DOI: 10.11817/j.ysxb.1004.0609.2021-36705

X含量对W-X合金微观组织与性能的影响

刘文扬,黄宇峰,蔡青山,段欣昀,张 勇,刘文胜,马运柱

(中南大学 轻质高强结构材料国家级重点实验室,长沙 410083)

摘 要:以高纯钨粉和高纯X粉为原料,通过放电等离子烧结技术 (SPS)制备了不同X含量的W-X合金材料,并结合X射线衍射仪、扫描电镜、透射电镜等分析手段,研究X含量对W-X合金材料微观组织及强韧性的影响。结果表明:W-X合金材料的主要相组成为W-X固溶体和X的氧化产物X2O5;X元素的加入改变了纯钨的变形机制,在螺位错的基础上,出现了刃位错;随着X含量的增加,X固溶到钨晶粒中的比例逐渐增大,晶粒尺寸发生长大;随着X含量的增加,W-X合金材料的相对密度先增加后趋于稳定,压缩强度呈现先增大后减小的规律;当X含量为30%(质量分数)时,W-X合金呈现最佳性能,压缩强度达2044 MPa,压缩应变达24%。

关键词:高强;高韧;钨;固溶体;放电等离子烧结

文章编号:1004-0609(2021)-07-1707-10 中图分类号:TF841.1 文献标志码:A

引文格式:刘文扬, 黄宇峰, 蔡青山, 等. X含量对W-X合金微观组织与性能的影响[J]. 中国有色金属学报, 2021, 31(7): 1707-1716. DOI: 10.11817/j.ysxb.1004.0609.2021-36705

LIU Wen-yang, HUANG Yu-feng, CAI Qing-shan, et al. Effect of X content on microstructure and properties of W-X alloy[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(7): 1707-1716. DOI: 10.11817/ j.ysxb.1004.0609.2021-36705

金属钨因其高熔点(3410 ℃)、高密度(19.3 g/cm3)、高强度、高硬度、良好的导热性及低热膨胀系数等优异特性,广泛应用于航空航天、军工、先进制造业等领域[1-3]。然而,由于钨的体心立方晶体结构(BCC)和少的滑移系统,室温下钨的塑性变形主要依赖于非平面的1/2 螺位错,而长直的螺位错可动性极差,同时,钨的韧脆转变温度较高,因此,钨具有本征脆性。此外,钨再结晶温度(1000~1200 ℃)比较低,钨晶粒在较低的温度下容易发生再结晶长大,因此钨具有再结晶脆性,极大地限制了钨在极端环境(高温高载荷)的应用[4-6]。

螺位错,而长直的螺位错可动性极差,同时,钨的韧脆转变温度较高,因此,钨具有本征脆性。此外,钨再结晶温度(1000~1200 ℃)比较低,钨晶粒在较低的温度下容易发生再结晶长大,因此钨具有再结晶脆性,极大地限制了钨在极端环境(高温高载荷)的应用[4-6]。

钨主要的断裂面是(100)晶面,而钨的最密排面是(110)晶面,出现这种原因是晶面(100)位错滑移到晶面(001)形成凿尖,导致裂纹的萌生,对位错起到钉扎作用,形成不动位错[7-8]。在实际的材料压缩或拉伸断裂中,金属钨的断裂是典型的脆性断裂,裂纹扩展非常迅速,形成典型的穿晶解理断裂形貌。总而言之,钨存在韧性不足的缺点。

针对钨的脆性问题,国内外开展了一定的研究工作。有学者通过添加铼到纯钨中,起到有效的强韧化作用,在一些领域已经有所应用,但是铼和钨容易产生金属间化合物,且铼的价格比较昂贵,极大地限制了钨铼合金的应用领域[9-11]。通过添加钾形成气泡强化钨效果不错,主要是用来制备钨灯丝,但是制备的钨丝属于一种多孔的材料,且由于钾难以脱除,导致钨内部存在残余的钾[12-14]。高密度难熔金属X具有较好的延展性,储量丰富。根据相图和计算模拟表明[15-17],X原子可以完全固溶到钨晶格中,部分代替钨。体模量与剪切模量的比值(B/G)、泊松比、柯西压力和材料的韧性呈正相关关系,相比于纯钨,X元素的固溶使得W-X合金的这些值都增大。这也就意味着添加X元素可能改善纯钨的脆性。然而,相关实验的研究鲜有报道。

