm之间;相比沉积态,涂层厚度变化率在2.5%~4.6%之间,若考虑涂层厚度的不均匀或测量误差等因素,经不同参数纯热暴露处理后Ta-W涂层的厚度变化较小(<5.0%);Ta-W涂层在纯热暴露处理过程中保持稳定、有效。结合2.3、2.4节讨论可知,难熔金属元素Ta、W良好的稳定性及元素Ta、Ti在Ta-Ti体系中扩散系数的差异是导致Ta-W涂层在纯热暴露处理过程中保持稳定、有效的主要原因。

基于Fick定律,并作相关假设,可推导出互扩散层(反应层)厚度与真空热处理时间关系如下[28]:

x=B+kt1/2 (1)

式中:x为界面互扩散层(反应层)厚度,μm;t为扩散时间(热处理时间),s;k为与浓度和扩散系数有关的常数;B为修正系数,主要考虑短路扩散及扩散系数对扩散过程的影响。若定义Ta-W涂层/互扩散层界面Ta含量突变处至互扩散层/钛合金基体界面Ta含量突变处的距离为扩散层的厚度,则由图2~3则可以获得经不同参数纯热暴露处理后Ta-W涂层/钛合金体系互扩散层的厚度值,从而获得互扩散层厚度与纯热暴露时间t1/2关系的拟合图,如图4(b)~(d)所示。由图4(b)~(d)可知,在550、750和950 ℃纯热暴露处理时,体系互扩散层厚度(x)与处理时间(t)的关系可分别表示为

x=0.69381+9.44771×10-4t1/2 (μm) (2)

x=0.08797+8.46×10-3t1/2 (μm) (3)

x=15.19152+6.104×10-2t1/2 (μm) (4)

由式(2)~(4)可知:Ta-W涂层/钛合金体系互扩散层的形成(厚度变化)受元素扩散因素控制;随着温度的升高,式(1)中k值呈数量级增加,说明随着温度的升高元素扩散行为明显加剧,这是界面互扩散层厚度随着温度的升高而增加的主要原因。温度低于钛合金基体的ATT时(如750 ℃),k值虽然比550 ℃时的高一个数量级,但B值却比550 ℃时的低一个数量级,因此扩散层厚度变化并不十分明显。温度高于钛合金基体的ATT时(如950 ℃),k值和B值都比550 ℃、750 ℃时的高两个数量级,因此扩散层厚度随时间变化明显。当纯热暴露温度高于钛合金基体的ATT时,短路扩散及扩散系数对体系的扩散行为的影响(由式(1)中B值体现)加剧。

图4 Ta-W涂层/钛合金体系真空热处理前后涂层及互扩散层厚度变化

Fig. 4 Coating(a) and inter-diffusion layer thickness of Ta-W coating/titanium alloy system before and after vacuum heat treatment versus heat treatment parameter at 550 ℃(b), 750 ℃(c) and at 950 ℃(d)

图5 Ta-W涂层/钛合金体系纯热暴露过程行为示意图

Fig. 5 Schematic diagrams of behaviors of Ta-W coating/titanium alloy system during pure thermal exposure

2.5 Ta-W涂层/钛合金体系纯热暴露行为

综上分析,Ta-W涂层/钛合金体系纯热暴露过程中的行为可用图5示意。不同参数热暴露处理过程中:Ta-W涂层由多晶α-Ta(W)组成,相组成、微观组织形貌无明显变化,Ta-W涂层厚度无明显变化;涂层元素Ta、W向钛合金基体方向扩散,基体主要元素Ti、Al向涂层方向扩散。由于元素Ta、Ti在Ta-Ti体系中扩散系数的差异及难熔金属元素Ta、W良好的稳定性,涂层中元素Ta、W含量始终维持在接近沉积态含量水平,无快速扩散、固溶于基体而失效的行为。涂层中Ti、Al元素始终维持较低含量,仅形成以涂层/基体原始界面为起点向基体方向生长的互扩散层,界面无空洞、裂纹缺陷和金属间化合物的形成。温度低于钛合金基体ATT时,温度或时间对体系界面行为影响有限,而高于此温度时其影响加剧。纯热暴露下体系呈现良好的热稳定性。

仅热稳定性而言,Ta-W涂层适合于钛合金表面高温、长时间防护的应用。但前期相关研究[3]表明,由于腐蚀性气氛(如氧气等)的介入将可能导致Ta-W涂层/钛合金体系在高温和腐蚀性气氛耦合环境下的行为变得复杂,并可能直接影响涂层的失效机理。若作为耐烧蚀防护用涂层,Ta-W涂层将遭受高温、高压侵蚀性气氛的作用,其作用时间可能较短(如火药对火炮身管的作用),但高温、高压和腐蚀气氛耦合作用下Ta-W涂层/钛合金体系的行为值得进一步研究。

