文章编号: 1004-0609(2006)03-0459-05

放电等离子烧结制备高性能NdFeB永磁材料

王公平, 岳 明, 张久兴, 刘卫强

(北京工业大学 材料科学与工程学院 新型功能材料教育部重点实验室, 北京 100022)

摘 要: 采用放电等离子烧结技术制备高性能新型NdFeB永磁材料, 研究烧结工艺和热处理工艺对磁体组织性能的影响。 采用扫描电子显微镜观察磁体的微观组织, 利用B-H回线仪检测磁体的磁性能。 结果表明: 较高的烧结温度有利于磁体的致密化, 但过高的温度则阻碍液相在主相晶界的浸润, 从而降低磁体的致密度。 在优化工艺条件下制备出具有独特的微观组织且最佳性能为Br=1.351T, Hci=674.4kA/m, BHm=360.4kJ/m3的新型SPS NdFeB磁体。

关键词: 放电等离子烧结; NdFeB永磁材料; 富钕相; 热处理 中图分类号: TM274

文献标识码: A

High performance NdFeB permanent magnetic material prepared by spark plasma sintering

WANG Gong-ping, YUE Ming, ZHANG Jiu-xing, LIU Wei-qiang

(Key Laboratory of Advanced Functional Materials, Ministry of Education,

College of Materials Science and Engineering, Beijing University of Technology, Beijing 100022)

Abstract: A new type of NdFeB magnet with high magnetic properties was prepared by spark plasma sintering(SPS) method. The effect of sintering and heat treatment techniques on microstructures and magnetic properties of magnets was systematically studied. The microstructures and magnetic properties of magnet materials were tested by scanning electronic microscope (SEM) and B-H loop-line instrument, respectively. The results show that the densification of magnets is greatly improved with the increase of sintering temperature, while exorbitant sintering temperature will decrease the density of magnets because the Nd-rich phase distributes poorly along the boundaries of the NdFeB grains. Under optimum processing conditions, the SPS NdFeB magnet possesses the best magnetic properties with remanence of 1.351T, coercive force of 674.4kA/m and maximum energy product of 360.4kJ/m3.

Key words: spark plasma sintering; NdFeB permanent magnet; Nd-rich phase; heat treatment

NdFeB永磁材料是迄今为止性能最好, 应用最广泛的永磁材料, 自1983被发明以来[1, 2], 人们从基础到应用[3-5], 从制备技术到产品开发[6-9]进行了许多卓有成效的研究。 一方面, 通过成分优化以及制备技术的改进, 烧结体的磁性能不断提升, 2002年德国VAC公司实验室采用双合金法研制出最大磁能积为451kJ/m3[10](达理论值509kJ/m3的87.2%)的NdFeB磁体, 但烧结体由于必须经过机加工工序从而使器件的生产成本升高; 另一方面, 随着IT、 自动化、 交通等领域新技术的进步, 其应用范围不断拓展, 永磁器件的异型化、 小型化正成为一种趋势, 粘结NdFeB以其形态自由度大、 尺寸精度高、 无需二次加工等优势近年来增长较快, 自1999年至2003年, 磁体增长率为35%, 其中48%以上主要用于计算机外围设备[11]。 目前生产粘结体最好的MQP-D磁粉的磁性能BHm为115~127kJ/m3[12]。 因此, 烧结体的成型性差和粘结体的磁性能较低[13-15]一直是研究者多年来面临的两大难点。 基于此, 本文作者在前期工作中将放电等离子烧结技术[16, 17]引入到NdFeB永磁材料的制备技术研究中, 利用SPS技术快速均匀的烧结特点和模具精确成型的优势, 成功地制备出一种组织独特、 成型性好、 磁性能和耐腐蚀性能良好的新型磁体[18], 为NdFeB永磁材料的研究提供了一种新的较为理想的技术。 然而, 这种新型磁体的最大磁能积只有240kJ/m3, 与传统烧结体[19]相比仍有待于提高。 因此, 本文作者以提高SPS NdFeB永磁体的磁性能为目的, 通过进一步优化SPS工艺及热处理工艺, 探索制备出具有优异磁特性的新型NdFeB永磁材料。

1 实验

将成分为 Nd10.2 Pr3Dy0.5Fe80Al0.3B6合金在感应炉中于Ar气氛下熔炼, 利用片铸(Strip-casting)技术制成厚度为200~300μm的快淬厚带, 其中, 熔体温度为1200~1500℃, 辊速为1m/s。 厚带在常温下吸氢之后于600℃真空脱氢, 经气流磨制成平均粒度约为5μm的粉末颗粒, 经磁场(1.5T)取向和预压后放入石墨模具进行SPS烧结。 烧结设备为日本住友石炭公司研制的SPS-3.20-MK-V型烧结系统。 SPS条件为: 烧结温度为800~1000℃, 升温速率为30℃/min, 压力为30~100MPa, 烧结保温时间为0~20min; 磁体的热处理工艺为: 温度900~1080℃, 时间1~2h。 采用HITACHI S-3500N扫描电子显微镜研究磁体的显微组织, 利用B-H回线仪检测磁体的磁性能。

