LF21铝合金薄板搅拌摩擦焊组织与性能

周鹏展1, 2,贺地求1,邓 航1

(1. 中南大学 机电工程学院,湖南 长沙,410083;

2. 株洲时代新材料科技股份有限公司,湖南 株洲,412007)

摘 要:采用搅拌摩擦焊方法对厚度为1.4 mm的LF21铝合金薄板进行单道对接焊实验。实验结果表明:在旋转速度为1 500 r/min,焊接速度为100~180 mm/min时,均可获得较好的焊接性能,焊缝的抗拉强度在125~134 MPa之间,焊接强度系数为基材强度的78%~83%,说明该铝合金薄板采用搅拌摩擦焊方法的焊接适应性好。硬度测试结果表明焊缝发生了软化,其软化区宽度约为25 mm。在焊接热循环的作用下,锰在焊缝区沿轧制方向析出并聚集成较粗大的脆性MnAl6化合物,降低了焊缝的抗拉强度。

关键词:搅拌摩擦焊;薄板;LF21铝合金;析出

中图分类号:TG453 文献标识码:A 文章编号:1672-7207(2007)05-0917-05

Microstructure and property of friction stir welded LF21 aluminum sheet

ZHOU Peng-zhan1, 2, HE Di-qiu1, DENG Hang1

(1. School of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China;

2. Zhuzhou Times New Materials Technology Co. Ltd., Zhuzhou 412007, China)

Abstract: Tests about friction stir butt-welds of LF21 aluminum sheet with 1.4 mm in thickness were made in a single pass. The experimental results show that when rotating speed is 1 500 r/min and welding speed is 100-180 mm/min, the good welds can be achieved. The tensile strength of welds is 125-134 MPa, which is between 78% and 83% of that of base metal. It shows that the welding adaptability of LF21 aluminum alloy is good. The micro-hardness result shows that the weld is softened, and the soften zone of weld is about 25 mm in width. The brittle MnAl6 compounds are precipitated along the rolling direction with the heat of welding, so the tensile strength of weld decreases.

Key words: friction stir welding; sheet; LF21 aluminum alloy; precipitate

搅拌摩擦焊(简称FSW)是一种通过高速旋转的搅拌头与被焊材料间的剧烈热机联合作用而实现的固相连接方法[1]。它适用于焊接用熔化焊方法难于焊接的轻合金,在铝合金、钛合金、镁合金等的焊接方面,具有无气孔和裂纹、焊接变形小、焊缝强度高、疲劳性能好等优点[2-10],显示出广阔的工业应用前景。

LF21铝合金属于铝锰系防锈铝的典型合金,是一种不可热处理强化的铝合金。该合金的特点是抗蚀性强、焊接性能好、并具有中等强度,在退火状态时塑性高,而在冷作硬化状态时塑性低但耐蚀性强,是一种应用最为广泛的防锈铝[11-15]。常用作液体或气体介质中工作的低载荷零件,如油箱、导管及各种异形 容器材料。

目前,LF21防锈铝的焊接一般采用熔化焊,但在实际焊接生产中容易产生多种焊接缺陷,如焊缝气孔超标、夹渣、焊接接头力学性能达不到标准要求、焊接变形过大等[13-15]。另外,在用熔化焊焊接存在加工硬化效果的LF21薄板时,板内残余应力较大,容易出现焊接翘曲与开裂现象。由于LF21薄板在有防腐蚀 与密封要求的低载荷工程环境中应用非常广泛,在此,本文作者选取厚度为1.4 mm的该合金薄板进行搅拌摩擦焊实验,对于解决该合金在工程应用中的焊接问题具有重要意义。

1 实验材料与方法

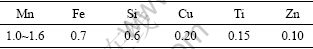

实验用材料是实测厚度为1.4 mm的LF21铝合金轧制板,尺寸规格(长×宽×厚)为300 mm×70 mm×1.4 mm,其主要化学成分和力学性能分别如表1和表2所示。LF21防锈铝的主要强化相为MnAl6,杂质相为(FeMn)Al6或(Fe, Mn, Si)Al6等,但其杂质的存在减小了Mn的偏析,对细化晶粒有一定的促进作用。

表 1 LF21铝合金的主要化学成分

Table 1 Main chemical composition of LF21 aluminum alloy w/%

表2 LF21铝合金的力学性能

Table 2 Mechanical properties of LF21 aluminum alloy

搅拌摩擦焊实验在自行研制的搅拌摩擦焊实验机上进行,焊接形式为沿试样长度方向进行单道对接拼焊。

由于螺旋形搅拌头有助于搅拌摩擦焊缝组织的致密成型,故本实验采用螺旋形搅拌头进行焊接,其搅拌头参数是:轴肩直径为10 mm,搅棒直径为3 mm,搅棒长度为1.2 mm。

