DOI:10.19476/j.ysxb.1004.0609.2017.07.06

旋转摩擦挤压7075铝合金组织及第二相形貌

邢 丽,朱杜桥,徐卫平,柯黎明

(南昌航空大学 轻合金加工科学与技术国防重点学科实验室,南昌330063)

摘 要:采用旋转摩擦挤压法(RFE)加工T6态7075铝合金,对挤压后的7075铝合金进行热处理,观察了7075铝合金的显微组织和第二相变化,测试了加工后材料的显微硬度。结果表明,RFE态的7075铝合金为未完全再结晶的细小等轴晶,平均晶粒尺寸约为15 μm。经热处理后,铝合金中未发生再结晶的晶粒继续完成再结晶,晶粒尺寸进一步细化均匀,约为8 μm。RFE加工使7075铝合金中保留的初生金属间化合物尺寸变小,原沉淀析出的第二相(MgZn2相)在RFE加工过程中大部分发生重溶,未重溶的MgZn2相发生粗化,经热处理后7075铝合金中析出的MgZn2相尺寸细小,呈弥散分布。RFE态7075铝合金显微硬度低于基材,但经T6热处理后,其硬度为177.5HV,高于基材,7075铝合金中第二相对基体的强化效果较细晶强化作用更显著。

关键词:7075铝合金;旋转摩擦挤压;热处理;显微组织;第二相

文章编号:1004-0609(2017)-07-1361-08 中图分类号:TG146 文献标志码:A

7075铝合金是Al-Zn-Mg-Cu系可热处理强化铝合金,由于其密度低、强度高、热加工性能和耐腐蚀性能好等优点,使得7075铝合金在航空航天、车辆、建筑桥梁等领域应用广泛[1-3]。但该系列铝合金存在硬度低、常温塑性差[4]等不足,研究表明,剧烈塑性变形法(Severe plastic deformation, SPD)可细化晶粒,提高材料的常温力学性能。等通道转角挤压(Equal channel angular pressing, ECAP)作为一种剧烈塑性变形方法,许多学者对其进行了研究。吴跃等[5]采用ECAP技术对7075铝合金进行改性,发现ECAP技术使铝合金发生动态再结晶,随着挤压道次的增加,晶粒逐步细化,与有限元软件对ECAP连续动态再结晶组织晶粒度的预报结果一致。郭海龙等[6]研究了在不同变形温度和变形速率下采用ECAP技术加工后的7075铝合金组织的演变,建立了再结晶模型。田佳等[7]在150~400 ℃对粉末冶金法(Powder metallurgy, PM)制备的7075铝合金进行1~4道次的ECAP,研究发现,随着ECAP道次的增加,合金硬度、致密度及室温抗拉强度等性能显著提高。综上所述,ECAP能够通过多道次挤压实现晶粒的细化从而提高材料力学性能,但是挤压速度、挤压温度、挤压模具对ECAP合金组织及性能影响很大,且加工效率不高、可挤压尺寸非常有限[8]。旋转摩擦挤压法(Rotational friction extrusion, RFE)作为一种新的材料加工技术,通过基材和搅拌棒摩擦挤压产生的热和塑性变形改善材料的组织,实现材料的改性。该方法还可用于制备复合材料。林毛古等[9]采用RFE制备了以纯Al为基体的CNTs/Al复合材料,研究发现制备的复合材料晶粒细小,组织均匀。

Al-Zn-Mg-Cu系合金通过固溶和时效处理具有明显的时效强化效应,在室温下屈服强度可达500MPa,其冲击韧性较其他系列合金的都更高[10]。经固溶+人工时效热处理后的7075铝合金抗拉强度可达到572 MPa,热处理后基体获得的弥散第二相对7075铝合金强度有很大影响。目前,有学者对挤压改性对7075铝合金性能的影响进行了研究,但都侧重于挤压过程中组织变化和组织均匀性,而对7075铝合金挤压过程中第二相发生的变化对材料性能的影响研究较少。本文作者采用RFE方法加工7075铝合金,观察并分析RFE工艺及加工后热处理对7075铝合金组织和第二相的影响。

