文章编号: 1004-0609(2006)06-0964-06

7A52铝合金厚板搅拌摩擦焊

周鹏展, 钟 掘, 贺地求

(中南大学 机电工程学院, 长沙 410083)

摘 要: 采用搅拌摩擦焊方法对厚度为25mm的7A52铝合金板进行了单道焊实验。 结果表明: 在焊接25mm板时, 工艺参数可调范围较窄, 在旋转速度为1500r/min, 且焊接速度为40mm/min时, 可以获得较好的焊接性能, 抗拉强度可以达到330MPa, 延伸率可以达到9.6%; 焊缝中存在3个组织变化区, 其中焊核区内是细小均匀的等轴晶, 平均晶粒大小在4μm左右; 焊缝两侧热机影响区组织存在较大差异, 前进侧为窄条状组织, 回退侧为扁平块状组织; 热影响区组织发生了回复、 再结晶和粗化; 焊缝显微硬度的最低值出现在前进侧, 说明前进侧是焊缝的薄弱环节; 厚板焊接时, 沿板厚方向的热机作用梯度过大, 造成焊缝金属难以获得优良焊接性能, 这是厚板焊接较困难的原因。

关键词: 7A52铝合金; 厚板; 搅拌摩擦焊; 单道焊 中图分类号: TG453+.9

文献标识码: A

Friction-stir welding on thick plate of 7A52 aluminum alloy

ZHOU Peng-zhan, ZHONG Jue, HE Di-qiu

(School of Mechanical and Electrical Engineering,

Central South University, Changsha 410083, China)

Abstract: Friction-stir welds of 7A52 aluminum plate of 25mm thickness were completed in a single pass. The experiment results demonstrate that the adjusting scope of process parameters is very narrow when welding the plate of 25mm thickness. When the rotating speed is 1500r/min and the welding speed is 40mm/min, the good weld is achieved, and the tensile strength of the weld reaches 330MPa, and the elongation reaches 9.6%. The welds consist of three different zones. The weld nugget zone consists of fine equiaxed grains which size is about 4μm. Regarding to the thermo-mechanically affected zone on the two sides, the advancing side consists of narrow slate grains, while the retreating side consists of flat and nubby grains. The grains of heat affected zone have showed some reversion, recrystallization and growth characteristics. The min micro-hardness occurs on the advancing side. For the grads of thermo-mechanical action at the thickness direction is very large, it is difficult to achieve good welds as welding thick plate.

Key words: 7A52 aluminum alloy; thick plate; friction stir welding; single pass welding

搅拌摩擦焊( Friction stir welding , 简称FSW)是通过高速旋转的搅拌头与被焊材料间的剧烈热机联合作用而实现的固相连接。 搅拌摩擦焊的焊接温度一般低于被焊材料的熔点, 从而可以避免常规熔焊时被焊材料由于熔化而产生的气孔、 裂纹、 变形等缺陷[1-8]。 近年来, 随着航天、 军工和汽车等行业对熔焊性差的高强铝合金等特殊材料的需求量不断增加, 推动了搅拌摩擦焊接技术的发展, 并成为国内外关注的热点之一[1-8]。

7A52铝合金是国内自行研制开发的一种可热处理强化的高强可焊铝合金结构材料, 熔铸方便, 成形性好, 经轧制能获得比较理想的板材, 通过适当的固溶及回归再时效处理, 可使该合金获得优良的综合性能, 目前已在建筑、 军用设施、 航空航天器与地面车辆和装备等焊接构件中获得批量应用[9-11]。 但目前该类合金的焊接主要采用MIG焊, 焊后焊缝中容易出现焊接变形和气孔, 残余应力较大, 且对应力腐蚀敏感。 MIG焊后其焊缝性能明显下降, 不能充分发挥材料的性能[11]。 因此, 探索新的焊接方法在7A52铝合金构件材料中的应用, 是非常必要和非常迫切的。

