DOI:10.19476/j.ysxb.1004.0609.2018.11.03

7075铝合金搅拌摩擦焊工艺对接头沉淀相析出行为影响

姜 月1, 2,朱 浩1, 2,刘家伦1, 2,赵熠朋1, 2,王 军3

(1. 石家庄铁道大学 材料科学与工程学院,石家庄 050043;

2. 河北省交通工程材料重点实验室,石家庄 050043;

3. 河北科技大学 材料科学与工程学院,石家庄 050018)

摘 要:采用搅拌摩擦焊(FSW)对厚度为6mm的7075铝合金进行不同工艺下的平板对接试验,使用光学显微镜、显微硬度仪、X射线衍射仪(XRD)及透射电镜(TEM)对接头微观组织、显微硬度及沉淀相种类与形貌进行分析。结果表明:接头中沉淀相主要有棒状MgZn2、椭圆状AlCuMg以及胶囊状Al2CuMg三种,AlCuMg和Al2CuMg强化效果好于MgZn2的。焊核区(WNZ)中沉淀相主要是AlCuMg与Al2CuMg,显微硬度较高;相比WNZ,热机影响区(TMAZ)中沉淀相AlCuMg和Al2CuMg相对较少,MgZn2相对较多,显微硬度降低;热影响区(HAZ)中的MgZn2相对更多,显微硬度进一步降低。随着转速(ω)的增加,WNZ和TMAZ中沉淀相尺寸增大,显微硬度先升高后降低;HAZ中沉淀相尺寸和数量变化不大。随着焊速(v)的增加,WNZ、TMAZ和HAZ中沉淀相数量增多、尺寸变小,显微硬度有所上升。

关键词: 7075铝合金;搅拌摩擦焊工艺;沉淀相

文章编号:1004-0609(2018)-11-2191-08 中图分类号:TG457.14 文献标志码:A

7075铝合金是Al-Zn-Mg-Cu系可热处理强化铝合金,其强度高、塑性好,广泛应用于航空航天、载运工具等领域。传统熔焊方法对其连接时容易产生气孔、热裂纹及HAZ软化等问题[1]。搅拌摩擦焊(Friction stir welding,简称FSW)是英国焊接研究所(The welding institute)于1991年开发的一种针对高强铝合金焊接性差的新型固相焊接技术。与传统的焊接方法相比,FSW具有优质、高效、低耗、焊接变形小、无污染等特点[2]。

目前,国内外学者关于铝合金FSW的研究方向主要有FSW接头微观组织及力学性能[3-7]、焊接工艺参数[8-9]、温度场和应力场的数值模拟[10-11]以及疲劳性能[12-13]等几个方面。而国内外关于铝合金中沉淀相的研究仅涉及未焊铝合金板材[14]和焊接接头沉淀相强化机制[15-17]等方面。然而,7075铝合金是时效强化铝合金,目前关于7075铝合金FSW接头沉淀相析出行为的研究甚少,这对于优化FSW焊接工艺、提高接头性能及保证铝合金结构安全可靠性具有重要的意义。

本文作者借助TEM对不同工艺参数下7075铝合金FSW接头的沉淀相形貌、分布等进行观察,并对沉淀相的晶格条纹间距进行测量,进而对沉淀相种类进行精确表征,以研究工艺参数对7075铝合金FSW接头不同微区沉淀相种类、尺寸、分布等的影响规律,进而指导FSW焊接工艺。