1 实验

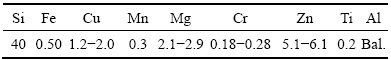

实验采用的材料为7075-T6态铝合金,化学成分如表1所列,进行RFE加工的试样尺寸为150 mm×12 mm×10 mm。

表1 7075铝合金化学成分

Table 1 Chemical composition of AA7075 (mass fraction, %)

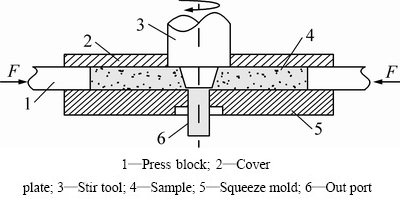

按图1所示原理对7075-T6态铝合金试样进行RFE加工。两件7075铝合金试样分别置于加工型腔两侧,在挤压块作用下推向中央区,高速旋转的搅拌棒在中央区对试样材料进行摩擦挤压,在搅拌棒与试样材料摩擦产生的热作用下,7075铝合金达到塑化状态。塑化的铝合金在挤压作用下沿出料口挤出,得到经RFE加工后的材料。实验所用的RFE参数为挤压速度0.28 mm/s,搅拌棒的旋转速度315 r/min,出料口直径为8 mm。

图1 RFE 制备方法原理图

Fig. 1 Principle diagram of RFE

经RFE加工后的7075铝合金试样进行(480 ℃,2 h, 固溶)+ (120 ℃, 24 h, 人工时效)热处理。将材料制备成金相试样,金相试样用1%HF+1.5%HCl+2.5% HNO3+95%H2O(体积分数)的试剂腐蚀,用4XB-TV型倒置金相显微镜观察试样的显微组织,用直线截距法测量铝合金的晶粒尺寸。用FEI QUANTA-200型扫描电子显微镜观察试样的第二相形貌,并进行能谱分析。

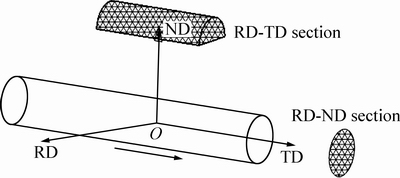

利用精密切割仪沿着棒状材料横截面方向(RD-ND面)截取TEM试样,如图2所示。试样尺寸为d8 mm×1 mm的圆片,用砂纸把试样打磨到厚度约为30 μm,用冲孔机冲出直径为3 mm的试样。用GANTA公司生产的Model-691型离子减薄仪对试样进行减薄。用JEM-2010(HR)型透射电子显微镜观察铝合金第二相形貌和显微组织。用Digital Micrograph 软件计算第二相的晶面间距,确定第二相成分。对加工后的试样用HVS-100型显微硬度仪测试试样的硬度。为区别试样不同的加工状态,将7075-T6态铝合金表示为基材,经RFE加工后的基材表示为RFE态7075铝合金,经RFE加工后再热处理的7075铝合金表示为RFE/T6态7075铝合金。

