文章编号:1004-0609(2009)07-1189-08

喷射成形Mg-9Al-xZn合金的微观组织演变

李永兵1,黄进峰1,崔 华2,蔡元华1,张 奎3,张济山1

(1. 北京科技大学 新金属材料国家重点实验室,北京 100083;

2. 北京科技大学 材料科学与工程学院,北京 100083;

3. 北京有色金属研究总院,北京 100088)

摘 要:利用喷射成形技术制备AZ91、AZ92和AZ93镁合金沉积柱坯,并对其微观组织演变进行观察。结果表明:铸态普通凝固AZ91合金的晶粒粗大,脆性β-Mg17Al12相连续分布成网状结构;而喷射成形AZ91、AZ92和AZ93合金的组织均匀,晶粒被充分细化,β-Mg17Al12相的网状结构被打破;喷射沉积快速凝固条件下高的冷却速率促进了过饱和α-Mg固溶体组织的形成,使得偏析相减少,形态改善;Zn含量的增加降低了Al在Mg中的溶解极限,促进了β-Mg17Al12相在晶界的析出及α-Mg+β-Mg17Al12离异共晶组织的形成;Zn元素的偏析倾向为激活成分过冷区内的形核质点提供了驱动力,从而阻碍了晶粒长大。

关键词:镁合金;喷射成形;微观组织

中图分类号:TG132.1+1 文献标识码:A

Microstructure evolution of spray-formed Mg-9Al-xZn alloys

LI Yong-bing1, HUANG Jin-feng1, CUI Hua2, CAI Yuan-hua1, ZHANG Kui3, ZHANG Ji-shan1

(1. State Key Laboratory for Advanced Metals and Materials, University of Science and Technology Beijing,

Beijing 100083, China;

2. School of Materials Science and Engineering, University of Science and Technology Beijing, Beijing 100083, China;

3. Beijing General Research Institute for Nonferrous Metals, Beijing 100088, China)

Abstract: The billets of AZ91, AZ92 and AZ93 magnesium alloys were synthesized by the spray-forming (SF) processing. The microstructure evolution of the alloys was observed. The microstructure analysis shows that the microstructure of the conventional as-cast AZ91 alloy consists of coarse grains, and the brittle β-Mg17Al12 phases distribute along the grain boundaries continuously to form network. The grains of the as-sprayed AZ91, AZ92 and AZ93 alloy are homogeneous and refined, and the networks of brittle β-Mg17Al12 phases are broken. The rapid solidification process under a higher supercooling condition can remarkably increase the forming of supersaturated microstructure of α-Mg, which results in the absence of macrosegregation and the improvement of precipitated phase shape. The solution limitation of Al in Mg decreases with increasing addition of Zn. The high content of Zn accelerates the precipitation of β-Mg17Al12 phases along the grain boundary and formation of α-Mg+β-Mg17Al12 divorce eutectic structure. The grain growth is limited because the segregation tendentiousness of Zn offers drive force for activation of nucleation sites in the component undercooling area.

Key words: magnesium alloy; spray-forming; microstructure

Mg-Al-Zn 系合金是目前应用最为广泛的镁合金之一,尤其是AZ91合金更是广受关注。

Zn元素在Mg-Al合金中的作用一方面表现为自身的固溶强化,另一方面,由于锌的作用可使Mg-Al-Zn合金的时效过程比Mg-Al合金更显著,时效强化效果更好。传统工艺条件下,Mg-9%Al(质量分数)合金中加入2%Zn后,其不平衡结晶温度间隔增加约 40 ℃,这就加大了合金的缩松倾向,因此常用铸造Mg-Al合金中Zn的含量一般比较低[1?3]。

作为制备高性能优质材料的一种先进技术,喷射成形技术的优点已被诸多文献所报道[4?6]。以合金化为基础,利用喷射成形先进制备技术独特优势,通过在Mg-Al合金中增加Zn 元素的添加量,综合利用Mg-Al、Mg-Zn两大镁合金系列中析出相的强化作用,以期实现在其他合金体系(如铝基、镍基等)中普遍采用的多元固溶、多相析出的综合强化效应[7?8],从而提高传统Mg-Al-Zn 系合金的综合性能,无疑将具有重要的理论意义和应用价值。