1 实验

实验材料选用厚度为6mm的7075高强铝合金挤压板材,供货状态为T6。焊件尺寸为300 mm×150 mm×6 mm,采用平板对焊的焊接方式。使用的搅拌头轴肩直径为15 mm,搅拌针长度为5.66 mm,搅拌针根部直径为5.20 mm,端部直径为3.10 mm。FSW焊接工艺参数如下:搅拌头旋转速度分别为600、800、1000 r/min,焊接速度分别为200、250、300 mm/min。金相试样腐蚀剂为Keller试剂,腐蚀时间为30 s。利用GX51型OLYMPUS金相显微镜观察FSW接头不同微区的微观组织。利用HVS-1000型数显显微硬度仪测试显微硬度分布。利用D8 ADVANCE 型XRD对合金进行物相分析。利用MTP-1A型磁力驱动电解双喷减薄器对TEM试样减薄至穿孔,双喷液成分为100 mL硝酸+300 mL甲醇,双喷温度为-30 ℃。利用JEM-2100型TEM对不同工艺参数下FSW接头焊核区(WNZ)、热机影响区(TMAZ)、热影响区(HAZ)以及母材(BM)中的沉淀相分布、尺寸和数量等进行观察,利用Digital Micrograph软件测量沉淀相的晶格条纹间距。

2 实验结果

2.1 接头微观组织及力学性能

不同焊接工艺下获得的接头不同微区组织如图1所示。从图1可以看出,不同焊接工艺的7075铝合金FSW接头均由WNZ、TMAZ及HAZ组成,接头的组织分布是极不均匀的。图1(a)所示为BM组织,板材经过挤压后,晶粒组织呈纤维状。长度方向上尺寸在200 μm左右,厚度方向上仅有30 μm左右。图1(b)所示为WNZ组织,由于搅拌头机械搅拌和焊接热作用,发生动态再结晶,晶粒呈细小的等轴晶,尺寸仅有2~3 μm。图1(c)所示为TMAZ组织,与BM相比,该区域晶粒在搅拌头机械搅拌带动下发生一定程度塑性变形,其晶粒取向发生一定的变化。图1(d)所示为HAZ组织,与BM相比,HAZ晶粒在热输入的影响下在宽度方向上发生了一定程度的粗化。

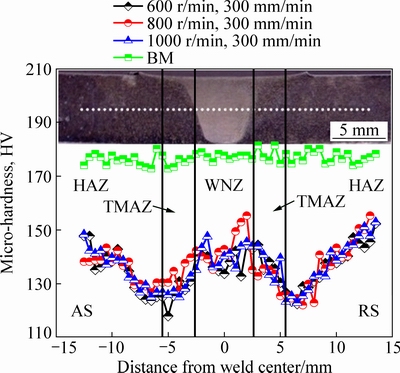

图2所示为焊速v一定、不同转速ω下FSW接头显微硬度分布。图3所示为ω一定,不同v下FSW接头显微硬度分布。从图2和图3可以明显看出,与BM相比,接头显微硬度明显低于BM,且分布极不均匀,呈现不对称的“W”型分布。通过图1(b)可以看出,WNZ的晶粒细小,但其显微硬度相比BM下降。下文基于纳观尺度,利用TEM对FSW接头不同微区沉淀相析出行为进行研究。

2.2 接头沉淀相种类及形貌

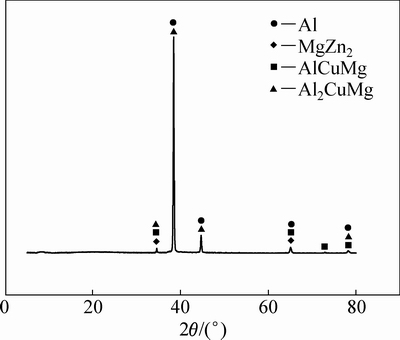

7075铝合金XRD分析结果如图4所示。从图4可以看出,合金中沉淀相主要包括MgZn2、AlCuMg和Al2CuMg相。

7075铝合金FSW接头中沉淀相形貌图如图5所示。从图可以看出,沉淀相基本上分为3种形貌:棒状、椭圆状以及胶囊状。为了进一步确定这3种形貌沉淀相的种类,对3种形貌沉淀相的晶格条纹进行观察。晶格条纹是晶体中不同晶面所成的像,通过测量晶格条纹间距,可以确定沉淀相的种类[18]。不同形态沉淀相晶格条纹形貌及测量结果如图6所示。