图2 金相取样示意图

Fig. 2 Schematic diagram of metallographic samples

2 结果与讨论

2.1 7075铝合金的显微组织

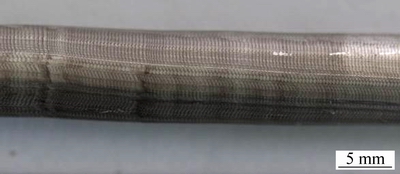

图3所示为RFE法制备的棒状复合材料宏观形貌,棒材长度最长可达250~260 mm。由图3可见,棒材表面除轻微的挤压痕迹外,较光滑。

图3 复合材料的宏观形貌

Fig. 3 Macroscopic morphology of composites

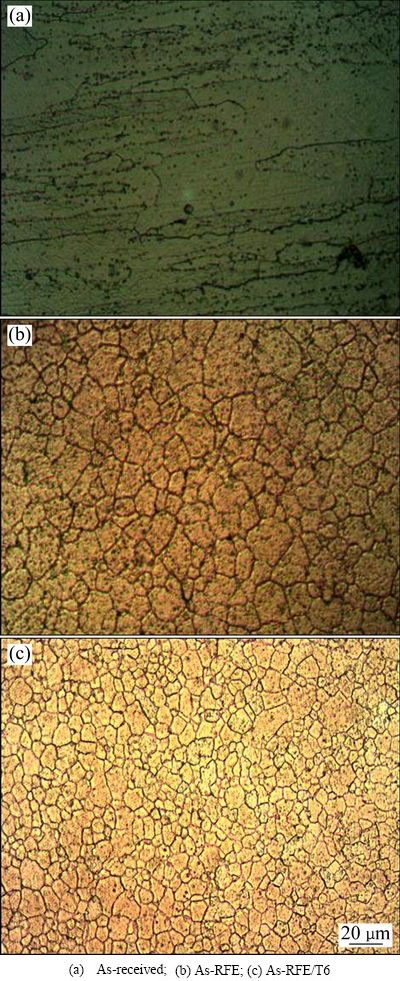

图4所示为7075铝合金显微组织。图4(a)所示为基材显微组织,T6态基材组织沿轧制方向呈不规则条带状。图4(b)所示为基材经RFE加工后的显微组织,呈明显的等轴晶,用截距法测得晶粒平均尺寸为15 μm,个别尺寸较大的晶粒约为30 μm。图4(c)所示为RFE加工后的7075铝合金经热处理后的显微组织,其晶粒为等轴晶,但晶粒尺寸更小,较均匀,平均尺寸约为8 μm。

可见,经RFE加工后的7075铝合金晶粒比基材细小,热处理后晶粒进一步细化。基材在RFE加工过程中,搅拌棒与基材旋转摩擦产生大量热量,使得材料温度升高,在热和搅拌棒的作用下,材料发生了大的塑性变形,在热和大塑性变形的作用下,材料发生了连续的动态再结晶,形成了细小的等轴晶[11-12]。由于RFE加工过程时间较短,铝合金导热快,当材料沿挤出口挤出后,材料的温度急剧下降,使部分晶粒没有完成再结晶,导致RFE态7075铝合金中还有一些未完成再结晶的较大晶粒。这些未完成再结晶的较大晶粒存储有较大的形变能,当进行热处理时,由于加热时间长,为其继续完成再结晶提供了驱动力,导致热处理后的RFE态7075铝合金晶粒进一步细化。