本文作者针对纯钨本征脆性问题,通过添加一种高密度的X元素,使其完全固溶到纯钨中,置换部分钨原子,以期提高纯钨的韧性,进而提升钨的综合性能。通过将混合均匀的W-X粉末冷压成型,再通过放电等离子烧结技术(SPS)对W-X压坯进行烧结,制备高强韧W-X合金材料,重点研究了不同成分和烧结工艺对W-X合金材料的固溶特性以及其强韧性的影响规律。

1 实验

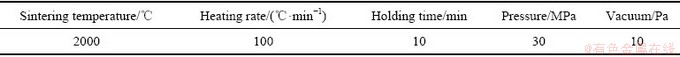

实验所采用的原材料为:高纯W粉末(粒径3~5 μm,纯度99.95%),由厦门虹鹭钨钼工业有限公司提供;高纯X粉末(粒径≤1 μm,纯度99.99%)是由长沙天久有限公司提供。按设计的成分配比称量原料倒入混料罐中,通入氩气保护气体,在立体式混料机上进行混料,转速12 r/min,球料比为1:1,球磨时间9 h。W-X混料后的粉末形貌如图1所示,可见W和X的颗粒分布均匀。将W-X混合粉末冷压成型为W-X预制块,然后在LABOX-325R型放电等离子烧结炉中进行烧结,随炉冷却,其SPS工艺参数如表1所示。

采用“排水法”(GB/T 1423—1996)测量试样密度;采用美国Instron3369型电子万能试验机测试材料压缩强度,加载速率为1 mm/min;采用Advance D型X射线衍射仪对试样进行物相分析;试样经过磨抛机粗磨、精磨、抛光后,使用V(H2O2): V(NH3·H2O)=3:1腐蚀液进行腐蚀,腐蚀时间20 s,采用ZYJ-330型正置光学显微镜观察金相组织;采用日本JXA-8530F型场发射电子探针对材料的元素分布进行分析;采用美国FEI Quanta 250 FEG型场发射扫描电子显微镜(SEM)和德国布鲁克能谱仪(EDS)对材料的微观结构和微区成分进行分析;采用美国的FEI公司的Helios NanoLab 600i型双束扫描电镜装载的聚焦离子束对试样进行切片、减薄,制备透射样品;采用美国的FEI公司的Tecnai G2 F20场发射透射电镜对材料的微观形貌、结构和组织进行分析。

图1 W-X粉末经3D立式混料机混合后的形貌

Fig. 1 Morphology of W-X powder after being mixed by 3D vertical mixer

2 结果与讨论

2.1 不同X含量对W-X合金微观组织的影响

采用放电等离子烧结技术制备不同X含量的W-X合金,其XRD谱如图2所示。由图2可看出,在不同X含量的样品中均未发现单质X的衍射峰,只有钨的衍射峰和衍射峰强度较低的X2O5峰,由此初步可以判断X固溶到钨中形成W-X固溶体以及与O反应形成物相X2O5。与纯钨的标准衍射卡片对比可以发现,固溶的钨衍射峰峰宽变宽,衍射峰整体向左偏离。随着X含量的增加,W-X合金的衍射峰发生偏移,向低角度方向偏移,衍射峰有一定程度的宽化。X原子半径大于钨原子半径,当X原子代替了钨晶格中的钨,即实现了X的固溶,X原子的固溶使钨的晶格点阵常数变大,晶面间距增大,根据布拉格方程2dsinθ=nλ,当晶面间距增大时,θ值相应的减小。所以,随着X固溶含量的增加,W-X合金晶面间距增大,衍射角向低角度偏移。

