热处理对FeCrNi激光熔覆涂层显微组织和力学性能的影响

来源期刊:中国有色金属学报(英文版)2016年第8期

论文作者:龚福宝 沈骏 高润华 张涛 谢雄 李洋

文章页码:2117 - 2125

关键词:激光熔覆;显微组织;显微硬度;拉伸强度;热处理

Key words:laser cladding; microstructure; microhardness; tensile strength; heat treatment

摘 要:采用FeCrNi合金粉末在FV520B 钢的梯形槽内构建多道激光熔覆涂层,并研究热处理对FeCrNi激光熔覆涂层的显微组织和力学性能的影响。实验结果表明,1073 K到1273 K热处理的二次淬火效应能够细化基体材料的晶粒,从而除去熔合区和母材之间的硬度软区。当热处理温度为1073 K时,抗拉强度达到了最大值。然而这种高温热处理对涂层的耐磨性有一定程度的不利影响。

Abstract: The FeCrNi alloy powders were used on the dovetail groove of FV520B steel to fabricate the multilayer laser cladding layers. The effects of heat treatment on the microstructure and mechanical properties of FeCrNi layers were investigated. The results showed that the heat treatment at the temperature ranged from 1073 to 1273 K refined the grains of the substrate materials and removed the soft zone of hardness between the fused zone (FZ) and base material (BM) effectively mainly due to a secondary quench of heat treatment. When the temperature of heat treatment was 1073 K, the maximum ultimate tensile strength (UTS) values of the laser cladding component were obtained. However, the heat treatment at high temperature had a bad effect on wear resistance of coatings at some extent.

Trans. Nonferrous Met. Soc. China 26(2016) 2117-2125

Fu-bao GONG, Jun SHEN, Run-hua GAO, Tao ZHANG, Xiong XIE, Yang LI

State Key Laboratory of Mechanical Transmission, College of Material Science and Engineering, Chongqing University, Chongqing 400044, China

Received 9 August 2015; accepted 6 January 2016

Abstract: The FeCrNi alloy powders were used on the dovetail groove of FV520B steel to fabricate the multilayer laser cladding layers. The effects of heat treatment on the microstructure and mechanical properties of FeCrNi layers were investigated. The results showed that the heat treatment at the temperature ranged from 1073 to 1273 K refined the grains of the substrate materials and removed the soft zone of hardness between the fused zone (FZ) and base material (BM) effectively mainly due to a secondary quench of heat treatment. When the temperature of heat treatment was 1073 K, the maximum ultimate tensile strength (UTS) values of the laser cladding component were obtained. However, the heat treatment at high temperature had a bad effect on wear resistance of coatings at some extent.

Key words: laser cladding; microstructure; microhardness; tensile strength; heat treatment

1 Introduction

Laser cladding is an important technology for surface modification in industry. Compared with traditional welding methods, direct laser metal deposition has characteristics such as rapid solidification, high energy density, small heat affected zone, high repeatability and excellent controllability, contributed to particular microstructure and good mechanical properties [1-5]. Therefore, laser cladding has activated wide interests in many industrial areas, and has been applied to fabrication of near net shaped parts, surface coatings, repairing components, and production of functionally graded materials. However, compared with conventional processing methods, the production rate of laser cladding is relatively low. Therefore, this technology is usually used for repairing or constructing of high-value components with low production volume [6], like mending crack defects of compressors.