图4 7075铝合金的显微组织

Fig. 4 Microstructures of AA7075

2.2 7075铝合金中的第二相形貌

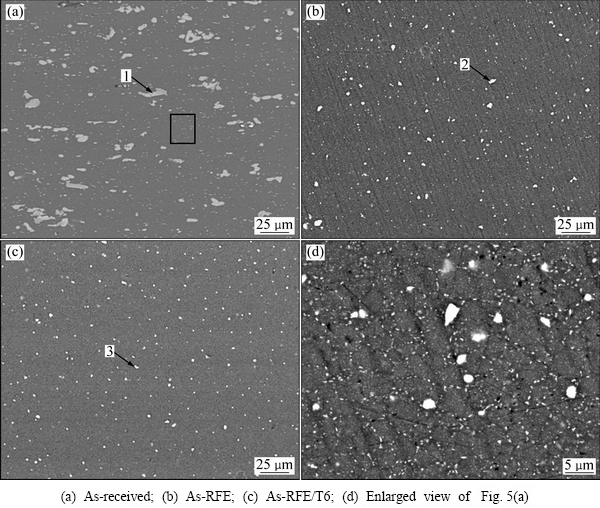

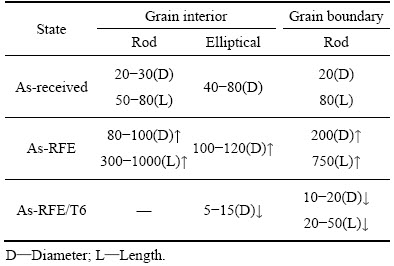

图5所示为7075铝合金背散射电子(Back scattered electron,BSE)像。图5(a)所示为基材BSE像,可见,基材中的第二相呈粗大的板条状和细小的椭圆状。图5(b)所示为RFE态7075铝合金BSE像,经RFE加工后板条状的第二相大多转变为椭圆状,尺寸变小,弥散分布。图5(c)所示为RFE/T6态的7075铝合金BSE像,可见,经固溶时效处理后的第二相比RFE态更细小,分布较均匀。对图5(a)~(c)中的白色第二相进行EDS点扫描分析,表2所列为图5中点1~3位置的EDS点扫描结果。由表2可知,基材中的第二相成分为Al、Cu和Fe元素,结合文献[13-15]分析认为这种第二相主要是FeAl和AlCu初生金属间化合物,它们是铸锭在凝固过程中形成的,经轧制及后续热处理后,尺寸较大,一般为微米级,较脆,不容易产生变形,对铝合金力学性能不利。

经RFE加工后7075铝合金中初生金属间化合物中的Cu元素含量下降,Fe元素上升。这是因为挤压过程中,当温度升高时,AlCu化合物中的Cu原子以固溶原子的形式重新溶入铝合金中,而FeAl化合物为难熔的金属间化合物。经热处理后,Cu元素含量较RFE态升高,但是含量仍低于基材,这是因为在热处理过程中溶入基体中的部分Cu原子有可能以AlCu相形式再度析出。

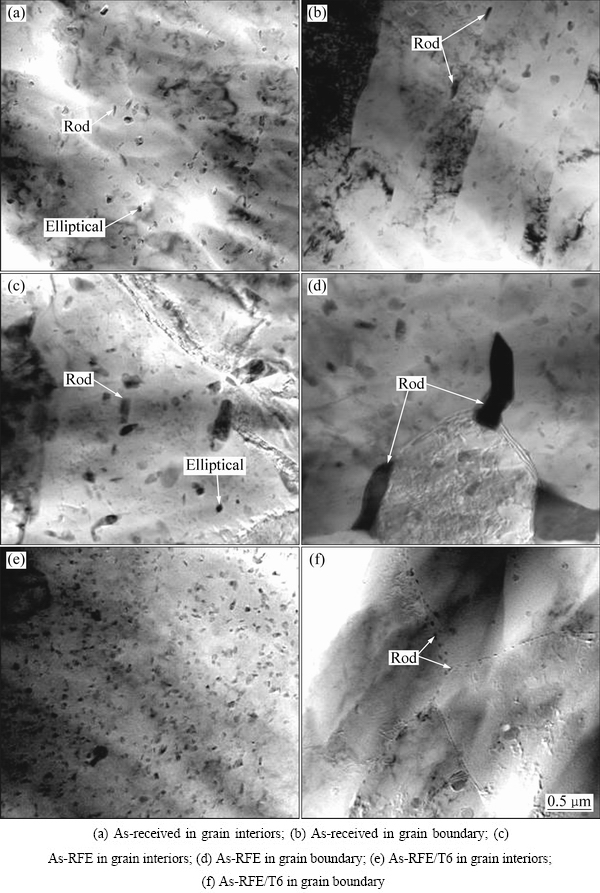

图5(d)所示为图5(a)中黑色框部位的高倍像。由图5(d)可见,组织中除了有微米级第二相,还含有纳米级的第二相,这些纳米级别的第二相分布均匀,数量更多。图6所示为采用TEM技术对7075铝合金中纳米级的细小第二相进行分析结果。图6(a)和(b)所示分别为在基材晶内和晶界的第二相形貌,可见,在晶内,第二相主要为棒状和椭圆状,呈细小弥散分布。其中,棒状第二相直径为20~30 nm,长度为50~80 nm;椭圆形第二相的直径为40~80 nm。在晶界,第二相为棒状,呈断续状分布,相邻间距离较大,棒状第二相的直径为20 nm,长度为80 nm;图6(c)和(d)所示分别为RFE态7075铝合金中的晶内和晶界处第二相的形貌。在晶内,棒状第二相的直径约为80~100 nm,长度约为300~1000 nm;椭圆状第二相的直径为100~120 nm。第二相的分布不均匀,数量较少;在晶界处,第二相为棒状,长度为750 nm,直径为200 nm;图6(e)和(f)所示为RFE/T6态的7075铝合金中晶内和晶界处第二相的形貌。RFE态的7075铝合金经过热处理后,在晶内,第二相分弥散布,基本上都呈椭圆形状,直径为5~15 nm;在晶界处,第二相为棒状,呈断续的链状分布,个别处呈连续分布,第二相的数量较T6态基材增加。棒状第二相的直径为10~20 nm,长度为20~50 nm。

