文章编号:1004-0609(2013)10-2747-07

7075铝合金热变形时动态再结晶晶粒度演化模型

杨 栋1,陈文琳1,王少阳2,马 勇1,张金鹏1,周 瑞1,赵亚培1,王欣芳1

(1. 合肥工业大学 材料科学与工程学院,合肥 230009;

2. 成都飞机工业(集团)有限责任公司,成都 610092)

摘 要:7075铝合金在热变形过程中主要发生连续动态再结晶,在温度为250~450 ℃、应变速率为0.1~1 s-1的条件下,对多组圆柱试样进行热模拟压缩实验。采用金相定量法对热变形后材料的显微组织晶粒度进行测量,建立7075铝合金热变形时动态再结晶晶粒度演化模型。结果表明:根据唯象理论的指数模型,利用线性回归方法求得7075铝合金热塑性变形组织晶粒度的演化模型;将该模型导入到有限元软件中能够预报7075铝合金热变形过程的连续动态再结晶晶粒度;预报结果与实验结果非常接近,说明将该演化模型导入有限元软件中可以较为准确地预测7075铝合金热变形过程动态再结晶晶粒度。

关键词:7075铝合金;热压缩;连续动态再结晶;有限元;组织晶粒度预报

中图分类号:TG316 文献标志码:A

Dynamic recrystallization grain size evolution model of 7075 aluminum alloy during hot deformation

YANG Dong1, CHEN Wen-lin1, WANG Shao-yang2, MA Yong1, ZHANG Jin-peng1,

ZHOU Rui1, ZHAO Ya-pei1, WANG Xin-fang1

(1. School of Materials Science and Engineering, Hefei University of Technology, Hefei 230009, China;

2. Chengdu Aircraft Industrial Corporation, Chengdu 610092, China)

Abstract: Continuous dynamic recrystallization (CDRX) of 7075 aluminum alloy occurs during hot deformation. The thermal compression experiment about the group of cylindrical specimen was done at the temperature of 250-450 ℃ and the strain rate of 0.1-1 s-1. The microstructure grain size of 7075 aluminum alloy was measured by the metallographic quantitative method, the microstructure grain size evolution model of 7075 aluminum alloy. The result shows that, according to the exponential model of phenomenological theory and the linear regression method, the microstructure grain size evolution model of 7075 aluminum alloy during the thermoplastic deformation can be worked out. And then, by the finite element software with the evolution model continuous dynamic recrystallization grain size of 7075 aluminum alloy during hot deformation was predicted. The forecasting result is very close to the experimental one. Therefore, by finite element software with the evolution model, dynamic recrystallization grain size of 7075 aluminum alloy during the hot deformation process can be accurately predicted.

Key words: 7075 aluminum alloy; hot compression; continuous dynamic recrystallization; finite element; microstructure grain size prediction

7075铝合金是一种典型的高强度变形铝合金,属于Al-Zn-Mg-Cu合金,具有较高的强度质量比,在航空、航天、船舶、兵器工业中具有不可替代的地位,拥有极其广泛的应用前景。

7075铝合金属于高层错能金属,在热塑性变形过程中动态回复强烈,位错密度难以升高,不易发生“形核-长大”机制的非连续动态再结晶(Discontinuous dynamic recrystallization, DDRX)。仅在变形温度、速度较高的情况下,可能出现部分非连续动态再结晶,7075铝合金热变形时主要发生连续动态再结晶(Continuous dynamic recrystallization, CDRX)[1-2]。连续动态再结晶是金属变形时位错不断向小角度晶界聚集,从而转变为大角度晶界,形成新的细小晶粒的过程。金属晶粒度随连续动态再结晶进行而显著减小,得到非常细小的晶粒组织,能够显著提高铝合金材料的力学性能。因此,铝及铝合金的连续动态再结晶在工业生产中具有重要的意义,逐渐被研究学者所关注[3-5]。

