文章编号:1004-0609(2008)07-1199-06

异种镁合金AZ31B与AZ61A的搅拌摩擦焊工艺

王希靖,张永红,张忠科

(兰州理工大学 有色金属合金及加工教育部重点实验室,兰州 730050)

摘 要:对异种变形镁合金AZ31B与 AZ61A进行搅拌摩擦焊对接实验,研究了工艺参数对接头组织及力学性能的影响。结果表明:当采用凹面圆台形搅拌头,且将AZ31B置于后退侧进行施焊时较易得到成型良好、无焊接缺陷的对接接头,接头抗拉强度最高可达到母材AZ31B的90.5%。对焊缝的端面微观组织特征分析发现:接头各区域组织差异很大,前进侧热力影响区组织呈层状分布且较宽。当工艺参数不恰当时,该区域层间易产生氧化物和杂质物的富集。夹杂层的存在和应力集中是造成接头在前进侧热力影响区力学性能下降的主要原因。

关键词:AZ31B镁合金;AZ61A镁合金;搅拌摩擦焊;力学性能;层状组织

中图分类号:TG 453 文献标识码:A

Friction stir welding process of

AZ31B and AZ61A magnesium alloy

WANG Xi-jing, ZHANG Yong-hong, ZHANG Zhong-ke

(Key Laboratory of Advanced Non-ferrous Alloy and Processing, Ministry of Education,

Lanzhou University of Technology, Lanzhou 730050, China)

Abstract: Dissimilar AZ61A and AZ31B magnesium alloys were welded with friction stir welding. The influence of welding parameters on the microstructure and mechanical properties of the joint was investigated. Experimental results show that when using concave round platform tool and placing AZ31B at the retreating side, the beautiful welded joints without discontinuity are easily obtained. The maximum tensile strength of joint can reach 90.5% that of the AZ31B base material. The microstructure analysis of joint reveals that the microstructures of the various regions are very different, and the microstructure distribution is layered and wide on the mechanical heat-affected zone. When the process parameters are not appropriate, the oxide and impurity congregate between the layered microstructures. The existence of the impure stratum structure and stress concentration is the main reason that causes the drop of mechanical properties in the mechanical heat-affected zone.

Key words: AZ31B magnesium alloy; AZ61Amagnesium alloy; friction stir welding; mechanical properties; stratum structure

搅拌摩擦焊(Friction Stir Welding,简称FSW)作为一种新型的低熔点有色金属连接工艺,在铝合金的焊接方面具有得天独厚的优势[4?6]。在对镁合金的搅拌摩擦焊方面,NAKATA[7]和JOHNSON[8]分别对AZ31、AZ61、AZ91系列镁合金板材和AM50、AM60等压铸镁合金进行了搅拌摩擦焊研究,结果表明以上几种材料上均可获得优质焊件,但与铝合金相比,镁合金搅拌摩擦焊的最优工艺参数的选择范围较窄。在国内,文献[9~11]对AZ31镁合金的搅拌摩擦焊进行了比较全面的研究,文献[12~14]针对我国航天航空工业中常用的MB8、AZ81镁合金进行了摩擦焊工艺研究。以上都是对同种镁合金搅拌摩擦焊的研究,但对更具广泛性和实用价值的不同成分镁合金材料间的搅拌摩擦焊却研究很少,考虑到各种镁合金性能差异较大,有必要进行异种镁合金的搅拌摩擦焊工艺研究。本就较常见的变形镁合金AZ31B与AZ61A进行了搅拌摩擦焊试验研究。

1 实验

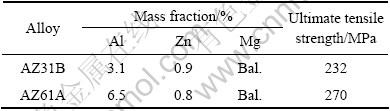

实验采用挤压态变形镁合金AZ31B和AZ61A,经机械加工后制成尺寸为200 mm×80 mm×5 mm的板件进行焊接。材料主要成分和力学性能如表1。

表1 镁合金成分和力学性能

Table 1 Components and mechanical properties of magnesium alloy

实验设备为FSW?3LM?015型搅拌摩擦焊机,焊速10~2 000 mm/min,转速250~2 500 r/min,对铝合金最大焊接厚度为14 mm,完全满足本实验镁合金的搅拌摩擦焊连接。实验时,在保持其它工艺条件和参数不变的条件下,通过改变搅拌摩擦头型式、调整搅拌旋转速度ω和焊接速度v,获得成型良好、无宏观缺陷的接头;然后对不同参数下接头横向截取试样进行力学性能测试;最后选取适当的接头部位截取横截面试样,经研磨、抛光,用3%硝酸溶液腐蚀、纯酒精清洗、吹干,在光学显微镜下进行金相组织观察和显微硬度检测。

