文章编号: 1004-0609(2004)09-1534-05

铝合金LF6与工业纯铜T1的搅拌摩擦焊工艺

柯黎明, 刘鸽平, 邢丽, 夏春

(南昌航空工业学院 材料科学与工程系, 南昌 330034)

摘 要: 利用搅拌摩擦焊技术成功地焊接了防锈铝LF6和工业纯铜T1对接接头, 研究了工艺参数对接头组织与性能的影响。 结果表明: 搅拌头旋转速度与焊接速度的比值大小是保证接头致密性和决定组织、 性能的关键因素, 合适的焊接工艺参数可以获得组织、 性能优良的Al/Cu接头。 板材厚度较小时, 形成良好焊缝的规范参数范围较宽, 焊接过程中接头内部发生了剧烈的塑性流动。 由于摩擦热与变形能的共同作用, 在焊缝内部形成了Al3.892Cu6.108型金属间化合物, 使焊缝局部区域硬度升高。

关键词: Al/Cu焊接; 搅拌摩擦焊; 焊接过程 中图分类号: TG453

文献标识码: A

Friction stir welding process of aluminum alloy LF6 with copper T1

KE Li-ming, LIU Ge-ping, XING Li, XIA Chun

(Department of Materials Science and Engineering, Nanchang Institute of Aeronautical Technology, Nanchang 330034, China)

Abstract: The butt joint of dissimilar metals, aluminum alloy LF6 and copper T1, was welded with friction stir welding method. The influence of welding parameters on the microstructure and properties of the joint was investigated. The results show that the ratio of the rotation speed of the welding tool to the welding speed, i.e. ω/v, is the main factor to control the soundness, microstructures and properties of the weld. Suitable welding parameters can obtain the Al/Cu welding joint with good weld microstructures and properties. If the sheet is relatively thin, the range of welding parameters obtained that can get better weld quality is wider. Heavily plastic flow of the weld metal occurs inside the weld during the process. And a kind of intermetallic compound, Al3.892Cu6.108, is formed within the weld because of the cooperation effect of the friction heat and plastic deformation energy of the metals, and this compound increases the hardness of the local area in the weld.

Key words: Al/Cu welding; friction stir welding; welding process

铜和铝都是导电性能优良的材料, 但铜的密度大、 价格高, 因而, 在很多场合常用铝代替铜, 将铝与铜连接起来, 焊接是满足接头导电性能的可靠的连接方法。 但是, 由于铝与铜的熔点相差较大, 且高温下铝会强烈氧化, 因此, 在熔焊时需采取措施防止氧化并去除熔池中的氧化物[1, 2]。 同时, 由于铜和铝能形成多种金属间化合物, 影响焊接接头的强度、 塑性, 因此, 在实际生产中, 往往利用压焊的方法制成铜-铝过渡接头, 从而避开异种金属熔焊的困难。

铜与铝的压焊方法有电阻对焊、 闪光对焊、 摩擦焊、 真空扩散焊、 爆炸焊等[3-5]。 对焊时, 一般要求有较大的焊接电流; 摩擦焊一般只能焊接轴类零件; 真空扩散焊和爆炸焊常受到设备和接头形式限制, 因而, 在很多场合不能使用。

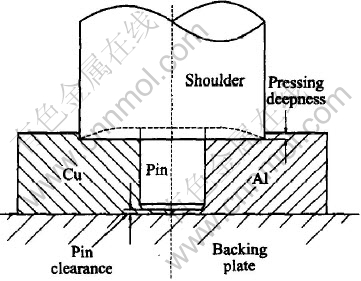

搅拌摩擦焊( friction stir welding, 简称FSW)是20世纪90年代发展起来的一种新型固相焊接技术, 图1所示为这种工艺的示意图。 FSW利用一种带有探针(pin)和轴肩(shoulder)的特殊形式的搅拌头。 焊接前, 将两待焊板材放在刚性底板(backing plate)上并压紧, 将搅拌头的探针插入待焊板材接缝内, 保持探针顶端离底板有一定距离(pin clearance), 搅拌头的轴肩与板材的表面紧密接触或压入一定深度(pressing deepness)。 焊接时, 搅拌头高速旋转并沿待焊板材的接缝运动, 摩擦热使探针周围金属处于热塑性状态, 探针前方塑性状态的金属在搅拌头的驱动下向后方流动, 在此处塑性融合, 从而使待焊件压焊为一个整体。 由于焊接过程中, 焊缝金属不发生熔化, 从而避免了焊缝金属的剧烈氧化及气孔、 裂纹等缺陷[6, 7]。 目前, 国内外进行较多的是各种铝和铝合金搅拌摩擦焊以及异种铝合金的搅拌摩擦焊技术的研究[8-10]。 关于异种金属, 尤其是铜与铝的搅拌摩擦焊的研究较少。 LI等[11, 12]研究了银/铝合金的搅拌摩擦焊, 为观察焊缝金属的组织特征, 焊接了铝合金与紫铜对接接头。 本文作者主要研究铝合金与紫铜对接接头的搅拌摩擦焊工艺及其组织和性能, 为这种新型技术在异种金属焊接中的应用提供技术依据。

