文章编号:1004-0609(2015)06-1567-12

钛合金表面Ta-W涂层的制备及循环氧化行为

彭小敏1,夏长清2,吴安如1,董丽君1,李东锋1, 2,谭季秋1

(1. 湖南工程学院 机械工程学院,湘潭 411101;

2. 中南大学 材料科学与工程学院,长沙 410083)

摘 要:采用电弧离子镀(AIP)在Ti-6.48Al-0.99Mo-0.91Fe(质量分数,%)钛合金表面制备Ta-10W(质量分数,%)涂层。通过扫描电镜(SEM)与能谱(EDS)分析、透射电镜(TEM)分析、电子探针分析(EPMA),X衍射分析(XRD),划痕及纳米压痕试验,研究钛合金基体与Ta-W涂层经900 ℃大气循环氧化前后的物相组成、组织形貌及性能,讨论涂层/基体的氧化行为。结果表明:沉积态Ta-W涂层连续、均匀、致密,由颗粒细小(≤50 nm)的α-Ta(W)堆积成100~250 nm的等轴晶组成,硬度为14.4~15 GPa,与基体的临界载荷为58.5 N;经900 ℃大气循环氧化后,钛合金表面形成带裂隙的层状TiO2、Al2O3疏松混合氧化膜,氧化膜明显脱落;Ta-W涂层能明显提高钛合金的抗循环氧化性能,形成以β-Ta2O5为主的致密氧化膜;随着氧化的进行,氧化膜中TiO2、Al2O3含量增加并出现AlTaO4、AlWO4相,氧化膜始终保持完整;氧化过程中,基体中Ti、Al元素及涂层中Ta、W元素互扩散,在界面形成AlTa2、Al2Ta3、Al3Ti、TixW1-x相,O元素扩散并固溶于基体,在近界面基体处形成厚度逐渐增加的富Ta、W、Al、O、α-Ti固溶体(稳定)区,涂层元素向氧化膜和基体扩散而被消耗为其失效的主要原因。

关键词:Ta-W涂层;钛合金;循环氧化;元素扩散

中图分类号:TB43 文献标志码:A

Preparation of Ta-W coating on titanium alloy and its oxidation behavior

PENG Xiao-min1, XIA Chang-qing2, WU An-ru1, DONG Li-jun1, LI Dong-feng1, 2, TAN Ji-qiu1

(1. School of Mechanical Engineering, Hunan Institute of Engineering, Xiangtan 411101, China;

2. School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: Ta-10W (mass fraction, %) coating was deposited on Ti-6.48Al-0.99Mo-0.91Fe (mass fraction, %) titanium alloy by arc ion plating (AIP). Scratch test, nano indentation test, SEM, EDS, TEM, EPMA and XRD analysis were carried out to study the phase composition, microstructure and properties of the substrate and coating before and after cyclic oxidation at 900 ℃ in air. The oxidation behavior of the coating/substrate was discussed. The results show that the as-deposited Ta-W coating is continuous, uniform and compact with fine α-Ta(W) particles (≤50 nm) aggregating to form 100-250 nm equiaxed grains. The coating with hardness of 14.4-15 GPa and critical load of 58.5 N is obtained from the scratch test. Laminar Al2O3 and TiO2 mixed scale with fissuring is formed and desquamated obviously on the substrate after cyclic oxidation at 900 ℃ in air. Ta-W coating can evidently improve the cyclic oxidation resistance of the substrate. An integrity and compact scale, which is mainly made up of β-Ta2O5, formed on Ta-W coating. With the oxidation going on, the contents of TiO2, Al2O3, AlTaO4 and AlWO4 in the scale increase. The coating elements (Ta and W) and substrate elements (Ti and Al) interdiffuse during the oxidation. AlTa2, Al2Ta3, Al3Ti, TixW1-x phases form on the interface. With the diffusion of Ta, W, Ti, Al and O, α-Ti solid solution layer (stabilized layer) forms in the substrate near the interface. The degradation of Ta-W coating mainly attributes to the consumption of coating elements to form scale and dissolve in the substrate.

Key words: Ta-W coating; titanium alloy; cyclic oxidation; element diffusion

钛合金因密度小、比强度高、耐蚀性良好等特点在航空航天、兵器、船舶、化工等领域得到广泛应用。在航空航天、兵器等领域,对零部件减轻质量的需求日益迫切,钛及钛合金可能成为替代钢铁及超合金的理想材料而在上述领域应用[1-3]。上述领域中,钛合金将可能应用于烧蚀气氛,如燃气轮机叶片、枪炮身管、发动起排气阀等。此类零件往往遭受高温、高压含H2S、CO、O2、H2、H2O、N2及残留固体颗粒等侵蚀性气体的腐蚀、冲刷及热震冲击。钛合金高温下欠佳的抗氧化、耐烧蚀及耐磨损性能限制了其在上述领域的应用[4-6]。

涂覆保护性涂层被认为是改善钛合金性能经济而有效的方法[2-4, 7]。目前,关于电镀耐烧蚀防护Cr层在钢基体枪炮身管及其他高温压力容器中的应用及研究较多,并已得到工程应用[8-11]。但电镀Cr层在使用初期,甚至在沉积后容易产生裂纹,导致侵蚀性气氛快速到达基体。且即使电镀Cr层出现小部分开裂现象,烧蚀气氛也容易进入镀层导致冲蚀失效[12]。电镀Cr产生的六价Cr是一种公认的强致癌性环境污染 物[13]。因此,Ta、W、Ta-W、Ta-Cr、氧化物和碳化物等环境友好型高温涂层被认为是替代电镀Cr层的理想耐烧蚀材料[11, 14-15]。纯Ta涂层具有良好的物理和化学性质,如高熔点、低热导率、良好的抗化学腐蚀能力[16]、良好的塑性(BCC)[14]等得到了广泛关注。LEE等[14-15]采用溅射沉积及电化学熔盐方法在钢基体表面制备了15~125 μm纯Ta层,分别经1500次及5034次实弹测试后,涂层仍保持完整。由于塑性较佳的(硬度为8~12 GPa)BCC结构α-Ta较脆性亚稳态四方结构β-Ta(硬度为18~20 GPa)具有更加优异的耐烧蚀性能[13, 17],目前,绝大部分研究集中在溅射沉积参数对α-Ta及β-Ta相含量的影响上[14-15, 18-19]。在纯Ta中添加W元素后,Ta合金表现出良好的综合性能,如高熔点、高密度、高温下良好的塑性、高强度(特别是在高应变率下)[20-21]。Ta-W合金上述性能将有利于进一步提高纯Ta层在含固体残余颗粒的烧蚀气氛中的耐烧蚀性能。根据二元相图,Ta、W和Ti间无脆性金属间化合物,理论上Ta-W涂层适合钛及其合金的耐烧蚀防护。