近年来,金属变形微观组织预测和控制成为国际上材料科学领域的热门研究方向,其根本就是对金属变形组织演化规律的研究[6-10]。对于7075铝合金热变形中连续动态再结晶过程的显微组织演化规律是当前研究的热点[8-12]。李俊鹏等[10]研究温度对7075铝合金热变形过程中的显微组织演化的影响,在此基础上,徐庆军等[13]研究温度和应变速率对7075铝合金热变形过程中力学性能及显微组织的影响,王煜等[14]研究挤压态7075铝合金高温流变行为及神经网络本构模型。但他们主要是对7075铝合金热变形微观组织演化规律及本构模型的研究,对于7075铝合金热变形时动态再结晶晶粒度演化模型的建立及动态再结晶晶粒度预报的研究尚未见报道。本文作者通过热模拟压缩实验,对7075铝合金在热镦粗过程中不同温度、不同应变速率、不同变形量条件下晶粒的显微组织方面进行研究,得到7075铝合金热变形动态再结晶晶粒度演化模型。该研究主要通过两个途径:一是利用热模拟压缩实验采用线性回归的方法得到热变形过程动态再结晶晶粒度的演化模型;二是将该演化模型导入有限元软件来预报热变形过程中各部分晶粒度的演化趋势,验证演化模型和有限元模型的正确性。

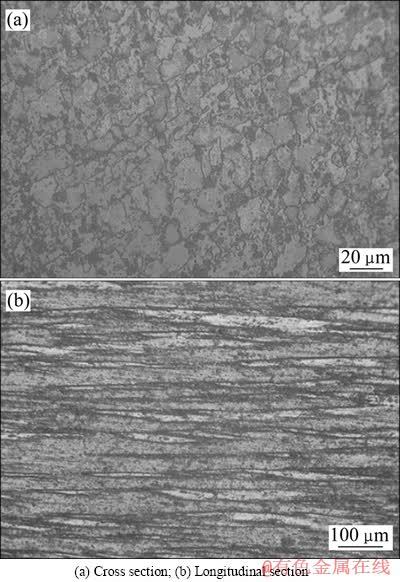

1 热模拟压缩实验

实验材料为7075铝合金挤压棒料,化学成分如表1所列,制得镦粗试样尺寸为d 10 mm×15 mm。为减轻材料的偏析,在460 ℃对所有试样进行5 h的均匀化处理。均匀化处理后立即淬火,得到的初始组织如图1所示。可见,晶粒明显沿挤压方向伸长,呈“纺锤形”,垂直于挤压方向,晶粒呈现等轴状,用金相定量法测得其初始晶粒尺寸为40 μm。