Fe-based alloy powders as coating materials possess economic and the same level of performance compared with Ni-based and Co-based alloys, these properties broaden the application of Fe-based alloy in laser cladding. ZHANG et al [7] obtained in situ TiC-VC reinforced Fe-based cladding layer on low carbon steel surface by laser cladding of Fe-Ti-V-Cr-C-CeO2 alloy powders, with higher hardness and better wear resistance. ZHOU and DAI [8] prepared Fe+50%WC (mass fraction) composite coating by laser induction hybrid rapid cladding (LIHRC) on steel substrate. They found that the microhardness of Fe-based WC composite coating was three times higher than that of the substrate. Generally, although the hardness and wear resistance of the laser coatings had been improved, the ductility and toughness of them decreased, which increased the tendency of cracks. Therefore, a few special metal elements were added into Fe-based alloy powders in order to improve the microstructure of the alloy coatings. For example, FeCrBSi alloy powders with higher Cr content were clad on the substrates to increase the ductile property, lower the thermal expansion coefficient, and reduce the crack sensitivity of the cladding layers [9]. HOU [10] presented a study on effects of Mo element on the microstructure and mechanical properties of Fe-based alloy coatings. The best abrasive wear resistance and thermal shock resistance were achieved in the 4% Mo-added coating. HAN et al [11] mixed Cr3C2 into Fe-based powders and found that the microhardness and the wear resistance of the coatings increased, and the coefficients of friction decreased with the change of Cr3C2 content in the composite coatings. According to these researches mentioned above, it can be seen that addition of Mo, Ni and other elements into Fe-based alloy powders increased the ductile regions and decreased the cracking susceptibility of the coatings.

Although addition of alloying elements improved the microstructure and mechanical properties of the coatings, the thermal damage of laser cladding process still resulted in the formation of a soft zone at the outer of heat-affected zone (HAZ) and then limited the life of fixed parts. FARABI et al [12] and ZENG et al [13] both mentioned this phenomenon and believed that the soft zone was one of crack sources. This was because the failure in most situations of their researches happened at soft zone rather than at the fused zone in the tensile samples after the laser coatings. Hence, it is important to eliminate the soft zone for the purpose of enhancing the mechanical properties and extending service life of the laser-clad components.

However, the reports about the effects of the heat treatment on the soft zone at the outer of heat-affected zone and the relationship between the soft zone and the UTS value of the laser cladding components are still limited. Based on the fact that FeCrNi coatings have excellent cladding properties such as the low thermal expansion coefficient and crack sensitivity, FeCrNi superalloy metallurgy powder was chosen as the cladding material. So, in this work, in order to further settle the problems in laser cladding, a study was designed to investigate the influence of heat treatment on the microstructure and mechanical properties of FeCrNi coatings produced by laser cladding for removing soft zone.

2 Experimental

The substrate material used in this research was the FV520B steel (<70.7% Fe, <17.8% Cr, <8.2% Ni, provided by Baosteel Group, China), which has excellent mechanical properties and good cladding properties. The cladding material is self-made FeCrNi superalloy metallurgy powders with a size between 150 and 200 μm. The actual chemical composition of the powders was analyzed by an X-ray fluorescence spectrometer (XRF-800CCDE, made by Shimadzu Corporation, Japan) and the results are listed in Table 1.

Table 1 Chemical composition of cladding material (mass fraction, %)

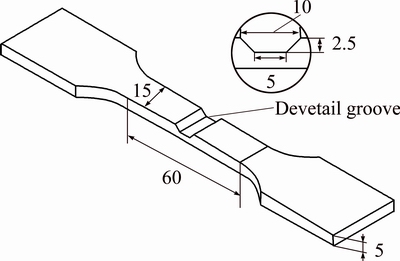

Substrate plates (170 mm × 100 mm) used for the experiments were cut down from a rolled plate with a thickness of 5 mm. Prior to cladding, in order to avoid the influence of impurities on the surface (such as surface contaminates and the oxides film) in the cladding tests, the surface of the samples was polished lightly with diamond powders and then cleaned with a solution of pure C2H5OH. Before the cladding tests, the cladding materials were kept in the drying oven at 373 K for 2 h in order to get rid of the moisture. Six plates with a dovetail groove were machined from the rolled plate. An uncoaxial powder-feeding laser cladding process was employed at a same power (1300 W), powder feed rate (8 g/min) and laser spot (3 mm × 3 mm) for all the plates. The samples were annealed at 973, 1073, 1173, 1273, 1373 and 1473 K, respectively for 2 h followed by cooling in still air. Then, three tensile specimens were cut down from each plate transversely to the cladding track to conduct static tensile tests. Figure 1 shows the schematic drawing of a tensile piece with a repaired dovetail groove. The tensile tests were carried out with a tensile test machine (SANS XYA105C) at room temperature and the tensile direction was perpendicular to the cladding track. Three tensile test results were collected in samples with the same heat treatment temperature and the average values of them were adopted for discussion. After tensile tests, the samples were sectioned carefully and the cross-sections of the cladding track were prepared by using standard metallographic procedures (grinding, polishing and etching with a solution of 33% HF + 67% HNO3 for 30-60 s). An optical microscope (MDJ200) and a scanning electron microscope (TESCAN, Inc. VegaIIL MU SEM) were used for microstructural observations. Energy dispersive X-ray spectroscopy (OXFORD, Inc. ISIS300) and XRD (Rigaku D/max 2500PC) were used to determine the phases formed in the cladding coatings. The microhardness tests were performed with a Vickers hardness tester (V-1000) with a period of 20 s, a load of 300 g and a step size of 0.2 mm. The values of the microhardness of the fused zone (FZ) and HAZ were made from an average value of three data points. A high-speed reciprocating friction tester (HSR-2M) was used to obtain the friction coefficient curve of the coatings under different processing temperatures.