2 结果与讨论

温度是烧结过程所需热力学、 动力学的首要条件, 前期的研究工作表明[20], 烧结温度是SPS各工艺参数中对磁体组织性能影响最大的参数。 NdFeB材料的烧结从液相的形成、 浸润、 流动分布到主相颗粒的固相烧结, 经历了几个阶段, 对应着不同的温度区间, 烧结温度的高低直接影响富钕相在磁体中的形貌及其分布和磁体的致密度, 从而影响磁体的磁性能。

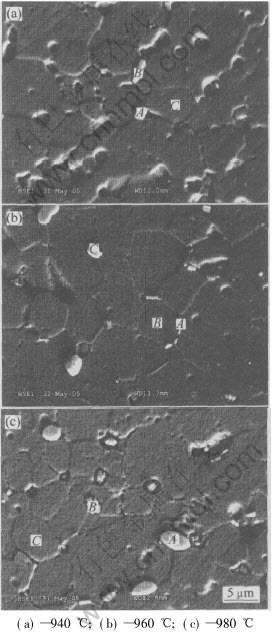

图1所示为不同烧结温度下的SPS NdFeB磁体的扫描电子显微组织。 由图1可看出, 随着烧结温度的升高, 主相颗粒趋于增大, 富钕相的形貌分布、 主相颗粒的大小差异以及主相颗粒间空隙的大小和数量等各具特征。 940℃烧结的样品, 主相颗粒较小, 晶粒周围散布较多的孔洞和颗粒状的富钕相。 在烧结过程中, 伴随着主相细小晶粒在液相中的溶解和在较大晶粒上的析出, 液相的生成量及其在晶粒间的浸润流动方式对消除样品的主相颗粒间的空隙, 以及实现样品的致密化有重要影响。 在其它工艺参数不变的情况下, 温度越高, 液相量越多, 细小晶粒在其中的溶解度越大, 液相的粘滞力减小, 在毛细管力作用下, 液相在主相颗粒间浸润更充分。 图1中的众多孔洞多数处于颗粒间的三角交汇点, 其中一部分蓄积了富钕相(烧结过程为液相), 在磨样过程中脱落。 说明烧结温度的偏低影响了液相的生成与浸润以及空隙的消除。

图1 不同温度下烧结并经1050℃热处理的SPS NdFeB永磁材料的SEM像

Fig.1 SEM images of SPS NdFeB permanent magnets sintered at different temperatures after heat treatment at 1050℃

960℃烧结时, 主相晶粒均匀合适, 孔洞和颗粒状富钕相较少, 组织致密, 此温度为最佳的烧结温度。 980℃烧结时, 主相晶粒大小差异大, 且出现粗大富钕相、 孔洞和间隙。 一般来说, 烧结温度越高, 样品的致密度越高。 980℃烧结体不同寻常的形貌特征与样品成分中的稀土含量及SPS的烧结特征有关。 升高烧结温度虽然有助于液相的生成、 浸润, 但烧结温度过高则使晶粒长大速度增大且不均匀, 这种快速且不均匀的晶粒长大速度容易使颗粒间形成结合颈部, 这种不断增大的颈部阻碍了液相流动, 液相因此容易在三角晶界处的空隙形成较大的积留, 从而影响样品的致密度。

由此可见, 尽管烧结温度相差不大(温差仅为40℃), 但磁体的显微组织却显示磁体经历了不同的烧结过程, 显示出特殊的致密特征。 说明对于稀土含量较低的磁体而言, 获取理想组织结构的温区较窄, 最佳烧结温度较高。 这一结果与本文作者前期[20]对高稀土含量磁体的研究结果不同。