表1 W-X混合粉末的SPS工艺参数

Table 1 SPS process parameters of W-X mixture powder

图2 SPS法制备的不同X含量下W-X合金的XRD谱

Fig. 2 XRD patterns of W-X alloys with different X content prepared by SPS

图3 SPS法制备的不同X含量下W-X合金的SEM像

Fig. 3 SEM images of W-X alloy with different X content prepared by SPS (Grain size distribution is labeled in upper-right corner for each sample)

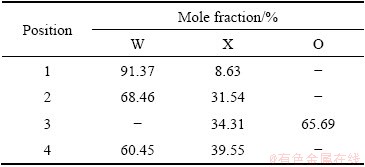

图3所示为放电等离子烧结技术制备的不同X含量下W-X合金的SEM像。由图3可知,W-X合金材料的晶粒主要以等轴状以及少量板条状的形貌组成。从粒径分布图(见插图)可以看出,W-X合金晶粒尺寸主要集中在5~10 μm,随着X含量的增加,W-X合金材料小尺寸的晶粒减少,部分晶粒发生长大,即粗大的晶粒增多。添加的X是熔点远低于钨的典型难熔金属元素,在获得相同的激活能条件下,即烧结温度相同时,X原子更容易发生扩散和迁移,导致在固态合金化过程中原子之间的扩散增加。X的导电性和导热性均高于钨,更多的X加入,意味着W-X在更短的时间能够实现材料的致密化;致密化完成后,晶粒的长大速率增大,导致更多的晶粒之间发生吞并长大。晶粒之间的界面处存在大量的黑色颗粒,少量的黑色颗粒分布在晶粒内部。添加的X是一种极容易氧化的元素,初步推测这种黑色的颗粒主要是X的氧化物。这种氧化物呈弥散均匀分布,颗粒尺寸主要为1~7 μm,少量颗粒为纳米级,颗粒与基体的结合界面较好。氧化物的形成主要是发生在烧结的过程中,这种原位生成的氧化颗粒与基体有较好的润湿性,部分颗粒形成在晶粒的内部。随着X含量的增大,W-X合金形成大量的氧化物颗粒,导致氧化物发生严重的团聚长大。晶粒长大的过程中,一般由大晶粒吞并小晶粒,氧化物颗粒被晶粒吞并的可能性小,仅见少数的氧化物颗粒被吞并,分布在钨基固溶体晶粒内部,大部分的氧化物颗粒被逐步的排挤到晶界富集,形成大的氧化物颗粒,即在扫描电镜下呈现大尺寸的氧化物颗粒;尤其是X的含量达到50%(质量分数)时,部分氧化物颗粒已经形成微米级颗粒,颗粒尺寸高达7 μm;部分区域氧化物颗粒较多,附近的晶粒长大被抑制,导致材料内部组织不均匀。从表2可以看出,基体是W-X合金。由于钨与X是完全互溶的元素,XRD也没有检测其他W-X金属间化合物,因此判断基体是W-X的固溶体。对W-10X、W-30X、W-40X基体进行点扫描分析,其中钨与X的摩尔分数比分别为91.37:8.63、68.46:31.54和60.45:39.55 (见表3),与设计的成分基本吻合。X主要是通过固溶的形式进入钨基体形成W-X固溶体。基体周围的黑色颗粒主要是X的氧化物,结合其X与O的摩尔分数比为34.31:65.69,这与X2O5物相的摩尔比2:5相近,初步判断该相为X2O5颗粒。