目前,一般采用溅射沉积的方法来制备纯Ta涂 层[14-15, 17-19],但存在如下问题:1) 较难获得高α-Ta含量的涂层[17];2) 由于溅射层存在较大的残余应力,厚度大于10 μm时容易剥落;3) 较小的沉积速度及典型的柱状晶结构可为腐蚀气氛提供短程扩散通道。由于沉积过程中连续或周期性的离子轰击可有效改善涂层的结合力及显微结构[22],电弧离子镀有可能改善上述问题,且电弧离子镀在工程应用中有较理想的沉积速度。目前,还没有关于电弧离子镀(AIP)制备Ta-W涂层(薄膜)及Ta-W涂层应用于钛合金表面的相关报道。

烧蚀性气氛往往含高温氧化性组分,若Ta-W涂层作为耐烧蚀性涂层应具备较好的抗氧化及抗热震性能。Ta氧化物平衡相为Ta2O5,Ta2O5有正交(β,<1593 K)和六方(δ)结构,正交晶Ta2O5可分为高温态和低温态(L-Ta2O5)两种形式,在1360 ℃发生可逆转变。致密的Ta2O5氧化膜具有较佳的抗化学腐蚀能力,可在基体表面形成钝化层[23]。W的氧化物形式主要为多晶型WO3,在正菱形和正四边形间转变,转变温度为740 ℃。三氧化钨为黄色粉末,850 ℃在空气中易升华[24]。目前,钛及钛合金的氧化行为研究较多,而关于Ta-W合金或Ta-W涂层(薄膜)氧化行为的报道较少,研究Ta-W涂层/钛合金体系的高温循环氧化行为对钛合金的防护及Ta-W涂层的应用具有较好的工程指导意义。

本文作者利用电弧离子镀在高温钛合金表面制备Ta-W涂层,研究沉积态Ta-W涂层相组成、组织形貌及性能,探讨Ta-W涂层对钛合金基体900 ℃大气循环氧化行为的影响。

1 实验

1.1 材料及涂层制备

选择由宝钛集团研制的某α+β型高温钛合金挤压棒材作为试验基材(名义成分Ti-6.48Al-0.99Mo- 0.91Fe(质量分数,%)),试样加工成尺寸为d 35 mm× 10 mm的圆片。基体试样先在500号砂纸上磨光,去除氧化物,然后依次在碱液、蒸馏水中清洗,最后在丙酮溶液中超声清洗,干燥后置于沉积设备。

采用电弧离子镀(AIP)技术在合金基体表面沉积Ta-10W(质量分数,%)涂层,Ta-W靶材直径为100 mm,单靶静态沉积。沉积工艺参数为:先抽真空为5×10-3 Pa,沉积前进行预溅射,轰击偏压700 V,轰击电流为100 A,时间为5~10 min,涂层沉积时,加工作偏压50 V,工作电流450 A,沉积时间60 min。

1.2 循环氧化实验

将试样放入已烧至恒量的氧化铝坩埚中,在大气环境中将样品从室温(23℃)加热至900 ℃保温10 min后再取出冷却至室温,上述过程循环50次,期间每隔一定的次数称取质量以记录样品质量变化,称取质量用天平精确度为0.1 mg。

1.3 检测分析

采用Rigaku D/Max 2500型X射线衍射仪对氧化前后试样相组成进行分析,试验使用Cu 靶Kα1射线,波长0.154 056 nm,加速电压36 kV,电流30 mA,扫描速率4 (°)/min,步宽0.02°;采用JEM-2100F场发射高分辨率透射电镜对涂层微观形貌进行观察,利用电子衍射确定涂层相组成,操作电压为200 kV。透射试样由基体侧向涂层侧减薄至30 μm后,冲成d 3 mm圆片,再进行离子减薄;采用Sirion200场发射扫描电镜(SEM)观察氧化前后试样表面及截面微观形貌,并使用其自带的GENESIS60E能谱仪(EDS)及JAX-8230电子探针仪(操作电压15 kV)分析氧化前后试样元素分布情况;采用瑞士CSM划痕仪检测涂层与基体结合力,试验参数为:速度2 mm/min,最大载荷100 N,加载速度20 N/min,压头圆角半径为50 μm;采用带Berkovich压头的CSM纳米压痕仪检测涂层硬度,载荷为20 mN,压痕深度为50 nm,平行位置测试3次取平均值。