3 结论

1) 采用电弧离子镀技术在钛合金表面制备了约32 μm厚的纯α-Ta(W)涂层。纯热暴露过程中,涂层相组成无明显变化,均由α-Ta(W)相组成;经热处理3 h后其平均晶粒尺寸由沉积态的46 nm小幅增至750 ℃的49 nm和950 ℃的51 nm。Ta-W涂层呈现良好的相稳定性。

2) 纯热暴露过程中,由于元素Ta、Ti在Ta-Ti体系中扩散系数的差异及Ta、W元素良好的稳定性,Ta-W涂层/钛合金体系呈现良好的界面及元素稳定性:涂层中Ta、W元素始终维持在接近沉积态含量水平,而元素Ti、Al在涂层中维持低含量,涂层元素无快速扩散、固溶于基体而失效的行为;界面仅形成以涂层/基体原始界面为起点向基体方向生长的元素互扩散层,无空洞、裂纹缺陷和金属间化合物形成,互扩散层中元素Ta维持相对较高含量;温度高于钛合金基体ATT时,由于元素互扩散加剧及涂层元素在α-Ti、β-Ti中的固溶度差异,导致温度和时间对体系界面行为影响加剧。

3) 纯热暴露过程中,Ta-W涂层厚度随时间变化小,涂层保持稳定、有效。基于Fick定律,550 ℃、750 ℃、950 ℃时,互扩散层厚度与时间的关系可分别表示为:x=0.69381+9.44771×10-4t1/2,x=0.08797+ 8.46×10-3t1/2,x=15.19152+6.104×10-2t1/2。

REFERENCES

[1] LEYENS C, PETERS M. Titanium and titanium alloys: Fundamentals and applications[M]. Weinheim: Wiley-VCH, 2006.

[2] 金和喜, 魏克湘, 李建明, 周建宇, 彭文静. 航空用钛合金研究进展[J]. 中国有色金属学报, 2015, 25(2): 280-292.

JIN He-xi, WEI Ke-xiang, LI Jian-ming, ZHOU Jian-yu, PENG Wen-jing. Research development of titanium alloy in aerospace industry[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(2): 280-292.

[3] 彭小敏, 夏长清, 吴安如, 董丽君, 李东锋, 谭季秋. 钛合金表面Ta-W涂层的制备及循环氧化行为[J]. 中国有色金属学报, 2015, 25(6): 1567-1578.

PENG Xiao-min, XIA Chang-qing, WU An-ru, DONG Li-jun, LI Dong-feng, TAN Ji-qiu. Preparation of Ta-W coating on titanium alloy and its oxidation behavior[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(6): 1567-1578.

[4] 彭超群, 黄伯云, 贺跃辉, 王健农. TiAl基合金的抗氧化性及其改善[J]. 稀有金属材料与工程, 1999, 28(2): 93-96.

PENG Chao-qun, HUANG Bai-yun, HE Yue-hui, WANG Jian-nong. Oxidation resistance and its improvement of the Ti-Al based alloys[J]. Rare Metal Materials and Engineering, 1999, 28(2): 93-96.

[5] PENG X M, XIA C Q, DAI X Y, WU A R, DONG L J, LI D F, TAO Y R. Ablation behavior of NiCrAlY coating on titanium alloy muzzle brake[J]. Surface and Coatings Technology, 2013, 232: 690-694.

[6] 张永刚. 金属间化合物结构材料(第二卷)[M]. 北京:国防工业出版社, 2003: 782.

ZHANG Yong-gang. Structural Intermetallics (Volume Ⅱ)[M]. Beijing: National Defense Industry Press, 2003: 782.

[7] UNDERWOOD J H, VIGILANTE G N, MULLIGAN C P, TODARO M E. Thermomechanically controlled erosion in army cannons: A review[J]. Journal of Pressure Vessel Technology, Transactions of the ASME, 2006, 128(2): 168-172.

[8] MENTHE E, RIE K T. Plasma nitriding and plasma nitrocarburizing of electroplated hard chromium to increase the wear and the corrosion properties[J]. Surface and Coatings Technology, 1999, 112(1/3): 217-220.