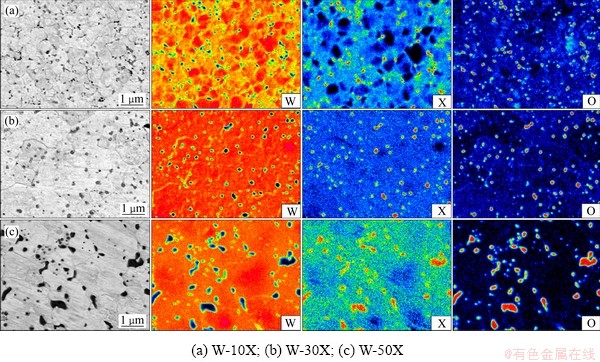

图4所示为放电等离子烧结技术制备的W-X合金材料的电子探针面扫描图。图4(a)所示为W-10X合金的EPMA图,图4(b)所示为W-30X合金的EPMA图,图4(c)所示为W-50X合金的EPMA图。不同X含量的W-X合金中元素具有相似的分布特征,钨元素主要分布在基体,部分X元素的分布特征与钨元素的分布特征一致,在颗粒区域未发现钨的富集。另外,还存在部分X元素主要分布在氧化物颗粒区域,这部分 X的分布特征与氧具有非常相似的分布特征,即均在氧化物颗粒处发生偏聚富集,氧元素未在基体内出现明显的偏聚,这与XRD物相的分析结果相一致。从图4(a)可以看出,W-10X合金存在均匀分布的X的贫瘠区域,此区域与钨富集的区域相对应,这是未发生固溶的钨基体。W-10X合金的氧富集区域与W-30X合金、W-50X合金相比较小,说明其氧化物较少。随着X含量的增加,氧化物颗粒增多并发生团聚,尤其是高X含量的W-50X合金,出现了大块的氧富集区域。

表2 图1中各位置能谱分析结果

Table 2 EDS results of each position in Fig. 3

图4 SPS法制备的W-X合金的电子探针面扫描图

Fig. 4 Electron microprobe surface scanning images of W-X alloy prepared by SPS

图5 SPS法制备的W-X合金的TEM像

Fig. 5 TEM images of W-X alloy materials prepared by SPS

为进一步分析X添加对于W-X合金晶格缺陷、变形机制等方面的影响,对不同X含量W-X合金进行了TEM分析,其结果如图5所示。图5(a)所示为W-10X合金明场像。由图5(a)可见,晶粒之间结合良好,无明显的裂纹或间隙;右上角插图为相应区域选区电子衍图,通过衍射斑点确定所选区域为W-X合金基体。图5(b)所示为相应区域的高分辨图片。由图5(b)可见,基体保持较为完整的晶体结构,且其内部未发现明显的位错结构。经分析W-10X合金的衍射图和高分辨图的变化,并结合W-10X合金材料XRD检测结果,纯钨晶面指数(110)的晶面间距为2.23802  ,W-10X合金晶面指数(110)的晶面间距为2.24870

,W-10X合金晶面指数(110)的晶面间距为2.24870  ,X的固溶使得晶面间距增大,晶格常数增大,这与XRD衍射峰向左偏移相一致,说明外加的X元素固溶到钨晶格中。钨与X的结构类型都是BCC结构,X的固溶并没有改变钨的BCC结构,即W-X固溶体依然保持体心立方结构。图5(c)所示为W-30X合金材料明场像,图5(d)所示为相应区域的高分辨像。W-30X合金的晶粒之间依然保持着较好的结合,无明显的裂纹或间隙,内部无明显的位错缺陷。W-30X合金晶面指数(110)的晶面间距为2.27066

,X的固溶使得晶面间距增大,晶格常数增大,这与XRD衍射峰向左偏移相一致,说明外加的X元素固溶到钨晶格中。钨与X的结构类型都是BCC结构,X的固溶并没有改变钨的BCC结构,即W-X固溶体依然保持体心立方结构。图5(c)所示为W-30X合金材料明场像,图5(d)所示为相应区域的高分辨像。W-30X合金的晶粒之间依然保持着较好的结合,无明显的裂纹或间隙,内部无明显的位错缺陷。W-30X合金晶面指数(110)的晶面间距为2.27066  ,与W-10相比晶面间距增大,这与W-30X的XRD衍射峰进一步向低角度(向左)偏移相一致。图5(e)所示为W-50X合金明场像,图5(f)所示为相应区域的高分辨像。W-50X合金晶粒内部无明显位错缺陷,保持着较为完整的晶体结构,与W-10X合金、W-30X合金的结构相比较,W-50X合金的晶面间距增大,W-50X合金晶面指数在(011)的晶面间距为2.28764