目前国内外在高强铝合金的搅拌摩擦焊研究中, 采用的单道对接焊厚度一般为1~8mm, 焊接性能较好, 焊缝强度一般在60%以上[1-8, 11-15], 但对单道焊厚度在10mm以上高强铝合金板焊接性能的研究很少, 其原因在于该类铝合金厚板进行搅拌摩擦焊的焊接难度大, 采用薄板常用的搅拌头、 焊接工艺和焊接设备时, 实现不了优良焊接的目的。 厚度大于10mm的铝合金板是国防应用的重要材料, 因此, 本文作者选取25mm的7A52铝合金厚板进行单道对接搅拌摩擦焊实验, 研究该合金厚板的搅拌摩擦焊工艺与组织性能特点, 提高其作为构件材料应用的整体强度, 具有重要的实用价值。

1 实验

焊接实验用材料为25mm厚的7A52铝合金轧制板, 焊件尺寸规格为300mm×150mm, 已经过淬火与人工时效处理, 其主要化学成分如表1所示[9]。 搅拌摩擦焊实验在自行设计制作的焊接设备上进行。 实验用搅拌头的轴肩直径为30mm; 搅棒直径为10mm, 搅棒长度略小于板的厚度。 焊接方式为单道对接拼焊。 焊接前, 将两块待焊铝合金厚板刚性固定在钢垫板上。

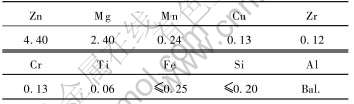

表1 7A52铝合金的主要化学成分

Table 1 Main chemical compositions of 7A52 Al alloy(mass fraction, %)

焊接时, 搅拌头高速旋转钻入待焊板材接缝, 当搅拌头轴肩压实铝板后, 沿接缝前进以完成焊接过程。 焊接工艺参数选取如下: 搅拌头旋转速度为1300~1700r/min, 搅拌头沿焊缝方向的焊接速度为40mm/min。 焊接后, 在拼焊板上沿焊缝横向分别取样, 制取金相试样和拉伸试样, 在CSS-44100电子万能实验机上进行拉伸实验, 在POLYVAR-MET光学显微镜上观察微观组织, 在KYKY-2800扫描电镜上对拉伸断口进行观察分析。

2 实验结果

2.1 工艺参数对焊缝强度的影响

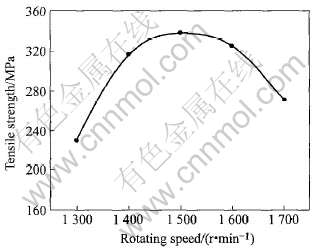

在厚板焊接时, 对焊缝强度影响最大的是旋转速度, 因此本文选取一定的焊接速度v=40mm/min, 在搅拌头旋转速度N=1300~1700r/min的条件下, 考察旋转速度对焊缝强度的影响, 实验结果如图1所示。

图1 厚板焊缝抗拉强度与旋转速度的关系

Fig.1 Relationship between tensile strength and rotating speed of thick plate welds

从图1可见, 在厚板焊接时, 能获得优良焊缝性能的工艺参数的可调节范围较窄。 对厚度为25mm的7A52铝合金焊缝而言, 在旋转速度大约为1400~1600r/min, 且焊接速度为40mm/min时, 可以获得比较好的焊缝性能, 在旋转速度为1500r/min时, 焊缝的抗拉强度最好, 达到了330MPa。

2.2 焊缝的宏观形貌

在旋转速度为1500r/min, 且焊接速度为40mm/min时, 7A52铝合金厚板焊缝横截面的宏观形貌如图2所示。 从图可以看出, 轴肩的热机作用只能影响到厚板焊缝大约2/3的厚度范围, 而焊缝底部厚度方向大约8mm的厚度范围, 以搅棒的热机作用为主。 在此工艺参数下得到的焊缝连接较好, 没有发现焊接缺陷。