2 结果与分析

2.1 材质差异和搅拌头形状对FSW焊缝成型的影响

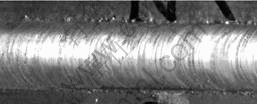

变形镁合金AZ61A与AZ31B相比,AZ61A的Al元素质量分数约为3%,表现在性能上即为材料的强度和硬度的提高,而塑性变形能力却明显下降。这使得在它们之间进行搅拌摩擦焊要比在同种材料之间进行搅拌摩擦焊要困难许多。实验结果表明,当AZ31B置于后退侧、AZ61A置于前进侧进行施焊时易得到外观成型良好、无宏观缺陷的接头(见图1),所适用的工艺参数范围也比较宽。反之,很难得到形成完好的焊缝,总产生表面沟槽或焊缝内部隧道型缺陷。这主要是由于与AZ31B相比,AZ61A的塑性变形能力差、实验状态的母材晶粒更粗大、晶界上二次相Mg17Al12和杂质也更多。

图1 AZ31B/AZ61A搅拌摩擦接头

Fig.1 Photo of AZ31B/AZ61A FSW joint

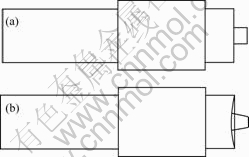

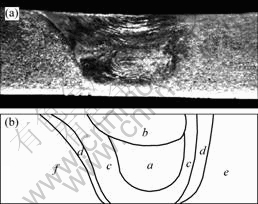

本实验采用2种不同搅拌针的搅拌头进行焊接(如图2)。结果表明,圆柱形搅拌头(见图2(a))施焊时接头表面成形差,往往出现表面沟槽或在焊缝内部出现孔洞及隧道型缺陷。圆台内凹形搅拌头(见图2(b))容易得到外观成形良好、无宏观缺陷的接头。图3所示为AZ31B/AZ61A FSW接头横截面的宏观形貌。由图3明显观察到沿着焊核与母材的分界线金属流线由后退侧上部流向焊核,然后再流向前进侧上部,形成与搅拌针形状一致的流线。这样在母材金属塑性流动性差的情况下,圆台形搅拌针比圆柱形搅拌针更有助于塑性金属的流动。另外,由图3可看到,在焊缝表面及近表面金属流线呈较大内凹状,这使得内凹形肩轴与工件表面处形成的空间更有利于塑化金属填充搅拌针所流下的间隙,这也是圆台内凹形搅拌头比圆柱形搅拌头更适合异种镁合金AZ31B与AZ61A搅拌摩擦焊接的原因。

图2 搅拌摩擦头形状

Fig.2 Model of friction stir tool: (a) Cylinder pint; (b) Concave round platform pin

图3 AZ31B/AZ61A FSW接头横截面宏观照片

Fig.3 Section macrograph of AZ31B/AZ61A FSW joint: (a) Transverse metallographic section of welds; (b) Different zones of section macrograph. a—Nugget zone; b—Crown zone; c—Mechanical heat-affected zone (MHAZ); d—Heat-affected zone (HAZ); e—AZ31B base metal; f—AZ61A base metal