,与W-10相比晶面间距增大,这与W-30X的XRD衍射峰进一步向低角度(向左)偏移相一致。图5(e)所示为W-50X合金明场像,图5(f)所示为相应区域的高分辨像。W-50X合金晶粒内部无明显位错缺陷,保持着较为完整的晶体结构,与W-10X合金、W-30X合金的结构相比较,W-50X合金的晶面间距增大,W-50X合金晶面指数在(011)的晶面间距为2.28764  。

。

图6所示为室温准静态压缩变形后的W-X合金的TEM像。图6(a)所示为压缩变形态W-10X合金明场像,变形后的W-10X合金晶粒内部出现大量的位错,通过选区电子衍射分析,未出现除基体外的第二套衍射斑点,其晶面间距比纯钨稍大,为W-X固溶体。图6(b)所示为图6(a)的区域在[111]带轴的成像条件下的高分辨像,可观察到W-X基体内部存在高密度的位错;与图5(a)所示未变形的W-10X合金相比,随着压缩应变的加载,晶格中逐渐积累的剪切应变导致晶体结构内部的畸变严重,组织内部产生大量位错,并出现刃位错,如D1与D2区域为刃位错区域。图6(c)所示为压缩变形态W-30X合金明场像,变形后的W-30X合金晶粒内部的位错急剧的增加;结合图6(d)所示该区域在[110]带轴的成像条件下的高分辨像,进一步证实变形后W-30X合金组织内部产生大量位错,也观察到了刃位错D3。图6(e)所示为压缩变形态W-50X合金明场像,变形后的W-50X合金内部存在高密度的位错。图6(f)所示为图6(e)的区域在[110]带轴的成像条件下高分辨像,可观察到W-50X合金晶粒内部存在较高密度的位错,D4区域为刃位错区域。这与传统的纯钨变形形成鲜明的对比,在室温下,块体金属钨的塑性变形通常由螺位错控制,是以(001)面的 螺位错的运动为主要变形机制;[111]螺位错的核心分散在3个不同的滑移面上,这使得螺旋位错很难在任何一个滑移面上滑移,这种变形机制的位错迁移率较低[19-20]。X的加入改变了钨的变形机制,形成刃位错的运动机制,部分取代长而直的螺位错滑移,形成的刃位错比螺位错具有更高的位错迁移率,即提高了位错的可动性。形成刃位错代替螺位错的变形机制非常有利于提升钨的强韧性,在性能上表现为压缩强度高达2044 MPa,压缩应变高达24%。

螺位错的运动为主要变形机制;[111]螺位错的核心分散在3个不同的滑移面上,这使得螺旋位错很难在任何一个滑移面上滑移,这种变形机制的位错迁移率较低[19-20]。X的加入改变了钨的变形机制,形成刃位错的运动机制,部分取代长而直的螺位错滑移,形成的刃位错比螺位错具有更高的位错迁移率,即提高了位错的可动性。形成刃位错代替螺位错的变形机制非常有利于提升钨的强韧性,在性能上表现为压缩强度高达2044 MPa,压缩应变高达24%。

2.2 不同X含量对W-X合金性能的影响

图7所示为放电等离子烧结技术制备的不同X含量下W-X合金的实际密度及相对密度变化图。由图7可知,随着X含量的增加,W-X合金的实际密度呈现直线下降的趋势,这主要是X与钨相比密度较低;同时,X含量的增加促进了W-X的致密化过程,当X的含量为30%时,实际密度降低的趋势减小。随着X含量的增加,W-X合金的相对密度逐渐升高后趋于不变,相对密度最高可达98%,相对密度的提升主要与材料X的含量有关,如前所述,X含量的增加大大促进了 W-X合金的致密化。

