文章编号:1004-0609(2009)06-0992-07

喷射成形高强度AZ91镁合金的组织与力学性能

崔 华1,李永兵2,黄进峰1,余红燕1,熊柏青3,张济山1

(1. 北京科技大学 材料科学与工程学院,北京 100083;

2. 机械科学研究总院 先进制造技术研究中心,北京 100083;

3. 北京有色金属研究总院,北京100088)

摘 要:在保护气氛中采用喷射成形制备技术制备了形状完整的AZ91镁合金沉积圆柱坯。对沉积坯进行显微组织分析,结果表明:喷射沉积AZ91镁合金具有均匀、细小的等轴晶组织,平均晶粒尺寸约17 μm,有效地改善了离异共晶β-Mg17Al12相在晶界的偏析;挤压变形过程引发的动态再结晶使喷射成形AZ91镁合金的组织进一步细化;经175 ℃时效时,析出相中多数为不连续析出,连续析出所占比例很小;后期阶段时效过程加快,长时间时效未见片状及针状析出物球化现象。喷射成形AZ91 镁合金经挤压变形和T6处理后,抗拉强度和屈服强度分别达到435和360 MPa,伸长率为9.2%,实现了强度和韧性的同步大幅度提高。

关键词:AZ91镁合金;喷射成形;显微组织;力学性能

中图分类号:TG 132.1+1 文献标识码: A

Microstructures and mechanical properties of

high strength AZ91 Mg alloy by spray forming technology

CUI Hua1, LI Yong-bing2, HUANG Jin-feng1, YU Hong-yan1, XIONG Bai-qing3, ZHANG Ji-shan1

(1. School of Materials Science and Engineering, University of Science and Technology Beijing,

Beijing 100083, China;

2. Advance Manufacture Technology Center, China Academy of Machinery Science and Technology,

Beijing 100083, China;

3. Beijing General Research Institute for Nonferrous Metals, Beijing 100088, China)

Abstract: AZ91 magnesium preform with complete shape was prepared using spray forming technology under protective atmosphere. The microstructure analysis shows that AZ91 Mg alloy has homogeneous and equiaxial-grains structure, the average grain size is 17 μm. The segregation tendentiousness of divorce eutectic β-Mg17Al12 phase towards the grain boundary is greatly improved. The further grain refinement is attributed to the dynamic recrystallization during extrusion processing. When aging at 175 ℃, two kinds of precipitates exist which are the majority of lamellar discontinuous precipitates and a small amount of dispersive continuous precipitates. During the latter aging, β-Mg17Al12 phase precipitates quickly and no spheroidized lamellar is observed. The average tensile ultimate, yield strength and elongation of the sprayed AZ91 Mg alloy after extruded T6 treatment are 435 MPa, 360 MPa and 9.2%, respectively, at the room temperature, which indicates a better combination of toughness and strength.

Key words: AZ91 magnesium alloy; spray forming; microstructure; mechanical property

镁合金是目前质量最轻的金属结构材料,具有较高的比强度和比刚度,优良的散热、电磁屏蔽、减震和机械加工等物理性能,产品满足环保要求易回收利用,在汽车和飞机制造等一些工业领域因其较低的密度和易回收特点而逐渐被大批量地应用[1?2],有望成为21世纪重要的商用轻质结构材料[3?5]。

Mg-Al-Zn 系合金是目前应用最为广泛的镁合金之一,尤其是AZ91合金更是广受关注。由Mg-Al二元合金相图可以看出,Mg-Al系合金具有较宽的凝固范围,在普通铸造方式下,很容易产生偏析带、凝固缩松、热裂等铸造缺陷[6?7]。Mg 原子半径较大,具有较强的电负性,大多数合金元素在镁合金中的固溶度较低,倾向于与Mg形成化合物,以离异共晶的形式析出,形成沿晶界分布的粗大形态,对合金力学性能产生不利影响[8]。传统Mg-Al-Zn 系合金中,沿晶界分布的高比例分数形态粗大的脆性β-Mg17Al12相虽然可使合金硬度有所提高,但却降低了合金的塑韧性,使后续变形加工变得困难[9]。

作为制备高性能优质材料的一种先进技术,喷射成形技术的优点已被诸多报道[10?12]。利用喷射成形先进制备技术的独特优势,综合细晶强化、固溶强化、弥散强化、位错强化等强韧化机制,提高传统Mg-Al-Zn系镁合金系的综合性能以满足结构材料的使用要求已经成为目前镁合金研究的一个重要的方向。本文作者利用喷射成形方法制备了AZ91镁合金沉积坯件,然后对其进行挤压加工,研究了合金的组织变化及材料的性能。