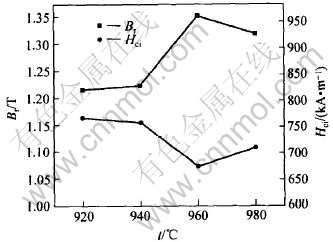

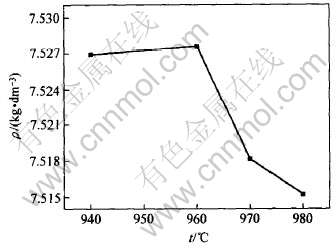

SPS烧结温度对SPS NdFeB 磁体的磁性能影响如图2所示。 由图2可看出, 随着烧结温度的升高, 磁体的剩磁先增大后减小, 增大阶段的主要原因是由于磁体致密度的提高, 减小的主要原因是由于过高的烧结温度下晶粒的不均匀长大造成磁体密度的下降。 矫顽力则呈现整体下降趋势, 其主要原因是由于晶粒的长大。 磁体密度随烧结温度的变化特征显示这种磁体在烧结致密化过程中具有的不同特征, 结果如图3所示。 由图3可看出, 随着温度的升高, 密度先增加后减少。 说明这种磁体在SPS致密过程中存在两种不同的趋势, 即液相的生成、 浸润和主相颗粒间形成的颈部对液相浸润的阻碍。 在较低烧结温度阶段, 当以前一种趋势为主时, 密度增加; 在较高烧结温度阶段, 当以后一种趋势为主时, 密度则减少, 这与图1中所显示的组织一致, 这种情形与稀土含量较高的磁体制备中密度随温度的增加而增加的趋势不同。

图2 SPS烧结温度对经1050℃热处理的SPS NdFeB永磁材料磁性能的影响

Fig.2 Effect of SPS sintering temperatures on magnetic properties of SPS NdFeB permanent magnets after heat treatment at 1050℃

图3 SPS烧结温度对经1050℃热处理的SPS NdFeB永磁材料密度的影响

Fig.3 Effect of SPS sintering temperatures on density of SPS NdFeB permanent magnets after heat treatment at 1050℃

2.2 热处理温度对磁体显微组织及其性能的影响

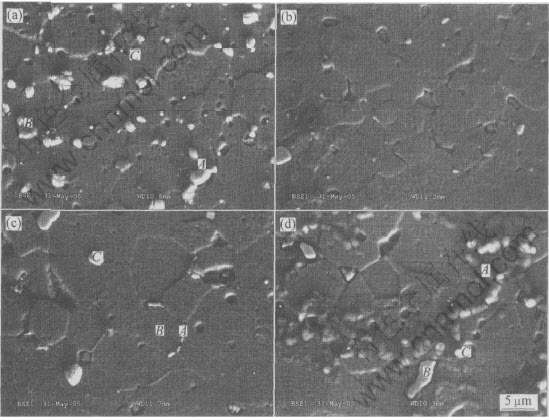

SPS过程可以使样品获得晶粒均匀细小的致密组织, 但快速烧结过程很难使液相充分浸润在主相边界, 且易使边界相形成一些非平衡态, 因此热处理对改善微组织结构和提高磁性能是必要的, 结果如图4所示。 由图4可看出, SPS NdFeB烧结磁体(见图4(a))存在较多颗粒状的富钕相, 经过不同温度热处理后, 磁体的颗粒状富钕相明显减少, 说明热处理使富钕相分布更为均匀, 原来颗粒状稀土相所占的空位消失, 因而更为致密。 但在较低热处理温度(图4(b))下, 磁体仍存在空隙; 过高的温度(图4(d))则使部分颗粒开始熔化, 并出现较多的颗粒状富钕相。 合适的热处理温度(图4(c))将使磁体更为致密, 主相晶粒大小更为均匀, 富钕相分布更为理想。

图4 960℃烧结磁体热处理前后的SEM像

Fig.4 SEM images of SPS NdFeB permanent magnets before(a) and

after heat treatment at 900℃(b), 1050℃(c) and 1080℃(d)

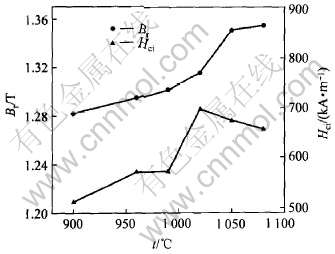

图5所示为不同热处理温度对同一SPS NdFeB烧结磁体磁性能的影响。 由图5可看出, 随着热处理温度的升高, 剩磁先增加后趋于稳定, 矫顽力则是先增加后减少。 说明随着热处理温度的升高, 磁体的致密度提高, 富钕相分布更为均匀。 但过高的温度使部分主相晶粒开始熔化, 且颗粒状富钕相增多, 因此矫顽力下降。

图5 热处理温度对烧结温度为960℃的SPS NdFeB永磁材料磁性能的影响

Fig.5 Effect of heat treatment temperatures on magnetic properties of SPS NdFeB permanent magnets sintered at 960℃

3 结论

采用SPS技术制备的高性能NdFeB永磁材料, SPS过程中液相在晶粒间的浸润流动直接影响着磁体的致密度。 在SPS过程特定温度下, 一方面发生液相浸润分布从而促使样品致密; 另一方面由于颗粒间的接触由点而面的增大, 造成对液相均匀分布的遏制, 从而影响磁体的致密。 这两种并存趋势的交互作用使得这种稀土含量较少的磁体致密化最佳温度区间更为狭小。 通过温度对磁体组织性能影响的研究得出, 最佳烧结温度为960℃, 最佳热处理温度为1050℃, 制备的SPS NdFeB磁体最佳磁性能为Br=1.351T , Hci=674.4kA/m, BHm=360.4kJ/m3。

REFERENCES

[1]Sagawa M, Fujimura S, Togawa N, et al .New material for permanent magnets on a base of Nd and Fe[J]. Appl Phys, 1984, 55(6): 2083-2085.