图1 搅拌摩擦焊接头的微观组织

Fig. 1 Microstructures of FSW joints

图2 焊速为300 mm/min时转速对接头显微硬度的影响

Fig. 2 Effect of rotation speed on microhardness of joints at weld speed of 300 mm/min

图3 转速为1000 r/min时焊速对接头显微硬度的影响

Fig. 3 Effect of weld speed on microhardness of joints at rotation speed of 1000 r/min

图4 7075铝合金的XRD分析结果

Fig. 4 XRD result of 7075 Al alloy

从图6可以看出,利用Digital Micrograph软件测量3种不同形貌沉淀相的晶格条纹间距如下:椭圆状沉淀相(4 0 11)晶面的晶面间距d=0.8900 nm,棒状沉淀相(3 3 2)晶面的晶面间距d=0.8530 nm,胶囊状沉淀相(2 2 5)晶面的晶面间距d=0.9000 nm,通过与标准相的晶面间距结果进行比较,确定椭圆状沉淀相是AlCuMg,棒状沉淀相是MgZn2,胶囊状沉淀相是Al2CuMg。

图5 沉淀相的形貌

Fig. 5 Morphology of precipitated phase

图6 沉淀相的晶格条纹

Fig. 6 Lattice fringe of precipitated phase

同时,通过TEM观测到了接头无析出区(PFZ),如图7所示。由于接头的晶界附近无析出区的存在,缺少沉淀强化作用,所以会在一定程度上降低接头的力学性能,这也是导致接头显微硬度低于BM的原因之一。

2.3 工艺参数对沉淀相分布的影响

由文献[19-20]可知,6 mm厚7075铝合金FSW接头WNZ区温度范围为446~500 ℃,TMAZ的温度范围为393~446 ℃,HAZ的温度范围为340~393 ℃。根据Al-Zn-Mg-Cu系铝合金相图可知370~465 ℃是Al2CuMg的析出温度范围,320 ℃以下是MgZn2的析出温度范围。

图8为接头沉淀相分布对比图。从图8中可以看出,WNZ中的AlCuMg、Al2CuMg的数量占多数,同时也有少量的MgZn2析出。所以,虽然WNZ晶粒比BM小,但显微硬度低于BM。与WNZ相比,由于TMAZ峰值温度低于WNZ,所以TMAZ中AlCuMg、Al2CuMg的数量相对减少,棒状沉淀相MgZn2的数量相对增多,而MgZn2的强化效果相对AlCuMg、Al2CuMg较差,所以TMAZ的显微硬度相比WNZ有所下降。同时,从图1(c)可以看出,TMAZ的晶粒呈纤维状,有一定的塑性变形痕迹,可以推测TMAZ中可能含有一定数量的位错,这在一定程度上起到了形变硬化的效果。但综合来看,相比于位错强化,沉淀相种类、数量等对显微硬度的影响较显著。与TMAZ相比,HAZ的温度位于MgZn2的析出温度区间,棒状沉淀相MgZn2的数量相比TMAZ的增多,AlCuMg与Al2CuMg的数量相对减少。同时,从图1(d)还可以看出,相比于TMAZ,HAZ的晶粒在焊接过程中几乎没有塑性变形痕迹,形变硬化的作用减弱,所以HAZ的显微硬度进一步降低,同时受热作用和晶粒粗化程度的影响,HAZ与TMAZ交界处显微硬度达到整个接头的最低值。

图7 接头无析出区形貌

Fig. 7 Morphology of PFZ in joints

2.3.1 转速对沉淀相分布的影响

在v=300 mm/min时不同ω下的FSW接头WNZ、TMAZ与HAZ中沉淀相分布对比如图8所示。

从图8(a)、(c)、(e)中可以看出,v为300 mm/min时,随着ω的增大,接头WNZ中沉淀相的尺寸变大,数量增多。这是由于随着ω的增大,热输入不断增大,使得沉淀相聚集长大。同时,随着ω的增大,搅拌针的机械破碎作用增强,晶粒细化程度增加,细晶强化使WNZ显微硬度增加,而随着ω的继续增大,热输入不断增大,使得沉淀相聚集长大更加明显,所以综合作用下,WNZ显微硬度先升高后降低。