1 试验

1.1 试验材料

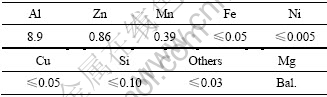

试验原料选用工业用铸造AZ91镁合金(国内牌号ZM5)铸锭,其成分符合GBPT117721991“铸造镁合金”的规定,具体化学成分如表1所列。

表1 镁合金的化学成分

Table 1 Chemical composition of AZ91 magnesium alloy (mass fraction, %)

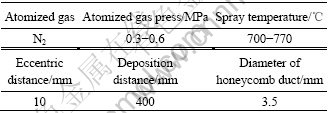

1.2 喷射成形AZ91镁合金材料的制备

喷射成形AZ91镁合金试验在北京科技大学新金属材料国家重点实验室真空感应雾化沉积系统上进行,氩气保护气氛下熔炼,合金熔化经电磁搅拌混合均匀后,静置降温,倾倒至中间包,经导流嘴流出,高压雾化气体雾化,雾化液滴沉积到接受极板形成柱状沉积坯。采用环孔式非限制型雾化喷嘴,喷射沉积AZ91镁合金主要工艺参数如表2所列。

表2 喷射成形AZ91镁合金工艺参数

Table 2 Processing parameter of spray-formed AZ91 magnesium alloy

依据选定的制坯参数,采用喷射成形方法制备了AZ91镁合金锭坯,沉积坯的实际照片如图1所示。沉积坯底部直径约为140 mm,顶部直径约100 mm,高约150 mm。从图1可以看出,去除底部过渡区,沉积坯主体部分近于圆柱形,表面光洁平整,没有沉积时液相含量较高而出现的塌陷或起瘤现象,表明雾化沉积时液相含量较适宜。

图1 喷射成形AZ91镁合金沉积坯照片

Fig.1 Photo of sprayed magnesium AZ91 alloy billet

将喷射成形AZ91合金坯件线切割成d 90 mm圆柱,在 TXJ?650 挤压机上进行挤压变形,最大挤压力650 t,挤压筒直径d 93 mm。圆柱坯料在保温炉内升温至410 ℃,保温30 min,挤压筒温度325~350 ℃,挤压成d15 mm棒材,挤压比22?1,挤压速率约为16 mm/s。取挤压棒料在箱式电阻炉中进行不同工艺的固溶及时效处理后水淬,固溶处理温度为415和175 ℃下进行等温时效处理,最长时效时间为36 h。固溶处理时将试样埋入石墨粉内,以防止表面氧化。

1.3 喷射成形AZ91镁合金材料组织分析与性能测试

通过leitz2DMIXT型光学显微镜、X射线衍射仪、Cambridge?S250型扫描电镜(SEM/EDS)、Hitachi800型透射电镜(TEM)等对沉积态AZ91镁合金进行组织观察与分析,金相试样浸蚀剂分别为:4%(体积比)硝酸乙醇溶液和5 g苦味酸+10 mL冰醋酸+10 mL蒸馏水+ 80 mL无水乙醇溶液。采用平均截线法(d=1.74 L, d为平均晶粒尺寸,L为截线长度)及Image-Pro Plus软件多视场统计平均晶粒尺寸d。透射电镜用试样从块体材料上用线切割方法截取厚0.5 mm的镁合金片,经机械减薄至0.08~0.10 mm,然后电解双喷减薄,双喷减薄液为5%HClO4+95%CH3OH(体积比),工作温度为?50~?30 ℃,工作电压15~20 V。采用HVS?1000 Digital Microhardness Tester维氏硬度测量仪进行硬度测试。试样拉伸力学性能测试按GB/T228—2002取样,在MTS2810力学性能实验机上进行拉伸试验。