图5 7075铝合金的BSE像

Fig. 5 BSE images of AA7075 for different states

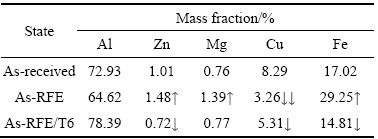

表2 图5中第二相EDS点分析结果

Table 2 EDS analyses results of second phase in Fig. 5

表3所列为7075铝合金中第二相尺寸的变化,可见基材经RFE加工后,晶内的棒状第二相和椭圆状第二相尺寸变大;经热处理后,晶内的棒状第二相全部转变为椭圆状,且尺寸变小。而在晶界处,经RFE加工后,原棒状的第二相尺寸变大;热处理后,这些棒状第二相尺寸变小。上述结果表明,基材经过RFE加工后,第二相都发生了长大,而且晶内的第二相形貌发生了转变,即由大的棒状转变为细小的椭圆状。经重新热处理后,晶内和晶界处的第二相尺寸都变小,且尺寸小于原基材中第二相的尺寸,7075铝合金中的第二相得到了细化。

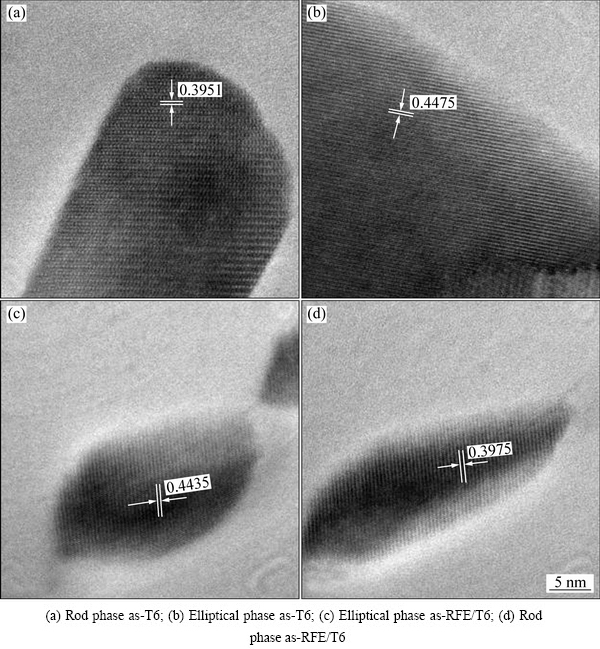

图7所示为基材和RFE/T6态7075铝合金沉淀析出第二相的高分辨透射电镜(High Resolution Transmission Electron Microscopy, HRTEM)像。图7(a) 和(b)所示分别为基材中棒状和椭圆状第二相HRTEM像,计算得棒状第二相晶面间距为0.3951 nm,椭圆状第二相晶面间距为0.4475 nm。图7(c)和(d)所示分别为RFE/T6态7075铝合金中椭圆状和棒状第二相的HRTEM像,经计算得到,椭圆状第二相晶面间距为0.4435 nm,棒状第二相晶面间距为0.3975 nm。

表3 不同状态7075铝合金中的析出相尺寸

Table 3 Size of precipitated phase in AA7075 for different states(nm)

图6 7075铝合金析出相的TEM像

Fig. 6 TEM images of precipitated phase in AA7075

图7中的棒状第二相的晶面间距与MgZn2(η相)的(101)面的晶面间距0.3969很相近,椭圆状第二相的晶面间距与MgZn2(η相)的(100)面的晶面间距0.4486很相近。结合文献[16]分析认为,图6中沉淀析出第二相为MgZn2相(η相)。