从图8(b)、(d)、(f)中可以看出,v为300 mm/min时,接头TMAZ中沉淀相的尺寸随着ω的增大而增大。这是因为随着ω的增大,热输入增大,沉淀相聚集长大。同时随着ω的增大,晶粒塑性变形程度增加,晶粒取向变形更加明显,形变硬化使显微硬度升高,然而随着ω继续增加,热输入增加明显,TMAZ沉淀相尺寸受热输入影响而增加,沉淀相聚集长大明显,抵消了一部分形变硬化的效果,所以综合来看,TMAZ显微硬度先升高后降低。

从图8(g)、(h)、(i)中可以看出,随着ω的增大,接头HAZ中的沉淀相尺寸、数量与分布变化不大。这是由于HAZ距离搅拌头比较远,所以热输入的增大对HAZ中的沉淀相影响很小,沉淀相不易发生聚集长大,HAZ显微硬度变化不大。

2.3.2 焊速对沉淀相分布的影响

ω=1000 r/min时不同v下的FSW接头WNZ、TMAZ与HAZ沉淀相分布对比如图9所示。

从图9中可以看出,ω为1000 r/min时,随着v的增加,接头WNZ、TMAZ与HAZ中沉淀相数量增多,尺寸变小。这是因为随着v增大,FSW焊接过程中各微区热输入降低,使得沉淀相不容易聚集长大,沉淀强化效果较好。所以v增加,显微硬度有所上升。

3 结论

1) 通过透射电镜对7075铝合金FSW接头中沉淀相的晶格条纹进行观测,以实现沉淀相种类的精确表征。

2) 7075铝合金FSW接头中沉淀相主要为棒状MgZn2、椭圆状AlCuMg以及胶囊状Al2CuMg, AlCuMg和Al2CuMg的强化效果好于MgZn2的。

3) WNZ中沉淀相主要是AlCuMg和Al2CuMg;相比WNZ,TMAZ中AlCuMg和Al2CuMg比较少,MgZn2相对较多;HAZ中MgZn2相对更多。

4) v一定时,随着ω的增加,接头WNZ与TMAZ中沉淀相尺寸增大,显微硬度先升高后降低;HAZ中沉淀相的尺寸和数量变化不大,显微硬度几乎不变。ω一定时,随着v的增加,WNZ、TMAZ和HAZ中沉淀相数量增多,尺寸变小,显微硬度有所上升。

图8 转速对FSW接头沉淀相分布的影响

Fig. 8 Effect of rotational speed on precipitation distribution in FSW joints with 300 mm/min

图9 焊速对FSW接头沉淀相分布的影响

Fig. 9 Effect of weld speed on precipitation distribution in FSW joints with 1000 r/min

REFERENCES

[1] 刘会杰, 闫久春, 魏艳红, 刘爱国. 焊接冶金与焊接性[M]. 北京: 机械工业出版社, 2007: 205-219.

LIU Hui-jie, YAN Jiu-chun, WEI Yan-hong, LIU Ai-guo. Welding metallurgy and weldability[M]. Beijing: China Machine Press, 2007: 205-219.

[2] 张 华, 林三宝, 吴 林, 冯吉才, 栾国红. 搅拌摩擦焊研究进展及前景展望[J]. 焊接学报, 2003, 24(3): 91-96.

ZHANG Hua, LIN San-bao, WU Lin, FENG Ji-cai, LUAN Guo-hong. Current progress and prospect of friction stir welding[J]. Transactions of the China Welding Institution, 2003, 24(3): 91-96.

[3] 王希靖, 孙桂苹, 张 杰, 徐 成, 李树伟, 牛 勇. 焊后热处理对高强铝合金搅拌摩擦焊接头的影响[J]. 中国有色金属学报, 2009, 19(3): 484-489.