图2 厚板焊缝横截面形貌

Fig.2 Section of thick plate welds

2.3 焊缝的微观组织

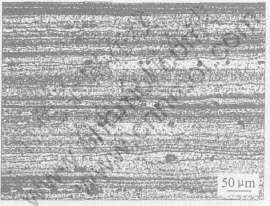

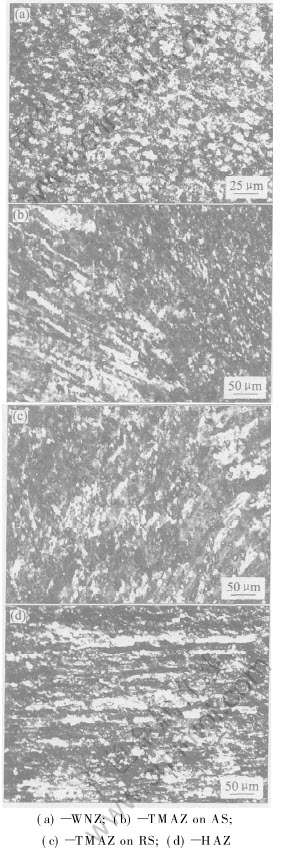

焊接前, 7A52铝合金的微观组织是典型的轧制组织, 经淬火与人工时效处理后, 轧制组织由再结晶组织与变形的带状组织组成, 化合物被破碎并沿轧制方向排列, 但不是十分明显, 如图3所示。 7A52铝合金的主要强化机制是析出强化, 合金的强度主要由基体析出相的大小、 数量和弥散度决定[9, 10]。 7A52铝合金中的主要强化相是亚稳相η′相[9, 10], 均匀弥散分布在基体中。

图3 7A52铝合金的微观组织

Fig.3 Microstructure of 7A52 aluminum alloy

7A52铝合金的搅拌摩擦焊缝同样存在3个组织性能变化区, 即焊核区(WNZ) 、 热机影响区(TMAZ)和热影响区(HAZ)[1-6]。 不同区域的微观组织如图4 所示。

焊核区是发生了完全动态再结晶的组织。 焊核区位于焊缝的中间部位, 近似于搅棒尺寸, 该区由于受到搅拌头强烈的机械搅拌作用, 以及由剧烈摩擦产生的局部高温作用, 组织发生完全动态再结晶, 由基材原始的带状轧制组织转变为细小的等轴晶组织, 焊核区晶粒的大小在4μm左右, 如图4(a)所示。

热机影响区是发生了塑性变形与动态再结晶的焊缝组织。 位于焊缝两侧的热机影响区是不同的。 其中, 前进侧(Advancing side, 简称AS)对应于搅拌头旋转方向与焊接方向相同的一侧; 而回退侧(Retreating side, 简称RS)对应于搅拌头旋转方向与焊接方向相反的一侧, 图4(b)和(c)所示分别对应于前进侧与回退侧热机影响区的微观组织。 从图可以看出, 两侧的热机影响区与焊核区之间都有比较明显的过渡区, 但前进侧中的过渡区较窄, 且过渡区两边的晶粒尺寸相差很大, 在接近焊核区附近区域, 晶粒沿界面方向被拉长, 整个区域为呈放射状的窄条状组织, 晶粒大小约在5~50μm之间, 前进侧中晶粒与水平方向的塑性变形角较小, 在本研究工艺条件下为30°左右, 且与焊核区有明显的分界面。 而在回退侧中被拉伸的晶粒呈扁平块状分布, 晶粒过渡区较宽, 且呈有序排列状态, 但在接近焊核区的再结晶组织呈无序粗化状态, 晶粒大小在5~50μm之间, 回退侧中晶粒与水平方向的塑性变形角较大, 在本研究工艺条件下为60°左右, 表明该区域的金属承受了较大的拉伸变形和热循环作用。

图4 7A52铝合金焊缝的微观组织

Fig.4 Microstructures of 7A52 welds

热影响区是焊缝组织没有发生塑性变形的区域。 该区域的材料因受热循环的影响, 微观组织和力学性能均发生了变化。 热影响区的组织是经过了时效处理的组织, 在焊接热循环的作用下, 焊缝组织各部位发生不同程度的粗化、 静态再结晶和回复, 并因过时效而软化, 但仍保留了基材带状轧制组织的部分形貌, 如图4(d)所示。

2.4 焊缝的力学拉伸性能

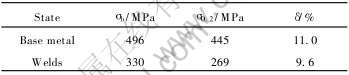

在搅拌头旋转速度为1500r/min、 焊接速度为40mm/min焊接工艺下, 7A52板基材与焊缝力学拉伸性能的对比情况如表2所示。 从表2可见, 焊缝的抗拉强度为330MPa, 达到了基材强度的68%, 而且焊缝的延伸率也比较高, 达到了9.6%, 从强度和塑性两方面来综合考虑, 7A52铝合金厚板搅拌摩擦焊焊缝的综合力学拉伸性能较好。