2 结果与讨论

2.1 沉积态Ta-W涂层

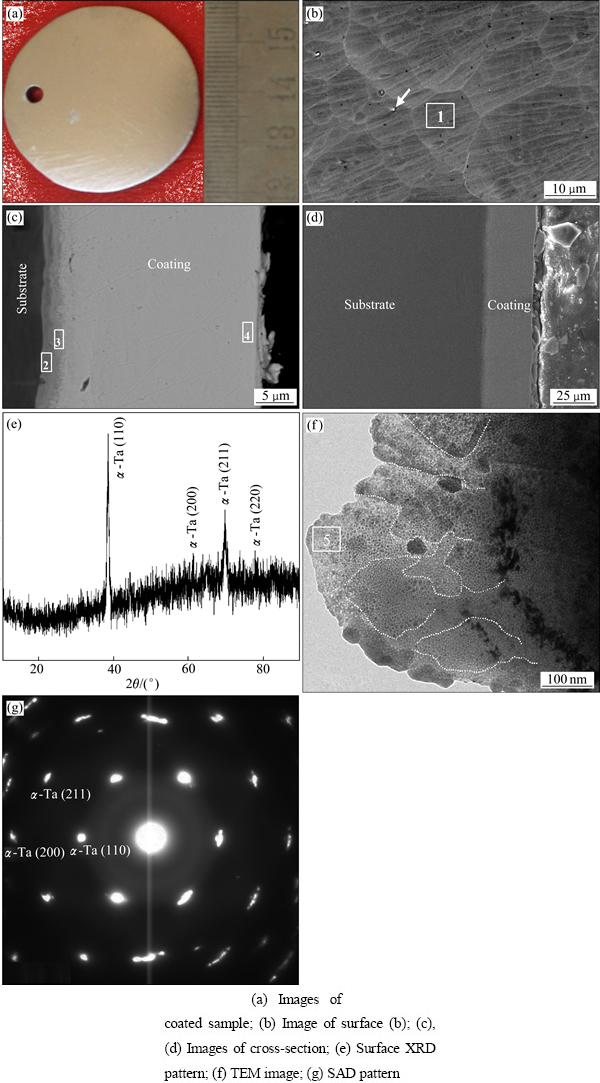

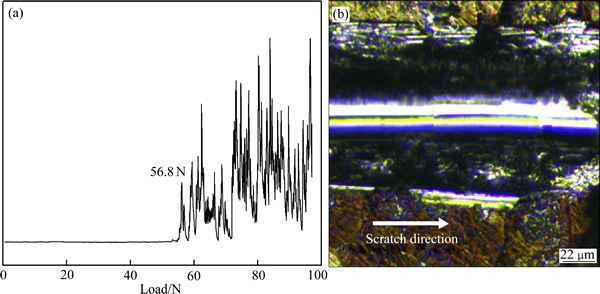

图1所示为沉积态Ta-W涂层显微组织及XRD谱。如图1(a)所示,Ta-W涂层试样表面光滑呈银白色金属光泽,无宏观剥落。Ta-W涂层表面致密、粗糙并存在少量大尺寸粒子(如图1(b)中箭头所示)。电弧蒸发效应的存在,电弧离子镀涂层往往会出现大尺寸颗粒,单靶、静止和大功率沉积都将增加大尺寸颗粒出现的几率[22]。通常可采用多靶、转镀和增加磁控系统来减少涂层中大尺寸颗粒出现的几率。沉积过程中,高能离子轰击所带来的“刻蚀”作用导致了Ta-W涂层的粗糙表面,证明涂层沉积过程中高电离化金属等离子体和高能粒子的存在。如图1(c)和(d)所示,Ta-W涂层厚度约为32 μm,涂层与基体结合紧密没有明显裂纹和空洞出现。根据元素能谱分析结果(表1中点2、3)可知,Ta-W涂层与基体间存在轻微元素互扩散,涂层与基体的冶金结合有利于提高涂层与基体的结合强度。由图1(e)可知,沉积态Ta-W涂层由纯α-Ta (JCPDS-04-0788, a=0.3306 nm)组成。由元素能谱分析结果(见表1中的点1、4)、X射线衍射结果(见图1(e))及TEM像(见图1(f)和(g))可知,涂层中Ta、W以α-Ta(W)固溶体形式存在,并具有(110)面择优取向。W固溶于α-Ta中,使得α-Ta衍射峰轻微向高角度偏移。由于α-Ta的形成相比亚稳相β-Ta需更多能量,沉积过程中α-Ta更难于形成。动力学因素(形核和长大)对β→α的转变起到重要作用,外部因素(如基体温度、离子轰击和沉积负偏压等)可提高粒子的迁移能力进而促进α-Ta的形成[17, 25-26]。因此,电弧离子镀过程中持续的离子轰击、高电离化金属等离子体所带来的高粒子迁移能力、高能量离子及相对较高的沉积温度(350 ℃)都将促进α-Ta的形成。由图1(f)涂层TEM明场像可知,与传统溅射纯Ta涂层柱状晶组织不同[17-18],电弧离子镀涂层为细小致密的等轴组织。细小均匀的Ta-W颗粒(≤50 nm)堆积成100~250 nm较大颗粒(图1(f)虚线所示)。涂层沉积过程中的高电流(450 A)说明沉积过程中体系维持高的离子密度,将促进涂层细小颗粒的形成。利用纳米压痕试验检测沉积态Ta-W涂层硬度值沿截面在14.4~15 GPa范围内变化,明显高于LEE等[13]报道的溅射纯Ta涂层的8~12 GPa及MYERS等[17]报道的8~10 GPa。由于固溶强化作用,在纯Ta中添加W元素后合金的屈服强度和加工硬化率将明显提高[27]。ZHANG等[28]报道:由于细晶强化的效果,平均尺寸为76.5 nm的纯α-Ta薄膜硬度可达到11.6 GPa,认为相比FCC及HCP金属,细晶强化对BCC金属效果更明显。可认为添加W后的固溶强化[27]及细晶强化[28]将导致电弧离子镀Ta-W涂层硬度的明显提高。在实际烧蚀气氛中(如大口径火炮),零部件及其防护涂层往往要承受含固体残余颗粒、高压、高速气体的机械冲蚀,并可能导致其失 效[4]。在纯Ta中添加W元素及电弧离子镀工艺形成的等轴细晶组织在不牺牲纯Ta涂层塑性的同时,提高其硬度,将改善涂层的抗冲蚀能力。划痕试验表明:Ta-W涂层临界载荷为58.6 N时出现明显塑性磨损失效,涂层/基体结合强度可满足工程应用,且涂层具有良好的塑性,如图2所示。

图1 沉积态Ta-W涂层显微组织及XRD 谱

Fig. 1 Microstructures and XRD pattern of as-deposited Ta-W coating

图2 沉积态Ta-W涂层划痕试验载荷-声发射曲线及划痕

Fig. 2 Acoustic emission signal peaks versus normal loads curve(a) and optical images of end scratch(b) of as-deposited Ta-W coating

表1 沉积态Ta-W涂层元素能谱分析结果

Table 1 EDX analysis results of elements of as-deposited Ta-W coating shown in Fig. 1