WANG Xi-jing, SUN Gui-ping, ZHANG Jie, XU Cheng, LI Shu-wei, NIU Yong. Effects of heat treatment after welding on friction stir welding joints of high-strength aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(3): 484-489.

[4] RAO T S, REDDY G M, RAO S R K. Microstructure and mechanical properties of friction stir welded AA7075-T651 aluminum alloy thick plates[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(6): 1770-1778.

[5] FADAEIFARD F, MATORI K A, TOOZANDEHJANI M, DAUD A R, ARIFFIN M K A M, OTHMAN N K, GHARAVI F, RAMZANI A H, OSTOVAN F. Influence of rotational speed on mechanical properties of friction stir lap welded 6061-T6 Al alloy[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(4): 1004-1011.

[6] BAYAZID S M, FARHANGI H, ASGHARZADEH H, RADAN L, GHAHRAMANI A, MIRHAJI A. Effect of cyclic solution treatment on microstructure and mechanical properties of friction stir welded 7075 Al alloy[J]. Materials Science & Engineering A, 2016, 649: 293-300.

[7] KUMAR P S, SHASTRY C S R, DEVARAJU A. Influence of tool revolving on mechanical properties of friction stir welded 5083 aluminum alloy[J]. Materials Today: Proceedings, 2017, 4: 330-335.

[8] GHOSH M, KUMAR K, KAILAS S V, RAY A K. Optimization of friction stir welding parameters for dissimilar aluminum alloys[J]. Materials and Design, 2010, 31(6): 3033-3037.

[9] RAJAKUMAR S, MURALIDHARAN C, BALASUBRAMANIAN V. Influence of friction stir welding process and tool parameters on strength properties of AA7075-T6 aluminium alloy joints[J]. Materials and Design, 2011, 32: 535-549.

[10] SELVARAJ M, MURALI V, RAO S R K. Thermal model for friction stir welding of mild steel[J]. Multidiscipline Modeling in Materials and Structures, 2013, 9(1): 49-61.

[11] ZHANG P, GUO N, CHEN G, MENG Q, DONG C L, ZHOU L, FENG J C. Plastic deformation behavior of the friction stir welded AA2024 aluminum alloy[J]. International Journal of Advanced Manufacturing Technology, 2014, 74(5/8): 673-679.

[12] 孙国芹, 牛江佩, 王 冬, 陈树君, 曹方莉. 2219-T6铝合金FSW接头疲劳寿命预测[J]. 中国有色金属学报, 2014, 24(10): 2460-2464.

SUN Guo-qin, NIU Jiang-pei, WANG Dong, CHEN Shu-jun, CAO Fang-li. Fatigue life prediction of FSW joints for 2219-T6 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(10): 2460-2464.

[13] SIVARAJ P, KANAGARAJAN D, BALASUBRAMANIAN V. Fatigue crack growth behaviour of friction stir welded AA7075-T651 aluminium alloy joints[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(8): 2459-2467.

[14] FENG C, SHOU W B, LIU H Q, YI D Q, FENG Y R. Microstructure and mechanical properties of high strength Al-Zn-Mg-Cu alloys used for oil drill pipes[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(11): 3515-3522.

[15] 杨淑娟, 曲文卿, 董春林, 栾国红, 李 光. 铝合金搅拌摩擦焊焊缝微观组织[J]. 航空制造技术, 2011(23): 101-104.

YANG Shu-juan, QU Wen-qing, DONG Chun-lin, LUAN Guo-hong, LI Guang. Microstructure of friction stir welded joints in aluminum alloy[J]. Welding Technologies for Aviation Industry, 2011(23): 91-94.

[16] MARTINEZ N, KUMAR N, MISHRA R S, DOHERTY K J. Microstructural variation due to heat gradient of a thick friction stir welded aluminum 7449 alloy[J]. Journal of Alloys and Compounds, 2017, 713: 51-63.