2 结果与分析

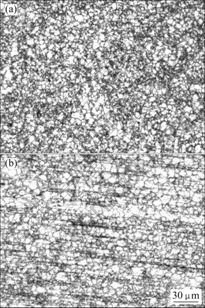

2.1 喷射成形AZ91合金沉积态显微组织

图2所示为铸态和喷射沉积AZ91镁合金的金相显微组织。铸态AZ91镁合金的显微组织(图2(a))是由α-Mg基体及连续分布的α-Mg和β-Mg17Al12部分离异共晶组织组成,晶粒粗大。脆性β-Mg17Al12相连续分布成网状结构,具有Mg-Al系合金典型铸造组织特征。图2(b)所示为喷射沉积AZ91合金为典型的等轴晶组织,平均晶粒尺寸约为17 μm。图3所示为喷射成形AZ91镁合金沉积态SEM和TEM显微组织分析。由图3可看出,少量细小β-Mg17Al12第二相在基体中呈弥散分布,其析出形态有两种:一种是沿晶界析出,约1~2 μm(见图3(a));另一种是晶内的非常细小的析出,透射照片(见图3(b))显示这种细小析出相呈针状,长度为几百纳米。

图2 AZ91镁合金的金相显微组织

Fig.2 Optical micrographs of AZ91 Mg alloys: (a) As-cast; (b) As-sprayed

图3 喷射成形AZ91镁合金沉积态显微组织分析

Fig.3 Micrographs of as-sprayed AZ91 Mg alloy: (a) SEM image; (b) TEM dark field image

喷射沉积过程高压雾化气流与熔体之间强烈的对流换热使得AZ91镁合金雾化熔滴获得较高的冷却速率,晶体的形核与生长模式均发生了较大的变化。共晶反应L→α-Mg+β-Mg17Al12被抑制,固?液界面前沿Al和Zn等溶质原子的扩散和迁移在高的过冷度条件下受到阻碍,溶质截留效应显著,大量Al原子固溶到基体中成为代位原子,离异共晶β-Mg17Al12相在晶界的偏析被有效改善,形成过饱和近乎单相的α-Mg固溶体组织,晶粒被充分细化,这对于提高AZ91镁合金的可加工性能,获得优异的强度与塑韧性的同步提高是十分有利的。

2.2 喷射成形AZ91镁合金的挤压变形显微组织

图4所示为喷射沉积AZ91合金经420 ℃挤压变形后横断面和纵断面(沿挤压方向)的金相显微组织。由图4可看出,挤压变形后的显微组织为典型的动态再结晶等轴晶粒组织,组织得到进一步细化,晶粒尺寸在3~10 μm之间,沿晶界位置有少量的第二相析出,为挤压后期及挤压完成后空冷至室温过程所形成;第二相的析出可钉扎晶界,稳定晶粒,阻碍晶粒长大,从而起到细化晶粒的作用。但第二相的过早析出,消耗了可能以连续方式析出的第二相的量,不利于后续时效过程的析出强化。

图4 挤压态样品的金相显微组织

Fig.4 Optical microstructures of as-extruded alloys: (a) Cross-sectional transect part (vertical to extruded direction); (b) Longitudinal sections (along extruded direction)

镁合金由于具有密排六方结构,在室温下只有{0001}滑移面,低温变形能力较差,但其在250 ℃以上可增加{10 1}二次滑移面并沿着该滑移面的〈11

1}二次滑移面并沿着该滑移面的〈11 0〉晶向滑移,即发生所谓的棱锥滑移,从而使镁合金在热挤压时呈现相当好的塑性变形能力,并伴随动态再结晶的发生。这种动态再结晶是通过再结晶核心的形成和长大两个过程进行的:在挤压应力和挤压热的作用下,首先形成亚结构,进而通过亚晶合并机制形成大角度晶界,随后通过大角度晶界的迁移以及亚晶进一步转动和合并,形成细小的等轴晶粒[13]。挤压过程所引发的动态再结晶是喷射成形镁合金组织进一步得到细化的主要原因。

0〉晶向滑移,即发生所谓的棱锥滑移,从而使镁合金在热挤压时呈现相当好的塑性变形能力,并伴随动态再结晶的发生。这种动态再结晶是通过再结晶核心的形成和长大两个过程进行的:在挤压应力和挤压热的作用下,首先形成亚结构,进而通过亚晶合并机制形成大角度晶界,随后通过大角度晶界的迁移以及亚晶进一步转动和合并,形成细小的等轴晶粒[13]。挤压过程所引发的动态再结晶是喷射成形镁合金组织进一步得到细化的主要原因。