比较3种状态7075铝合金中的沉淀析出相可以发现,RFE态的沉淀析出相尺寸明显大于基材,数量较基材少;而RFE/T6态的7075铝合金中沉淀析出第二相尺寸小于基材,数量较基材更多。经RFE加工后沉淀第二相发生变化的原因如下:RFE加工时,由于材料经历了较高温度,其材料温度可达到400~430 ℃[12],会导致基材中的第二相部分重新固溶,使RFE态7075 铝合金中的沉淀第二相数量减少,而未重溶的部分η相在热作用下会长大,发生粗化。

分析认为,RFE/T6态铝合金中的第二相较基材更细小弥散的原因,可能是加工过程使第二相形核位置增多、形核率增加造成的。由于RFE/T6态铝合金中主要的沉淀析出第二相是经T6热处理后得到的,其析出顺序一般为[15]:α(过饱和固溶体)→GP区→亚稳定η′相(MgZn2)→η相(MgZn2),析出相一般在空位和位错处形核。7075铝合金在固溶过程中,空位由晶界向晶内扩散,在淬火时,这些空位在铝合金中保留下来,在随后的时效过程中,空位开始聚集,这些聚集的空位成为了GP区的形核位置。从图3中可以看到,经RFE加工和热处理,铝合金晶粒细化,晶界数量相对于基材更多。晶界的增加导致空位增多[17],从而导致了沉淀第二相的形核位置增多,促进了第二相的形核。RFE是一个剧烈的塑性变形过程,铝合金经RFE加工发生不完全动态再结晶(见图4),材料内部存在大量位错,故RFE态7075铝合金有着更多的储存能[18],在时效过程中,这些储存能会促进沉淀第二相形核速度和长大速度,先期析出第二相的长大速度增加会导致溶质原子溶解度降低,使得后期沉淀析出第二相尺寸变小。这些原因导致了RFE/T6态的7075铝合金中第二相体积分数增加,尺寸也变得更细小,分布得更弥散。

图7 第二相的HRTEM像

Fig. 7 HRTEM images of second phase

2.3 7075铝合金的硬度

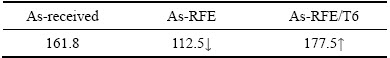

对不同状态7075铝合金进行硬度测试,结果如表4所示。基材的平均硬度为161.8HV;RFE态7075铝合金平均硬度为112.5HV;RFE/T6态7075铝合金平均硬度为177.5HV;表明基材经RFE加工后,RFE态7075铝合金硬度下降,经热处理后,RFE/T6态7075铝合金硬度升高,高于基材的硬度。

Al-Zn-Mg-Cu合金中力学性能的变化主要由第二相和组织决定。通过对3种状态的铝合金中晶粒尺寸和第二相比较发现,RFE/T6态7075铝合金组织均匀,晶粒尺寸最小,细晶强化作用效果更好;初生的金属间化合物经RFE和热处理后,尺寸变更小,分布也更均匀,对材料的影响最小;沉淀析出第二相分布的更弥散,尺寸更细小,数量更多,第二相强化效果更佳。RFE/T6态的7075铝合金的硬度最高。可见7075铝合金中细晶强化效果不如第二相的强化效果。

表4 不同状态7075铝合金的显微硬度

Table 4 Microhardness(HV) of AA7075 for different states

3 结论

1) RFE加工可以细化7075铝合金的晶粒,加工后的晶粒为等轴晶,平均晶粒尺寸约为15 μm;热处理可使RFE态7075铝合金晶粒更细小均匀,约为8 μm。

2) RFE加工可使微米级的初生金属间化合物尺寸变小,分布均匀;大部分原沉淀析出的纳米级第二相重溶,而未重溶的则粗化。热处理后,沉淀析出第二相的数量增多,尺寸变小。沉淀析出的第二相MgZn2在晶内呈椭圆状,直径为5~15 nm;晶界处呈棒状,直径为10~20 nm,长度为20~50 nm。

3) RFE态7075铝合金显微硬度低于基材,RFE态7075铝合金经T6热处理后,硬度提高且高于基材的显微硬度。7075铝合金第二相对基体的强化效果较细晶强化效果强。

REFERENCES

[1] 刘 兵, 彭超群, 王日初, 王小锋, 李婷婷. 大飞机用铝合金的研究现状及展望[J]. 中国有色金属学报, 2010, 20(9): 1705-1715.

