热轧工艺对Cu-Cr-Zr合金力学性能和电学性能的影响

吴一凤1,夏承东1, 2,汪明朴1, 3,张婉1,张睿1

(1. 中南大学 材料科学与工程学院,湖南 长沙,410083;

2. 铜陵有色金属集团控股有限公司 有色金属加工研究所,安徽 铜陵,244001;

3. 中南大学 有色金属材料科学与工程教育部重点实验室,湖南 长沙,410083)

摘要:应用热轧在线淬火和随后的形变热处理相结合的工艺制备Cu-Cr-Zr合金板材,通过显微硬度、电导率、金相和TEM测试手段分析合金在加工制备过程中性能和组织的变化。研究结果表明:合适的热轧在线淬火工艺只需一次加热便能完成均匀化和快速热轧-淬火处理,达到在线固溶的目的;经热轧在线淬火工艺处理的合金组织细小、均匀,为后续的冷加工和时效处理提供良好的组织准备;于920 ℃热轧在线淬火能更好地满足实际生产和综合性能的要求。当热轧温度为920 ℃时,热轧在线淬火后的Cu-Cr-Zr合金,经80%冷轧并在450 ℃时效30 min后其硬度和电导率分别可达180和80.1%IACS。

关键词:Cu-Cr-Zr 合金;高强高导合金;热轧;在线淬火

中图分类号:TG146 文献标志码:A 文章编号:1672-7207(2013)03-0930-06

Effect of hot rolling process on mechanical properties and electrical properties of Cu-Cr-Zr alloy

WU Yifeng1, XIA Chengdong1, 2, WANG Mingpu1, 3, ZHANG Wan1, ZHANG Rui1

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Tong ling Nonferrous Metals Group Holdings Co. Ltd., Institute of Nonferrous Metal Processing, Tongling 244001, China;

3. Key Laboratory of Nonferrous Metal Materials Science and Engineering of Ministry of Education, Central South University, Changsha 410083, China)

Abstract: Strips of Cu-Cr-Zr alloy were manufactured by online hot rolling-quenching process and subsequent thermo- mechanical treatments. To optimize the manufacturing process which was suitable for commercial production of the alloy with best combination of strength and conductivity, the properties and microstructure of the alloy were investigated by measurements of hardness and electrical conductivity, and observations of optical microscopy (OM) and transmission electron microscopy (TEM). The results show that online hot rolling-quenching process only needs heating treatment once to finish homogenization and online quenching and achieves on-line solution treatment. Fine microstructure can be obtained in the process of online hot rolling-quenching, and a good microstructure can be provided for subsequent cold working and heat treatment. After online hot rolling-quenching at different rolling temperatures, the variations in hardness and electrical conductivity of Cu-Cr-Zr alloy are studied during aging, and the results show that 920 ℃ is the optimum hot rolling temperature. After online hot rolling-quenching at 920 ℃ and cold rolling with 80% reduction and then aging at 450 ℃ for 30 min, the hardness and electrical conductivity of the alloy reach 180 and 80.1%IACS, respectively.

Key words: Cu-Cr-Zr alloy; high-strength and high-conductivity alloy; hot rolling; on-line quenching

铜合金具有优良的电学性能和力学性能,在诸多行业得到广泛的应用。随着大规模与超大规模集成电路的发展,对铜合金框架材料提出了更高的要求。此类电路采用的框架材料的理想性能指标为:抗拉强度大于600 MPa,电导率大于80%IACS(IACS为国际退火铜标准电导率)[1-3]。在诸多高强高导铜合金中,Cu-Cr-Zr合金是备受青睐的能够满足此要求的合金。Cu-Cr-Zr合金传统的制备工艺是将高温固溶淬火和形变热处理相结合[3-5]。钟建伟等[6]研究的Cu-Cr-Zr合金经固溶淬火和随后的形变热处理后,其抗拉强度和电导率分别可达到527 MPa和82%IACS。然而,这种传统的制备方法需要专门的高标准的固溶设备,且需要将热轧带坯重新加热到固溶温度,大大增加了生产成本,企业难以接受。另外,采用快速凝固和定向凝固等技术[2]也可以提高Cu-Cr-Zr合金的强度和电导率。Liu等[7]采用快速凝固方法制备的Cu-0.3%Cr- 0.24%Zr-0.05%Mg(质量分数,下同)合金,其电导率和强度分别可达88%IACS和460 MPa。但这种方法尚处于实验室研究阶段,距铜合金板带材工业化批量生产还存在很大的差距。Cu-Cr-Zr合金传统的生产工艺对于生产机械零部件来说并不困难,但要大批量生产合金板带材,则因生产周期较长而使其实际应用受限。对于时效强化型铜合金板带材,其加工的核心问题是如何在板带加工生产线上实现合金的固溶和时效处理,从而降低生产成本[3-5]。与传统的固溶工艺相比,热轧在线淬火工艺只需1次加热,便可完成Cu-Cr-Zr合金均匀化、热轧开坯和在线固溶3道工序,从而降低能耗与生产成本[8-10]。本文作者尝试采用高温热轧在线淬火结合形变热处理的工艺来制备Cu-Cr-Zr合金,并研究合金的组织与性能,以便为该系合金制定合理的生产工艺提供依据。