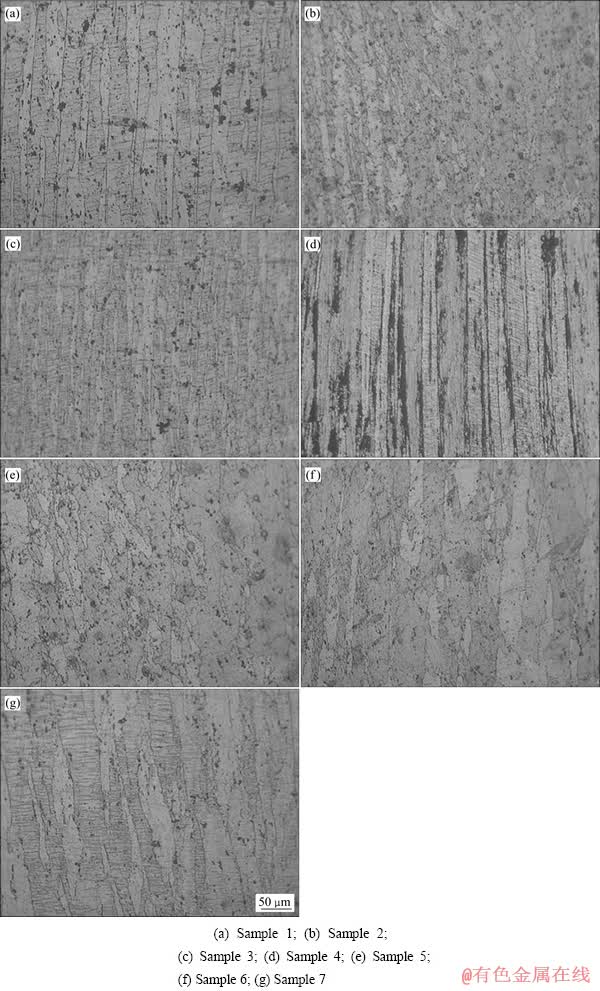

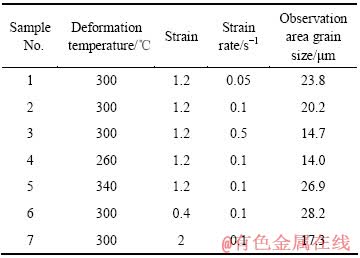

对均匀化处理后的7个试样进行不同温度、应变速率、变形程度的热模拟压缩实验,在圆柱试样两端的浅槽内充填润滑剂,并贴石墨片,以减少摩擦的影响。压缩温度分别为260、300、340 ℃,应变速率分别为0.05、0.1、0.5 s-1,真应变为0.4、1.2、2。压缩过程中通过程序设定保持恒定应变速率,温度由热模拟机的系统进行自动补偿,保持基本恒定。试样通过电阻直接加热,加热速度2 ℃/s,保温时间3 min。

实验后将试样迅速放入水中淬火以保留高温组织,沿试样镦粗方向将其剖切开来,采用砂纸打磨-光面布金刚石粗抛-绒面布氧化铝细抛-科勒腐蚀剂腐蚀进行制样,得到各试样中心区域的金相组织如图2所示,然后通过金相定量法对各试样金相组织进行晶粒度测量,如表2所列。

表1 7075铝合金成分

Table 1 Component of 7075 aluminium alloy (mass fraction, %)

图1 7075铝合金初始金相组织

Fig. 1 Initial metallographic microstructures of 7075 aluminum alloy

图2 压缩实验后试样中心区域的金相组织

Fig. 2 Metallographic microstructures of central regions of samples after compression experiments

表2 压缩实验试样中心区域变形参数表

Table 2 Deformation parameters of central region after of sample compression experiments

2 动态再结晶晶粒度演化模型建立

根据GOURGET等[1]的研究,铝合金动态再结晶组织的晶粒尺寸随应变、应变速率、温度的变化可用基于唯象理论的指数模型进行描述[15-16]:

(1)

(1)

式中:dCDRX为动态再结晶后的平均晶粒度;d0为初始晶粒度; 为应变速率;

为应变速率; 为塑性应变;R为摩尔气体常数;T为温度;a为系数项;Q为激活能;k、n、m、p为指数项,由于本实验只针对初始晶粒度d0=40 μm的7075铝合金,故n=0。

为塑性应变;R为摩尔气体常数;T为温度;a为系数项;Q为激活能;k、n、m、p为指数项,由于本实验只针对初始晶粒度d0=40 μm的7075铝合金,故n=0。

2.1 激活能的确定

铝合金的热变形晶粒演化是一种热激活的过程,激活能反映了材料热激活的难易程度。当温度升高,原子的热振动加剧,其迁移能力随之升高,晶界的移动速度也会提高,组织晶粒度也会相应增大。因此,用于预报铝合金热变形组织晶粒度的指数模型中,其预报值dCDRX也与此有关。试样2、4、5观测区的应变速率和应变相同,因此,其晶粒度仅仅正比于[exp(Q/RT)]k,即

(2)

(2)

式中:dCDRX为连续性动态再结晶晶粒尺寸;k为常系数;Q为激活能;T为变形时的绝对温度。对式(2)两边取对数,得

(3)

(3)