本文作者以Mg-9%Al合金为基础合金,在较宽的范围内增加Zn的添加量,采用喷射成形技术制备AZ91、AZ92、AZ93合金沉积坯,研究喷射成形条件下Zn合金化对Mg-9%Al合金微观组织演变的影响,为该系合金的成分优化、合金相控制及力学性能的进一步提高提供理论依据。

1 实验

实验原料选用工业用铸造AZ91镁合金为基础合金,其成分符合GBPT1177—1991“铸造镁合金”的规定。在AZ91合金基础上提高Zn元素的添加量,配制成名义成分为AZ92、AZ93的新牌号合金,具体化学成分如表1所列。

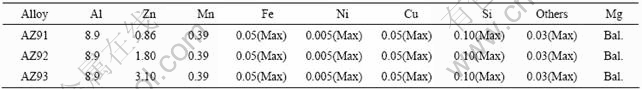

表1 实验用镁合金的化学成分

Table 1 Chemical composition of magnesium alloy selected for study (mass fraction, %)

*: Max is the highest content.

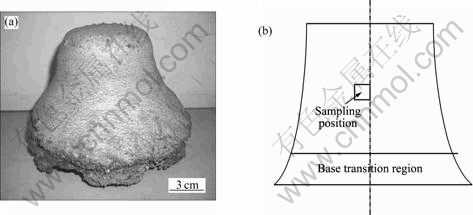

喷射成形AZ91、AZ92、AZ93合金试验在北京科技大学新金属材料国家重点实验室真空感应雾化沉积系统上进行,氩气保护气氛下熔炼,合金熔化经电磁搅拌混合均匀后,静置降温,倾倒至中间包,经导流嘴流出,高压雾化气体雾化,雾化液滴沉积到接受极板形成柱状沉积坯。喷射沉积镁合金的主要工艺参数为:雾化气体为N2,雾化气体压力0.3~0.6 MPa,喷射时熔体温度740~770 ℃,导流管直径3.5 mm,偏心距10 mm,沉积距离400 mm,采用环孔式非限制型雾化喷嘴。沉积坯的实物照片如图1(a)所示,从图1(a)中可以看出,去除底部过渡区,沉积坯主体部分近于圆柱形,表面光洁平整,没有明显的因沉积时液相含量较高而出现的塌陷或起瘤现象,表明雾化沉积时液相含量较适宜。

图1 沉积坯的实物照片及取样部位

Fig.1 Photograph of spray formed magnesium alloy billet(a) and sampling position for microstructure analysis(b)

沉积坯显微组织分析样品取样部位如图1(b)所示。通过X射线衍射仪、leitz2DMIXT 型光学显微镜、Cambridge?S250型扫描电镜(SEM/EDS)、Hitachi800型透射电镜(TEM)等对铸态AZ91合金及沉积态AZ91、AZ92、AZ93合金进行组织观察与分析。金相试样浸蚀剂分别为:4%(体积比)硝酸乙醇溶液(铸态AZ91合金)和5 g苦味酸+10 mL冰醋酸+10 mL蒸馏水+80 mL无水乙醇溶液(沉积态AZ91、AZ92和AZ93合金);采用平均截线法(d=1.74L, d为平均晶粒尺寸,L为截线长度)及Image-Pro Plus软件多视场统计平均晶粒尺寸d。透射电镜用试样从块体材料上用线切割方法截取厚0.5 mm的镁合金片,经机械减薄至0.08~0.10 mm,然后电解双喷减薄,双喷减薄液为5%HClO4+95%CH3OH(体积比),工作温度为?30~ ?50 ℃,工作电压15~20 V。