Fig. 1 Schematic drawing of tensile piece with repaired dovetail groove (unit: mm)

3 Results and discussion

3.1 Influence of heat treatment on microstructure of FeCrNi layers coated by laser cladding

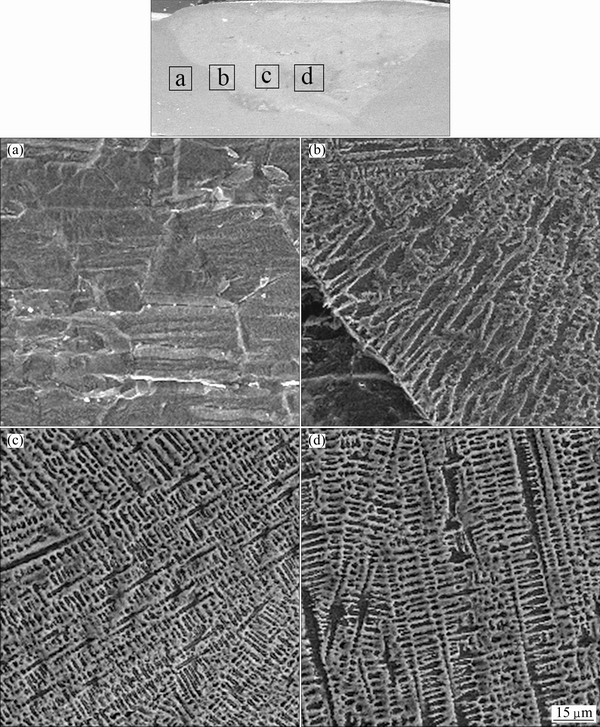

Figure 2 shows the typical microstructures of the base metal and the coatings at 973 K for 2 h. The clad joint was mainly composed of a base material (BM), a narrow heat affect zone (HAZ) and a fused zone (FZ) area. The BM was characterized by a typical martensitic structure (the average grain size is about 40 μm), as shown in Fig. 2(a). The FZ mainly consisted of a fine and uniform dendrite growing epitaxially from the substrates (Fig. 2(b)). The growth direction of the dendrites tended to be perpendicular to the horizontal direction in the case that they were closed to the central part of laser cladding coatings (Fig. 2(d)).

In this work, FeCrNi powders were deposited on the dovetail grooves of the substrate (FV520B). So, heat diffused not only from the deposits at the back of the melt pool, under the pool and the coatings, but also at the lateral of the substrate. Therefore, the resultant heat flux direction was not perpendicular to the substrate [14] or at a simple angle of more than 45° and less than 90° with the substrate [15]. Hence, the growth direction of the dendrites was opposite to the combination of many direction of the heat loss.