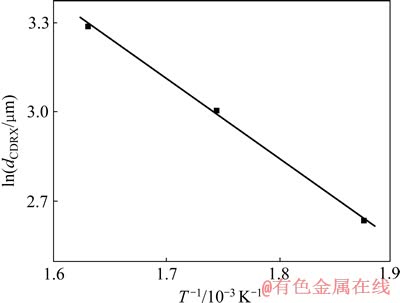

对试样2、4、5观测区的变形参数按式(3)处理,可得图3。根据两数据点确定的直线,其斜率即为kQ/R,可求得 kJ/mol。

kJ/mol。

7075铝合金的激活能为140 kJ/mol[15],可得k=0.068。

图3 ln dCDRX—1/T拟合直线

Fig. 3 ln dCDRX—1/T fitting straight-line

2.2 应变速率指数的确定

同理,当变形温度、应变相同时,变形组织晶粒度正比于应变速率的指数值 ,即

,即

(4)

(4)

对式(4)两边取对数,得

(5)

(5)

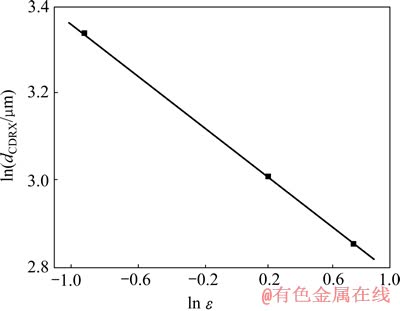

将试样1、2、3观测区的参数按式(5)进行处理,可得图4。根据图4中三数据点确定的直线的斜率,可得m=-0.2。此结果与BUFFA等[17]在7075铝合金摩擦搅拌焊组织晶粒度演化模型中的研究结果接近。

图4 ln dCDRX— 拟合直线

拟合直线

Fig. 4 ln dCDRX— fitting straight-line

fitting straight-line

2.3 应变指数的确定

7075铝合金热塑性变形组织晶粒度随应变值 增加而明显减低,根据GOURDET研究结果,在铝合金塑性变形开始后其组织晶粒度随应变急剧降低,并在较大应变值时稳定在某一值附近。同样,使用指数关系式可以描述此过程:

增加而明显减低,根据GOURDET研究结果,在铝合金塑性变形开始后其组织晶粒度随应变急剧降低,并在较大应变值时稳定在某一值附近。同样,使用指数关系式可以描述此过程:

(6)

(6)

当应变速率、变形温度相同时,对式(1)两边同时取对数可得

(7)

(7)

同样,将试样2、6、7观测区参数按式(7)处理,对数据点采用线性拟合可得图5。根据图中直线斜率,可求得

将上述k、Q、m、n及各观测区参数代入式(1),求得 。综上所述,可得7075铝合金热塑性变形组织晶粒度的演化模型为

。综上所述,可得7075铝合金热塑性变形组织晶粒度的演化模型为

(8)

(8)

3 动态再结晶晶粒度演化模型验证

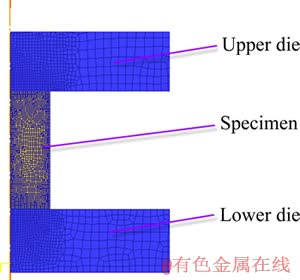

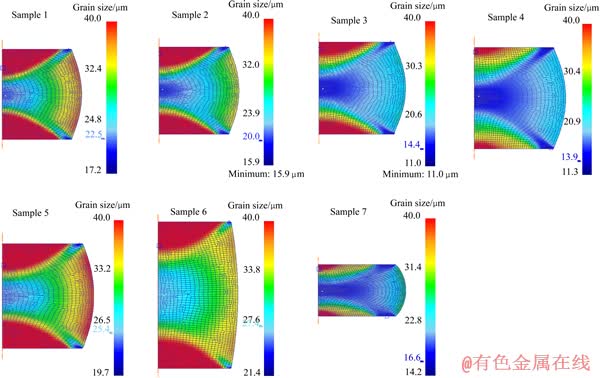

采用有限元软件进行模拟,试样的几何模型按镦粗实验试样的尺寸建立,为提高计算效率,采用轴对称平面有限元模型。变形温度、变形量与变形速率与实验条件一致。试样初始晶粒尺寸为40 μm,将上述连续动态再结晶晶粒尺寸演化模型嵌入有限元软件,对热压缩过程组织晶粒尺寸进行预报,所建立的有限元模型如图6所示。