表2 7A52铝合金焊接前后基材与焊缝的力学性能

Table 2 Mechanical properties of base metal and welds of

7A52 aluminum alloy

2.5 焊缝的显微硬度

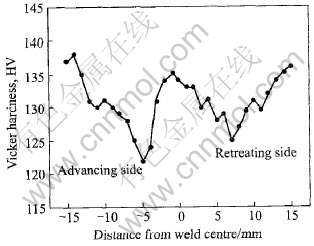

图5所示为厚度为25mm的7A52铝合金板搅拌摩擦焊缝横截面中部的显微硬度分布曲线图。 从图可以看出, 沿焊缝横截面硬度的分布呈W形, 即焊缝两侧基材硬度最高, 到热机影响区硬度逐渐降低, 到焊核区硬度又逐渐升高, 并接近于基材的硬度, 硬度最低处位于前进侧的TMAZ/HAZ过渡区。

图5 7A52焊缝的显微硬度分布

Fig.5 Microhardness of 7A52 welds

对于无缺陷的搅拌摩擦焊缝, 由于合金成份没有改变, 其拉伸强度特性和断裂的位置只与微观硬度有关。 因此, 焊缝前进侧TMAZ/HAZ的过渡区是焊缝的薄弱环节。

2.6 焊缝断口分析

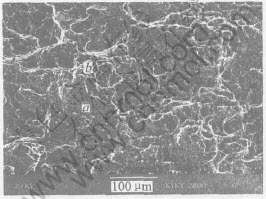

7A52铝合金厚板焊缝的拉伸试样断口形貌如图6所示。 由图可见, 断口断裂于TMAZ/HAZ的过渡区, 在断口上大韧窝的窝里还分布着许多的小韧窝。 大韧窝的平均直径在50μm左右, 小韧窝的平均直径在10μm左右, 可见大韧窝不是单个第二相大粒子脱落留下的, 而是类似于纤维束的粒子塑性滑移后断裂留下的, 在断口上还可见到明显的延性棱, 显示焊缝断口具有较好的塑性。 而焊缝延伸率达到了9.6%, 也说明焊缝的塑性较好。 焊缝的总体断裂形式为韧性断裂。

图6 7A52焊缝断口形貌

Fig.6 Fractograph of 7A52 welds

3 分析与讨论

厚板焊接时, 为获得优良焊缝性能, 焊接工艺参数的可调节范围比较窄, 这是因为如果旋转速度过高引起焊缝中上部的焊接温度过高, 就会使焊缝中的强化相发生分解或转变, 使焊缝强度降低。 如果旋转速度过慢引起焊缝下部的焊接温度过低, 就会使焊缝下部金属的塑性流动与焊接成型困难, 甚至出现焊不合的现象。 总之, 搅拌头产生的热机梯度作用沿板厚方向相差过大, 使焊缝金属难以获得优良焊接性能, 是造成厚板焊接较困难的原因。

焊缝两侧的热机影响区的晶粒呈现出较大的差异, 这是由于焊缝两侧搅拌头的旋转方向与焊接方向不同所致。 焊接过程中, 由于前进运动引起搅拌头后方产生的低压空腔作用, 使搅拌区内两侧焊缝金属沿搅棒外表面以不同方向被挤压至搅拌头的后方, 但在搅拌头高速旋转产生的剪切作用下, 基材金属还会产生与搅拌头旋转方向一致的流动。 因此, 在前进侧, 由于焊缝金属塑性流动方向与基材金属塑性流动方向相反, 使基材金属与焊缝金属之间存在很大的相对变形差, 造成前进侧的过渡区较窄; 在回退侧, 焊缝金属塑性流动方向与基材金属塑性流动方向一致, 基材金属平滑地与焊缝金属一起变形, 因而造成了回退侧金属明显被拉长、 弯曲变形。 这与对焊缝两侧金属的金相观察是一致的。