2 结果

2.1 XRD分析及金相显微组织观察

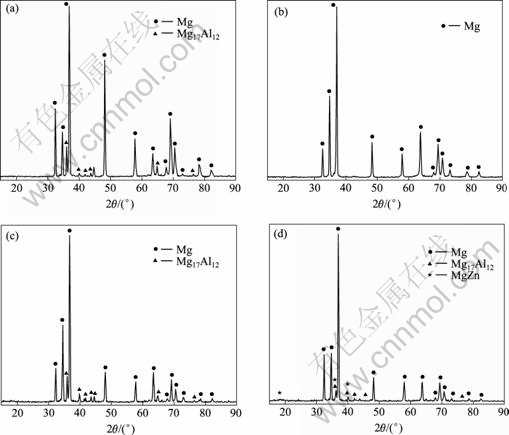

图2所示为铸态AZ91合金和喷射沉积AZ91、AZ92和AZ93合金的XRD谱。由图2可以看出,铸态镁合金是由α-Mg和β-Mg17Al12两相组成,沉积态AZ91合金由单相的α-Mg衍射峰构成,无明显的β-Mg17Al12第二相峰。随着Zn含量的增加,沉积态AZ92和AZ93合金中α-Mg的相对量减少,β-Mg17Al12第二相逐渐增多,AZ93合金中显示有较弱的二元MgZn相峰。

图2 AZ系列镁合金的XRD谱

Fig.2 XRD patterns of each magnesium alloys: (a) As-cast AZ91; (b) As-sprayed AZ91; (c) As-sprayed AZ92; (d) As-sprayed AZ93

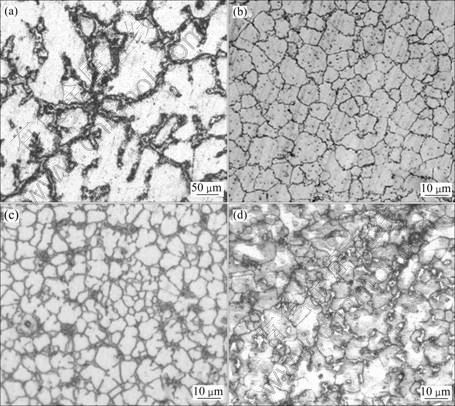

图3所示为铸态AZ91合金和喷射沉积AZ91、AZ92、AZ93合金的金相显微组织。铸态AZ91合金的显微组织(见图3(a))是由α-Mg基体及连续分布的α-Mg+ β-Mg17Al12部分离异共晶组织组成,呈现六次对称枝晶组织形态,晶粒粗大,脆性β-Mg17Al12相连续分布成网状结构,具有Mg-Al系合金典型铸造组织特征,多视场统计表征组织为二次枝晶臂,枝晶臂间距15~25 μm。与铸态合金相比,沉积态合金组织明显细化。沉积态AZ91合金(见图3(b))为典型的等轴晶粒组织,晶粒尺寸细小均匀,平均晶粒尺寸小于20 μm,与铸态AZ91合金相比(见图3(a)),组织明显细化,沿晶界连续分布的粗大离异共晶组织消失。图3(c)和(d)所示分别为沉积态AZ92和AZ93合金的微观组织,随着Zn含量的提高,沿晶界析出相数量逐渐增多。AZ92合金虽然仍是等轴晶组织结构,但细小枝晶组织数量明显增多;沉积态AZ93合金呈现完全离异共晶组织形态,粗化的离异共晶析出相分布在等轴晶粒边界,这种沿晶界形成的共晶化合物的存在将降低合金的韧性,对后续加工造成不利影响。

图3 镁合金的金相组织

Fig.3 Optical micrographs of each magnesium alloys: (a) As-cast AZ91; (b) As-sprayed AZ91; (c) As-sprayed AZ92; (d) As- sprayed AZ93

2.2 析出相结构SEM, EDS及TEM分析

Mg原子半径较大,具有较强的电负性,大多数合金元素在镁合金中的固溶度较低,倾向于与Mg形成化合物,以离异共晶的形式析出,形成沿晶界分布的粗大形态,对合金力学性能产生不利影响[9]。传统Mg-Al-Zn 系合金中,沿晶界分布的数量较多形态粗大的脆性β-Mg17Al12相虽然可使合金硬度有所提高,但却降低了合金的塑韧性,粗大β-Mg17Al12相的存在将产生大的应力集中,使后续变形加工变得困难[10],因而系统研究喷射沉积过程中溶质元素的迁移规律及微观组织的演变机制是非常重要的。