2.2 接头的组织分析

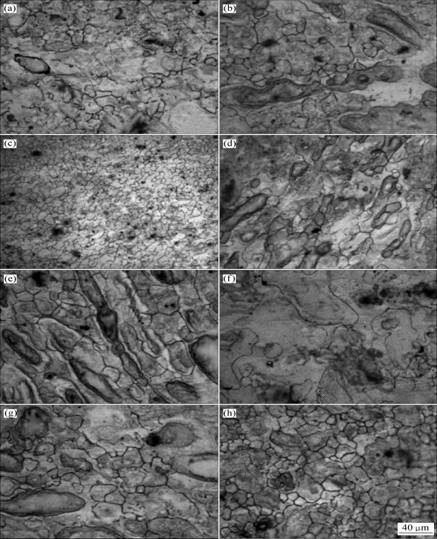

对搅拌摩擦焊接头金相腐蚀发现,焊核区较母材难腐蚀许多。腐蚀后肉眼即可看到焊核区比母材区明亮许多,各区域能明显区分,热力影响区金属塑性变形和流动非常明显,焊核区“洋葱环”和冠状区形貌十分清晰。图4(a)~(h)所示为接头各区域微观组织。由于母材为挤压态变形镁合金,图4(a)和(b)所示的组织呈大小很不均匀的等轴晶,个别晶粒非常粗大,相互之间由较小晶粒填充,在晶界上还明显分布着一些大小不等的杂质。相比而言,AZ61A母材的晶粒更粗大。

图4 焊缝接头的金相照片

Fig.4 Metallographs of FSW joint: (a) AZ31B base metal; (b) AZ61A base metal; (c) Nugget; (d) AZ31B side MHAZ; (e) AZ61A side MHAZ; (f) AZ31B side HAZ; (g) AZ61A side HAZ; (h) Crown zone

图4(c)所示为焊核区组织。由图可知,与母材相比,焊核区晶粒得到很大程度的细化,且分布均匀。这主要是因为该区金属在搅拌头的作用下温度最高、应变速率最大,发生强烈的塑性变形和流动,粗大的母材晶粒不断地被打碎,再结晶晶粒来不及长大,形成等轴细小的晶粒,同时杂质也受到很大程度的破碎弥散于晶粒间。

图4(d)和(e)所示为热力影响区组织形态,可以看到热力影响区在连续热和机械搅拌的联合作用下,组织呈层状分布。初始粗大晶粒被明显拉长,具有一定的流向性,而初始较小晶粒回复长大明显,晶粒尺寸较焊核区大许多,但母材整体不均匀性减小。另外AZ61A侧(前进侧)热力影响区比AZ31B侧(后退侧)宽许多,层状分布也更明显。

图4(f)和(g)所示分别为AZ31B和AZ61A的热影响区组织,可以看到热影响区初始粗大晶粒通过合并小晶粒使自身得到进一步长大,从而使大晶粒直接相连,这主要是因为该区域在连续热循环作用下,晶粒得到回复和长大。相比而言,AZ31B侧(后退侧)热影响区晶粒长大更明显,这与搅拌摩擦焊过程中,后退侧温度略高于前进侧相关。

图4(h)所示为接头冠状区组织,可以看到冠状区晶粒也比较细小,但比焊核区要大许多且不够均匀。该区域主要受到肩轴的热机械作用,温度很高,但搅拌却不是很充分。

2.3 焊接参数对接头力学性能的影响

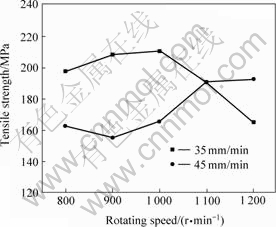

实验表明,在保持其他参数不变的条件下,当旋转速度在750~1 300 r/min、焊接速度在30~50 mm/min调节时能获得成形良好、无宏观缺陷的焊接接头,对该工艺参数范围内施焊所得的1#~10#接头分别横向截取试样进行拉伸实验。图5所示为焊接参数与抗拉强度关系。

由图5可见,在一定的焊接速度下,接头抗拉强度随着ω的增加而增大,但当ω过大时抗拉强度反而降低。当v = 35mm/min,ω = 1 000 r/min时接头抗拉强度达到最大值210 MPa,为母材AZ31B抗拉强度的90.5%。对拉伸试样断裂位置分析发现,所有的断裂全部发生在AZ61A侧(前进侧)热力影响区附近。断口与受力方向呈45?解理断裂,断口塑性很小,近似脆性断裂,尤其在抗拉强度较低时表现得更明显。