图1 FSW工艺示意图

Fig.1 Schematic graph of friction stir welding

1 实验

1.1 搅拌摩擦焊工艺

选用厚度为2~3mm的LF6铝合金和T1紫铜板, 焊前用丙酮清洗工件表面油污, 在自制搅拌摩擦焊设备上进行焊接工艺实验。

搅拌摩擦焊的工艺参数主要为搅拌头对工件施加的压力p、 搅拌头旋转速度ω、 搅拌头沿焊缝方向的移动速度(即焊接速度)v, 其中搅拌头对工件施加的压力大小对焊缝成形影响较大。 由于现有的设备难于定量地测量压力的大小, 但搅拌头使工件表面的下压量(pressing deepness )间接地反映了此压力值, 因此, 在本工艺实验中, 将焊缝表面下压量控制为一定值, 研究搅拌头旋转速度ω和焊接速度v对焊缝成形的影响。 其工艺参数的选用范围: 搅拌头旋转速度ω为375~1500r/min, 焊接速度v为23.5~150mm/min。

1.2 接头组织和性能分析

焊接接头金相试样沿垂直于焊缝方向的横截面、 平行于试样表面的截面切取, 将试样抛光后直接观察或腐蚀后观察焊缝组织形态。 腐蚀时, 铝合金侧采用keller试剂(3mL硝酸, 6mL盐酸, 6mL氢氟酸, 150mL水)腐蚀; 紫铜侧采用4mL饱和氯化钠, 2g重铬酸钾, 100mL水, 8mL硫酸腐蚀液进行腐蚀, 用Leica图像分析仪进行组织分析。

焊接接头的拉伸性能实验按国标GB/T16865-1997, 在WDS-100电子万能试验机上进行。 用71型显微硬度计测量焊缝区显微硬度。

2 结果及分析

2.1 焊接工艺参数对接头成形的影响

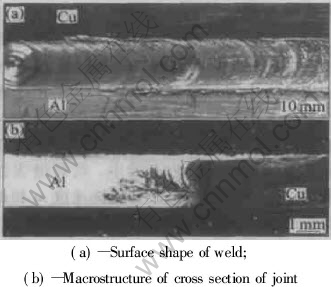

图2所示为典型的铝合金与铜的搅拌摩擦焊焊接接头成形情况, 其中图2(a)为表面外观形貌, 图2(b)为相应的横截面的宏观组织。 由图2可见, 铝合金与紫铜焊接接头可以获得良好的焊缝, 其成形情况与焊接工艺参数和板材厚度等因素有关。

对于厚度为2mm的板材, 良好焊缝成型的工艺参数范围: 搅拌头旋转速度ω为375~1180r/min, 焊接速度v为30~150mm/min。 对于厚度为3mm的板材, 相同的工艺很难获得满意的焊缝, 且获得良好焊缝成形的规范范围较窄, 当搅拌头旋转速度ω=750r/min, 焊接速度v为60~75mm/min时, 可以获得无宏观缺陷的焊缝。

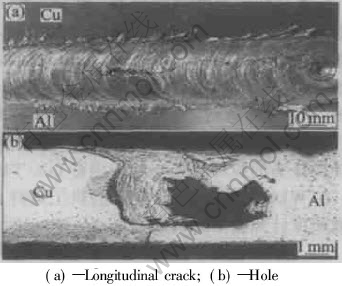

规范参数不当时, 在焊缝中会产生缺陷。 焊缝缺陷主要表现为焊缝表面成形不好, 出现裂纹或沟槽, 或在焊缝内部出现孔洞或隧道型缺陷。 隧道型缺陷为表面成形良好、 无裂纹, 而在焊缝内部, 孔洞呈连续状态。 图3所示为焊缝中出现的缺陷形貌, 其中图3(a)为焊缝的纵向裂纹, 图3(b)为孔洞。 类似于熔化焊时的焊缝金属结晶裂纹, 搅拌摩擦焊焊缝的纵向裂纹在焊接过程中随着搅拌头的运动不断延伸。 由图3(a)还可见, 焊缝表面粗糙, 两侧有较多的飞边。 在旋转速度一定的情况下, 搅拌头行走速度过低, 容易产生裂纹; 行走速度过高, 则易出现沟槽型缺陷。