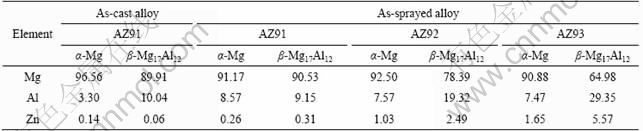

表2所列为铸态AZ91及沉积态AZ91、AZ92和AZ93合金基体和第二相的EDS分析结果,相比铸造合金,沉积态AZ91、AZ92和AZ93合金中Al和Zn元素在α-Mg基体中的固溶度大幅增加。AZ93合金中两个主要的合金化元素Al和Zn有不同程度的析出,Zn元素在第二相中的偏聚增加。但从EDS分析Mg、Al和Zn 3种元素的摩尔比来看,Zn元素的含量明显偏低,不符合三元共晶Ф-Al2Mg5Zn2相或者τ-Mg32-(Al, Zn)49相的成分配比。

表2 铸态及沉积态合金相组成的EDS分析结果

Table 2 EDS energy dispersion analyzing results of phase composition for as-cast and as-sprayed alloys (mole fraction, %)

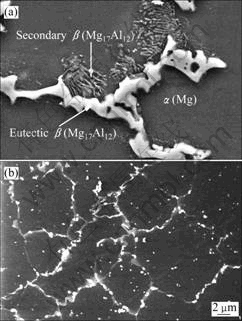

图4所示为铸态、喷射沉积态AZ91合金共晶组织结构的SEM形貌。在图4(a)中,晶界上黑白相混的区域是粗大的α-Mg+β-Mg17Al12部分离异共晶组织,其中白色部分是共晶β-Mg17Al12相,被β-Mg17Al12相包围的黑色部分是α-Mg共晶相,沿晶界灰色层片状析出相为次生β-Mg17Al12相。在图4(b)中,喷射成形AZ91合金中第二相β-Mg17Al12在基体中呈弥散分布,其析出形态有两种:一种是沿晶界的较粗大析出颗粒,约1~2 μm;另一种是晶内的非常细小的析出颗粒。图5所示为喷射沉积AZ91合金的TEM暗场相。由图5可以看出,这种细小析出β-Mg17Al12相为针状,长度为几百纳米。

图4 AZ91合金的SEM形貌

Fig.4 SEM micrographs of AZ91 magnesium alloys: (a) As- cast; (b) As-sprayed

图5 喷射沉积AZ91合金的TEM暗场相

Fig.5 Dark field TEM image of as-sprayed AZ91 alloy

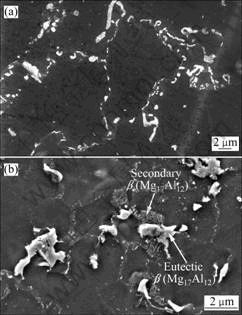

图6所示为喷射沉积AZ92和AZ93合金共晶组织结构的SEM形貌。在AZ91 基础上,AZ92和AZ93合金的Zn 含量增大,总体上看随着Zn含量的增加,β相沿晶界析出数量逐渐增多,尺寸增大。AZ93合金中有大块β-Mg17A112相沿晶界析出,断续分布,从形态上看类似于铸态AZ91合金中的离异共晶组织(见图4(a)),区别在于β-Mg17A112相尺寸、形态与分布得到有效改善。

图6 沉积态合金的SEM形貌

Fig.6 SEM micrographs of as-sprayed magnesium alloys: (a) AZ92; (b) AZ93

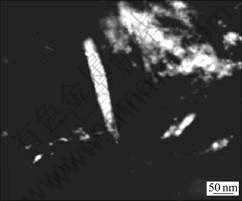

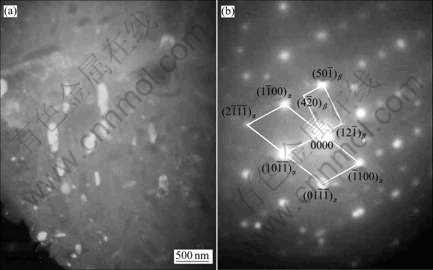

图7所示为喷射沉积AZ92合金的TEM明场像及选区电子衍射谱,基体组织有第二相颗粒析出,其形状有块状、条状以及颗粒状,尺寸在200~500 nm 范围,对析出物进行选区电子衍射分析表明其为β-Mg17Al12相(见图7(b))。