[2]Croat J J, Herbst J F, Lee R W, et al . High-energy product Nd-Fe-B permanent magnets[J]. Appl Phys Lett, 1984, 44(1): 148 -149.

[3]Herbst J F, Croat J J, Pinkerton F E, et al. Relationships between crystal structure and magnetic properties in Nd2Fe14B[J]. Physical Review B, 1984, 29(7):4176-4178.

[4]Sagawa M, Fujimura S, Togawa N, et al. New material for permanent magnets on a base of Nd and Fe (invited)[J]. J Appl Phys, 1984, 55(6): 2083-2087.

[5]Hirosawa S, Matsuura Y. Magnetization and magnetic anisotropy of R2Fe14B measured on single crystals[J]. J Appl Phys, 1986, 59(3): 873-879.

[6]Ormerod J, Constantinides S. Bonded permanent magnets: Current status and future opportunities (invited)[J]. J Appl Phys, 1997, 81(8): 4816-4820.

[7]Hinz D, Kirchner A, Brown D N, et al. Near net shape production of radially oriented NdFeB ring magnets by backward extrusion[J]. Journal of Materials Processing Technology, 2003, 135(2-3): 358-365.

[8]Tian Z J, Li S D, Peng K, et al. The microstructure and magnetic properties of NdFeB magnets directly solidified at a low cooling rate[J]. Materials Science and Engineering A, 2004, 380(1-2): 143-146.

[9]Liu J F, Vora P, Walmer M H, et al. Microstructure and magnetic properties of sintered NdFeB magnets with improved impact toughness[J]. J Appl Phys, 2005, 97: 10H101-10H103.

[10]Rodewald W, Wall B, Katter M, et al. Extraordinary strong Nd-Fe-B magnets by controlled microstructure[A]. Proc of 17th International workshop on rare earth magnets and their applications[C]. Newark Delaware: Rinton Press, 2002. 18-22.

[11]Croat J J. The current status and future outlook of the bonded neodymium magnet industry[A]. 2004 China Magnet Symposium[C]. Xian: Shanghaimag Information Consulting Co Ltd, 2004. 30-34.

[12]Ma B M, Herchenroeder J W, Smith B, et al. Recent development in bonded NdFeB magnets[J]. Journal of Magnetism and Magnetic Materials, 2002, 239: 418-423.

[13]Takeshita T, Morimoto K. Anisotropic Nd-Fe-B bonded magnets made from HDDR powders (invited)[J]. J Appl Phys, 1996, 79(8): 5040-5044.

[14]Croat J J. Current status and future outlook for bonded neodymium permanent magnets (invited)[J]. Appl Phys, 1997, 81(8): 4804-4809.

[15]Panchanathan V, McMullen A T, Croat J J, et al. Properties of bonded anisotropic magnets[J]. J Appl Phys, 1991, 70(10): 6465-6467.

[16]Mamoru O. Sintering, consolidation, reaction and crystal growth by the spark plasma system(SPS)[J]. Materials Science and Engineering A, 2000, 287(2): 183-188.

[17]Yamazaki K. PAS (plamasa actived sintering): transient sintering process control for rapid cosolidation of powders[J]. Mater Pro Tech, 1996, 56: 955-965.

[18]Yue M, Zhang J X, Liu W Q, et al. Chemical stability and microstructure of NdFeB magnets prepared by spark plasma sintering[J]. Magnetism and Magnetic Material, 2004, 271: 364-368.

[19]Scott D W, Ma B M, Liang Y L, et al. Microstructural control of NdFeB cast ingots for achieving 50 MGOe sintered magnets[J]. J Appl Phys, 1996, 79(8): 4830-4832.

[20]Yue M, Zhang J X, Xiao Y F, et al. New kind of NdFeB magnet prepared by spark plasma sintering[J]. IEEE Transactions on Magnetics, 2003, 39(6): 3551-3553.

基金项目: 国家自然科学基金资助项目(50371002); 北京市教委科技发展计划资助项目(Km200310005019); 北京市科技新星计划资助项目(2003B03)

收稿日期: 2005-09-14; 修订日期: 2005-12-22

作者简介: 王公平(1963-), 男, 博士研究生

通讯作者: 岳 明, 副教授, 博士; 电话: 010-67391760; 传真: 010-67392840; E-mal: yueming@bjut.edu.cn

(编辑李艳红)