图8所示为放电等离子烧结技术制备的不同X含量下W-X合金的压缩强度及压缩应变变化图。由图8可知,随着X含量的增加,钨基固溶体合金的压缩强度先增大后减小;当X的含量为30%(质量分数)时,压缩强度达到最大值2044 MPa。随着X含量的增加,X在W-X合金中的固溶量增加,形成高X含量的钨基固溶体,在压缩变形过程中形成高可动性的刃性位错,有助于提升材料的抗裂纹扩展的能力,在宏观上表现为材料的力学性能提升。然而,随着固溶的X含量增多,X也将承受更多应力;由于X相对钨是一种软质材料,其强度远低于钨,因此,过高含量的X元素也会导致W-X合金材料的力学性能下降。这与文献[21-22] 的模拟结果具有相似的规律。在本材料中,存在不可忽视的氧化问题,X形成的氧化物颗粒与基体的界面是影响材料性能的重要因素;界面处的缺点多,畸变能较高,极容易成为裂纹源,严重降低钨基固溶体材料的性能。当X含量低于30%(质量分数)时,氧化形成的氧化颗粒细小呈弥散分布。文献[23]报道的纳米颗粒一般与基体能保持较好的界面关系。XIE等[24]发现细化氧化颗粒可以起到更好的增强增韧的作用。当X含量高于30%(质量分数)时,大量的氧化颗粒形成团聚以及部分钨基固溶体晶粒的长大,加剧了内部组织的不均匀性。研究表明,当氧化物颗粒(如Y2O3)为微米级尺寸(1~10 μm)时,失去应有的强化作用[25-27]。随着氧化物颗粒的长大,颗粒与基体的共格性降低,导致颗粒与基体的界面结合力逐渐地降低,使得材料内部裂纹萌生和扩展更加容易发生;粗大的氧化物颗粒强化效果不佳,使得W-X合金材料的压缩强度降低。

图6 准静态压缩变形后的W-X合金的TEM像

Fig. 6 TEM images of W-X alloy materials after quasi-static compression deformation

图7 SPS法制备的不同X含量下W-X合金的实际密度及相对密度的变化

Fig. 7 Change of density and relative density of W-X alloy with different X content prepared by SPS

图8 SPS法制备的不同X含量下W-X合金的压缩强度与压缩应变的变化

Fig. 8 Variation of compressive strength and compressive strain of W-X alloy with different X content prepared by SPS

3 结论

1) 通过放电等离子烧结技术制备了不同X含量的W-X合金,W-X合金的主要物相是W-X固溶体和氧化物X2O5;随着X含量的增加,W-X合金材料的相对密度增加,晶粒尺寸增大,X的加入促进了钨基固溶体晶粒的长大。

2) X元素的加入对W基体的结构影响显著,X的固溶引起晶格的畸变,晶格常数增大,晶面间距增大;变形后W-X合金组织内部产生大量位错,X的加入改变了纯钨的变形机制,形成刃位错与螺位错混合的变形机制。

3) X元素的加入对W基体的性能影响显著,随着X含量的增加,W-X合金材料压缩强度先增大后减小;当X含量为30%(质量分数)时,W-X合金性能最佳,压缩强度达2044 MPa,压缩应变达24%。

REFERENCES

[1] CHUVILDEEVV N, NOKHRIN A V, BOLDINM S, et al. Impact of mechanical activation on sintering kinetics and mechanical properties of ultrafine-grained 95W-Ni-Fe tungsten heavy alloys[J]. Journal of Alloys and Compounds, 2019, 773: 666-688.

[2] LI Yuan-yuan, HU Ke, LI Xiao-qiang, et al. Fine-grained 93W-5.6Ni-1.4Fe heavy alloys with enhanced performance prepared by spark plasma sintering[J]. Materials Science and Engineering A, 2013, 573: 245-252.

[3] WANG Kai-fei, ZHANG Guo-hua. Synthesis of high-purity ultrafine tungsten and tungsten carbide powders[J]. Transactions of Nonferrous Metals Society of China, 2020, 30(6): 1697-1706.

[4] NEMETH A, REISTER J, AMSTRONGDAVID E J, et al. The nature of the brittle-to-ductile transition of ultra fine grained tungsten (W) foil[J]. International Journal of Refractory Metals and Hard Materials, 2015, 50: 9-15.