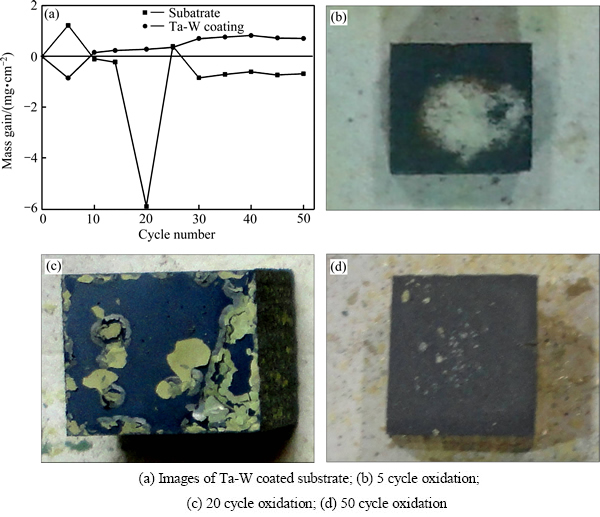

2.2 氧化动力学

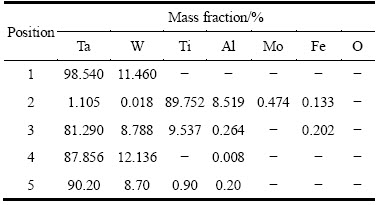

经900 ℃、15次(150 min)循环后,氧化钛合金基体表面形成深蓝色氧化膜 (氧化前呈金属光泽),氧化膜完整;循环氧化16次(160 min)后,氧化膜有轻微的剥落现象,剥落处形成浅黄色氧化膜;20次(200 min)循环后,氧化膜大面积剥落(见图3(c)),氧化膜为深蓝色和浅黄色混合膜。在900 ℃、1~50次(500 min)循环氧化过程中,涂覆Ta-W涂层试样氧化膜呈黑色,氧化膜完整,无剥落现象(见图3(d))。涂覆Ta-W涂层试样在1~5次循环氧化过程中,氧化膜表面出现淡黄色氧化物(见图3(b))。由图3(a)可知,在氧化初期,由于钛合金基体表面氧化物迅速形成,氧化质量增加明显,之后由于氧化膜的剥落开始质量损失。钛合金基体经20次(200 min)循环后,氧化膜大面积剥落,氧化质量损失明显。经25次(250 min)循环氧化后,由于裸露的基体继续氧化,基体试样出现轻微的氧化质量增加,但此后的氧化中一直处于失重状态。涂覆Ta-W涂层试样,在氧化初期(1~5次),虽可以形成完整氧化膜,但由于W2O3在850 ℃以上易升华[24]而导致其轻微的氧化质量损失。经5次(50 min)循环氧化后,涂覆Ta-W涂层试样便进入稳定的氧化质量增加期,其质量增加不大,维持在0.5 mg/cm2以下。经25次(250 min)循环氧化后,带Ta-W涂层试样的氧化速率有所提高,氧化质量增加提高到0.7~0.8 mg/cm2。其原因可能是由于氧化时间的延长,基体中Ti、Al元素向外扩散与氧结合形成氧化物,应用于钛合金表面的其他防护涂层也可观察到类似现象[3]。由上述分析可知,900 ℃大气循环氧化条件下,钛合金形成的氧化膜在循环热应力作用下易剥落并不能起到有效的防护,而Ta-W涂层可形成完整的氧化膜,对钛合金基体起到有效防护。

2.3 氧化后相组成及组织形貌

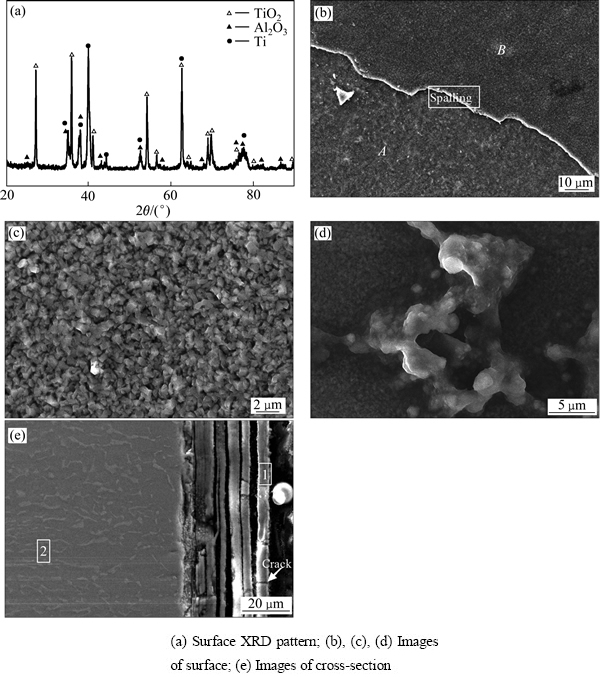

图4所示为Ti-6.48Al-0.99Mo-0.91Fe钛合金基体经900 ℃循环氧化50次(500 min)后的XRD谱及显微组织形貌。由图4(a)可知,钛合金基体经900 ℃、50次循环氧化后,氧化膜主要由金红石型TiO2(JCPDS PDF 21—1276)组成并含少量α-Al2O3(JCPDS PDF 10—0173)。由于氧化膜明显剥落,XRD谱中出现了大量的基体相α-Ti(JCPDS PDF 44—1294)。由红金石型TiO2组成的氧化膜往往呈片状结构,片层与片层之间的过渡区域结合弱,甚至为裂隙,并不能对基体起到理想的防护效果[29]。如图4(b)所示,基体经900 ℃、50次循环氧化后,氧化膜在热应力作用下明显剥落。氧化膜剥落后A区显微组织形貌如图4(c)所示,为典型的块状金红石型TiO2,氧化膜疏松,表明氧化膜剥落后在表面迅速形成TiO2。图4(d)所示为氧化膜剥落前B区形貌图,在TiO2氧化膜表面出现典型的颗粒状α-Al2O3向外生长。钛合金氧化过程中,首先在表面形成TiO2氧化膜,Al元素沿疏松TiO2膜外扩散与氧结合成Al2O3。DU等[30]认为:TC4钛合金氧化时首先形成TiO2氧化膜,随着TiO2氧化膜增厚,氧元素内扩散受阻,Al元素向外扩散与氧结合形成Al2O3层。同理,Al2O3层生长到一定厚度时,Ti元素向外扩散与氧反应形成TiO2层,从而TiO2层和Al2O3层交替出现。如图4(e)所示,基体氧化后形成约30 μm厚氧化膜,氧化膜成层状,层与层之间结合弱,且存在明显裂隙,最外层氧化膜出现垂直于基体/氧化膜界面的裂纹。由于基体与TiO2和Al2O3的线膨胀系数差别并不大(都约为7×10-6~8×10-6 K-1),每次循环氧化后,在氧化膜中积累的热应力并不大。只有循环氧化一定次数后,热应力积累到一定程度,氧化膜才开始出现裂纹,并最终导致剥落(见图3(c))。由能谱分析结果(表2的1~2点)可知,每层氧化膜为TiO2与Al2O3混合物,且Al含量明显高于基体含量,基体中氧含量高达53.80%(质量分数),说明基体氧化过程中Al元素明显向氧化膜方向扩散,氧化膜并不能有效阻挡O元素的内扩散。

图3 钛合金基体及Ta-W涂层900 ℃循环氧化动力学曲线及各阶段的形貌

Fig. 3 Cycle oxidation kinetics of substrate and Ta-W coating at 900 ℃ and morphologies after different cycles oxidation