图5 ln dCDRX— 拟合直线

拟合直线

Fig. 5 ln dCDRX— fitting straight-line

fitting straight-line

图6 有限元模型

Fig. 6 Finite element model

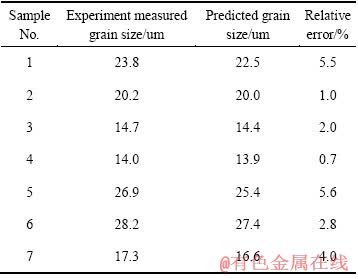

采用如图6所示的有限元模型对不同条件下(条件按照表2所列的条件)热压缩过程组织晶粒尺寸进行预报,结果如图7所示。试验后试样中心处金相图所测得的晶粒尺寸与有限元软件预测的晶粒尺寸比较如表3所列。

表3 观测区晶粒度实测值与预报值对比

Table 3 Comparison of measured grain size and predicted grain size in observation area

从表3可以看出,测得的晶粒尺寸与有限元预报结果非常接近,相对误差在5.5%以内。说明利用建立的7075铝合金热变形时动态再结晶晶粒度演化模型能够导入有限元软件中实现晶粒度预报的功能。同时,该有限元模型能够准确地预测7075铝合金热塑性变形的组织晶粒度的变化趋势,并能在一定误差范围内给出晶粒尺寸的估计值,验证该演化模型的正确性。

图7 不同条件下有限元软件晶粒度预报值

Fig. 7 Predicted grain size by FEM under different conditions

4 结论

1) 通过热模拟压缩试验、金相分析、数据处理,求出用于描述7075铝合金热变形时动态再结晶晶粒度演化模型:

2) 将该动态再结晶晶粒度演化模型导入有限元软件中能够实现预测热模拟压缩试验条件下试样中心区域的晶粒度的功能。

3) 使用该模型预报的晶粒尺寸与试验结果非常接近,误差最大不超过5.5%,验证该演化模型的正确性,说明该演化模型可以较为准确的预测7075铝合金热变形时的组织晶粒度的变化趋势,并能在较小误差范围内给出晶粒尺寸的预报值。

REFERENCES

[1] GOURDET S, MONTHEILLET F. A model of continuous dynamic recrystallization[J]. Acta Materialia, 2003, 51: 2685-2699.

[2] 王少阳, 陈文琳, 李志杰, 杨 栋, 周 瑞. 金属热变形组织晶粒度预报的应用现状[J]. 热加工工艺, 2012,41(6): 165-167.

WANG Shao-yang, CHEN Wen-lin, LI Zhi-jie, YANG Dong, ZHOU Rui. Application status of hot deformation metal grain size predicted[J]. Hot Working Technology, 2012, 41(6): 165-167.

[3] SAKAI T. Continuous dynamic recrystallization during the transient severe deformation of aluminum 7475[J]. Acta Material A, 2009, 57: 153-162.

[4] YANG Yong-biao, ZHANG Zhi-min, MENG Mu. Microstructure characterization of hot extruded 7075 Al bar with different passes and temperatures[J]. Advanced Materials Research, 2011, 217: 1679-1682.

[5] 颜文煅, 傅高升, 陈贵清. 1235铝合金动态再结晶动力学模型及氧化夹杂的影响[J]. 材料热处理学报, 2012, 33(2): 149-154.

YAN Wen-duan, FU Gao-sheng, CHEN Gui-qing. Study on dynamic recrystallization kinetics model and effect of oxide inclusion in 1235 aluminum alloy[J]. Transactions of Materials and Heat Treatment, 2012, 33(2): 149-154.

[6] SELLARS C M. Modeling microstructural development during hot rolling[J]. Material Science Technology, 1990, 16(11): 1072-1078.