[5] PAN Zhi-liang, KECSKESL J, WEI Qiu-ming. The nature behind the preferentially embrittling effect of impurities on the ductility of tungsten[J]. Computational Materials Science, 2014, 93: 104-111.

[6] OODE VRIELINKM A, VAN DOMMELENJ A W, GEERSM G D. Numerical investigation of the brittle-to- ductile transition temperature of rolled high-purity tungsten[J]. Mechanics of Materials, 2020, 145: 103394.

[7] REN C, FANG Z Z, MARK K, et al. Methods for improving ductility of tungsten—A review[J]. International Journal of Refractory Metals and Hard Materials, 2018, 75: 170-183.

[8] BUTLERB G, PARAMOREJ D, LIGDA J P, et al. Mechanisms of deformation and ductility in tungsten–A review[J]. International Journal of Refractory Metals and Hard Materials, 2018, 75: 248-261.

[9] FINK P J, JOSSHUA L M, DOUGLAS G K. Rhenium reduction—Alloy design using an economically strategic element[J]. JOM, 2010, 62(1): 55-57.

[10] NOGAMI S, HASEGAWA A, FUKUDA M, et al. Tungsten modified by potassium doping and rhenium addition for fusion reactor applications[J]. Fusion Engineering and Design, 2020, 152: 111445.

[11] LI Yu-hao, ZHOU Hong-bo, LIANG Lin-yun, et al. Transition from ductilizing to hardening in tungsten: The dependence on rhenium distribution[J]. Acta Materialia, 2019, 181: 110-123.

[12] TANURE L, TERENTYEV D, NIKOLIC V, et al. EBSD characterization of pure and K-doped tungsten fibers annealed at different temperatures[J]. Journal of Nuclear Materials, 2020, 537: 152201.

[13] HUANG Bo, HE Bo, XIAO Ye, et al. Microstructure and bubble formation of Al-K-Si doped tungsten prepared by spark plasma sintering[J]. International Journal of Refractory Metals and Hard Materials, 2016, 54: 335-341.

[14] PHILIPP L, CARSTEN B, WOLFGANG P, et al. Comparison of K-doped and pure cold-rolled tungsten sheets: As-rolled condition and recrystallization behaviour after isochronal annealing at different temperatures[J]. International Journal of Refractory Metals and Hard Materials, 2019, 85: 105047.

[15] 祝佳林, 毛宇成, 刘施峰, 等. 高纯钽退火过程中储存能演变及其对再结晶行为的影响[J]. 中国有色金属学报, 2019, 29(1): 54-65.

ZHU Jia-lin, MAO Yu-cheng, LIU Shi-feng, et al. Stored energy evolution of high-purity tantalum during annealing and its effect on recrystallization behavior[J]. The Chinese Journal of Nonferrous Metals, 2019, 29(1): 54-65.

[16] LI Hong, STEFAN W, CHRISTIAN M, et al. Dislocation- core symmetry and slip planes in tungsten alloys: Ab initio calculations and microcantilever bending experiments[J]. Acta Materialia, 2012, 60: 748-758.

[17] JIANG Di-you, WANG Qing-ling, HU Wei, et al. The effect of tantalum (Ta) doping on mechanical properties of tungsten (W): A first-principles study[J]. Journal of Materials Research, 2016, 31(21): 3401-3408.

[18] 舒德龙, 田素贵, 吴 静, 等. 热处理对4.5%Re单晶镍基合金高温蠕变行为的影响[J]. 中国有色金属学报, 2015, 25(6): 1480-1489.

SHU De-long, TIAN Su-gui, WU Jing, et al. Effects of heat treatment on creep behaviors of 4.5%Re nickel-based single crystal superalloy at high temperature[J].The Chinese Journal of Nonferrous Metals, 2015, 25(6): 1480-1489.

[19] CHENG G M, JIAN W W, XU W Z, et al. Grain size effect on deformation mechanisms of nanocrystalline BCC metals[J]. Materials Research Letters, 2012, 1(1): 26-31.

[20] ROMANER L, AMBROSCH-DRAXL C, PIPPAN R. Effect of rhenium on the dislocation core structure in tungsten[J]. Physical Review Letters, 2010, 104(19): 195503.