图2 Al/Cu搅拌摩擦焊接头表面成形形貌

Fig.2 Appearance of FSW joint of Al/Cu

图3 焊缝中的缺陷

Fig.3 Defects in weld

在焊接过程中还发现, 与单一金属铝合金或紫铜的焊接或厚度为2mm的铝-铜异种金属的焊接相比, 焊接厚度为3mm的铝-铜接头极易发生搅拌头堵塞的现象, 即焊缝中的材料粘合在轴肩和探针的凹陷处, 破坏了搅拌头的原有形貌。 这种现象一般出现在焊接一定长度的焊缝之后。 一旦搅拌头出现堵塞现象, 正常的焊接过程就被破坏, 焊缝表面的成形变差, 甚至出现沟槽型缺陷。 实验发现, 这种现象与搅拌头材料有关, 搅拌头经不同的表面处理后, 影响焊缝成形的效果, 可以焊接的合格焊缝的长度不同。

分析认为, 对于铝-铜异种材料的搅拌摩擦焊, 裂纹的产生与焊缝中Al/Cu金属间化合物的形成有关。 根据Al-Cu二元相图, 铝与铜能形成多种以金属间化合物为主的固溶体相, 包括AlCu2、 Al2Cu3、 AlCu、 Al2Cu等[13]。 搅拌摩擦焊时, 搅拌头与工件间的摩擦热使焊缝温度提高。 同时, 焊缝区的铝与铜在搅拌头的作用下混合, 并经历剧烈塑性变形, 二者的综合作用使焊缝在固态下形成铜铝金属间化合物。

焊缝温度的升高与搅拌头在单位长度焊缝上产生的热量有关, 即与搅拌头旋转速度和焊接速度的比值(ω/v)有关。 在摩擦面所受压力一定的情况下, 单位长度焊缝内摩擦热的生成随ω/v的增大而增大。 当搅拌头旋转速度一定时, 若焊接速度过低, 则单位长度焊缝上产生的热量就会过多, 温度上升就过高, 在摩擦热与变形能的共同作用下, 焊缝中的铝和铜可能形成上述金属间化合物, 从而使这一部位的材料变脆。 而工件是在强拘束条件下进行焊接的, 在焊接拘束应力的作用下, 脆性焊缝有可能断裂, 从而形成焊缝宏观裂纹。

隧道型缺陷的形成往往与ω/v值和搅拌头对工件施加的压力大小有关。 在ω/v值一定的情况下, 若搅拌头压力过低, 工件表面下压量过小, 易在焊缝内部出现孔洞或沟槽型缺陷。 若ω/v过低, 由于单位长度焊缝上摩擦产生的热量过少, 焊缝区温度偏低, 不能形成Al/Cu塑性状态下的连接, 从而使接头出现沟槽型宏观缺陷。

2.2 焊缝金相组织分析

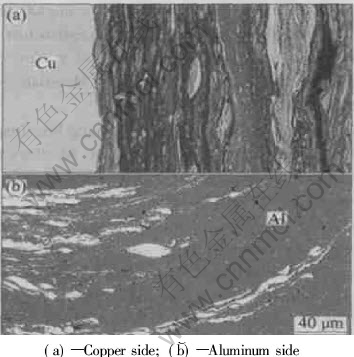

图4所示为焊缝紫铜侧的金相照片, 其中图4(a)为焊缝横截面形貌, 图4(b)为离焊缝上表面约1mm处平行于试样表面的截面形貌。 由图可见, 在紫铜侧, 焊缝与母材间有非常明显的分界面, 在焊缝内部, 铜与铝在搅拌头的作用下相互呈片状交迭。