Fig. 2 SEM images of base metal and coatings annealed at 973 K for 2 h

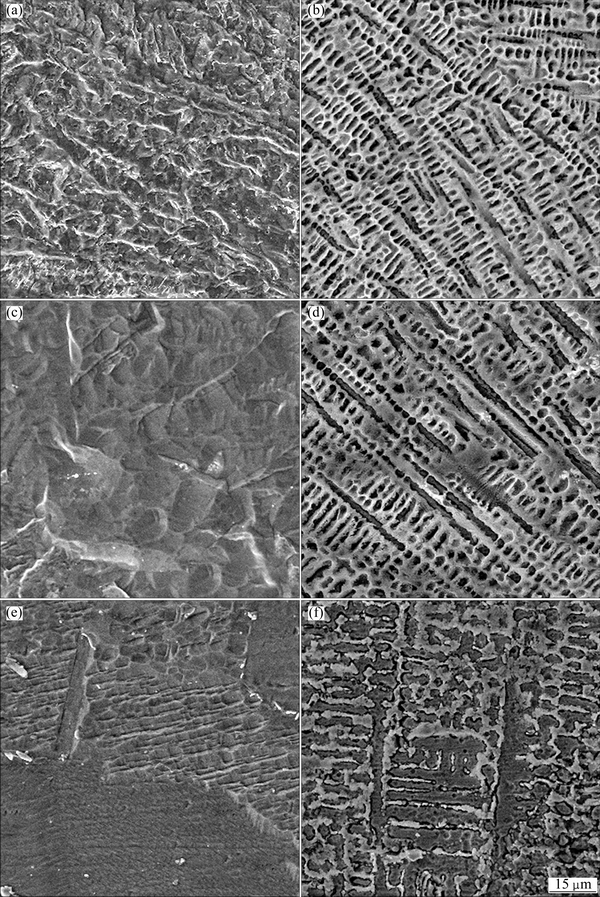

Fig. 3 SEM images of base material areas (a, c and e) and fusion zones (b, d and f) suffered heat treatment at temperatures of 1073 K (a, b), 1273 K (c, d) and 1373 K (e, f) for 2 h

