文章编号:1004-0609(2009)03-0484-06

焊后热处理对高强铝合金搅拌摩擦焊接头的影响

王希靖1, 2,孙桂苹1, 2,张 杰1, 2,徐 成1, 2,李树伟1, 2,牛 勇1, 2

(1. 兰州理工大学 甘肃省有色金属新材料国家重点实验室,兰州 730050;

2. 兰州理工大学 材料科学与工程学院,兰州 730050)

摘 要:对航空用厚5 mm的7075铝合金搅拌摩擦焊试样热处理前后的焊缝微观组织及性能进行研究。结果表 明:当搅拌头旋转速度为600 r/min、焊接速度为60 mm/min时,接头抗拉强度达到381 MPa,是母材强度的84.6%;焊核区由6~7 μm等轴晶组成;经热处理后接头抗拉强度达到415 MPa;硬度的最低处在前进侧热机影响区;断口的微观形貌具有强化相的韧窝特征,且断裂几乎发生在前进侧的热机影响区;7075铝合金搅拌摩擦焊接头的薄弱点在热机影响区。

关键词:7075铝合金;搅拌摩擦焊;微观组织

中图分类号:TG 453+.9; TG 166.3 文献标识码:A

Effects of heat treatment after welding on friction stir welding joints of high-strength aluminum alloy

WANG Xi-jing1, 2, SUN Gui-ping1, 2, ZHANG Jie1, 2, XU Cheng1, 2, LI Shu-wei1, 2, NIU Yong1, 2

(1. State Key Laboratory of Advanced Non-ferrous Metal Materials, Gansu Province,

Lanzhou University of Technology, Lanzhou 730050, China;

2. School of Materials Science and Engineering, Lanzhou University of Technology, Lanzhou 730050, China)

Abstract: The microstructure and property before and after heat treatment of friction stir welded 5 mm aero 7075 aluminum alloy were investigated. The results show that when the rotating speed of stirring joint is 600 r/min and the welding speed is 60 mm/min, the tensile strength can reach 381 MPa that is 84.6% of the base metals, which are regarded as the most ideal parameters under experimental conditions. There are equiaxed grains with size of 6?7 μm in weld nugget. After heat treatment, the tensile strength can reach 415 MPa. The lowest hardness appears in thermomechanically affected zone (TMAZ) of advancing side. The fractography has a characteristic of dimples of strengthening phase and the strain fracture appears in TMAZ of advancing side of joints. The weak point of friction stir welding joint for 7075 aluminum alloy occurs in the TMAZ.

Key words: 7075 aluminum alloy; friction stir welding; microstructure

搅拌摩擦焊(FSW)是英国焊接研究所发明的一种固相连技术[1],自发明以来,在世界范围内引起了广泛的关注[2?5]。与传统工艺相比,搅拌摩擦焊具有连接温度低、焊后残余应力小、接头性能高等一系列优 点[6?10],在航空航天、造船、汽车等领域,尤其是高强铝合金的连接方面具有广阔的应用前景。目前,应用搅拌摩擦焊成功连接的材料有Mg合金、铅、锌、铜、不锈钢、低碳钢等同种或异种材料[11],该技术已成为21世纪国内外研究的热点[12?16]。7075铝合金是一种可热处理强化的A1-Mg-Zn-Cu系超硬铝合金材料,熔铸方便,成形性好,经轧制能获得比较理想的板材,通过固溶及回归再时效处理,可获得优良的综合性能。

7075铝合金为高强轻质材料,广泛应用于航空航天工业。目前,该类合金的焊接主要采用惰性气体保护焊,焊后焊缝中容易出现焊接变形和气孔,残余应力较大,且对应力腐蚀敏感,不能充分发挥材料的性能。利用搅拌摩擦焊技术可以更好地保持基体材料的力学性能,并且能够减少或消除熔焊时产生的焊接缺陷。本文作者选取厚5 mm的7075铝合金进行单道平板对接搅拌摩擦焊,研究该合金焊接接头热处理前后的组织与力学性能,该研究对工程生产有重要帮助。