[7] SHEN J, GOTTSTEN G. Modelling of microstructure evolution of aluminium alloy during thermomechanical processing[J]. Materials Science and Technology, 2001, 9(3): 329-333.

[8] 李周兵, 沈 健, 闫亮明, 李俊鹏, 闫晓东, 毛柏平. 应变速率对7055铝合金显微组织和力学性能的影响[J]. 稀有金属, 2010, 34(5): 643-647.

LI Zhou-bing, SHEN Jian, YAN Liang-ming, LI Jun-peng, YAN Xiao-dong, MAO Bo-ping. Effects of strain rate on microstructure and mechanical properties of 7055 aluminum alloy[J]. Rare metals, 2010, 34(5): 643-647.

[9] LI Jun-peng, SHEN Jian, YAN Xiao-dong, MAO Bai-ping, YAN Liang-ming. Microstructure evolution of 7050 aluminum alloy during hot deformation[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(1): 189-194.

[10] 李俊鹏, 沈 健, 闫晓东, 毛柏平, 闫亮明. 温度对7075铝合金热变形显微组织演化的影响[J]. 中国有色金属学报, 2008, 18(11): 1951-1957.

LI Jun-peng, SHEN Jian, YAN Xiao-dong, MAO Bo-ping, YAN Liang-ming. Effects of temperature on microstructure evolution of 7075 aluminum alloy in process of hot deformation[J]. The Chinese Journal of Nonferrous Metals Society, 2008, 18(11): 1951-1957.

[11] QUAN Guo-zheng, LIU Ke-wei, ZHOU Jie, CHEN Bin. Dynamic softening behaviors of 7075 aluminum alloy[J]. Transactions of Nonferrous Metals Society of China, 2009, 19(S3): s537-s541.

[12] YAN Liang-ming, SHEN Jian, LI Jun-peng. Dynamic recrystallization of 7055 aluminum alloy during hot deformation[J]. Materials Science Forum, 2010, 650: 295-301.

[13] 徐庆军, 张治民, 杨勇彪. 7075铝合金高温热变形性能的研究[J]. 热加工工艺, 2012, 41(7): 33-35.

XU Qing-jun, ZHANG Zhi-min, YANG Yong-biao. Study on thermal deformation performance of 7075 alloy[J]. Hot Working Technology, 2012, 41(7): 33-35.

[14] 王 煜, 孙志超, 李志颖, 杨 合. 挤压态7075铝合金高温流变行为及神经网络本构模型[J]. 中国有色金属学报, 2011, 21(11): 2880-2887.

WANG Yu, SUN Zhi-chao, LI Zhi-ying, YANG He. High temperature flow stress behavior of as-extruded 7075 aluminum alloy and neural network constitutive model[J]. The Chinese Journal of Nonferrous Metals Society, 2011, 21(11): 2880-2887.

[15] FRATINI L, BUFFA G. CDRX modelling in friction stir welding of aluminium alloys[J]. International Journal of Machine Tools & Manufacture, 2005, 45: 1188-1194.

[16] 杨智春, 李 斌, 马光来. 7075高强度铝合金锻造晶粒细化原理的数值仿真研究[J]. 稀有金属材料与工程, 2006, 4: 642-646.

YANG Zhi-chun, LI Bin, MA Guang-lai. Numerical simulation of grain refinement of 7075 aluminum alloy in forging processing[J]. Rare Metal Materials and Engineering, 2006, 4: 642-646.

[17] BUFFA G. CDRX modelling in friction stir welding of AA7075-T6 aluminum alloy: Analytical approaches[J]. Journal of Materials Processing Technology, 2007, 191: 356-359.

(编辑 李艳红)

基金项目:教育部科学技术研究重大项目(311025)

收稿日期:2012-12-03;修订日期:2013-06-15

通信作者:陈文琳,教授,博士;电话:0551-2904578;传真:0551-2901362;E-mail: chenwl@hfut.edu.cn