[17] SIDHAR H, MISHRA R S, REYNOLDS A P, BAUMANN J A. Impact of thermal management on post weld heat treatment efficacy in friction stir welded 2050-T3 alloy[J]. Journal of Alloys and Compounds, 2017, 722: 330-338.

[18] 朱和国, 王恒志. 材料科学研究与测试方法[M]. 南京: 东南大学出版社, 2008.

ZHU He-guo, WANG Heng-zhi. The research and test methods of material science[M]. Nanjing: Southeast University Press, 2008.

[19] 郭 柱, 朱 浩, 崔少朋, 王彦红. 7075铝合金搅拌摩擦焊接头温度场及残余应力场的有限元模拟[J]. 焊接学报, 2015, 36(2): 92-96.

GUO Zhu, ZHU Hao, CUI Shao-peng, WANG Yan-hong. Finite element simulation of friction stir welding temperature field and residual stress field of 7075 aluminum alloy[J]. Transactions of the China Welding Institution, 2015, 36(2): 92-96.

[20] 郭 柱. 7075铝合金搅拌摩擦焊温度场及残余应力场的数值模拟[D]. 石家庄: 石家庄铁道大学, 2015.

GUO Zhu. FEM of Temperature field and residual stress field in FSW of 7075 aluminum alloy[D]. Shijiazhuang: Shijiazhuang TIEDAO University, 2015.

Influence of 7075 aluminum alloy FSW process on precipitation behavior of precipitated phases for joints

JIANG Yue1, 2, ZHU Hao1, 2, LIU Jia-lun1, 2 , ZHAO Yi-peng1, 2, WANG Jun3

(1. School of Materials Science and Engineering, Shijiazhuang Tiedao University, Shijiazhuang 050043, China;

2. Hebei Provincial Key Laboratory of Traffic Engineering Materials, Shijiazhuang 050043, China;

3. School of Materials Science and Engineering, Hebei University of Science and Technology, Shijiazhuang 050018, China)

Abstract: The flat butt welding was carried out on 7075 aluminum alloy with the thickness of 6 mm using friction stir welding under different processes. The microstructure, microhardness and the kinds, morphology of precipitated phase among the joints were analyzed by optical microscope, microvickers hardness tester, X-ray diffractometer (XRD) and the transmission electron microscopy (TEM). The results show that the precipitated phases are MgZn2 with rod shape, AlCuMg with elliptical shape and Al2CuMg with capsule shape. The strengthen effect of the AlCuMg and Al2CuMg is better than that of the MgZn2. The precipitated phases in WNZ mainly include AlCuMg and Al2CuMg. The microhardness in this zone is pretty high. The numbers of the AlCuMg and Al2CuMg in TMAZ is lesser and the number of the MgZn2 is more compared with the WNZ, which leads the microhardness to decrease. The number of the MgZn2 in HAZ is relatively more and the microhardness is further reduced. With the rotation speed (ω) increasing, the sizes of the precipitated phase WNZ and TMAZ among the joints increase, and the microhardness increases firstly and then decreases. There is little change in the size and number of the precipitated phase among the HAZ. With the weld speed (v) increasing, the numbers of the precipitated phase in WNZ, TMAZ and HAZ increase and the sizes are smaller. Therefore, the microhardness increases.

Key words: 7075 aluminum alloy; friction stir welding process; precipitated phase

Foundation item: Project(2016210050) supported by the Hebei Provincial Natural Science Foundation of China; Project (BK20141181) supported by the Jiangsu Provincial Natural Science Foundation of China

Received date: 2017-08-24; Accepted date: 2018-11-28

Corresponding author: ZHU Hao; Tel: +86-13784402173; E-mail: zhuhao@stdu.edu.cn

(编辑 王 超)

基金项目:河北省自然科学基金(2016210050);江苏省自然科学基金(BK20141181)

收稿日期:2017-08-24;修订日期:2018-11-28

通信作者:朱 浩,教授,博士;电话:13784402173;E-mail:zhuhao@stdu.edu.cn