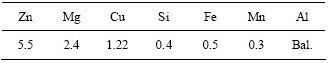

1 实验

焊接试验使用的材料为厚5 mm的7075铝合金轧制板材,焊件尺寸为160 mm×20 mm×5 mm,其化学成分与热处理前接头拉伸性能分别如表1与表2所列。试验用搅拌头轴肩直径为20 mm,搅拌针直径为5 mm,长度为4.8 mm。试验采用平板对接方式进行搅拌摩擦焊接。试验用搅拌摩擦焊机为FSW?3LM? 015,焊接工艺参数为:搅拌头旋转速度600 r/min,搅拌头沿焊缝方向的焊接速度60 mm/min。焊接后在岛津AG?10TA电子万能拉伸机上进行拉伸试验,对成形良好的焊接接头进行硬度试验并制作金相试样观察组织形貌,用HX?1000TM型显微硬度计进行显微硬度试验,在Me-F3金相光学显微镜上观察微观组织。腐蚀剂成分为:2 mL HF、3 mL HC1、5 mL HNO3、190 mL H2O,腐蚀时间为10 s。热处理工艺为:固溶温度466 ℃,2 h室温水淬;120 ℃,24 h人工时效。

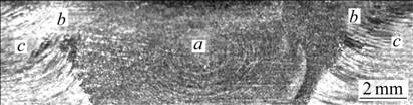

表1 7075铝合金的化学成分

Table 1 Chemical compositions of 7075 Al alloy (mass fraction, %)

表2 热处理前接头的抗拉强度

Table 2 Joint tensile strength before heat treatment

2 结果与分析

2.1 工艺参数对焊件抗拉强度的影响

接头力学性能如表2所列,在搅拌头旋转速度为600 r/min、焊接速度为60 mm/min时,焊件的抗拉强度最好,为381.07 MPa,达到母材强度的84.6%。

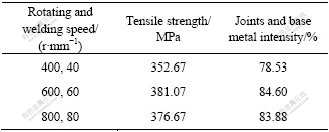

由表3可知,在热处理后试样的强度明显提高,为母材强度的89.50%,这证明在该参数下7075铝合金板经搅拌摩擦焊后其接头力学性能良好,在经过热处理后可获得更高强度的接头。

表3 热处理后接头的抗拉强度

Table 3 Joint tensile strength after heat treatment

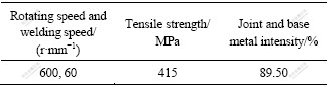

2.2 接头的宏观形貌

图1所示为铝合金接头的宏观横断面,其中a区为焊核区,材料在该区发生了剧烈的变形,在焊核区可以观察到洋葱环形貌,它的形成是由于当搅拌头旋转沿焊缝走过时,不断向搅拌头的返回边挤压塑性金属流的结果,b区为热机影响区,材料在该区有变形迹象,但由于搅拌头的旋转作用,左右两边的流线方向有所不同;c区为热影响,b区和c区有较明显的分界。