1 实验

用电解铜、纯Cr和Cu-13%Zr中间合金,在中频感应真空熔炼炉中熔炼Cu-0.4%Cr-0.15%Zr合金,熔炼温度为1 300 ℃。熔炼后在铁模中浇注成尺寸为35 mm(宽)×60 mm(厚)×180 mm(高)的扁锭。铸锭除去表面缺陷后,取一部分样品在二辊机上快速热轧(热轧温度为920 ℃)至5 mm,将此部分样品分为6份,分别在800,840,880,920,960和1 000 ℃固溶1 h后淬火;从铸锭上取另一部分样品分成3份,分别在880,920和960 ℃下保温6 h均匀化,然后在二辊机上15 s内(以保证最终热轧温度不低于800 ℃)快速热轧至5 mm,热轧后立即在室温水中淬火冷却。将这2部分经过不同处理的合金试样分别在四辊机上进行冷轧,变形量为80%,冷轧后2部分样品都在盐浴炉中等温时效,时效温度为450 ℃[11]。研究结果表明:Cu-Cr-Zr合金在450 ℃时效后综合性能较好,时效时间为1,2.5,5,10,15,30,60,120,240,360,480,720,960,1 080,1 200和1 800 min,盐浴炉控温精度为±2 ℃。时效后测定合金硬度和电导率随时效时间的变化规律。

在MODEL HV-5型小负荷维氏硬度机上测定合金硬度,载荷为20 N,加载时间为15 s。在QJ19型单双臂两用电桥上测量合金的电阻,并根据样品尺寸(长×宽×高为3 mm×0.7 mm×120 mm)转换为电导率。金相样品用FeCl3盐酸水溶液腐蚀,然后,在LEICA EC3型金相显微镜上进行组织观察。在JEOL 2100F透射电镜上进行TEM显微组织观察,操作电压为200 kV。

2 实验结果

2.1 固溶处理和在线热轧淬火后合金的硬度和电导率

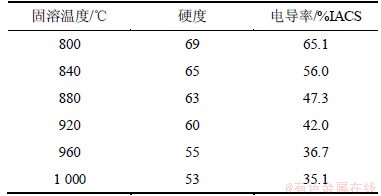

表1所示为不同固溶温度下,Cu-Cr-Zr合金固溶(1 h)淬火后的硬度和电导率。由表1可见:随着固溶温度的升高,合金硬度和电导率均下降;当固溶温度为880 ℃时,合金的硬度和电导率分别为63和47.3%IACS;当固溶温度为960 ℃时,合金的硬度和电导率分别下降到55和36.7%IACS。进一步升高固溶温度到1 000 ℃,合金的电导率变化微小,较960 ℃时减少量仅为1.6%IACS,这表明固溶温度为960 ℃时,溶质原子在基体中已溶解的相当充分。

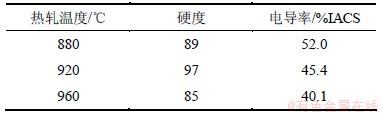

表2所示为在不同热轧温度下,Cu-Cr-Zr合金经快速热轧并立即淬火后的硬度和电导率。由表2可见:热轧温度为880,920和960 ℃时合金的硬度分别为89,97和85,表明合金的硬度是先随着热轧温度的升高而增大,在920 ℃达到峰值后,合金的硬度开始随着热轧温度的升高而降低;电导率的变化趋势与固溶处理时的相同,即热轧温度越高,电导率越低。

表1 Cu-Cr-Zr合金在不同温度下固溶1 h后的电导率和硬度

Table 1 Hardness and conductivity of Cu-Cr-Zr Samples solution treated at different temperatures

表2 Cu-Cr-Zr合金的不同温度热轧后的电导率和硬度

Table 2 Hardness and conductivity of Cu-Cr-Zr Samples hot rolled from different temperatures