图5(a)所示为焊缝与铜界面处的背散射电子像, 可清楚地看到铜与铝交迭。 图5(b)所示为焊缝内靠铝合金侧的背散射电子像, 白色组织为纯铜, 焊缝中除有与搅拌头旋转形成的塑性流动痕迹一致的大块弧形条状铜带外, 在焊缝内还有较多分布比较均匀的铜颗粒。 弧形条状铜带的存在说明在搅拌摩擦焊过程中, 塑性状态的金属随搅拌头的旋转而[CM(22]流动, 而焊缝内均匀分布着铜颗粒, 说明部分金属在搅拌头的驱动下可以从焊缝一侧移动到另一侧。

图4 焊缝宏观金相组织

Fig.4 Macrostructure of weld

图5 焊接接头金属的背散射电子像

Fig.5 Backscattered diffraction electron image of weld

搅拌头的搅拌作用是影响局部金属塑性流动状态的关键因素, 是形成致密焊缝的充分条件。 在Al/Cu搅拌摩擦焊中, 由于温度和搅拌力的共同作用, 处于热塑性状态的铝合金在焊缝内由探针的前方流向后方, 并产生动态再结晶现象, 而一部分处于热塑性状态的铜也在搅拌头的驱动下离开铜母材与铝合金一同向搅拌头后方的空腔流动, 从而使得热塑性状态的铝合金和铜相互结合形成了图4和5所示的涡流状交迭区。

2.3 焊接接头的力学性能

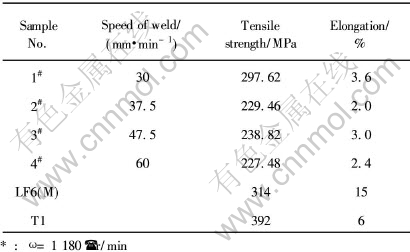

在搅拌头压力一定的情况下, 搅拌摩擦焊焊缝的形成与搅拌头旋转速度和焊接速度有关。 因此, 分析铝-铜搅拌摩擦焊接头的力学性能时, 选择厚度为2mm的铝合金LF6与纯铜T1, 控制一定的工件表面下压量, 给定搅拌头旋转速度ω=1180r/min, 在不同的焊接速度v时, 对获得的焊缝成形良好的试件进行接头力学性能实验。 表1所列为接头的拉伸实验结果, 在焊缝表面成形较好的情况下, 当搅拌头旋转速度ω=1180r/min、 焊接速度v=30mm/min时, 接头抗拉强度最高; v为37.5~60mm/min时, 接头抗拉性能相差不大, 与紫铜母材的抗拉强度相近。 因此, 铝合金-铜异种材料焊接接头在搅拌摩擦焊时, 可以获得较好的力学性能。

表1 铝/铜搅拌摩擦焊接头的拉伸性能*

Table 1 Tensile properties of Al/Cu FSW joint

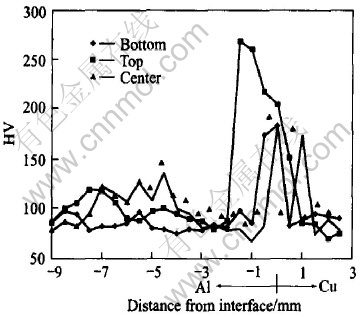

图6所示为LF6铝合金-紫铜焊缝横截面的显微硬度分布。 由图6可见, 接头硬度介于紫铜T1和铝合金LF6之间, 接头中间硬度较高, 部分点的硬度远远高于Al和Cu母材的硬度, 在某些区域, 硬度值在HV300以上, 但如此高的硬度值不是加工硬化造成。 由金相图可知, 高硬度点在显微镜下对应为白亮区域, 而铝合金基体为灰色区域, 因此可以判断形成了Cu-Al金属间化合物。

利用BRUKER D8 X射线衍射仪对焊缝物相进行分析, 表明焊缝中除存在原始的铜和铝外, 还有部分新的物相Cu6.108Al3.892, 与文献[6]中研究Cu/Al扩散焊时, 在界面处发现的Cu32Al19型金属间化合物的成分类似。 同时, 由于在搅拌摩擦焊过程中焊缝材[CM(22]料经历了较大塑性变形, 使两种金属晶格发生畸变,因而, 铜和铝的波峰与标准样品的波峰有所偏离。