图1 搅拌摩擦焊接头的横截面宏观照片

Fig.1 Section macrograph of friction stir welding joint

2.3 接头的微观组织

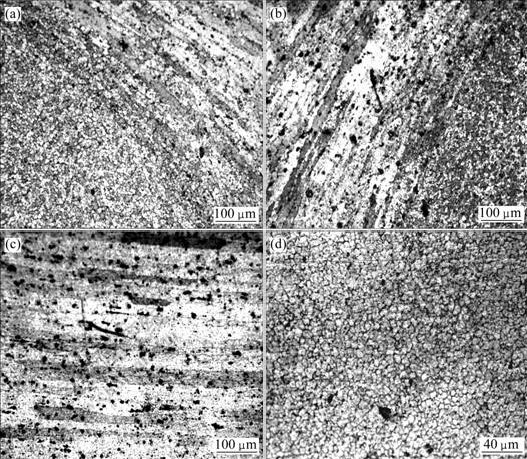

热处理前接头的微观组织如图2所示。母材和焊缝区的分界线在前进面和后退面不同,前进面分界线比较明显,后退面的分界线比较模糊,如2(a)、(b)所示。母材为典型的轧制状态,微观形貌为沿轧制方向的板条组织,如图2(c)所示。焊核区为细小的等轴晶,如图2(d)所示。出现在前进面和后退面的分界线可能是在搅拌摩擦焊过程中,搅拌头经过区域的金属处于完全塑性状态,两侧的金属根据离搅拌头的距离远近不同而处于不同的塑性状态,并且都会随着搅拌头的旋转而塑性流动,其流动方向不一致[17]。在前进面,母材塑性变形方向朝前,与焊接方向一致;在后退面母材塑性变形方向朝后,与焊接方向相反;在焊缝内,由于搅拌头旋转过程中的空腔作用,使搅拌区内前进面的金属沿搅拌头的外表面逆时针地被挤压至搅拌头的后方。因此,在前进面,焊缝金属塑性流动方向与母材金属塑性流动方向相反,使母材金属与焊缝金属之间存在很大的相对变形差;在后退面,金属塑性流动方向与母材金属塑性流动方向相同,因而造成前进面焊缝与焊缝区有明显的分界线[18]。

图2 热处理前接头的微观组织

Fig.2 Microstructures of joint before heat treatment: (a) Retreating side; (b) Advancing side; (c) Base metal; (d) Nugget

焊核区晶粒细小均匀,呈等轴晶,这是由于此处的金属在搅拌头的作用下,温度较高且应变速率较大,使之不断地形成再结晶晶核,并发生有限的长大所致,搅拌头对晶粒的破碎作用也使该区晶粒细小。而热机影响区晶粒被拉长,晶粒变形没有焊核区剧烈,但由于该处晶粒受到搅拌头肩轴的挤压作用,使晶粒变长。

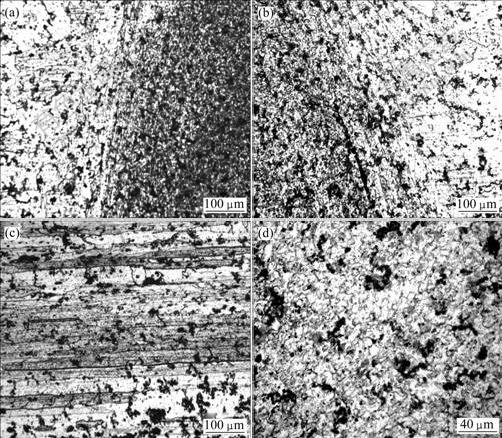

图3所示为热处理后各区的微观组织。从图3(d)中可以看到焊核区晶粒比原始状态更为细小,显微组织晶粒呈扁平状或近等轴状分布。过渡区分界线较之前模糊(图3(a)和(b))。图3(d)可以看出,母材板条组织逐渐消失,轧制组织由再结晶组织与变形的板条状组织组成,化合物被破碎并沿轧制方向排列,但不是十分明显。析出相数量较热处理前多,弥散分布均匀且弥散度大。

图3 热处理后接头的微观组织

Fig.3 Microstructures of joint after heat treatment: (a) Advancing side; (b) Retreating side; (c) Base metal; (d) Nugget

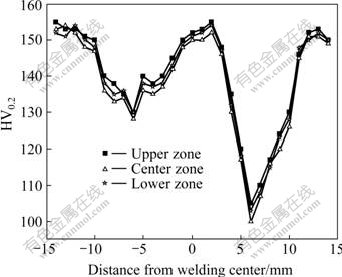

2.4 接头的显微硬度

图4所示为7075铝合金搅拌摩擦焊接头的显微硬度。实验中对试样上、中、下部进行显微硬度测试。由图4可知,过渡区硬度低于母材。由于温度的作用,弥散分布的细小强化相发生了集聚,材料出现了过时效。在焊核区尽管强化相已固溶于基体,但在焊核区发生了动态再结晶使得晶粒细化,硬度升高。硬度的最低处出现在前进侧的热机影响区。不同部位的微观硬度有所不同,在同一焊缝的不同部位,顶部同时受到搅拌焊头的焊针和轴肩的摩擦、搅拌作用,因此,其微观结构特性与中部和底部不同,反映在微观硬度上就是其数值比较高,其强度也相应较高。焊缝的中部无轴肩的摩擦及搅拌作用,其热量输入小于顶部,且热量的输出小于底部,所以,焊缝中部吸收的热量大于底部,材料更为软化,硬度值最低。