图7 喷射沉积AZ92合金TEM明场像及选区衍射分析

Fig.7 TEM bright image(a) and SAD pattern(b) of as-sprayed AZ92 alloy

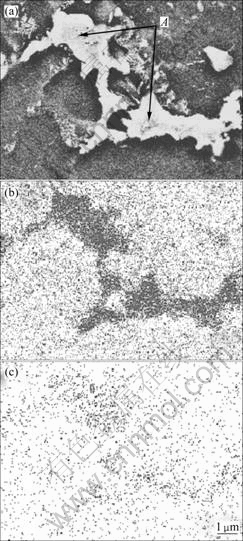

图8所示为喷射沉积AZ93合金的背散射电子像及2种主要合金元素的面扫描分析结果。由图8可以看出,Al 和Zn存在偏析,其中尤以Al 为甚。合金化元素Al与Mg形成的金属间化合物β-Mg17Al12相是择优析出的,故呈现明显的偏聚,主要沿晶粒边界析出,固溶在镁基体中的Al则均匀地分布在镁合金基体中;而Zn则在β-Mg17Al12相中有少量偏聚(图中A处暗灰色区域)。

图8 沉积态AZ93合金的背散射电子像及元素能谱面扫描分析结果

Fig.8 SEI back scattered electron image and EDS spectrums of Al and Zn in as-sprayed AZ93 alloy: (a) SEI back scattered electron image; (b) Profile of Al; (c) Profile of Zn

根据Mg-Al-Zn三元相图,Al与Zn质量比超过3?1的Mg-Al-Zn系合金将形成三元共晶Ф-Al2Mg5Zn2相或τ-Mg32(Al, Zn)49相[1, 11]。从凝固动力学的角度来说,当液相中存在较多的Al和Zn富集,且其成分符合一定的比例,才会出现三元共晶相。传统铸造工艺条件下较低的冷却速率使得Zn很容易在β-Mg17Al12相中富集,使得β-Mg17Al12相的成分向三元相靠近。而在喷射沉积过程的急冷条件下,Zn元素的偏析倾向受到抑制,使得Zn元素较多地固溶到α-Mg中,只是在凝固过程后期阶段,由于Al和Zn溶质原子在Mg中扩散速度较慢,逐渐在固/液界面前沿少量富集,从而有少量Zn在β-Mg17Al12相偏聚,这也是XRD分析中没有出现三元共晶Ф-Al2Mg5Zn2相或τ-Mg32- (Al, Zn)49相峰值的主要原因。

3 分析与讨论

3.1 喷射成形镁合金晶粒细化机理

晶粒细化是改善合金力学性能的重要手段,镁合金的 Hall-Petch 常数因子k值为200~320 MPa·μm1/2,而铝合金的k值仅在68 MPa·μm1/2左右[12],因此,晶粒细化提高镁合金力学性能的潜力要高于铝合金的。

喷射沉积合金原始坯料晶粒尺寸dG决定于凝固过程形核率I 和长大速度vsl,三者的关系为[13]

可见,晶粒大小随形核率的增大而减小,随长大速度的增加而增大。而形核率和长大速度都与有效冷却速率有关,有效冷却速率增加,结晶驱动力大,形核率和长大速度均随之增加,但两者的增加速度不一样,在喷射沉积过程高的过冷度条件下,形核率的增长率会大于长大速度。因此,有效冷却速率越大,比值vsl/I越小,晶粒越细小。

喷射沉积快速凝固条件下高压雾化气流与熔体之间强烈的对流换热使得镁合金凝固时获得较高的冷却速率,晶体的形核与生长模式均发生了较大的变化。Mg-Al-Zn合金L→α-Mg的转变过程中,α-Mg晶体生长速度很快,固?液界面前沿Al、Zn等溶质原子的扩散和迁移在高的过冷度条件下受到阻碍,溶质截留效应显著,Mg-9Al-xZn系列合金原始坯料获得了较为理想的过饱和α-Mg固溶体组织,晶粒被充分细化,β-Mg17Al12相形态、尺寸、数量和分布得到改善,这对于提高合金材料的可加工性能,获得优异的强度与塑韧性的同步提高是十分有利的。