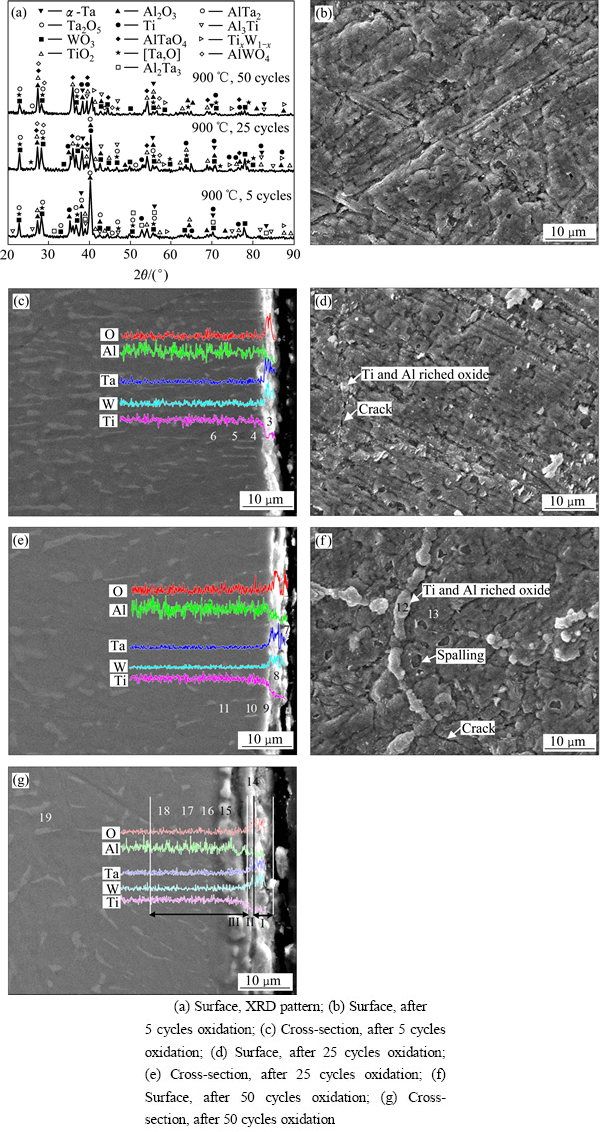

图5所示为Ta-W涂层/钛合金基体经900 ℃循环氧化不同次数后的XRD谱及显微组织结构。由图5(a) 可知,Ta-W涂层经900 ℃不同次数(时间)循环氧化后仍含不同量的α-Ta相,涂层仍保持完整有效。经900 ℃循环氧化5次后,氧化膜主要由β-Ta2O5(JCPDS PDF 25-0922)、WO3(JCPDS PDF 33-1378)、[Ta, O]固溶体相(JCPDS PDF 19-1299)及少量金红石型TiO2及Al2O3(JCPDS PDF 10-0173)组成,并出现一定量的金属间化合物AlTa2(JCPDS PDF 18-0064)、Al2Ta3 (JCPDS PDF 14-0482)及Al3Ti(JCPDS PDF 26-0038)相,此时图谱以钛合金基体相α-Ti及TixW1-x(JCPDF 49-1140,a=0.3165 nm)为主。随着循环氧化次数(时间)增加至25次,其氧化膜由Ta2O5、WO3、[Ta, O]固溶体、TiO2及Al2O3相组成,且TiO2、Al2O3的含量明显增加(衍射强度明显增加),并出现一定量的AlWO4(JCPDS PDF 29-0096)及AlTaO4(JCPDS PDF 47-1796)相,未发现AlTa2、Al2Ta3相,α-Ti及TixW1-x仍为主要相。经50次循环氧化后,氧化膜成分TiO2、Al2O3、AlTaO4、AlWO4相含量继续增加并成为主要相,Ta2O5、WO3相含量减少,TixW1-x相含量明显减少,未发现AlTa2、Al2Ta3相。由图5(b)和(c)可知,5次循环氧化后,Ta-W涂层表面氧化膜完整致密与基体结合紧密(见图5(c)),无剥落和裂纹出现,涂层元素Ta、W主要分布氧化膜区域,氧元素被有效阻挡在氧化膜区域(图5(b)插图元素线分布,点6氧含量仅3.56%(质量分数))。随着氧化次数(时间)的增加,至25次循环氧化后,涂层氧化膜仍保持完整,无明显剥落,但开始出现裂纹,在裂纹处出现富Ti及Al混合氧化膜,氧元素被有效阻挡在氧化膜区域(见图5(d),图 5(e)插图元素线分布及点11氧含量仅4.98%(质量分数))。随着循环氧化次数增加至50次,氧化膜表面保持完整与基体结合紧密,无明显剥落、垂直界面裂纹出现,但出现富Ti及Al混合氧化膜裂纹沿网状分布(对比表2点12、13元素含量),并有小面积块状剥落,氧元素被有效阻挡在氧化膜区域(见图5(f)),图5(g)插图元素线分布及点19氧含量仅4.21%(质量分数))。随着氧化时间的增加,基体Ti、Al元素向外扩散,并沿着氧化膜裂纹快速扩散至表面形成氧化物,正如图3所示涂层/基体试样25次循环氧化质量增加比较明显。

图4 钛合金基体循环氧化后XRD谱及显微组织

Fig. 4 XRD pattern and microstructures of titanium alloy after 50 cyclic oxidation

由于Ta2O5的生成自由能最负(Ta2O5的 为-1541237 J/mol;Al2O3 的

为-1541237 J/mol;Al2O3 的 为-1303739 J/mol; WO3的

为-1303739 J/mol; WO3的 为-545610 J/mol;TiO2的

为-545610 J/mol;TiO2的 为-732710 J/mol),Ta-W涂层氧化初期优先形成Ta2O5膜。致密的Ta2O5膜能有效阻挡O元素向基体的扩散[23]。Ta属于β-Ti稳定元素,在α-Ti中的溶解度为5%(摩尔分数),与β-Ti形成连续固溶体[31],氧化过程中Ta元素向基体扩散并固溶于基体,从氧化膜至基体方向(图5(c) 3~6点、图5(e) 7~11点、图5(g) 14~18点)Ta元素含量逐渐减少。根据Ta-O相图,O在Ta中的溶解度为6%(摩尔分数)[31],氧化过程中O可溶解于α-Ta形成[Ta, O]固溶体。氧化过程中,涂层W元素部分与α-Ta基体脱溶并扩散至氧化膜表面形成WO3,但空气中850 ℃以上时WO3易升华[24]导致涂层氧化物中W含量较低(图4中3、7、13、14点W含量均小于2%(质量分数))。根据Ti-W二元相图[31-32],W属可形成快共析反应的β-Ti稳定元素,在α-Ti中固溶度为0.2%(摩尔分数),与β-Ti形成连续固溶体。W元素在氧化过程中同时向氧化膜和基体扩散,并有可能在界面处富集(图5(e) 9点W含量达4.24%(质量分数))。向基体扩散的W元素在900 ℃时与β-Ti固溶,试样冷却过程中发生共析反应形成α-Ti及富W的β-Ti固溶体TixW1-x 区(a=0.3165 nm,与β-Ti有相似的晶体结构及点阵参数,在该区域图5(e) 9点α-Ti稳定元素Al含量仅为0.6%(质量分数))。氧化过程中,基体Al元素向氧化膜方向扩散,由于氧化膜对其外扩散的阻挡作用,Al在近界面处富集(图5中点4~6、10~11、15~17的Al元素含量明显高于基体6.48%(质量分数)的含量),而氧化膜中Al含量则相对较低(如图5中点3、7、14的Al元素含量均低于2.5%(质量分数))。随循环氧化次数(时间)的增加,氧化膜中出现的裂纹可为Ti、Al元素的短路扩散提供条件,导致涂层氧化膜表面形成富Ti、Al网状分布的混合氧化物。根据Ta-Al相图[32],Ta-Al可形成AlTa2、AlTa、Al2Ta及Al3Ta等相,Ta含量在3.5%~13.5%(质量分数)区间可形成AlTa2等低Al含量金属间化合物。氧化初期(5次循环氧化),Al元素外扩散并在界面富集形成AlTa2,Al2Ta3低Al含量金属间化合物提供了动力学条件。随循环氧化次数(时间)的增加,元素的氧化及向基体扩散使Ta、Al、W被逐渐消耗,AlTa2、Al2Ta3、TixW1-x等相分解以提供Ta、Al、W元素,导致25次及50次循环氧化后,未检测到AlTa2,Al2Ta3相和TixW1-x相含量也明显减少,如图5(a)所示。随氧化的进行,Ti、Al元素向基体扩散并氧化,氧化膜中TiO2、Al2O3含量明显增加,经50次循环氧化后,TiO2、Al2O3成为氧化膜主要相。随着氧化膜中TiO2、Al2O3含量的增加,如下反应得以进行:Al2O3+Ta2O5→AlTaO4,Al2O3+ WO3→AlWO4。因此,在25次循环氧化后,氧化膜中出现AlTaO4和AlWO4相,50次后,其含量明显增加,如图5(a)所示。