2.3 喷射沉积AZ91镁合金挤压棒材的热处理

固溶时间对合金硬度的影响见图5(a)所示。由图5(a)可看出,在固溶温度一定的情况下,保温2 h后,硬度值迅速降低,延长保温时间硬度值变化不明显,因此选择固溶处理温度为415 ℃,保温时间为2 h。如此迅速的回溶可能是由于β-Mg17Al12相非常细小,且在整个样品中分布均匀,减少了扩散的距离。此外,这些析出物主要是在热挤压完成后空冷过程中过早析出的产物,而不是凝固过程中的初生相,易于回溶。对AZ91合金在175 ℃不同时间进行人工时效后硬度值的变化曲线如图5(b)所示。由图5(b)可看出,随着时效过程的进行,硬度值迅速升高,在时效12 h后达到峰值,之后硬度值缓慢下降。

图5 喷射沉积AZ91合金挤压棒材在不同保温时间下的硬度随固溶时间和时效时间变化

Fig.5 Change of Vicker hardness with solution treatment time (a) and aging time (b) of AZ91 Mg alloy produced by spray forming

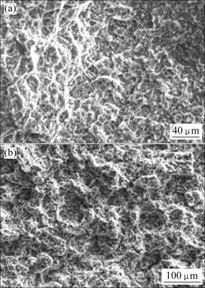

通过扫描电镜观察挤压合金经固溶处理后在175 ℃等温时效不同时间的微观组织演变如图6所示。由图6可以看出,显微组织主要呈现两种不同形态,类似珠光体的片层状组织和沿晶界少量的球状颗粒为典型的不连续析出(即胞状析出),细小弥散分布的短棒状二次相多集中在晶粒内部,为典型的连续性弥散析出。组织观察表明,析出相中超过90%以上为不连续析出,连续析出所占比例很低。后期阶段时效过程加快,长时间时效未见片状及针状析出物球化现象。

图6 喷射成形AZ91镁合金挤压棒材经175 ℃时效的SEM像

Fig.6 SEM images of sprayed and extruded AZ91 Mg alloy aged at 175 ℃: (a) 4 h; (b) 8 h; (c) 12 h; (d) 36 h

图7所示为峰时效析出物的TEM眀场照片和连续析出的衍射花样照片。由图7(a)可以看出,不连续析出是由主干析出和分枝构成的。由图7(b)可以看出,连续析出尺寸小于1 μm,并按照图中箭头方向生长,具有取向关系。由图7(c)衍射花样表明,析出物是按[0001]α//[111]β方向生长的。析出物与基体的位相关系为:(0001)α//(111)β, ,

, 3组界面指数均为

3组界面指数均为 。由于其对称关系,任何一组均可当作惯习面。其析出面为基体棱面,据报道这种β-Mg17Al12相连续析出沿基体棱面析出 方式在常规铸造的AZ91镁合金时效过程中只占析出物的不到10%,而90%第二相易于沿基面析出。但Mg基体中的滑移面是基面(0001),所以,平躺在基面上的板条状的第二相不能很好的阻碍位错的滑移, 而沿棱面析出的第二相尺寸较小,对位错的滑移阻力更大。

。由于其对称关系,任何一组均可当作惯习面。其析出面为基体棱面,据报道这种β-Mg17Al12相连续析出沿基体棱面析出 方式在常规铸造的AZ91镁合金时效过程中只占析出物的不到10%,而90%第二相易于沿基面析出。但Mg基体中的滑移面是基面(0001),所以,平躺在基面上的板条状的第二相不能很好的阻碍位错的滑移, 而沿棱面析出的第二相尺寸较小,对位错的滑移阻力更大。

图7 AZ91镁合金峰值时效样品的TEM像

Fig.7 TEM images of peak-aged sample of AZ91 Mg alloy: (a) Lamellar morphology of discontinuous precipitation (DP) along grain boundary; (b) Needle shaped morphology of continuous precipitation (CP) within grain; (c) [0001]α//[111]β diffraction pattern of needle shaped continuous precipitation

在Mg-9Al合金时效过程中过饱和的α(Mg)固溶体不经“GP”区和过渡相阶段直接析出非共格稳定金属间化合物β-Mg17Al12 相(BCC结构)。时效过程中同时存在两种时效析出机制:即连续析出和非连续析出(胞状析出)机制[14?16]。由于连续析出相多呈细小的片状弥散分布于基体中,使材料具有良好的机械性能。而非连续析出相多呈粗大的层片状,以镁基体的 (0001)基面为惯习面(在3类析出相中占90%以上),其轴线也与基面平行,因此,不能有效地阻挡以基面为滑移面的位错滑移,且析出相板条粗大,间隔太宽,不能起以粒子?位错交互作用为机制的Orowan强化作用,因此,对材料的强化作用较小。因此,Mg-9Al合金的时效强化效果与连续和非连续析出相的比例密切相关。