焊接前,没有对焊接件的对接面进行特殊的去除氧化膜处理。在清除待焊工件对接面的表面污垢及灰尘后,将2块待焊件拼合后,固定在工作台上。

焊接时,搅拌头高速旋转钻入待焊板材接缝,当搅拌头轴肩压实铝板后,沿接缝前进以完成焊接过程。焊接中采用的工艺参数是:搅拌头旋转速度为1 500 r/min, 搅拌头沿接缝方向的焊接速度为100~180 mm/min。

对LF21铝合金薄板进行单道对接搅拌摩擦焊后,在焊接件上沿焊缝横向分别取样,制取金相试样和拉伸试样,在POLYVAR-MET光学金相显微镜上观察焊后各区微观组织,在CSS-44100电子拉伸机上进行拉伸测试,在HMV-2维氏硬度仪上进行显微硬度测试。

2 实验结果

2.1 焊缝力学性能

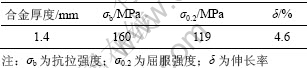

在搅拌头旋转速度为1 500 r/min,焊接速度为100~180 mm/min的焊接工艺下,厚度为1.4 mm的LF21铝合金其FSW焊缝的力学性能如图1所示。可见,所焊1.4 mm厚的焊缝的抗拉强度在125~134 MPa之间,与表2所示基材强度比较可知,焊接强度系数为基材强度的78%~83%。由此可见,用FSW方法焊接该合金薄板时,具有较好的焊接适应性。焊缝拉伸测试时均断裂于热影响区。

图 1 LF21铝合金焊接速度与抗拉强度的关系

Fig.1 Relationship between tensile strength and welding speed of LF21 aluminum alloy

由图1可见,随着焊接速度的增加,焊缝强度呈现出先升高后降低的趋势,这是因为在旋转速度为1 500 r/min时,若焊接速度过慢,则作用在焊缝单位长度上的热流量较大,使焊接温度过高,会使焊接区组织过热,从而使焊缝强度降低;另一方面,若焊接速度过快,则作用在焊缝单位长度上的热流量较少,使焊接温度过低,焊缝中热塑性金属的流动性变差,焊缝中金属难以扩散连接成一整体,可能使焊缝组织出现弱结合,从而降低焊缝强度。所以,在焊接速度变化时,焊缝强度会存在1个峰值。

2.2 焊缝微观组织分析

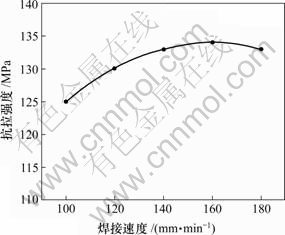

在转速为1 500 r/min,焊接速度为160 mm/min的焊接工艺下,厚度为1.4 mm的LF21铝合金搅拌摩擦焊缝的横截面形貌如图2所示。

图 2 LF21焊缝的横截面形貌

Fig.2 Cross-section image of LF21 welds

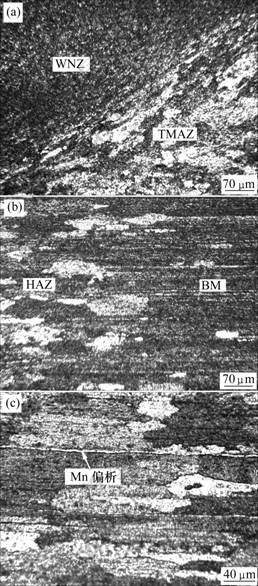

由图2可见,LF21薄板的搅拌摩擦焊缝同样也存在4个区:焊核区(简称WNZ)、热机影响区(简称TMAZ)、热影响区(简称HAZ)和基材区(简称BM),其放大倍数的微观组织如图3所示。

(a) 焊核区和热机影响区; (b) 热影响区和基材区; (c) 热影响区

图 3 LF21焊缝的微观组织

Fig.3 Microstructures of LF21 welds

从图3可见,LF21的搅拌摩擦焊缝成型良好,没有产生孔洞、组织疏松、热裂纹等常见的焊接缺陷。另外从图3还可见,由于焊接过程中热机联合作用方式不同,焊缝中各区的组织性能存在较大差异。在焊接摩擦热的局部高温作用下,焊核区受到搅拌头的直接机械搅拌作用,发生完全动态再结晶,形成了细小的等轴晶组织;热机影响区受到搅拌头的间接机械搅拌作用,其轧制组织发生了较大程度的弯曲变形和不完全动态再结晶;热影响区没有受到搅拌头的机械搅拌作用,但在焊接热循环的作用下,发生了不同程度的回复、静态再结晶或晶粒粗化现象,另外,在热影响区,锰沿轧制方向析出并聚集成较粗大的脆性MnAl6化合物(见图3(c))。