[9] LI Huai-xue, CHEN Guang-nan, ZHANG Kun, LUO Geng-xing, YE Zhi-jun. Degradation failure features of chromium-plated gun barrels with a laser-discrete-quenched substrate[J]. Surface and Coatings Technology, 2007, 201(24): 9558-9564.

[10] UNDERWOOD J H, VIGILANTE G N, MULLIGAN C P. Review of thermo-mechanical cracking and wear mechanisms in large caliber guns[J]. Wear, 2007, 263(7/12): 1616-1621.

[11] LEE S L, DOXBEC M, MUELLER J, CIPOLLO M, COTE P. Texture, structure and phase transformation in sputter beta tantalum coating[J]. Surface and Coatings Technology, 2004, 177/178: 44-51.

[12] LEE S L, WINDOVER D, AUDINO M, MATSON D W, MCCLANAHAN E D. High-rate sputter deposited tantalum coating on steel for wear and erosion mitigation[J]. Surface and Coatings Technology, 2002, 149(1): 62-69.

[13] LEE S L, CIPOLLO M, WINDOVER D, RICKARD C. Analysis of magnetron-sputtered tantalum coatings versus electrochemically deposited tantalum from molten salt[J]. Surface and Coatings Technology, 1999, 120-121: 44-52.

[14] KOIVULUOTO H, VUORISTO P, NAKKI J. Structure and corrosion behavior of cold-sprayed tantalum coatings[C]// Proceedings of the International Thermal Spray Conference. United States: ASM International, 2009: 314-319.

[15] MYERS S, LIN J L, SOUZA R M, SPROUL W D, MOORE J J. The β to α phase transition of tantalum coatings deposited by modulated pulsed power magnetron sputtering[J]. Surface and Coatings Technology, 2014, 214: 38-45.

[16] LEE S L, WINDOVER D. Phase, residual stress, and texture in triode-sputtered tantalum coatings on steel[J]. Surface and Coatings Technology, 1998, 108/109(1/3): 65-72.

[17] MATSON D W, MCCLANAHAN E D, RICE J P. Effect of sputtering parameters on Ta coatings for gun bore applications[J]. Surface and Coatings Technology, 2000, 133/134: 411-416.

[18] COLIN J J, ABADIAS G, MICHEL A, JAOUEN C. On the origin of the metastable β-Ta phase stabilization in tantalum sputtered thin films[J]. Acta Materialia, 2017, 126: 481-493.

[19] NIU Y S, CHEN M H, WANG J L, YANG L X, GUO C, ZHU S L, WANG F H. Preparation and thermal shock performance of thick α-Ta coatings by direct current magnetron sputtering (DCMS)[J]. Surface and Coatings Technology, 2017, 321: 19-25.

[20] CHEN C, WANG M P, WANG S, JIA Y L, LEI R S, XIA F Z, ZOU B, YU H C. The evolution of cold-rolled deformation microstructure of {001}<110> grains in Ta-7.5wt%W alloy foils[J]. Journal of Alloys and Compounds, 2012, 513: 208-212.

[21] 祁小红, 胡昌义, 蔡宏中, 郑 旭, 魏 燕. CVD Ta/W复合材料的力学性能及影响因素[J]. 稀有金属材料与工程, 2016, 45(1): 197-200.

QI Xiao-hong, HU Chang-yi, CAI Hong-zhong, ZHENG Xu, WEI Yan. Mechanical properties of the Ta/W composite prepared by CVD and their influencing factors[J]. Rare Metal Materials and Engineering, 2016, 45(1): 197-201.

[22] 武 扬, 虞 钢, 何秀丽, 宁伟健. 激光熔覆Ta-W合金组织及高温气动烧蚀性能[J]. 稀有金属材料与工程, 2012, 41(7): 1211-1215.

WU Yang, YU Gang, HE Xiu-li, NING Wei-jian. Microstructure and high temperature aerodynamic ablation property of Ta-W alloy deposited by coaxial laser cladding[J]. Rare Metal Materials and Engineering, 2012, 41(7): 1211-1215.

[23] NAGASAKI S, HIRABAYASHI M. Binary alloy phase- diagrams[M]. Tokyo: AGNE Gijutsu, 2002.

[24] MARTIN PETER M. Handbook of deposition technologies for films and coatings[M]. 3rd ed. Oxford: Elsevier, 2010: 297-313.

[25] 彭小敏, 夏长清, 吴安如, 董丽君, 李东锋, 陶友瑞. 真空热处理对NiCrAlY涂层组织与性能的影响[J]. 中国有色金属学报, 2013, 23(11): 3147-3153.