图5 焊接参数对接头性能的影响

Fig.5 Effects of FSW parameter on tensile strength

`挤压态变形镁合金组织比较粗大,在搅拌摩擦焊的过程中焊接参数对热力影响区影响非常大。分析认为旋转速度转速ω的变化直接影响热力影响区的组织形态及氧化物、夹杂物的分布,从而影响接头抗拉强度和断裂行为。当ω较低时热输入量小,热力影响区较窄,只有粗大晶粒得到拉长变形。搅拌头在搅拌区的摩擦和搅拌不足,不能有效去除试件施焊区上表面及端面的氧化物,在搅拌针的搅拌带动下塑性流动、与夹杂物一起在AZ61A侧(前进侧)热力影响区产生富集,从而形成一个力学性能较差的薄弱区域。随着ω的增大这个薄弱区域性能得到明显改善。这主要是因为ω的增加使得搅拌区的摩擦搅拌充分,施焊区上表面及端面的氧化物表面氧化膜得到去除,端面的氧化物和夹杂物被打碎,经搅拌混合扩散到焊核与机械热影响的过渡区域。同时热输入量随之增加、温度升高,为扩散渗透提供有利条件,热力影响区变宽,粗大组织在机械搅拌作用下拉长、细化,细小组织回复,使整体性能得到改善。但随着ω的进一步增大,热输入量过大,焊缝表面过热氧化严重,热力影响区与热影响区晶粒严重长大,反而使该区域力学性能迅速下降。

除组织结构不同的因素之外,应力集中也是造成AZ61B侧热力影响区发生断裂的重要因素[15]。观察搅拌摩擦焊接头,焊缝薄于母材,热力影响区与热影响区交界不是平滑过渡。另外,由于焊接过程中搅拌头向焊接方向倾斜,导致搅拌头两侧焊缝金属不均匀,前进侧金属比后退侧疏松且薄。这些因素都导致前进侧热力影响区成为整个接头中应力集中最严重的地方。

2.4 接头的硬度分布

图6所示为接头拉伸强度值最高的3#试样和拉伸强度值最低的10#试样接头横截面正中(2.5 mm深)显微硬度分布。由图可见,对于3#试样显微硬度分布曲线比较平缓,焊核区显微硬度略高于AZ31B母材硬度但远底于AZ61A母材硬度。AZ31B侧热力影响区显微硬度高于焊核区,在热影响区略有下降。AZ61A侧热力影响区显微硬度与焊核区相当,热影响区硬度由低向高过渡到母材。10#试样显微硬度分布曲线与3#试样在焊核区、热影响区基本相当,而在热力影响区却远远高于3#试样。这是由于当焊接参数不恰当时,在热力影响区出现大量呈层状分布氧化物和夹杂物富集带,这些富集带类似于经过了加工硬化,硬度非常高。而且在该处形成的残余应力集中也更大。另外,2条分布曲线在AZ31B母材区显微硬度并不一致,这与该母材组织不均匀相关。

图6 接头的显微硬度分布

Fig.6 Microhardness distribution of FSW joint

3 结论

1) 当采用圆台内凹形搅拌头、将AZ61B置于前进侧进行施焊时易得到成形良好、无焊接缺陷的AZ31B/AZ61A异种变形镁合金搅拌摩擦焊对接接头。

2) 适当的工艺参数范围较窄,接头的力学性能对搅拌头的旋转速度和焊接速度非常敏感。当取焊接速度v = 35 mm/min,搅拌头转速ω = 1 000 r/min时接头抗拉强度最高可达母材AZ31B标称强度的90.5%。

3) 前进侧热力影响区较宽,组织呈不均匀层状分布。当工艺参数不恰当时,前进侧热力影响区层状组织间存在氧化物和夹杂物富集,使得该区域显微硬度明显提高。该氧化物和夹杂物富集层的存在及严重的应力集中是造成接头在前进侧热力影响区力学性能下降、发生断裂的最主要原因。

REFERENCES

[1] MORDICK B L, EBERT T. Magnesium Properties- application-potential[J]. Mater Sci Eng A, 2001, 302: 37?45.

[2] 高 仑. 镁合金成形技术的开发与应用[J]. 轻合金加工技术, 2004, 32(3): 5?12.

GAO Lun. Exploit and application of magnesium alloy forming technology[J]. Light Alloy Fabrication Technology, 2004, 32(3): 5?12.