图4 接头的显微硬度分布

Fig.4 Microhardness distribution of joint

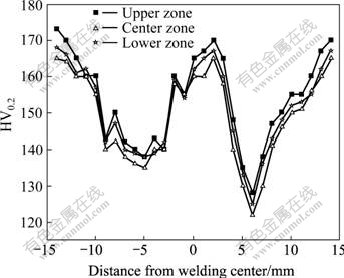

由图5可知,经热处理后试样的显微硬度明显提高,硬度分布更为均匀。这是由于固溶处理在不提高合金元素总含量的前提下提高了固溶体的过饱和度,使固溶的合金元素浓度增加,同时减少粗大未溶结晶相,对于提高时效析出程度和改善抗断裂性能具有积极意义。淬火后过饱和固溶体浓度提高,经时效后具有更高的强度,从而提高材料的综合性能。

图5 热处理后试样的显微硬度分布

Fig.5 Microhardness distribution of sample after heat treatment

2.5 拉伸试样的断口分析

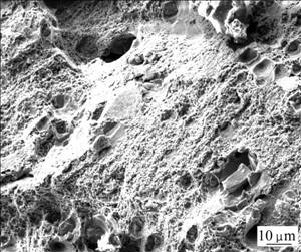

对接头进行力学性能测试发现,几乎所有试样被拉断时均断裂在前进侧的热机影响区,这与显微硬度分布相吻合,对于无缺陷的接头,其拉伸强度和断裂位置只与微观硬度有关。因此,焊缝的前进侧热机影响区是焊缝的最薄弱处,其断口的微观形貌如图6所示,表现为具有强化相的韧窝特征。7075铝合金的主要强化机制为析出强化,合金的强度主要由基体析出相的大小、数量和弥散度决定。金相照片中弥散分布着含铁、硅的强化相,这些强化相主要为Mg32(Al, Zn)49和Mg(Zn2, AlCu)[19]。强化相的强度、塑性和弹性模量等均与基体不同,塑性变形时,滑移沿基体滑移面进行,强化相起阻碍滑移的作用,在强化相前方形成位错塞积群,在强化相与滑移面交界处造成应力集中。

图6 热处理前接头断口的微观组织

Fig.6 Microstructure of fractography for joint before heat treatment

随着应变量的增大,塞积群中的位错个数增多,应力集中加剧。当集中应力达到强化相本身的强度或强化相与基体的界面结合强度时,便导致强化相本身折断或与界面脱离,形成最初开裂的微孔。随着加载的升高和基体塑性变形的加剧,相邻强化相质点周围的微孔间金属犹如两侧带有切口的小试样继续变形,塑性变形优先在微孔所在截面内发展,并由于形变强化使其承载能力提高,进一步的变形在该截面附近的材料中进行,结果该局部的材料被拉长,微孔钝化。此时,微孔间的材料犹如颈缩试样,在继续变形中伸长,并最终以内颈缩方式断裂,内颈缩的发展使微孔长大,局部断裂导致微孔连结,微孔连结遗留的痕迹便是断口上的韧窝。

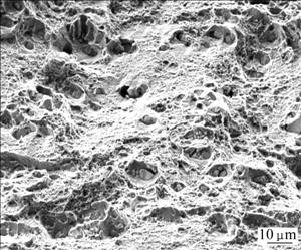

图7所示为扫描电镜观察的单级时效常温拉伸试样的断口形貌,时效制度为120 ℃,24 h。一些杂质元素在板材扎制过程中破碎,由于难溶于甚至不溶于固溶体,所以他们的形态和分布在随后的热处理中很少或不发生变化。这些脆性粒子在合金中起到缺口的作用,当基体受到应力作用发生塑性变形时,在颗粒内部或颗粒与基体的边界产生空洞或孔隙,萌生微细裂纹。随着应力的增加,这些微裂纹逐渐长大,裂尖应力不断增加。当裂尖附近局部区域内的应力超过材料的断裂强度后,基体发生断裂。