LIU Bing, PENG Chao-qun, WANG Ri-chu, WANG Xiao-feng, LI Ting-ting. Recent development and prospects for giant plane aluminum alloys[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(9): 1705-1715.

[2] WARNER T. Recently-developed aluminium solutions for aerospace applications[J]. Materials Science Forum, 2006, 519/521: 1271-1278.

[3] 张 珏. 铝合金在航空航天中的应用[J]. 铝加工, 2009(3): 50-53.

ZHANG Jue. Application of aluminum alloy to aerospace industry[J]. Aluminium Fabrication, 2009(3): 50-53.

[4] 湛利华, 贾树峰, 张 姣. 电脉冲时效对7075铝合金组织和性能的影响[J]. 中国有色金属学报, 2014, 24(3): 600-605.

ZHAN Li-hua, JIA Shu-feng, ZHANG Jiao. Effect of aging on the pulse point of microstructure and properties of 7075 aluminum alloy[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(3): 600-605.

[5] 吴 跃, 陈文琳, 杨 栋. 等通道转角挤压7075铝合金动态再结晶组织晶粒度预报[J]. 塑性工程学报, 2014, 21(6): 96-101.

WU Yue, CHEN Wen-lin, YANG Dong. Prediction of dynamic recrystallized grain size of 7075 aluminum alloy prepared by equal channel angular pressing[J]. Journal of Plasticity Engineering, 2014, 21(6): 96-101.

[6] 郭海龙, 孙志超, 杨 合. 挤压态7075 铝合金再结晶经验模型及应用[J]. 中国有色金属学报, 2013, 23(6): 1507-1515.

GUO Hai-long, SUN Zhi-chao, YANG He. Empirical recrystallization model and its application of as-extruded aluminum alloy 7075[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(6): 1507-1515.

[7] 田 佳, 李建平, 白亚平, 郭永春, 杨 忠. 等通道挤压对 7075 铝合金组织与力学性能的影响[J]. 材料热处理学报, 2016, 37(7): 61-68.

TIAN Jia, LI Jian-ping, BAI Ya-ping, GUO Yong-chun, YANG Zhong. Effect of equal channel angular pressing on microstructure and mechanical properties of 7075 aluminum alloy[J]. Transactions of Materials and Heat Treatment, 2016, 37(7): 61-68.

[8] 雷力明, 黄 旭, 段 锐, 曹春晓. 等通道转角挤压工艺研究进展[J]. 材料工程, 2009(5): 76-80.

LEI Li-ming, HUANG Xu, DUAN Rui, CAO Chun-xiao. Progress in equal channel angular extrusion process[J]. Material Engineering, 2009(5): 76-80.

[9] 林毛古, 徐卫平, 柯黎明. 旋转摩擦挤压制备 MWCNTs/Al 复合材料的界面微观结构[J]. 中国有色金属学报, 2015, 25(1): 98-102.

LIN Mao-gu XU Wei-ping, KE Li-ming. Interface microstructures of MWCNTs/Al composites prepared by rotational friction extrusion[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(1): 98-102.

[10] ROMETSCH P A, ZHANG Y, KNIGHT S. Heat treatment of 7xxx series aluminium alloys—Some recent developments[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(7): 2003-2017.

[11] GOURDET S, MONTHEILLET F. A Model of continuous dynamic recrystallization[J]. Acta Metallurgica Sinica, 2003, 51(9): 2685-2699.

[12] 熊其平. 碳纳米管增强铝基复合材料挤压线材的性能研究[D]. 南昌: 南昌航空大学, 2014.

XIONG Qi-ping. Study on the properties of extruded wire carbon nanotubes reinforced aluminum composites[D]. Nanchang: Nanchang Hangkong University, 2014.