由于焊接中使用的7A52铝合金是经淬火、 时效后的铝合金, 其主要强化相为时效析出的η′相[9, 10]。 在搅拌头的热机梯度作用的影响下, 基材中的这些沉淀相粒子将发生再次固溶、 析出、 时效等过程, 造成焊缝区的组织和性能发生转变, 破坏了细小的η′相与基材之间的共格关系, 使焊缝的整体强度或硬度低于基材。

焊缝显微硬度的W形变化, 与焊缝组织中主要强化相的转化和细晶强化机制有关。 在热影响区和热机影响区, 由于焊接热循环的作用, 使处于亚稳态的弥散分布的细小强化相η′相发生了聚集, 部分转变为平衡相η相, 材料出现了过时效, 使焊缝强度下降, 硬度降低。 文献[9, 10]指出: Al-Zn-Mg合金的晶内平衡析出相η相析出少, 亚稳相η′相析出多且尺寸小而弥散, 析出强化越显著。 可见7A52铝合金中η′相的转化是焊缝硬度或强度变化的内因。 在焊核区尽管强化相可能已重新固溶于基体, 但由于完全动态再结晶形成的晶粒特别细小, 所以其硬度或强度比热机影响区和热影响区中的要高些。 这也与焊缝拉伸时断裂于TMAZ与HAZ的过渡区相一致。

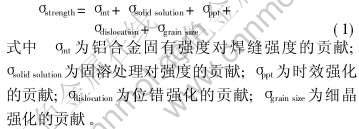

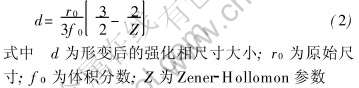

采用Hall-Petch方程σy=σ0+K·d-1/2可解释晶粒尺寸越小而屈服强度越高的现象, 它在解释单相合金的组织性能方面的比较有效, 但没有反映出温度、 应变、 相变等对组织性能的影响, 因而它不能解释焊核区硬度低于基材的原因。 文献[14, 15]认为焊缝强度是各影响因素的线性组合, 而焊缝强化相的长大与Z参数、 原始尺寸和体积分数有关, 可表示为

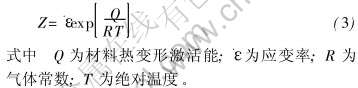

其物理意义为温度补偿应变速率, 它与应变率、 温度等有关, 如式(3)所示:

上述模型在解释焊核区动态再结晶晶粒尺寸的变化、 热机影响区在晶粒尺寸小于基材晶粒尺寸的情况下其力学性能低于基材的原因、 以及热影响区因过时效而软化的现象方面, 作出了贡献, 具有借鉴意义, 但有关搅拌摩擦焊缝组织性能的关系因其复杂性还有待进一步研究。

综上所述, 在厚板搅拌摩擦焊接中, 由于热机梯度作用与组织转变的复杂性, 目前还只能定性分析焊缝组织与力学性能之间的关系。 对于7A52铝合金厚板焊接而言, 主要强化相η′相因焊接热循环作用发生过时效转变为η相是焊缝强度低于基材强度的内因。 另外, 搅拌头在被焊材料中高速旋转产生的热机梯度作用沿板厚方向相差过大, 使焊缝金属难以获得优良的焊接性能, 是造成厚板焊接较困难的外因。

4 结论

1) 成功实现了厚度为25mm的7A52铝合金板的搅拌摩擦焊, 但其工艺参数可调范围较窄, 在旋转速度为1500r/min, 且焊接速度为40mm/min时, 可以获得较好的焊接性能, 抗拉强度可以达到330MPa, 延伸率可以达到9.6%。

2) 焊缝中存在3个组织变化区, 其中焊核区内是细小均匀的等轴晶, 平均晶粒大小在4μm左右; 焊缝两侧热机影响区组织存在较大差异, 前进侧为窄条状组织, 回退侧为扁平块状组织; 热影响区组织发生了回复、 再结晶、 粗化。

3) 焊缝显微硬度的最低值出现在前进侧, 说明前进侧是焊缝的薄弱环节。

4) 对于7A52铝合金厚板焊接而言, 主要强化相η′相因焊接热循环作用发生过时效转变为η相是焊缝强度低于基材强度的内因。 另外, 搅拌头在被焊材料中高速旋转产生的热机梯度作用沿板厚方向相差过大, 使焊缝金属难以获得优良的焊接性能, 是造成厚板焊接较困难的外因。

REFERENCES

[1]Thomas W M, Nicholas E D. Friction stir welding for the transportation industries[J]. Materials and Design, 1997, 18(6): 269-273.