为-732710 J/mol),Ta-W涂层氧化初期优先形成Ta2O5膜。致密的Ta2O5膜能有效阻挡O元素向基体的扩散[23]。Ta属于β-Ti稳定元素,在α-Ti中的溶解度为5%(摩尔分数),与β-Ti形成连续固溶体[31],氧化过程中Ta元素向基体扩散并固溶于基体,从氧化膜至基体方向(图5(c) 3~6点、图5(e) 7~11点、图5(g) 14~18点)Ta元素含量逐渐减少。根据Ta-O相图,O在Ta中的溶解度为6%(摩尔分数)[31],氧化过程中O可溶解于α-Ta形成[Ta, O]固溶体。氧化过程中,涂层W元素部分与α-Ta基体脱溶并扩散至氧化膜表面形成WO3,但空气中850 ℃以上时WO3易升华[24]导致涂层氧化物中W含量较低(图4中3、7、13、14点W含量均小于2%(质量分数))。根据Ti-W二元相图[31-32],W属可形成快共析反应的β-Ti稳定元素,在α-Ti中固溶度为0.2%(摩尔分数),与β-Ti形成连续固溶体。W元素在氧化过程中同时向氧化膜和基体扩散,并有可能在界面处富集(图5(e) 9点W含量达4.24%(质量分数))。向基体扩散的W元素在900 ℃时与β-Ti固溶,试样冷却过程中发生共析反应形成α-Ti及富W的β-Ti固溶体TixW1-x 区(a=0.3165 nm,与β-Ti有相似的晶体结构及点阵参数,在该区域图5(e) 9点α-Ti稳定元素Al含量仅为0.6%(质量分数))。氧化过程中,基体Al元素向氧化膜方向扩散,由于氧化膜对其外扩散的阻挡作用,Al在近界面处富集(图5中点4~6、10~11、15~17的Al元素含量明显高于基体6.48%(质量分数)的含量),而氧化膜中Al含量则相对较低(如图5中点3、7、14的Al元素含量均低于2.5%(质量分数))。随循环氧化次数(时间)的增加,氧化膜中出现的裂纹可为Ti、Al元素的短路扩散提供条件,导致涂层氧化膜表面形成富Ti、Al网状分布的混合氧化物。根据Ta-Al相图[32],Ta-Al可形成AlTa2、AlTa、Al2Ta及Al3Ta等相,Ta含量在3.5%~13.5%(质量分数)区间可形成AlTa2等低Al含量金属间化合物。氧化初期(5次循环氧化),Al元素外扩散并在界面富集形成AlTa2,Al2Ta3低Al含量金属间化合物提供了动力学条件。随循环氧化次数(时间)的增加,元素的氧化及向基体扩散使Ta、Al、W被逐渐消耗,AlTa2、Al2Ta3、TixW1-x等相分解以提供Ta、Al、W元素,导致25次及50次循环氧化后,未检测到AlTa2,Al2Ta3相和TixW1-x相含量也明显减少,如图5(a)所示。随氧化的进行,Ti、Al元素向基体扩散并氧化,氧化膜中TiO2、Al2O3含量明显增加,经50次循环氧化后,TiO2、Al2O3成为氧化膜主要相。随着氧化膜中TiO2、Al2O3含量的增加,如下反应得以进行:Al2O3+Ta2O5→AlTaO4,Al2O3+ WO3→AlWO4。因此,在25次循环氧化后,氧化膜中出现AlTaO4和AlWO4相,50次后,其含量明显增加,如图5(a)所示。

图5 Ta-W涂层/钛合金基体900 ℃循环氧化后的显微组织和XRD谱

Fig. 5 Microstructures and XRD pattern of Ta-W coating/titanium alloy after cyclic oxidation at 900 ℃

氧化过程中,O元素的扩散与分布值得注意。由图6可知,随着循环氧化次数(时间)的增加,近界面区基体中(图6虚线所示)深灰色相(α-Ti)含量明显增加,浅灰色相(β-Ti)减少,且该区域的厚度随氧化次数的增加而增加(15~50 μm)。由能谱分析可知,该区域富含O和Al元素(图6点20~22,O元素含量大于5.0%(质量分数),Al元素含量大于7.8%(质量分数))。根据Ti-O和Ti-Al相图[32],O在α-Ti中的固溶度为14.5%~15.5%(质量分数),Al在α-Ti中的固溶度为5%~31%(质量分数),O和Al均为α-Ti稳定元素。随着氧化的进行,O元素通过氧化膜向基体内扩散并固溶,同时Al元素在近界面基体处富集,从而形成了富O、Al元素的α-Ti稳定区。

综上分析,可把Ta-W涂层/钛合金基体50次循环氧化后沿截面大致分成3个区域(见图5(g)所示):1) Ta2O5、Al2O3、WO3、TiO2、AlTaO4 、AlWO4 混合氧化膜区域,该区域O、Ta、W、Ti、Al元素含量高;2) Ta-W 涂层区域,该区域Ta、W元素含量高但O元素含量明显减少,O以[Ta,O]固溶体形式存在,由于元素的消耗涂层厚度减薄至2 μm左右;3) α-Ti固溶体(稳定)区,该区域为富Ta、W、Al、O元素α-Ti固溶体。