[13] 张纪帅, 陈志国, 任杰克, 陈继强, 魏 祥, 方 亮. 新型热机械处理对Al-Zn-Mg-Cu合金显微组织与性能的影响[J]. 中国有色金属学报, 2015, 25(4): 910-917.

ZHANG Ji-shuai, CHEN Zhi-guo, REN Jie-ke, CHEN Ji-qiang, WEI Xiang, FANG Liang. Effect of new thermomechanical treatment on microstructure and properties of Al-Zn-Mg-Cu aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(4): 910-917.

[14] 杨修波. Al-Zn-Mg(Cu)合金的热处理、微观结构与性能研究[D]. 长沙: 湖南大学, 2014.

YANG Xiu-bo. Research on microstructures and properties of Al-Zn-Mg(Cu) alloy after different heat treatment[D]. Changsha: Hunan University, 2014.

[15] MARLAUD T, DESCHAMPS A, BLEY F, LEFEBVREC W,BAROUX B. Influence of alloy composition and heat treatment on precipitate composition in Al-Zn-Mg-Cu alloys[J]. Acta Materialia, 2010, 58(1): 248-260.

[16] BUHA J, LUMLEY R N, CROSKY A G. Secondary ageing in an aluminium alloy 7050[J]. Materials Science and Engineering A, 2008, 492(1/2): 1-10.

[17] 刘国勋. 金属学原理[M]. 北京: 冶金工业出版社, 1980.

LIU Guo-xun. Metallography principle[M]. Beijing: Metallurgical Industry Press, 1980.

[18] 戴启雷, 梁志芳, 吴建军, 孟立春, 史清宇. Al-Mg-Si 合金搅拌摩擦焊接头 DSC 测试过程中组织变化及能量释放分析[J]. 金属学报, 2014, 50 (5): 587-593.

DAI Qi-lei, LIANG Zhi-fang, WU Jian-jun, MENG Li-chun, SHI Qing-yu. Microstructure change and energy release of Friction Stir Welded Al-Mg-Si alloy during DSC test[J]. Acta Metallurgica Sinica, 2014, 50 (5): 587-593.

Microstructure and second phase morphology of rotational friction extruding 7075 Al alloy

XING Li, ZHU Du-qiao, XU Wei-ping, KE Li-ming

(National Defense Key Disciplines Laboratory of Light Alloy Processing Science and Technology, Nanchang Hangkong University, Nanchang 330063, China)

Abstract: 7075-T6 Al alloy with T6 state was processed by Rotational friction extrusion (RFE), and then they were heat treated. The microstructure and second phase of 7075 Al alloy were observed, the hardness was tested. The results show that, 7075 Al alloy after RFE is composed of fine equiaxed grains while they are recrystallized uncompletely, average grain size is about 15 μm. After heat treatment, the recrystallization behavior is finished in those unrecrystallized grains and grain becomes finer, about 8 μm. The primary intermetallic reserved in 7075 Al alloy becomes smaller after RFE. Most of aging precipitated phase (MgZn2) is re-dissolved, however, some un-dissolved precipitated phase particles become coarser. Many new second phase particles are re-precipitated in the extruded 7075 Al alloy after heat treatment, and they are distributed uniformly. The hardness of the as-RFE 7075 Al alloy is lower than that of the as-recieved material, but after T6 heat treatment, the hardness is 177.5HV, higher than that of the as-received material. The strengthening effect of second phase is greater than that of fine-grain in 7075 Al alloy.

Key words: 7075 Al alloy; rotational friction extrusion; heat treatment; microstructure; second phase

Foundation item: Project(51364037) supported by the National Natural Science Foundation of China

Received date: 2016-05-26; Accepted date: 2016-11-10

Corresponding author: XING Li; Tel: +86-13576103681; E-mail: xingli_59@126.com

(编辑 何学锋)

基金项目:国家自然科学基金资助项目(51364037)

收稿日期:2016-05-26;修订日期:2016-11-10

通信作者:邢 丽,教授;电话:13576103681;E-mail:xingli_59@126.com