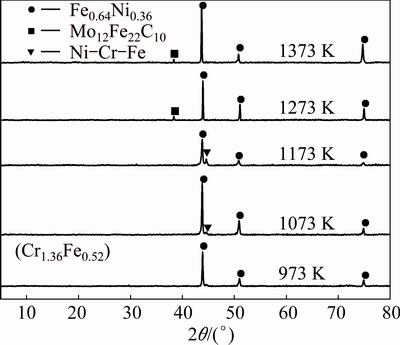

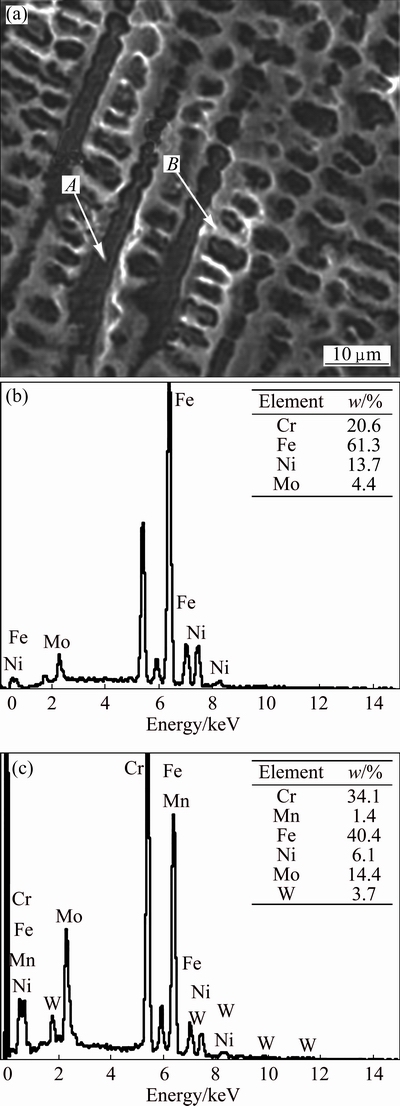

Figure 3 shows the SEM images of the base material areas (Figs. 3(a), (c) and (e)) and the fusion zones (Figs. 3(b), (d) and (f)) suffered heat treatment at the temperatures of 1073, 1273 and 1373 K. From Fig. 3(a), the martensitic grains in BM were finer than those of BM which suffered the heat treatment at lower temperature (see Fig. 2). Moreover, the grains of coatings mainly consisted of gray dendrites (Fig. 3 (b)). Figure 4 shows the results of the XRD pattern for the coatings at different annealing temperatures. In Ref. [16], Cr23C6, (FeCr)7C3 and other phases could not be reliably identified from the pattern due to the apparent absence of their other important peaks in the pattern, while Mo12Fe22C10 and Cr1.36Fe0.52 phases were identified clearly. According to the EDS results of the coatings at the temperature of 1173 K (Fig. 5), the black precipitated phase in Region A included Cr-Fe-Ni, Ni2Cr(γ′) and γ-(Fe,Ni), which were also confirmed by YANG et al [17]. The difference was that Cr-Fe-Ni was the only Fe-rich phase in their work. Based on the EDS result of Fig. 5(c), the gray net-like microstructures in the Region B were η-type carbides (e.g. M6C, M23C6) and other high melting temperature dendrites. These brittle hard phases (like Fe3C) were surrounded by low melting point Cr-Fe-Ni, Ni2Cr(γ′) and γ-(Fe,Ni). When the annealing temperature was elevated further to 1273 K, the martensite and gray dendrites grains started to coarsen (Figs. 3(c) and (d)). In the case that the temperature reached 1373 K, the BM obtained a dual phase structure of ferrite and martensite, the grey dendrites of the FZ also transformed into the black austenite (Figs. 3(e) and (f)).

Fig. 4 XRD patterns of fusion zones after heat treatment at different temperatures for 2 h

Based on the fact that A3 point of FV520B where the ferrite fused into austenite in heating process completely was about 1023 K, the heat treatment at 1073 K for 2 h followed by cooling in still air was a secondary quenching on the BM actually. Hence, the grains of the substrate became fine finally. But when the temperature of heat treatment was higher than 1073 K, the substrate became coarse martensite and even a dual phase structure includes ferrite and martensite. In this case, the coatings mainly consisted of gray net-like η-type carbides (e.g., M6C, M23C6) and other high melting temperature dendrites with other elements in solid solutions. But when the temperature was more than 1273 K, the austenite grains started to coarsen, and then the dendrites gradually fused into the ash black γ phase, obtaining a relevant supersaturated austenite (Cr1.36Fe0.52 and Fe0.64Ni0.36) structure after being cooled in still air.

Fig. 5 SEM image of fusion zone annealed at 1173 K for 2 h and relevant EDS results

3.2 Influence of heat treatment on mechanical properties of FeCrNi layers coated by laser cladding

3.2.1 Microhardness analyses

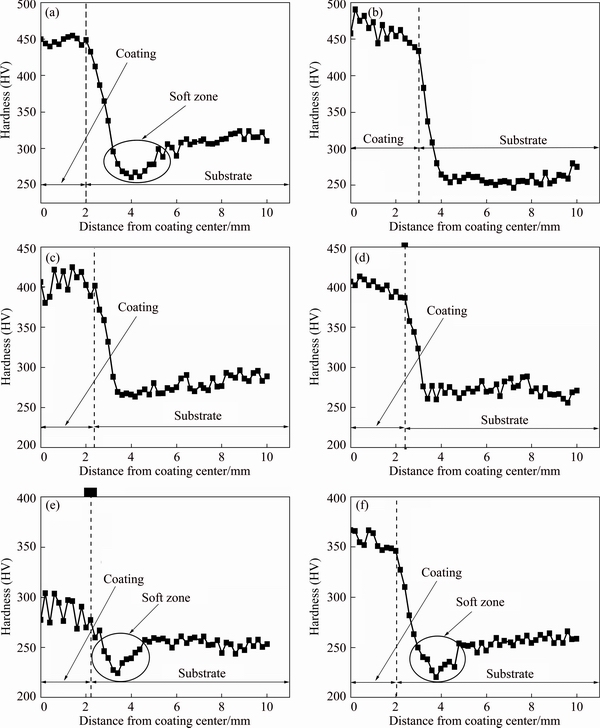

Figure 6 shows the results of microhardness tests profiles measured along the mid-thickness line of the cross-section of the base metal and the coatings under different heat treatments. For heat treatment at 973 K for 2 h, the soft zone of the microhardness between the FZ and BM regions had emerged (Fig. 6(a)). In the case of the temperature ranged from 973 K to 1073 K, the microhardness of substrate decreased from HV 300 to HV 250, while the microhardness of coatings showed a small rise (Fig. 6(b)). Moreover, when the annealing temperature was further elevated from 1173 K to 1273 K, the microhardness profile of the substrate barely changed (Figs. 6(c) and (d)). But when the annealing temperature was higher than 1373 K, the hardness of coatings decreased rapidly, while the hardness of substrate still remained about HV 250, and the soft zone of the microhardness between the FZ and BM regions emerged again, as shown in Figs. 6(e) and (f). It was also found that with the heat treatment temperature increasing, the hardness of coatings changed in a big range (HV 300-500), but a small range (HV 250-350) change happened in the hardness of substrates.