[21] TURCHI P E A, GONIS A, DRCHAL V, et al. First-principles study of stability and local order in substitutional Ta-W alloys[J]. Physical Review B, 2001, 64(8): 085112.

[22] MUZYK M, NGUYEN-MANH D, WROBEL J, et al. First-principles model for phase stability, radiation defects and elastic properties of W-Ta and W-V alloys[J]. Journal of Nuclear Materials, 2013, 442(1/3): S680-S683.

[23] LI Kai-lun, MA Guo-qiang, XING Lei-lei, et al. Crack suppression via in-situ oxidation in additively manufactured W-Ta alloy[J]. Materials Letters, 2019, 263: 127212.

[24] XIE Z M, LIU R, ZHANG T, et al. Achieving high strength/ductility in bulk W-Zr-Y2O3 alloy plate with hybrid microstructure[J]. Materials and Design, 2016, 107: 144-152.

[25] 张 涛, 严 玮, 谢卓明, 等. 碳化物/氧化物弥散强化钨基材料研究进展[J]. 金属学报, 2018, 54(6): 831-843.

ZHANG Tao, YAN Wei, XIE Zhuo-ming, et al. Recent progress of oxide/carbide dispersion strengthened W-based materials[J]. Acta Metallurgica Sinica, 2018, 54(6): 831-843.

[26] DONG Zhi, LIU Nan, MA Zong-qing, et al. Synthesis of nanosized composite powders via a wet chemical process for sintering high performance W-Y2O3 alloy[J]. International Journal of Refractory Metals and Hard Materials, 2017, 69: 266-272.

[27] HU Wei-qiang, DONG Zhi, WANG Hui, et al. Microstructure refinement and mechanical properties improvement in the W-Y2O3 alloys via optimized freeze-drying[J]. International Journal of Refractory Metals and Hard Materials, 2021, 95: 105453.

Effect of X content on microstructure and properties of W-X alloy

LIU Wen-yang, HUANG Yu-feng, CAI Qing-shan, DUAN Xin-yun, ZHANG Yong, LIU Wen-sheng, MA Yun-zhu

( National Key Laboratory of Science and Technology for National Defence on High-strength Structural Materials, Central South University, Changsha 410083, China)

Abstract: W-X alloy was prepared by spark plasma sintering (SPS) with high purity tungsten powder and X powder. The effect of X content on the solid solution characteristics and strength and toughness of W-X alloy was studied by means of X-ray diffraction (XRD), scanning electron microscopy (SEM), transmission electron microscopy (TEM) and energy dispersive spectroscopy (EDS). The results show that the main phases of the W-X alloy are W-X solid solution and X2O5. The addition of X changes the deformation mechanism of pure tungsten. On the basis of screw dislocation, the edge dislocations appear. The amount of X solid solution into tungsten grain increases gradually with the increase of X content. The grain size grows up with the increase of X content,which seriously reduces the mechanical properties of the W-X alloy. The relative density of the W-X alloy gradually increases with the increase of X content. The compressive strength of W-X alloy first increases and then decreases with the increase of X content. When the X content is 30% (mass fraction), the performance of W-X is the best, the compressive strength is 2044 MPa and the fracture strain is 24%.

Key words: high strength; high toughness; tungsten; solid solution; spark plasma sintering

Foundation item: Project(51931012) supported by the National Natural Science Foundation of China

Received date: 2021-02-25; Accepted date: 2021-05-10

Corresponding authors: LIU Wen-sheng; Tel: +86-731-88877998; E-mail: liuwensheng@csu.edu.cn

MA Yun-zhu; Tel: +86-731-88877825; E-mail: zhuzipm@csu.edu.cn

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51931012)

收稿日期:2021-02-25;修订日期:2021-05-10

通信作者:刘文胜,教授,博士;电话:0731-88877998;E-mail:liuwensheng@csu.edu.cn

马运柱,教授,博士;电话:0731-88877825;E-mail:zhuzipm@csu.edu.cn