3.2 Zn合金化对Mg-9Al合金显微组织演变的影响机理

Zn含量的增加促进了β-Mg17Al12相在晶界的析出及α-Mg+β-Mg17Al12离异共晶组织的形成。这是由于Zn在Mg中的合金分配系数ki在600 ℃时为0.13,比Al(其在Mg中的分配系数ki在600 ℃时为0.33)更容易在液相中偏析[14]。随着Zn含量的增加,Al在Mg中的溶解极限下降,从而促使Mg-Al-Zn合金共晶组织从部分离异向完全离异转变,这与NAVE等[14]的研究结果相同。

另外,Zn的加入对晶粒细化有一定的效果,但目前对于其作用机理尚缺乏深入的研究。合金凝固过程中,溶质原子的加入可以在凝固前沿固/液界面处形成成分过冷,在成分过冷区内,新的形核核心容易形成,已形成的形核核心不易消失或者激活已有的形核核心,以增大形核率,同时,在成分过冷区内,溶质原子扩散速度的减慢导致晶粒长大速度的减慢,这两个结果都有利于组织细化,这种机制被称为生长限制因子(GRF)机制,GRF越大,固/液界面处的成分过冷越大,晶粒的长大速度越慢,合金液中形成稳定形核核心的能力越强。形核质点的形核能力决定了凝固开始及成分过冷区内有效晶核的数量,溶质元素的作用可以用生长抑制因子GRF来表示[15?16]:

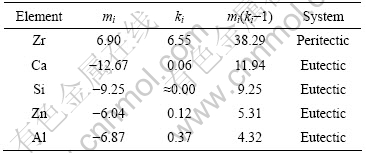

式中:mi为二元相图中液相线斜率;c0, i为溶质元素在合金中的浓度;ki为溶质的分配系数。

表3所列为各种合金元素在Mg中的GRF值[16]。在常用的Mg及其合金的细化元素中,Zr的GRF值最大,已被证实对Mg合金有强烈的细化效果。但是由于Zr与Mg-Al系中的Al、Mn和Si等元素之间会产生反应,因此,只能作为不含Al的Mg-Zn和Mg-RE等合金系的晶粒细化剂。

表3 各种合金元素在镁中的生长限制因子(GRF)值

Table 3 GRF value for various alloying elements in magnesium

Zn在Mg中的生长限制因子(GRF)值高于Al在Mg中的GRF值。由于溶质Zn元素的偏析倾向使得生长晶粒的液固界面前沿产生成分过冷区,为激活成分过冷区内的形核质点提供了驱动力,从而阻碍了晶粒长大。

4 结论

1) 采用保护气氛中的喷射成形技术制备出表面光洁、完整的镁合金沉积坯。喷射成形AZ91、AZ92和AZ93合金的组织均匀,晶粒细小,随着Zn含量的提高,β-Mg17Al12相沿晶界析出数量逐渐增多,呈断续分布。

2) 喷射沉积快速凝固条件下高压雾化气流与熔体之间强烈的对流换热使得镁合金凝固时获得较高的冷却速率,晶体的形核与生长模式均发生了较大的变化,平衡条件下发生的L→α-Mg+β-Mg17Al12共晶反应以及Zn在β-Mg17Al12相的偏析倾向受到抑制,从而得到理想的组织结构。

3) Zn含量的增加,降低了Al在Mg中的溶解极限,促进了β-Mg17Al12相在晶界的析出及α-Mg+ β-Mg17Al12离异共晶组织的形成。Zn元素的偏析倾向使得生长晶粒的液固界面前沿产生成分过冷区,为激活成分过冷区内的形核质点提供了驱动力,从而阻碍了晶粒长大。

REFERENCES

[1] ZHANG Z, ALAIN C, LUO A. An investigation of the properties of Mg-Zn-Al alloys[J]. Scripta Materialia, 1998, 39(1): 45?53.