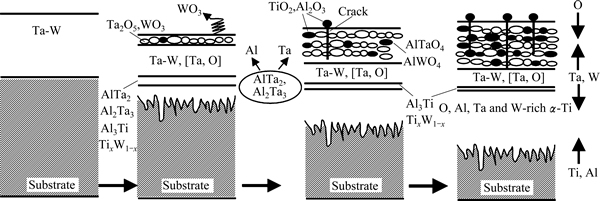

2.4 Ta-W涂层/钛合金基体循环氧化行为

Ti-6.48Al-0.99Mo-0.91Fe钛合金基体900 ℃、50次(500 min)循环氧化后形成层状Al2O3、TiO2混合氧化膜,氧化膜大面积剥落并不能有效地保护基体。Ta-W涂层在循环氧化过程中能形成以Ta2O5为主的致密混合氧化膜,可有效提高基体的抗氧化性能。氧化初期,基体Al元素在近界面基体区域富集,并与涂层扩散来的Ta元素反应形成AlTa2和Al2Ta3等低Al含量的金属间化合物。W元素向基体扩散与Ti元素在界面处形成TixW1-x固溶体相区。随着氧化的进行,基体Ti、Al元素逐渐扩散至氧化膜表面形成TiO2、Al2O3,由于Ta、W、Ti、Al元素的消耗,AlTa2、Al2Ta3、TixW1-x相分解以提供所需元素。随着氧化膜中TiO2、Al2O3含量的增加,Al2O3与Ta2O5及WO3反应,导致氧化膜中AlTaO4 、AlWO4含量明显增加。

根据Oxx[33]公式,温度变化时在涂层或氧化膜中产生的应力可用下式计算:σf=EfΔTΔα (式中σf为涂层或氧化膜中的应力,N/m2;Ef为涂层或氧化膜的弹性模量,N/m2;ΔT是氧化温度与冷却温度之差,K;Δα是涂层或氧化膜与基体在相同温度下的热膨胀系数之差,K-1)。Ta、Ti、TiO2、Al2O3的热膨胀系数分别为7.7×10-6 K-1、7.4×10-6 K-1、6.8×10-6~8.3×10-6 K-1、8.1×10-6 K-1。Ta2O5 热膨胀系数较小为-1.5×10-6~3.5×10-6 K-1,TiO2、Al2O3、WO3的添加可有效抑制Ta2O5相β→α转变,提高Ta2O5的热膨胀系数,特别是Al2O3的添加可使Ta2O5致密化、抗弯强度显著提高[34-35]。由于Ti基体与TiO2、Al2O3的热膨胀系数相差并不大,单次冷却后在TiO2、Al2O3混合氧化膜中形成的热应力并不大,但随着氧化次数的增加,热应力的积累,最终氧化膜出现裂纹(图4(e)所示)并可能剥落(见图3所示,20次循环氧化后基体氧化膜大面积剥落)。虽然Ta2O5膜与Ta-W涂层及钛合金基体的热膨胀系数有一定的差距,但由于氧化膜中TiO2、Al2O3含量随氧化次数的增加而增加,混合氧化膜的膨胀系数也随之增加,加之Al2O3能细化Ta2O5晶粒并提高其抗弯强度、涂层与基体元素互扩散等因素,Ta-W涂层在循环氧化过程中并没有明显剥落(见图3所示)。综合上述分析,Ta-W涂层/钛合金基体900 ℃大气循环氧化行为如图7所示。

图7 Ta-W涂层/钛合金基体900 ℃大气循环氧化行为示意图

Fig. 7 Schematic diagram of cyclic oxidation process of Ta-W coating/titanium substrate at 900 ℃ in air

3 结论

1) 采用电弧离子镀技术在Ti-6.48Al-0.99Mo- 0.91Fe(质量分数,%) 钛合金表面制备了约32 μm 纯α-Ta(W)涂层,涂层连续、均匀、致密,与基体结合紧密。涂层由颗粒细小的α-Ta(W) (≤50 nm)颗粒堆积而成的100~250 nm等轴晶组成。涂层硬度为14.4~15 GPa,明显高于纯Ta涂层和基体的硬度。涂层与基体临界载荷为58.5 N,具有良好的塑性。

2) 钛合金基体经900 ℃大气循环氧化,形成层状带裂隙的Al2O3和TiO2疏松混合氧化膜,氧化膜经20次循环氧化后明显脱落,不能有效保护基体。

3) 沉积Ta-W涂层可明显提高钛合金基体抗900 ℃大气循环氧化性能。氧化过程中可在涂层表面形成以β-Ta2O5为主的致密氧化膜,WO3明显向大气挥发,O可固溶于涂层形成[Ta, O]相,循环氧化次数增加,氧化膜中TiO2、Al2O3增加并出现AlTaO4、AlWO4相。氧化过程中,氧化膜始终保持完整,基体得到有效保护。

4) 循环氧化过程中,基体Ti、Al元素向涂层方向扩散,涂层元素向氧化膜及基体同时扩散并固溶于基体,O元素通过氧化膜及涂层扩散、固溶于基体。氧化初期在界面形成AlTa2,Al2Ta3、Al3Ti、TixW1-x相,界面处形成富Ta、W、Al、O、α-Ti固溶体(稳定)区。涂层的失效主因为其元素的消耗(氧化及扩散并固溶于基体)。

REFERENCES

[1] LEYENS C, PETERS M. Titanium and titanium alloys[M]. Weinheim: Wiley-VCH, 2003: 297-298.

[2] 彭小敏, 夏长清, 王志辉, 黄 珍, 王金惠. TiAl 基合金高温氧化及防护的研究进展[J]. 中国有色金属学报, 2010, 20(6): 1116-1130.

PENG Xiao-min, XIA Chang-qing, WANG Zhi-hui, HUANG Zhen, WANG Jin-hui. Development of high temperature oxidation and protection of TiAl-based alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(6): 1116-1130.

[3] 彭小敏, 夏长清, 王金惠, 刘莹颖, 刘 娟. TC4钛合金沉积NiCrAlY涂层的氧化行为[J]. 中国有色金属学报, 2008, 18(4): 601-607.

PENG Xiao-min, XIA Chang-qing, WANG Jin-hui, LIU Ying-ying, LIU Juan. Oxidation behavior of TC4 titanium alloy with NiCrAlY coating[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(4): 601-607.

[4] PENG X M, XIA C Q, Dai X Y, WU A R, DONG L J, LI D F, TAO Y R. Ablation behavior of NiCrAlY coating on titanium alloy muzzle brake[J]. Surface Coating and Technology, 2013, 232: 690-694.

[5] COPLAND E H, GLEESON B, YOUNG D J. Formation of Z-Ti50Al30O20 in the sub-oxide zones of γ-TiAl based alloys during oxidation at 1000 ℃[J]. Acta Materialia, 1999, 47(10): 2937-2949.

[6] FARTHING T W. Development of titanium and its alloys[C]// Institution of Metallurgists (Course Volume), Series 3. London: Institution of Metallurgists, 1983: 9-31.

[7] LEYENS C, VAN LIERE J W, PETERS M, KAYSSER W A. Magnetron-sputtered Ti-Cr-Al coatings for oxidation protection of titanium alloys[J]. Surface Coating and Technology, 1998, 108/109(1/3): 30-35.

[8] UNDERWOOD J H, VIGILANTE G N, MULLIGAN C P, TODARO M E. Thermomechanically controlled erosion in army cannons: A review[J]. Journal of Pressure Vessel Technology, Transactions of the ASME, 2006, 128(2): 168-172.