[3] 丁文斌, 蒋海燕, 曾小勤, 姚寿山. 镁合金焊接技术研究进展[J]. 轻合金加工技术, 2005, 33(8): 1?6.

DING Wen-bin, JIANG Hai-yan, ZENG Xiao-qin, YAO Shou-shan. Progress in welding technology of magnesium alloy[J]. Light Alloy Fabrication Technology, 2005, 33(8): 1?6.

[4] 栾国红, 郭德伦, 张田仓, 孙成彬. 铝合金的搅拌摩擦焊[J]. 焊接技术, 2003, 32(1): 1?4.

LUAN Guo-hong, GUO De-lun, ZHANG Tian-cang, SUN Cheng-bin. Friction stir welding of aluminium alloy[J]. Welding Technology, 2003, 32(1): 1?4.

[5] NICHOAS E D. Friction processing technologies[J]. Advanced Materials & Processes, 1999, 155(6): 69?71.

[6] COLLIGAN K. Material flow behavior during friction stir welding of aluminum[J]. Welding Journal, 1999, 78(7): 229?237.

[7] NAKATA K, INOKI S, NAGANO Y, HASHIMOTO T, JOHGAN S, USHIO M. Weld ability of friction stir welding of AZ91D magnesium alloy thixomolde Sheet[J]. Journal of Japan Institute of Light Metals(Japan), 2001, 51(10): 528?533.

[8] JOHNSON R. Friction stir welding of magnesium alloy[C]// 4th International Symposium on Friction Stir Welding. Park City, Utah, 2003: 14?16.

[9] 张 华, 林三宝, 吴 林. 镁合金AZ31搅拌摩擦焊接头的微组织[J]. 中国有色金属学报, 2003, 13(6): 1510?1513.

ZHANG Hua, LIN San-bao, WU Lin. Microstructure of friction stir welds in AZ31 magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(6): 1510?1513.

[10] ZHANG H, LIN S B, WU L, FENG J C, MA S L. Defects formation procedure and mathematic model for defect free friction stir welding of magnesium alloy[J]. Materials and Design, 2006, 27: 805?809.

[11] 张 华, 郭力杰, 林三宝, 吴 林, 冯吉才. 镁合金AZ31搅拌摩擦焊接塑性流体流动[J]. 焊接学报, 2004, 25(4): 67?69.

ZHANG Hua, GUO Li-jie, LIN San-bao, WU Lin, FENG Ji-cai. Material flow pattern in friction stir welding of AZ31 magnesium alloy[J]. Transactions of The China Welding Institution, 2004, 25(4): 67?69.

[12] 邢 丽, 柯黎明, 孙德超, 周细应. 镁合金薄板的搅拌摩擦焊工艺[J]. 焊接学报, 2001, 22(6): 18?20.

XING Li, KE Li-ming, SUN De-chao, ZHOU Xi-ying. Friction stir welding of MB8 magnesium alloy sheet[J]. Transactions of The China Welding Institution, 2001, 22(6): 18?20.

[13] 徐卫平. MB8镁合金薄板的搅拌摩擦焊[J]. 材料工程, 2002, 8: 35?36.

XU Wei-ping. Friction stir welding of magnesium alloy MB8[J]. Journal of Materials Engineering, 2002, 8: 35?36.

[14] 柯黎明, 邢 丽, 徐为平. AZ81镁合金焊接接头的组织与性能[J]. 材料工程, 2005(1): 41?44.

KE Li-ming, XING Li, XU Wei-ping. Microstructure and properties of welding joints for cast magnesium alloy AZ81[J]. Journal of Materials Engineering, 2005(1): 41?44.

[15] 张 华, 林三宝, 吴 林, 冯吉才. AZ31镁合金搅拌摩擦焊接头断裂机制[J]. 材料工程, 2005(1): 33?36.

ZHANG Hua, LIN San-bao, WU Lin, FENG Ji-cai. Fracture mechanism of friction stir welded AZ31 magnesium alloy[J]. Journal of Materials Engineering, 2005(1): 33?36.

收稿日期:2007-08-27;修订日期:2008-03-08

通讯作者:王希靖,教授,博士;电话:0931-2976706;传真:0931-2806962;E-mail: wangxj@lut.cn

(编辑 龙怀中)