图7 热处理后接头断口的微观组织

Fig.7 Microstrucutre of fractography for joint after heat treatment

3 结论

1) 实现了厚5 mm的7075铝合金的搅拌摩擦焊,工艺参数为:搅拌头旋转速度600 r/min,焊接速度60 mm/min;抗拉强度381 MPa,是母材强度的84.6%。经热处理后接头抗拉强度是母材强度的89.50%,有着良好的力学性能。

2) 7075铝合金搅拌摩擦焊接头焊核区为细小的等轴晶组织,晶粒大小为 6~7 μm。热处理后焊核区晶粒更为细化,显微组织晶粒呈扁平状或近等轴状分布。轧制组织由再结晶组织与变形的板条状组织组成,化合物被破碎并沿轧制方向排列,但不是十分明显。

3) 7075铝合金搅拌摩擦焊接头TMAZ/HAZ过渡区硬度低于母材,是焊件的薄弱环节。硬度的最低处出现在前进侧热机影响区。经热处理后接头的显微硬度明显提高,硬度分布更为均匀。

4) 力学性能测试发现,几乎所有试样被拉断时均断裂在前进侧的热机影响区,表现为具有强化相的韧窝特征,为韧性断裂。

REFERENCES

[1] 赵衍华, 林三宝, 申家杰, 吴 林. 2014铝合金搅拌摩擦焊接头的微观组织及力学性能[J]. 航空材料学报, 2006, 26(1): 67?70.

ZHAO Yan-hua, LIN San-bao, SHEN Jia-jie, WU Lin. Microstructures and mechanical properties of friction stir welding joint of 2014 aluminum alloy[J]. Journal of Aeronautical Materials, 2006, 26(1): 67?70.

[2] 赵衍华, 林三宝, 吴 林. 2014铝合金搅拌摩擦焊接过程塑性金属流变可视化[J]. 焊接学报, 2005, 26(6): 73?76.

ZHAO Yan-hua, LIN San-bao, WU Lin. Microstructures and mechanical properties visualization of friction stir welding process on plasticity metal flowing deformation of aluminum alloy 2014[J]. Transactions of the China Welding Institution, 2005, 26(6): 73?76.

[3] 赵衍华, 林三宝, 贺紫秋, 吴 林. 二维搅拌摩擦焊接过程的数值模拟[J]. 中国有色金属学报, 2005, 15(6): 865?869.

ZHAO Yan-hua, LIN San-bao, HE Zi-qiu, WU Lin. Numerical simulation of 2D friction stir welding process[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(6): 865?869.

[4] MISHRA R S, MA Z Y, CHARIT I. Friction stir processing: a novel technique for fabrication of surface composite[J]. Mater Sci Eng, 2003, 34(1/2): 307?310.

[5] 栾国红, NORTH T H, 郭德伦, 张田仓. 铝合金搅拌摩擦焊接头行为分析[J]. 焊接学报, 2002, 23(6): 62?66.

LUAN Guo-hong, NORTH T H, GUO De-lun, ZHANG Tian-cang. Characterizations of friction stir welding on aluminum alloy[J]. Transactions of the China Welding Institution, 2002, 23(6): 62?66.

[6] SQUILLACE A, de FENZO A, GIORLEO G, BELLUCCI F. A comparison between FSW and TIG welding techniques modifications of microstructure and pitting corrosion resistance in AA2024-T3 butt joints[J]. Journal of Materials Processing Technology, 2004, 152(1): 97?105.

[7] MISHRA R S, MA Z Y. Friction stir welding and processing[J]. Mater Sci Eng, 2005, 50(12): 178?185.

[8] 王训宏, 王快社, 徐可为, 胡 锴. LF2铝合金搅拌摩擦焊接头的疲劳特性[J]. 特种铸造及有色合金, 2006, 26(6): 379?380.

WANG Xun-hong, WANG Kuai-she, XU Ke-wei, Hu Kai. Fatigue properties of friction stir welded aluminum alloy LF2[J]. Special Casting & Nonferrous Alloys, 2006, 26(6): 379?380.

[9] 沈 洋, 王快社, 吕 爽, 孙 鹏. 7075铝合金搅拌摩擦焊研究[J]. 特种铸造及有色合金, 2007, 27(2): 145?147.