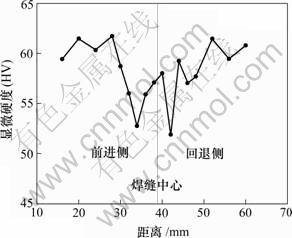

2.3 焊缝显微硬度分布

LF21防锈铝合金薄板搅拌摩擦焊缝横截面的显微硬度分布如图4所示。可见,焊缝在焊接过程中发生了软化,焊缝软化区总长度约为25 mm。焊核区的平均显微硬度为56左右。焊缝硬度的最低值出现在热机影响区(TMAZ)与热影响区(HAZ)的过渡区,最低硬度为52。受锰析出的影响,焊缝的显微硬度存在波动。另外,焊缝前进侧的显微硬度变化较平缓,而回退侧的显微硬度变化较剧烈。

图 4 LF21焊缝的显微硬度分布

Fig.4 Microhardness in LF21 welds

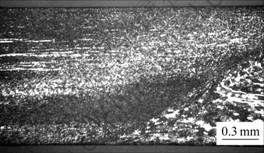

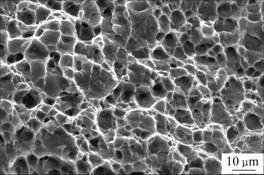

2.4 焊缝拉伸断口分析

LF21防锈铝合金搅拌摩擦焊缝的拉伸断口形貌如图5所示。可见,断面上分布着一些非等轴的大韧窝,其尺寸为15~40 μm。这是因为所焊轧制板材的晶粒在经过轧制后,发生了较大的变形,使其断口韧窝具有非等轴状待征。此外,在大韧窝上还分布众多细小的小韧窝,其形状接近等轴状,其尺寸在5 μm左右,显示断裂位置的晶粒在焊接过程中发生了再结晶。断面上较大较深的韧窝和撕裂棱显示焊缝具有较好的韧性,属韧性断裂。

图 5 LF21焊缝断口形貌

Fig.5 Fracture image of LF21 welds

3 分析与讨论

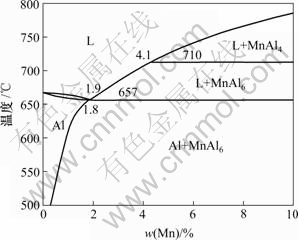

Mn是LF21合金中的主要组成元素,随着Mn含量的增加,合金的强度也随之提高。当锰含量为1.0%~1.6%时,合金不仅具有较高的强度,而且具有良好的塑性和抗腐蚀性能。从Al-Mn二元相图(见图6)可见,其液相(L)线与固相线之间的结晶间隔很小,仅相差0.5~1.0 ℃;Mn在铝中的最大固溶度为1.8%,随着温度的下降,Mn在铝基体中的固溶度急剧减少,这使得Mn含量在1.0%~1.6%的LF21合金在室温时能形成过饱和固溶体。此外,又由于Mn在铝合金中的扩散系数很小,使得LF21合金在退火处理时容易产生析出,形成粗大晶粒。LF21防锈铝合金的上述特点,决定了其搅拌摩擦焊的组织与性能。在焊接热循环的作用下,焊缝区铝基体中的Mn容易以铸轧时形成的细小析出物为形核核心,沿轧制方向析出并聚集成较粗大的脆性MnAl6化合物(如图3(c)所示),使焊缝的抗拉强度低于基材的抗拉强度。

图 6 Al-Mn合金二元相图

Fig.6 Binary phase figure of Al-Mn alloy

4 结 论

a. LF21铝合金薄板采用搅拌摩擦焊方法的焊接适应性好。当旋转速度为1 500 r/min,焊接速度为100~180 mm/min时,可获得较好的焊接性能,焊缝的抗拉强度为125~134 MPa,焊接强度系数为基材的78%~83%。

b. LF21铝合金薄板的搅拌摩擦焊组织存在4个区,即焊核区、热机影响区、热影响区和基材区。硬度测试结果表明焊缝发生了软化,软化区长度约为 25 mm。

c. 在焊接热循环的作用下,锰在焊缝热影响区沿轧制方向析出并聚集成较粗大的脆性MnAl6化合物,降低了焊缝抗拉强度。

参考文献:

[1] 周鹏展, 钟 掘, 贺地求, 等. 2519厚板搅拌摩擦焊接工艺组织分析[J]. 中南大学学报: 自然科学版, 2006, 37(4): 114-118.