[2]Dawes C J, Thomas W M. Friction stir process welds aluminum alloys[J]. Welding Journal, 1996, 75(3): 41-45.

[3]Joelj D. The friction stir welding advantage[J]. Welding Journal, 2001, 80 (5): 30-34.

[4]Mishra R S, Ma Z Y. Friction stir welding and processing[J]. Materials Science and Engineering, 2005, 50(1-2): 1-78.

[5]刘会杰, 陈迎春, 冯吉才. 中国搅拌摩擦焊技术的研究[J]. 焊接, 2004(12): 5-9.

LIU Hui-jie, CHEN Ying-chun, FENG Ji-cai. Review of progress in friction stir welding in China[J]. Welding, 2004(12): 5-9.

[6]张华, 林三宝, 吴林, 等. 搅拌摩擦焊研究进展及前景展望[J]. 焊接学报, 2003, 24(3): 91-96.

ZHANG Hua, LIN San-bao, WU Lin, et al. Current progress and prospect of friction stir welding[J]. Transactions of the China Welding Institution, 2003, 24(3): 91-96.

[7]Ericsson M, Sandstrom R. Influence of welding speed on the fatigue of friction stir welds, and comparison with MIG and TIG[J]. International Journal of Fatigue, 2003, 25(12): 1379-1387.

[8]Squillace A, De Fenzo A, Giorleo G. A comparison between FSW and TIG welding techniques: modifications of microstructure and pitting corrosion resistance in AA2024-T3 butt joints[J]. Journal of Materials Processing Technology, 2004, 152 (1): 97-105.

[9]黄兰萍, 陈康华, 李松, 等. 高温预析出对Al-Zn-Mg铝合金组织、 力学性能和应力腐蚀性能的影响[J]. 中国有色金属学报, 2005, 15(5): 727-733.

HUANG Lan-ping, CHEN Kang-hua, LI Song, et al. Effect of high-temperature pre-precipitation on microstructure, mechanical property and stress corrosion cracking of Al-Zn-Mg aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(5): 727-733.

[10]CHEN Kang-hua, HUANG Lan-ping. Strengthening-toughening of 7××× series high strength aluminum alloys by heat treatment[J]. Trans Nonferrous Met Soc China, 2003, 13(3): 484-494.

[11]张平, 王卫欣, 赵军军. 7A52铝合金搅拌摩擦焊接头特征分析[J]. 兵器材料科学与工程, 2004, 27(6): 38-42.

ZHANG Ping, WANG Wei-xin, ZHAO Jun-jun. Characteristic analysis for friction stir welding of 7A52 aluminum alloy[J]. Ordnance Material Science and Engineering, 2004, 27(6): 38-42.

[12]Cavaliere P, Squillace A. High temperature deformation of friction stir processed 7075 aluminium alloy[J]. Materials Characterization, 2005, 55(2): 136-142.

[13]Litynska L, Braun R, Staniek G. TEM study of the microstructure evolution in a friction stir-welded AlCuMgAg alloy[J]. Materials Chemistry and Physics, 2003, 81(3): 293-295.

[14]Jones M J, Heurtier P, Desrayaud C, et al. Correlation between microstructure and microhardness in a friction stir welded 2024 aluminium alloy[J]. Scripta Materialia, 2005, 52(8): 693-697.

[15]Oertelt G, Babu S S, David S A, et al. Effect of thermal cycling on friction stir welds of 2195 aluminum alloy[J]. Welding Journal, 2001, 80 (3): 71-79.

基金项目: 国家武器装备预先研究资助项目(41312020205)

收稿日期: 2005-09-30; 修订日期: 2006-01-13

通讯作者: 贺地求, 教授; 电话: 0731-8830293; E-mail: hdqzzp@163.com

(编辑何学锋)