[2] PENG Cao, MA Qian, StJohn D H. Native grain refinement of magnesium alloys[J]. Scripta Materialia, 2005, 53: 841?844.

[3] MORISHITA M, YAMAMOTO H, SHIKADA S, KUSUMOTO M, MATSUMOTO Y. Thermodynamics of the formation of magnesium-zinc intermetallic compounds in the temperature range from absolute zero to high temperature[J]. Acta Materialia, 2006, 54: 3151?3159.

[4] EBERT T, MOLL F, KAINER K U. Spray forming of magnesium alloys and composites[J]. Powder Metallurgy, 1997, 40: 126?130.

[5] CHEN C Y, CHI Y A T. Spray forming of AZ91 magnesium alloy with and without Si addition[J]. Materials Science Forum, 2005, 475/479: 2789?2794.

[6] YU Fu-xiao, CUI Jian-zhong, RANGANATHAN S, DWARAKADASA E S. Fundamental differences between spray forming and other semisolid processes[J]. Mater Sci Eng A, 2001, 304/306: 621?626.

[7] 张永安, 朱宝宏, 刘红伟, 张智慧, 熊柏青, 石力开. Zn 含量对喷射成形7×××系高强铝合金组织与性能的影响[J]. 中国有色金属学报, 2005, 15(7): 1013?1018.

ZHANG Yong-an, ZHU Bao-hong, LIU Hong-wei, ZHANG Zhi-hui, XIONG Bai-qing, SHI Li-kai. Influence of Zn content on microstructure and properties of spray-formed 7××× series aluminum alloys[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(7): 1013?1018.

[8] 孙剑飞, 沈 军, 贾 均, 李庆春. 喷射成形镍基高温合金的显微组织特征[J]. 中国有色金属学报, 1999, 9(S1): 143?146.

SUN Jian-fei, SHEN Jun, JIA Jun, LI Qing-chun. Microstructural characteristics of a nickel-based superalloy produced by spray forming[J]. The Chinese Journal of Nonferrous Metals, 1999, 9(S1): 143?146.

[9] DAHLE A K, LEE Y C, NAVE M D, SCHAFFER P L, StJohn D H. Development of the as-cast microstructure in magnesium- aluminium alloys[J]. Journal of Light Metals, 2001(1): 61?72.

[10] WANG Y, LIU G, FAN Z. Microstructural evolution of rheo-diecast AZ91D magnesium alloy during heat treatment[J]. Acta Materialia, 2006, 54: 689?699.

[11] ZHANG Z, TREMBLAY R, DUBE D, COUTURE A. Solidification microstructure of ZA102, ZA104 and ZA106 magnesium alloys and its effect on creep deformation[J]. Canadian Metallurgical Quarterly, 2000, 39(4): 503?512.

[12] HAN B Q, DUNAND D C. Microstructure and mechanical properties of magnesium containing high volume fractions of yttria dispersoids[J]. Mater Sci Eng A, 2000, 277: 297?304.

[13] LAVERNIA E J, WU Y. Spray atomization and deposition[M]. New York: John Wiley and Sons Ltd, 1996.

[14] NAVE M D, DAHLE A K, StJohn D H. The role of Zinc in the eutectic solidification of magnesium-aluminium-zinc alloys[C]// KAPLAN H I, HRYN J N, CLOW B. Magnesium Technology 2000. Warrendale, PA: The Minerals, Metals and Materials Society (TMS), 2000: 243?250.

[15] EASTON M, STJOHN D, Grain refinement of Al alloys: PartⅠ. The nucleant and solute paradigms—A review of the literature[J]. Metall Mater Trans A, 1999, 30(6): 1613?1623.

[16] LEE Y C, DAHLE A K, StJohn D H. The role of solute in grain refinement of magnesium[J]. Metall Mater Trans A, 2000, 31: 2895?2906.

基金项目:国家科技支撑计划资助项目(2006BAE04B01-5)

收稿日期:2008-09-20;修订日期:2009-05-04

通讯作者:张济山,教授,博士;电话:010-62334717;E-mail: lybustb@163.com

(编辑 李向群)