Fig. 6 Typical microhardness profiles of cladding samples annealed at temperatures of 973 (a), 1073 (b), 1173 (c), 1273 (d), 1373 (e), and 1473 K (f) for 2 h, respectively

The 973 K was lower than A3 point, so the heat treatment at 973 K for 2 h was actually an annealing process. The soft zone of interface contributed to the coarsening of grains during the laser cladding process and the annealing process (Fig. 2(b)). The similar phenomenon was also observed by DINDA et al [15]. It is well known that the laser cladding process resulted in the remarkable enhancement of hardness, and also led to the formation of the soft zone in the outer HAZ. However, the soft zone disappeared as the grains of the HAZ became uniform and fine when temperature was more than 1073 K. But when the temperature increased to 1173 K, the Ni2Cr(γ′) in the coatings transformed to a stable and incoherent austenite γ-(Fe,Ni) with Cr in solid solution. The solution strengthening effect of γ-(Fe,Ni) may be lower than that of Ni2Cr(γ′) due to the structure nature of coherent Ni2Cr(γ′), so the microhardness of the coatings decreased by about HV 50. When the temperature of heat treatment was above 1273 K, the soft zones appeared again as the grains of the interface coarsened due to the phenomenon of the recrystallization. However, as seen from Fig. 6, in a whole, the decrease in hardness of the coatings could be attributed to the enlargement of austenite phase, the coarsening of grains and the transformation of precipitates when the temperature of heat treatment ranged from 1073 K to 1473 K. The change of hardness in the small range for the HAZ and BM was because the Ac3 point of FV520B was about 1073 K, so process of heat treatment above 1073 K was a secondary quench as a fact, contributing to the formation of the martensite and retained austenite in HAZ/BM. Moreover, the small decrease of microhardness of the coatings was a result of the growth of austenite grains with the increase of annealing temperature. Especially under heat treatment at 1073 K, the substrate suffered a secondary quench and its grains also were fined, but its hardness was lower than that of the substrate at 973 K. The reason of the phenomena has been not clear so far. It might be concluded that the heat treatment with the temperature ranged from 1073 K to 1273 K removed the soft zone of hardness validly for laser cladding parts due to a secondary quench of heat treatment, however, when the temperature was more than 1273 K, the soft zones appeared again as a result of the phenomenon of the recrystallization.

3.2.2 Tensile strength analyses

The effects of different annealing temperatures on ultimate tensile strength (UTS) value of the samples are depicted in Fig. 7. The UTS value of FV520B substrate was approximately 1125 MPa. During the increase of annealing temperatures, the UTS value of samples of the laser cladding obtained the maximum value at 1073 K, then it took on the decreasing trend.

From the microstructural analyses, the heat treatment with the temperature ranged from 1073 K to 1273 K made the grains of the interface between BM and the coatings finer than the relevant grains suffered the heat treatment at the lower temperature. The microhardness test results indicated that the heat treatment with the temperature ranged from 1073 K to 1273 K also removed the soft zone between the FZ and BM. However, based on the results of Fig. 7, it was found that microstructural change and the disappearance of the soft zone had an effect on the UTS value of the laser cladding significantly. This probably was because the heat treatment decreased the hardness of the substrate materials and changed the microstructure of the coatings and the substrate materials.