ZHOU Peng-zhan, ZHONG Jue, HE Di-qiu, et al. Technique and microstructure of friction-stir welded 2519 thick plate[J]. Journal of Central South University: Science and Technology, 2006, 37(4): 114-118.

[2] 张 华, 林三宝, 吴 林, 等. 搅拌摩擦焊研究进展及前景展望[J] . 焊接学报, 2003, 24(3): 91-96.

ZHANG Hua , LIN San-bao, WU Lin, et al. Current progress and prospect of friction stir welding[J]. Transactions of the China Welding Institution, 2003, 24(3): 91-96.

[3] Thomas W M, Nicholas E D. Friction stir welding for the transportation industries[J]. Materials & Design, 1997, 18(6): 269-273.

[4] Dawes C J, Thomas W M. Friction stir process welds aluminum alloys[J]. Welding Journal, 1996, 75(3): 41-45.

[5] Mishra R S, Ma Z Y. Friction stir welding and processing[J]. Materials Science and Engineering, 2005, 50(1/2): 1-78.

[6] Ericsson M, Sandstr?m R. Influence of welding speed on the fatigue of friction stir welds, and comparison with MIG and TIG[J]. International Journal of Fatigue, 2003, 25(12): 1379-1387.

[7] FU Zhi-hong, HE Di-qiu, WANG Hong. Friction stir welding of aluminum alloys[J]. Journal of Wuhan University of Technology: Materials Science, 2004, 19(1): 61-64.

[8] Squillace A, de Fenzo A, Giorleo G, et al. A comparison between FSW and TIG welding techniques: modifications of microstructure and pitting corrosion resistance in AA2024-T3 butt joints[J]. Journal of Materials Processing Technology, 2004, 152(1): 97-105.

[9] Cavaliere P. Effect of friction stir processing on the fatigue properties of a Zr-modified 2014 aluminium alloy[J]. Materials Characterization, 2006, 57(2): 100-104.

[10] ZHOU Cai-zhi, YANG Xin-qi, LUAN Guo-hong. Investigation of microstructures and fatigue properties of friction stir welded Al–Mg alloy Materials[J] Chemistry and Physics, 2006, 98(2/3): 285-290.

[11] LIU Xue-song, TIAN Xi-tang, XU Wen-li. Dimensional instability of LF21 aluminum alloy weldments at room temperature and after thermal cycles[J]. China Welding, 2002, 11(1): 89-94.

[12] 吕昌平, 刘 刚. LF21合金挤压制品的生产实践[J]. 山东冶金, 1999, 21(6): 19-20.

L? Chang-ping, LIU Gang. Production practice of LF21 alloy extrusion product[J]. Shandong Metallurgy, 1999, 21(6): 19-20.

[13] 汤小红, 胡泽豪. 机车用防锈铝氩弧焊工艺性能研究[J]. 电焊机, 2001, 131(4): 30-31, 45.

TANG Xiao-hong, HU Zhe-hao. Study on the argon arc welding technological performance of antirust Al-alloy materials used in the locomotive[J]. Electric Welding Machine, 2001, 131(4): 30-31, 45.

[14] 刘志杰, 康 慧, 曲 平. LF21铝合金真空钎焊用铝基钎料的研究[J]. 航天制造技术, 2005(5): 13-15.

LIU Zhi-jie, KANG Hui, QU Ping. The study of aluminum solder used in LF21 aluminum alloy with vacuum brazing[J]. Aerospace Manufacturing Technology, 2005(5): 13-15.

[15] 许国良, 程兆谷, 夏金安,等. LF4、LF11、LF21、LY12铝合金的激光拼焊研究[J]. 应用激光, 1999, 19(5): 285-288.

XU Guo-liang, CHENG Zhao-gu, XIA Jin-an, et al. Study of CO2 laser butt welding on aluminum alloys LF4, LF11, LF21 and LY12[J]. Applied Laser, 1999, 19(5): 285-288.

收稿日期:2006-12-14;修回日期:2007-01-20

基金项目:国家自然科学基金资助项目(50675228)

作者简介:周鹏展(1973-),男,湖南沅江人,博士,从事搅拌摩擦焊工艺及机理研究

通信作者:周鹏展,男,博士;电话:0733-2884711;E-mail:zpz0731@163.com