连续沉淀与非连续沉淀的竞争机制是一个复杂的过程,因为它们的形核和长大速度不同。温度较高时,由于此时过冷度较小,形核驱动力也较小,故以连续沉淀的局部沉淀为主。随着温度的降低,形核驱动力增大,将形成连续的均匀沉淀。若晶内沉淀慢而晶界沉淀快,则晶界和晶内的化学自由焓差将推动界面移动,形成不连续的胞状沉淀。由两种沉淀机制可以知道,Mg-Al合金时效组织中连续析出相及非连续析出相所占比例与温度T、初始晶粒尺寸和初始固溶度c0有关。

通过晶粒细化,大量增加晶界的数量,减小胞状析出的规模,从而改善析出相的形态,或者细化析出相,减少析出相间距,是最直接有效的方法。喷射成形所得微细组织结构极大地细化了晶粒,提高了固溶度,从而为合金在热处理过程中获得最佳的沉淀强化提供了有利条件。

2.4 喷射沉积AZ91镁合金室温拉伸力学性能

表3所列为喷射成形AZ91合金不同状态样品室温拉伸力学性能。喷射成形AZ91 镁合金经挤压变形

表3 喷射沉积AZ91合金挤压和时效处理态样品室温拉伸力学性能

Table 3 Tensile properties of as-extruded billet and as-aged treatment samples at room temperature

和T6处理抗拉强度(σb)和屈服强度(σ0.2)分别达到435和360 MPa,伸长率(A)为9.2%,实现了强度和韧性同步的大幅度提高。这一结果远高于目前其它各种工艺方法(包括快速凝固/粉末冶金技术)制备所得AZ91镁合金的强度韧性水平。喷射成形AZ91镁合金经后续的热挤压变形可获得高致密化高性能的优质材料,其主要的强化机制包括细晶强化、固溶强化和沉淀强化等。喷射成形作为一种先进的材料制备技术,对于传统镁合金材料宏观力学性能的提高和协调晶粒间的变形能力从而改善塑性意义重大[17?18]。

图8所示为喷射沉积AZ91合金挤压棒材和T6处理态室温拉伸样品的断口形貌。由图8可看出,所有样品的宏观断口断裂面与拉伸应力皆成45?角,为典型的剪切断裂方式。从断口形貌的微观断面上看,挤压态合金呈现出明显的撕裂棱与韧窝形貌(见图8(a)),因为经过热挤压的强烈变形,沉积态合金的等轴晶组织被拉长,形成细小的纤维状组织,故断口韧窝尺寸细小,同时穿晶断裂为主要的断裂方式;合金经时效后析出相数量增加,(见图8(b)),由于沿晶界的不连续析出第二相存在,与基体不存在共格或半共格界面,在断裂过程中容易成为裂纹源,在提高强度的同时,给裂纹形核和扩展提供了通道,胞状团可能为裂纹优先产生的地点。

图8 喷射沉积AZ91镁合金挤压棒材室温拉伸试样的断口 形貌

Fig.8 Morphologies of tensile fracture surface of as-sprayed and extruded AZ91 Mg alloy billet: (a) As-extruded; (b) As-aged

3 结论

1) 采用保护气氛中的喷射成形制备技术,制备了形状完整的AZ91镁合金沉积圆柱坯。组织观察表明,喷射沉积AZ91镁合金具有均匀、细小的等轴晶组织,平均晶粒尺寸约17 μm,离异共晶β-Mg17Al12相在晶界的偏析被有效改善,少量细小β-Mg17Al12第二相在基体中呈弥散分布。

2) 挤压变形过程引发动态再结晶使喷射成形AZ91镁合金的组织得到进一步细化,平均晶粒尺寸为3~10 μm,沿晶界处有部分β-Mg17Al12相过早析出,主要是由于挤压完成后空冷过程冷却速度较慢所致。

3) 挤压态合金固溶处理过程在2 h时硬度趋于最低,延长固溶时间硬度变化不大。经175 ℃时效时,喷射成形AZ91挤压态合金T6处理的最高硬度值出现在12 h时。析出相中超过90%以上为不连续析出,连续析出所占比例很低。后期阶段时效过程加快,长时间时效未见片状及针状析出物球化现象。

4) 喷射成形AZ91镁合金经挤压变形和T6处理后的抗拉强度和屈服强度分别达到435 MPa和360 MPa,伸长率为9.2%,实现了强度和韧性同步的大幅度提高。

REFERENCES

[1] MORDIKE B L, EBERT T. Magnesium properties-applications- potential[J]. Mater Sci Eng A, 2001, 302: 37?45.