Fig. 7 Influence of heat treatment temperature on UTS value of components produced by laser cladding

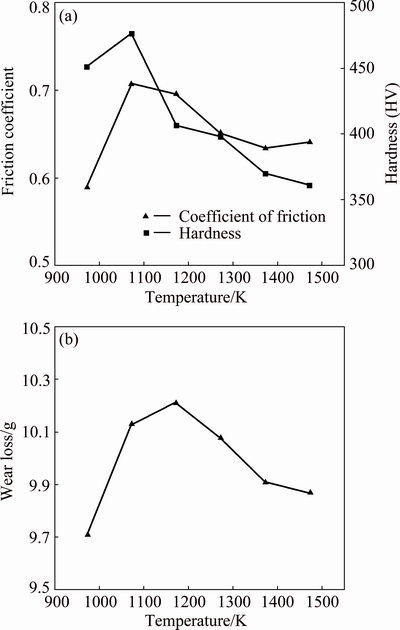

Fig. 8 Average hardness, friction coefficient (a) and wear loss (b) of coatings with period of 20 s, load of 300 g and step size of 0.2 mm at different heat treatment temperatures

3.2.3 Friction coefficient and wear loss analyses of coatings

Figure 8 shows the average friction coefficient values, the average hardness value and wear loss of the coatings with a period of 20 s, a load of 300 g and a step size of 0.2 mm at different temperatures of heat treatment. When the temperature of heat treatment was 973 K, the friction coefficient was 0.59, then it obtained a maximum value 0.7, and finally decreased to 0.64 with increasing the temperature of heat treatment. However, when the temperature of heat treatment was 1073 K, the hardness of coatings was HV 450, then it got a maximum value HV 470, and decreased. The wear loss of the coatings showed the similar change trend to the average friction coefficient.

According to molecular-kinetic and mechanical model theories of the fictional behavior of elastomeric materials, the value of the friction coefficient is negatively related to the hardness of the coating surface at some extent [18]. However, the fictional behavior of coatings suffered heat treatment was different, and the microstructure of coatings had changed, especially when temperature of heat treatment was more than 1073 K. As discussed above, when the temperature of heat treatment was elevated to 1073 K, many hard brittle phases which had high melting temperature were still reserved and acted as a function of skeleton, while the austenitic phase started to enlarge and became the soft zone of the skeleton, which enhanced wear resistance performance of coatings significantly. It can give the reasonable explanation why the change trend of the friction coefficient was consistent to the wear loss change of the coatings in Fig. 8(b). However, the value of friction coefficient still was more than 0.6 compared with that of coatings at the heat treatment temperature of 973 K, so the heat treatment with the high temperature had a bad effect on wear resistance of coatings relatively.

4 Conclusions

1) The heat treatment with the temperature ranged from 1073 K to 1273 K refined the grains of the substrate materials effectively and removed the soft zone between the FZ and BM due to a secondary quench of heat treatment.

2) The elimination of the soft zone can improve the UTS of the laser cladding components when the temperature of heat treatment was proper, but the high temperature heat treatment had a bad influence on wear resistance of laser cladding layers at some extent.

References

[1] ALAM M M, KAPLAN A F H, TUOMINEN J, VUORISTO P, MIETTINEN J, POUTALA J. Analysis of the stress raising action of flaws in laser clad deposits [J]. Mater Des, 2013, 46: 328-337.

[2] FARAYIBI P, FOLKES J, CLARE A, OYELOLA O. Cladding of pre-blended Ti-6Al-4V and WC powder for wear resistant applications [J]. Surf Coat Technol, 2011, 206: 372-377.

[3] YILBAS B, AKHTAR S, KARATAS C. Laser surface treatment of Inconel 718 alloy: Thermal stress analysis [J]. Opt Lasers Eng, 2010, 48: 740-749.

[4] WANG F, MEI J, WU X H. Compositionally graded Ti6Al4V+ TiC made by direct laser fabrication using powder and wire [J]. Mater Des, 2007, 28: 2040-2046.

[5] ZHANG Jian, HU Yu, TAN Xiao-jun, GUO Liang, ZHANG Qing-mao. Microstructure and high temperature tribological behavior of laser cladding Ni60A alloys coatings on 45 steel substrate [J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 1525-1532.

[6] WALL M B, ULRICH K T, FLOWERS W C. Evaluating prototyping technologies for product design [J]. Res Eng Des, 1992; 3: 163-177.