PENG Xiao-min, XIA Chang-qing, WU An-ru, DONG Li-jun, LI Dong-feng, TAO You-rui. Effect of vacuum heat treatment on microstructure and property of NiCrAlY coating[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(11): 3147-3153.

[26] 刘纯波, 于连生, 蒋显亮. 纳米ZrO2-8%Y2O3 粉末的相转变及晶粒生长动力学[J]. 中国有色金属学报, 2011, 21(12): 3120-3128.

LIU Chun-bo, YU Lian-sheng, JIANG Xian-liang. Phase transition and grain growth kinetics of nanocrystalline 8% yttria stabilized zirconia powder[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(12): 3120-3128.

[27] ROMING A D JR, CIESLAK M J. Interdiffusion in the Ta-W system[J]. Journal of Applied Physics, 1985, 58(9): 3425-3429.

[28] PENG X M, XIA C Q, Dai X Y, WU A R, DONG L J, LI D F, TAO Y R. Study on the interface reaction behavior of NiCrAlY coating on titanium alloy[J]. Surface and Coatings Technology, 2013, 232: 254-263.

[29] ANSEL D, THIBON I, BOLIVEAU M, DEBUIGNE J. Interdiffusion in the body cubic centered β-phase of Ta-Ti alloys[J]. Acta Materialia, 1998, 46 (2): 423-430.

[30] MCCULLOUGH C, VALENCIA J J, LEVI C G, MEHRABIAN R, MALONEY M, HECHT R. Solidification paths of Ti-Ta-Al alloys[J]. Acta Metallurgica et Materialia, 1991, 39(11): 2745-2758.

Stability of Ta-W coating/titanium alloy under pure thermal exposure

PENG Xiao-min1, DONG Li-jun1, SUN Xiao-gang1, WU An-ru1, XIA Chang-qing2

(1. School of Mechanical Engineering, Hunan Institute of Engineering, Xiangtan 411101, China;

2. School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: Ta-10W (mass fraction, %) coating was deposited on Ti-6.48Al-0.99Mo-0.91Fe (mass fraction, %) titanium alloy by arc ion plating (AIP). Vacuum heat treatment, XRD, SEM, EDS, TEM and EPMA analysis were carried out to study the phase composition, microstructure, elements distribution and interface behavior of the Ta-W coating/titanium alloy substrate system under pure thermal exposure. The thermal stability of the coating/substrate system was also evaluated. The results show that the coating/substrate system exhibits satisfying phase composition stability during the pure thermal exposure. The Ta-W coating always consists of polycrystalline α-Ta(W) without changes of phase composition before and after pure thermal exposure. Only a small increase in average grain size of the Ta-W coating, from 46 nm of as-deposited coating to 49 nm at 750 ℃ and 51 nm at 950 ℃, was observed. The coating/substrate system exhibits satisfying interface and element stability during the pure thermal exposure for the different diffusion coefficient of Ta and Ti in Ta-Ti binary system and the good stability of refractory metals of Ta and W. The Ta-W coating maintains as high Ta and W content level as the as-deposited coating without degradation due to the fast diffusion and solution into the titanium ally substrate. Only an inter-diffusion layer develops at the interface without the formation of voids, cracks and intermetallics. The allotropic transformation temperature (ATT) of the titanium alloy substrate has a significant influence on the coating/substrate system interface and element stability due to the different solid solubility of Ta and W inα-Ti and β-Ti or/and more violent element inter-diffusion. Compared with the as-deposited coating, the thickness of Ta-W coating maintains stability and shows no obvious changes during the pure thermal exposure. Based on Fick’s law, the relationship between the thickness of inter-diffusion layer and time at 550 ℃, 750 ℃ and 950 ℃ was discussed.

Key words: Ta-W coating; titanium alloy; pure thermal exposure; thermal stability; vacuum heat treatment

Foundation item: Projects(51671085, 51101054) supported by National Natural Science Foundation of China; Projects(16B058, 14B042) supported by Scientific Research Fund of Hunan Provincial Education Department, China; Project(14JJ3132) supported by Hunan Provincial Natural Science Foundation of China

Received date: 2018-07-30; Accepted date: 2018-10-16

Corresponding author: PENG Xiao-min; Tel: +86-731-58688521; E-mail: xmpeng@hnie.edu.cn

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51671085,51101054);湖南省教育厅资助科研项目(16B058,14B042);湖南省自然科学基金资助项目(14JJ3132)

收稿日期:2018-07-30;修订日期:2018-10-16

通信作者:彭小敏,博士,副教授;电话:0731-58688521;E-mail:xmpeng@hnie.edu.cn