SHEN Yang, WANG Kuai-she, L? Shuang, SUN Peng. A study on friction stir welds of 7075 aluminum alloy[J]. Special Casting & Nonferrous Alloys, 2007, 27(2): 145?147.

[10] ERICSSON M, SANDSTROM R. Influence of welding speed on the fatigue of friction stir welds, and comparison with MIG and TIG[J]. International Journal of Fatigue, 2003, 25(12): 1379?1387.

[11] 王希靖, 达朝炳, 李 晶, 张忠科. 搅拌摩擦焊中的洋葱环形成分析[J]. 中国有色金属学报, 2006, 16(10): 1672?1677.

WANG Xi-jing, DA Chao-bing, LI Jing, ZHANG Zhong-ke. Analysis of formation of onion rings in friction stir welding[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(10): 1672?1677.

[12] 邢 丽, 柯黎明, 周细应, 刘鸽平. 防锈铝LF6的固态塑性连接工艺[J]. 中国有色金属学报, 2002, 12(6): 1162?1166.

XING Li, KE Li-ming, ZHOU Xi-ying, LIU Ge-ping. Solid-state plasticized joining for aluminum alloy LF6[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(6): 1162?1166.

[13] 贺地求, 邓 航, 周鹏展. 2219厚板搅拌摩擦焊组织及性能分析[J]. 焊接学报, 2007, 28(9): 13?16.

HE Di-qiu, DENG Hang, ZHOU Peng-zhan. Microstructure and properties analysis of friction stir welding on thick plate of 2219 aluminum alloy[J]. Transactions of the China Welding Institution, 2007, 28(9): 13?16.

[14] 周鹏展, 钟 掘, 贺地求, 舒霞云. 2519厚板搅拌摩擦焊接工艺组织分析[J]. 中南大学学报, 2006, 37(4): 114?118.

ZHOU Peng-zhan, ZHONG Jue, HE Di-qiu, SHU Xia-yun. Microstructure and properties analysis of friction stir welding on thick plate of aluminum alloy 7A52[J]. Journal of Central South University: Science and Technology, 2006, 37(4): 114?118.

[15] 季亚娟, 栾国红, 严 铿. 5A05(LF5)铝合金搅拌摩擦焊接头的组织和性能[J]. 焊接技术, 2005, 34(4): 15?17.

JI Ya-juan, LUAN Guo-hong, YAN Keng. Microstructure and properties of friction stir welding of aluminum alloy LF5[J]. Welding Technology, 2005, 34(4): 15?17.

[16] 王大勇, 冯吉才, 王攀峰. 搅拌摩擦焊接Al-Li合金接头的微观组织及力学性能[J]. 金属学报, 2004, 40(5): 504?508.

WANG Da-Yong, FENG Ji-cai, WANG Pan-feng. Microstructure and properties of friction stir welding of Al-Li alloy[J]. Acta Metallurgica Sinica, 2004, 40(5): 504?508.

[17] 王希靖, 韩晓辉, 李常峰, 包 孔, 郭瑞杰. 厚铝合金板搅拌摩擦焊塑性金属不同深度的水平流动状况[J]. 中国有色金属学报, 2005, 15(2): 198?203.

WANG Xi-jing, HAN Xiao-hui, LI Chang-feng, BAO Kong, GUO Rui-jie. Horizontal flow status of plastic metal in different depth during friction stir welding for thick aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(2): 198?203.

[18] 邢 丽, 柯黎明, 刘鸽平. 铝合金拌摩擦焊组织及性能分析[J]. 焊接学报, 2002, 23(6): 55?58.

XING Li, KE Li-ming, LIU Ge-ping. Microstructure and properties analysis of friction stir welding of aluminum alloy[J]. The China Welding Institution, 2002, 23(6): 55?58.

[19] RHODES C G, MAHONEY M W, BINGEL W H, SPURLING R A, BAMPTON C C. Effects of friction stir welding on microstructure of 7075 aluminum[J]. Scripta Materialia, 1997, 36(1): 69?75.

基金项目:国家自然科学基金资助项目(10577010)

收稿日期:2008-06-25;修订日期:2008-11-21

通讯作者:王希靖,教授;电话:13321222432;传真:0931-2973892;E-mail: wangxj@lut.cn

(编辑 李向群)