[9] MENTHE E, RIE K T. Plasma nitriding and plasma nitrocarburizing of electroplated hard chromium to increase the wear and the corrosion properties[J]. Surface Coating and Technology, 1999, 112(1/3): 217-220.

[10] LI Huai-xue, CHEN Guang-nan, ZHANG Kun, LUO Geng-xing, YE Zhi-jun. Degradation failure features of chromium-plated gun barrels with a laser-discrete-quenched substrate[J]. Surface Coating and Technology, 2007, 201(24): 9558-9564.

[11] 彭小敏, 夏长清, 吴安如, 董丽君, 陶友瑞, 李东锋. 火炮身管烧蚀及其防护研究进展[J]. 四川兵工学报, 2014(3): 11-17.

PENG Xiao-min, XIA Chang-qing, WUAn-ru, DONG Li-jun, TAO You-rui, LI Dong-feng. Development of the ablation behavior and protection of gun barrel[J]. Journal of Sichuan Ordnance, 2014(3): 11-17.

[12] UNDERWOOD J H, VIGILANTE G N, MULLIGAN C P. Review of thermo-mechanical cracking and wear mechanisms in large caliber guns[J]. Wear, 2007, 263 (7/12): 1616-1621.

[13] LEE S L, DOXBEC M, MUELLER J, CIPOLLO M, COTE P. Texture, structure and phase transformation in sputter beta tantalum coating[J]. Surface Coatings and Technology, 2004, 177/178: 44-51.

[14] LEE S L, WINDOVER D, AUDINO M. MATSON D W, MCCLANAHAN E D. High-rate sputter deposited tantalum coating on steel for wear and erosion mitigation[J]. Surface Coatings and Technology, 2002, 149(1): 62-69.

[15] LEE S L, CIPOLLO M, WINDOVER D, RICKARD C. Analysis of magnetron-sputtered tantalum coatings versus electrochemically deposited tantalum from molten salt[J]. Surface Coatings and Technology, 1999, 120/121: 44-52.

[16] KOIVULUOTO H, VUORISTO P, NAKKI J. Structure and corrosion behavior of cold-sprayed tantalum coatings[C]// Proceedings of the International Thermal Spray Conference. United States: ASM International, 2009: 314-319.

[17] MYERS S, LIN J L, SOUZA R M, SPROUL W D, MOORE J J. The β to α phase transition of tantalum coatings deposited by modulated pulsed power magnetron sputtering[J]. Surface Coatings and Technology, 2014, 214: 38-45.

[18] LEE S L, WINDOVER D. Phase, residual stress, and texture in triode-sputtered tantalum coatings on steel[J]. Surface Coatings and Technology, 1998, 108/109(1/3): 65-72.

[19] MATSON D W, MCCLANAHAN E D, RICE J P. Effect of sputtering parameters on Ta coatings for gun bore applications[J]. Surface Coatings and Technology, 2000, 133/134: 411-416.

[20] PEREZ-PRADO M T, HINES J A, VECCHIO K S. Microstructural evolution in adiabatic shear bands in Ta and Ta-W alloys[J]. Acta Materialia, 2001, 49 (15): 2905-2917.

[21] CHEN C, WANG M P, WANG S, JIA Y L, LEI R S, XIA F Z, ZOU B, YU H C. The evolution of cold-rolled deformation microstructure of {001}<110> grains in Ta-7.5wt%W alloy foils[J]. Journal of Alloys and Compounds, 2012, 513: 208-212.

[22] MARTIN PETER M. Handbook of deposition technologies for films and coatings[M]. 3rd ed. Oxford: Elsevier, 2010: 297-313.

[23] CHANELIERE C, AUTRAN J L, DEVINE R A B , BALLAND B. Tantalum pentoxide(Ta2O5) thin films for advanced dielectric applications[J]. Materials Science and Engineering R, 1998, 22: 269-322.

[24] SURESH TELU, PATRA A, SANKARANARAYANA M, MITRA R, PABI S K. Microstructure and cyclic oxidation behavior of W-Cr alloys prepared by sintering of mechanically alloyed nanocrystalline powders[J]. International Journal of Refractory Metals and Hard Materials, 1998, 36(10): 1443-1450.

[25] LIN J, MOORE J J, SPROUL W D, LEE S L, WANG J. Effect of negative substrate bias on the structure and properties of Ta coatings deposited using modulated pulse power magnetron sputtering[J]. IEEE Transactions on Plasma Science, 2010, 38(11): 3071-3078.

[26] KNEPPER R, STEVENS B, BAKER S P. Effect of oxygen on the thermomechanical behavior of tantalum thin films during the β-α Phase transformation[J]. Journal of Applied Physics, 2006, 100(12): 123508.

[27] BRIANT C L, LASSILA D H. Effect of tungsten on the mechanical properties of tantalum[J]. Journal of Engineering Materials and Technology, Transactions of the ASME, 1999, 121(2): 172-177.

[28] ZHANG M, YANG B, CHU J, NIEH T G. Hardness enhancement in nanocrystalline tantalum thin films[J]. Scripta Materialia, 2006, 54(7): 1227-1230.

[29] 李美栓. 金属的高温氧化[M]. 北京:冶金工业出版社, 2001.

LI Mei-shuan. High temperature oxidation of metals[M]. Beijing: Metallurgy Industry Press, 2001.

[30] DU H L, DATTA P K, LEWIS D B, BURNELL-GRAY J S. Air oxidation behaviour of Ti-6Al-4V alloy[J]. Corrosion Science, 1994, 36(4): 631-642.

[31] SHABALIN IGOR L. Ultra-high temperature materials I[M]. London: Springer, 2014.

[32] NAGASAKI S, HIRABAYASHI M. Binary alloy phase-diagrams[M]. Tokyo: AGNE Gijutsu, 2002.

[33] DEADMORE D L, LOWELL C E. The effect of DT (oxidizing temperature minus cooling temperature) on oxide spallation[J]. Oxidation of Metal, 1977, 11: 91-107.

[34] WU S, CHAN H M, HARMER M P. Effect of alumina additions on microstructural aspects of the β to α transformation in tantalum (Ⅴ) oxide[J]. Journal of the American Ceramic Society, 2005, 88(9): 2369-2373.

[35] ZHOU J, ZHANG J, ZHANG X. Effect of Al2O3 addition on microstructure, thermal expansion and mechanical properties of Ta2O5 ceramics[J]. Key Engineering Materials, 2012, 512/515: 631-634.

(编辑 李艳红)

基金项目:国家自然科学青年基金资助项目(51101054);湖南省自然科学基金资助项目(14JJ3132);新金属材料国家重点实验室开放基金资助项目(2012-Z03)

收稿日期:2014-11-17;修订日期:2015-04-10

通信作者:彭小敏,讲师,博士;电话:0731-58688521;E-mail: tanfen1028@163.com