[2] BAGHNI M, WU Yin-shun, LI Jiu-qing, DU Cui-wei, ZHANG Wei. Mechanical properties and potential applications of magnesium alloys[J]. Trans Nonferrous Met Soc China, 2003, 13(6): 1253?1259.

[3] AGHION E, BRONFIN B. Magnesium alloys development towards the 21st century[J]. Materials Science Forum, 2000, 350/351: 19?23.

[4] MEHTA D S, MASOOD S H, SONG W Q. Investigation of wear properties of magnesium and aluminum alloys for automotive applications[J]. Journal of Materials Processing Technology, 2004, 155/156: 1526?1531.

[5] AGHION E, BRONFIN B, ELIEZER D. The role of the magnesium industry in protecting the environment[J]. Journal of Materials Processing Technology, 2001, 117: 381?385.

[6] AVEDESIAN M M, BAKER H. ASM specialty handbook-magnesium and magnesium alloys[M]. Ohio: ASM International, 1999: 258?263.

[7] ПОРТНИ К И, ЛЕБЕДЕВ А А. 镁合金手册[M]. 林裴, 译. 北京: 冶金工业出版社, 1959.

ПОРТНИ К И, ЛЕБЕДЕВ А А. Handbook of magnesium alloys[M]. LIN Pei, transl. Beijing: Metallurgical Industry Press, 1959.

[8] DAHLE A K, LEE Y C, NAVE M D, SCHAER P L, STJOHN D H. Development of the as-cast microstructure in magnesium- aluminium alloys[J]. Journal of Light Metals, 2001, 1: 61?72.

[9] WANG Y, LIU G, FAN Z. Microstructural evolution of rheo-diecast AZ91D magnesium alloy during heat treatment[J]. Acta Materialia, 2006, 54: 689?699.

[10] ENRIQUE J, LAVERNIA, WU Yue. Spray atomization and deposition[M]. New York: John Wiley and Sons Ltd, 1996.

[11] YU Fu-xiao, CUI Jian-zhong, RANGANATHAN S, DWARAKADASA E S. Fundamental differences between spray forming and other semisolid processes[J]. Mater Sci Eng A, 2001, 304/306: 621?626.

[12] HEHMANN F, SOMMER F, PREDEL B. Extension of solid solubility in magnesium by rapid solidification[J]. Mater Sci Eng A, 1990, 125: 249?253.

[13] MOHRI T, MABUCHI M, NAKAMURA M, ASAHINA T, IWASAKI H, AIZAWA T, HIGASHI K. Microstructure evolution and superplasticity of rolled Mg-9Al-1Zn[J]. Mater Sci Eng A, 2000, 290(1): 139?144.

[14] DULY D, SIMON J P, BRECHET Y. On the competition between continuous and discontinuous precipitations in binary Mg-Al alloys[J]. Acta Metall Mater, 1995, 43(1): 101?106.

[15] FOURNELLE R A, CLARK J B. The genesis of the cellular precipitation reaction[J]. Metall Trans, 1972, 3: 2757?2767.

[16] CELOTTO S, BASTOW T J. Study of precipitation in aged binary Mg-Al and ternary Mg-Al-Zn alloys using 27Al NMR spectroscopy[J]. Acta Materialia, 2001, 49: 41?51.

[17] EBERT T, MOLL F, KAINER K U. Spray forming of magnesium alloys and composites[J]. Powder Metallurgy, 1997, 40: 126?130.

[18] CHEN C Y, TSAO C Y A. Spray forming of AZ91 magnesium alloy with and without Si addition[J]. Materials Science Forum, 2005, 475/479: 2789?2794.

基金项目:国家科技支撑计划资助项目(2006BAE04B01-5)

收稿日期:2008-01-14;修订日期:2009-05-04

通讯作者:张济山,教授,博士;电话:010-62334717;E-mail: zhangjs@skl.ustb.edu.cn

(编辑 李艳红)