图6 接头显微硬度曲线

Fig.6 Microhardness of joint

3 结论

1) 选用恰当的焊接工艺参数, 能实现Al/Cu异种金属的搅拌摩擦焊连接, 且接头的组织、 性能优良。

2) 焊接工艺参数ω和v是保证接头致密性和决定组织、 性能的关键因素, 在高的搅拌头旋转速度 ω下能实现高速焊接。

3) Al/Cu搅拌摩擦焊接头的涡流状交迭区反应了在搅拌摩擦焊的过程中, 接头金属发生了塑性流动, 接头局部点硬度的突变表明有新物质生成, X射线物相分析表明新物质为Al3.892Cu6.108型金属间化合物。

4) 用搅拌摩擦焊方法焊接时, 容易形成金属间化合物的异种材料, 对于薄板, 形成良好焊缝成形的规范参数范围较宽; 对于厚板, 形成良好焊缝成形的规范参数范围较窄。

REFERENCES

[1]元永新, 杨瑞鹏. 铝铜焊接进展[J]. 焊接技术, 2000, 29(5): 4-5.

YUAN Yong-xin, YANG Rui-peng. Current situation in aluminum and copper welding[J]. Welding Technology, 2000, 29(5): 4-5.

[2]孙立权. 铜铝过渡伸缩节的焊接工艺[J]. 焊接, 1997(12): 14-16.

SUN Li-quan. Welding procedure of copper-aluminum expansion joint[J]. Welding, 1997(12): 14-16. [3]中国机械工程学会焊接学会. 焊接手册(第二卷)[M]. 北京: 机械工业出版社, 1992. 609-610.

Welding Institute of Chinese Mechanical Engineering Society. Welding Handbook(Vol 2)[M]. Beijing: Mechanical Industry Press, 1992. 609-610.

[4]刘中青, 刘凯. 异种金属焊接技术指南[M]. 北京: 机械工业出版社, 1997. 269-278.

LIU Zhong-qing, LIU Kai. Guide for Dissimilar Metal Welding[M]. Beijing: Mechanical Industry Press, 1997. 269-278.

[5]李亚江, 吴会强, 陈茂爱, 等. Cu/Al真空扩散焊接头显微组织分析[J]. 中国有色金属学报, 2001, 11(3): 424-427.

LI Ya-jiang, WU Hui-qiang, CHEN Mou-ai, et al. Microstructure analyses in vacuum diffusion welded joint of copper and aluminum[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(3): 424-427.

[6]柯黎明. 搅拌摩擦焊工艺及应用[J]. 焊接技术, 2000, 29(2): 7-8.

KE Li-ming. The process of friction stir welding and its application[J]. Welding Technology, 2000, 29(2): 7-8.

[7]Murr L E. Fundamental issues and industrial application of friction stir welding[J]. Mat Tech & Adv Perf Mat, 2000, 5(1): 37-48.

[8]Lee W B, Yeon Y M, Jung S B. The mechanical properties related to the dominant microstructure in the weld zone of dissimilar formed Al alloy joints by friction stir welding[J]. Journal of Materials Science, 2003, 38(20): 4138-4191.

[9]Won-Bae Lee, Yun-Mo Yeon, Seung-Boo Jung. The joint properties of dissimilar formed Al alloys by friction stir welding according to the fixed location of materials[J]. Scripta Materialia, 2003, 49(5): 423-428.

[10]Su J Q, Nelson T W, Mishra R, et al. Microstructural investigation of friction stir welded 7050-T651 aluminum[J]. Acta Materialia, 2003, 51(3): 713-729.

[11]LI Ying, Trillo E A, Murr L E. Friction stir welding of aluminum alloy 2024 to silver[J]. Journal of Materials Science Letters, 2000, 19(12): 1047-1051.

[12]Murr L E, LI Ying, Flores R D, et al. Intercalation vortices and related microstructural features in the friction-stir welding of dissimilar metals[J]. Mat Res Innovat, 1998, 2(3): 150-163.

[13]虞觉奇. 二元合金状态图集[M]. 上海: 上海科学技术出版社, 1987.

YU Jiao-qi. Handbook of Binary Alloy Phase Diagrams[M]. Shanghai: Shanghai Science and Technology Press, 1987.

基金项目: 江西省工业发展基金资助项目(BC200201014); 江西省自然科学基金资助项(9950010)

收稿日期: 2004-02-10; 修订日期: 2004-05-22

作者简介: 柯黎明(1960-), 教授, 硕士.

通讯作者: 柯黎明, 电话: 0791-8216261; E-mail: liming_ke@yahoo.com

(编辑 李艳红)