[7] ZHANG H, ZOU Y, ZOU Z D, WU D T. Microstructure and properties of Fe-based composite coating by laser cladding Fe-Ti-V-Cr-C-CeO2 powder [J]. Opt Laser Techno, 2015, 65: 119-125.

[8] ZHOU S F, DAI X Q. Microstructure evolution of Fe-based WC composite coating prepared by laser induction hybrid rapid cladding [J]. Appl Surf Sci, 2010, 256: 7395-7399.

[9] WANG Y B, ZHAO S S, GAO W Y, ZHOU C Y, LIU F, LIN X C. Microstructure and properties of laser cladding FeCrBSi composite powder coatings with higher Cr content [J]. J Mater Process Technol, 2014, 214: 899-905.

[10] HOU Q Y. Influence of molybdenum on the microstructure and properties of a FeCrBSi alloy coating deposited by plasma transferred arc hardfacing [J]. Surf Coat Technol, 2013, 225: 11-20.

[11] HAN B, LI M Y, WANG Yong. Microstructure and wear resistance of laser clad Fe-Cr3C2 composite coating on 35CrMo steel [J]. Mater Eng Perform, 2013, 22: 3749-3754.

[12] FARABI N, CHEN D L, LI J, ZHOU Y, DONG S J. Microstructure and mechanical properties of laser welded DP600 steel joints [J]. Mater Sci Eng A, 2010, 527: 1215-1222.

[13] ZENG C, TIAN W, LIAO W H, HUA L. Study of laser cladding thermal damage: A quantified microhardness method [J]. Surf Coat Technol, 2013, 236: 309-314.

[14]  M, BEZENCON C, CANALIS P, KURZ W. Single-crystal laser deposition of superalloys: Processing– microstructure maps [J]. Acta Mater, 2001, 49: 1051-1062.

M, BEZENCON C, CANALIS P, KURZ W. Single-crystal laser deposition of superalloys: Processing– microstructure maps [J]. Acta Mater, 2001, 49: 1051-1062.

[15] DINDA G P, DASGUPTA A K, MAZUMDER J. Laser aided direct metal deposition of Inconel 625 superalloy: Microstructural evolution and thermal stability [J]. Mater Sci Eng A, 2009, 509: 98-104.

[16] SHANG S, WELLBURN D, SUN Y Z, WANG S Y, CHENG J, LIANG J. Laser beam profile modulation for microstructure control in laser cladding of an NiCrBSi alloy [J]. Surf Coat Technol, 2014, 248: 46-53.

[17] YANG J X, MIAO X H, WANG X B, YANG F. Influence of Mn additions on the microstructure and magnetic properties of FeNiCr/60% WC composite coating produced by laser cladding [J]. Int J Refract Met Hard Mater, 2014, 46: 58-64.

[18] MOORE D F. The friction and lubrication of elastomer [M]. Oxford: Pergamon, 1972.

龚福宝,沈 骏,高润华,张 涛,谢 雄,李 洋

重庆大学 材料科学与工程学院,机械传动国家重点实验室,重庆 400044

摘 要:采用FeCrNi合金粉末在FV520B 钢的梯形槽内构建多道激光熔覆涂层,并研究热处理对FeCrNi激光熔覆涂层的显微组织和力学性能的影响。实验结果表明,1073 K到1273 K热处理的二次淬火效应能够细化基体材料的晶粒,从而除去熔合区和母材之间的硬度软区。当热处理温度为1073 K时,抗拉强度达到了最大值。然而这种高温热处理对涂层的耐磨性有一定程度的不利影响。

关键词:激光熔覆;显微组织;显微硬度;拉伸强度;热处理

(Edited by Yun-bin HE)

Foundation item: Project (51375511) supported by the National Natural Science Foundation of China, Project (CDJZR14130008) supported by the Fundamental Research Funds for the Central Universities of China; Project (CDJZR13130033) supported by the Fundamental Research Funds for the Central Universities of China; Project (CDJZR13130080) supported by the Fundamental Research Funds for the Central Universities of China

Corresponding author: Jun SHEN; Tel: +86-13883111150; E-mail: shenjun@cqu.edu.cn

DOI: 10.1016/S1003-6326(16)64328-5