比较表1与表2可见:固溶温度和热轧温度相同时,经固溶处理和热轧在线淬火处理的合金的硬度,后者明显大于前者,例如,920 ℃下经固溶处理和热轧在线淬火的合金的硬度分别为60和97。但是,在同一温度下,2种不同的处理工艺对合金的电导率影响不大,经热轧淬火后的试样的电导率只是略高于相同温度固溶态的电导率。

2.2 不同温度热轧淬火工艺对合金时效性能的影响

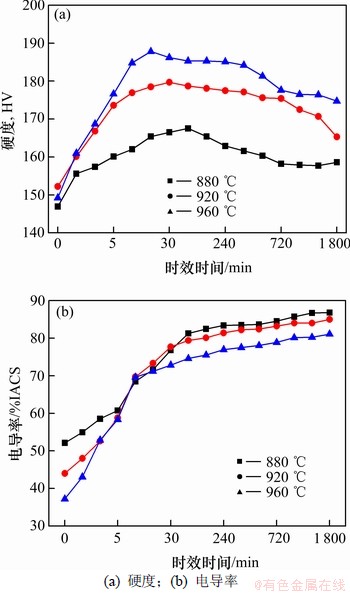

图1所示为合金经热轧在线淬火后于450 ℃时效时硬度和电导率的变化曲线。由图1(a)可见:于880 ℃热轧的合金时效硬度峰值为168,920 ℃热轧的合金时效硬度峰值为180,而960 ℃热轧的合金时效硬度峰值可达188。这表明随着热轧温度的升高,合金时效峰值硬度逐渐升高,同时到达峰值所需时间也逐渐减少。电导率的变化和硬度变化正好相反,热轧在线淬火温度越高,峰时效所获得的电导率就越低,如图1(b)所示。此外,由图1分析可知:450 ℃下时效6 h,880,920和960 ℃热轧在线淬火的试样其硬度增量分别为15,25和35,电导率增量分别为31.4%IACS,38.2%IACS和40.3%IACS。这一结果表明热轧温度越高,合金的时效效果越明显,硬度和电导率提升幅度也越大。

由图1还可看出:时效时间对硬度和电导率有不同的影响。由图1(a)可见:在时效初期,硬度随着时效时间的延长不断增加,达到峰值后开始缓慢下降;而合金的电导率却随着时效时间的延长不断上升,时效时间低于1 h时升高迅速,1 h后,随着时效时间的延长,电导率趋于稳定。

2.3 Cu-Cr-Zr合金热轧和冷轧态的显微组织

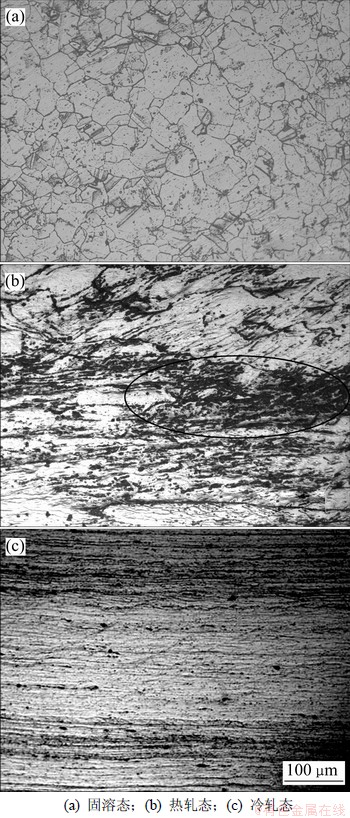

图2所示为Cu-Cr-Zr合金在不同处理条件下的金相组织。其中:图2(a)所示为热轧态合金经920 ℃固溶淬火处理后的金相组织;图2(b)所示为Cu-Cr-Zr合金经920 ℃热轧淬火后的金相组织。由图2(a)可见:固溶淬火后合金内部形成的是粗大的等轴状再结晶晶粒,并伴随有少量退火孪晶。由图2(b)可见:与经920 ℃固溶处理态相比,经此工艺处理的合金产生了较细小的动态再结晶晶粒,如图2(b)中椭圆标记的部分,合金其余部分为加工态组织,晶粒沿轧制方向被拉长。经热轧淬火后的合金,在随后的冷轧变形中晶粒都沿轧制方向拉长,使合金中晶粒形貌多呈现纤维态,如图2(c)所示。

图1 热轧温度对Cu-Cr-Zr合金450 ℃时效性能的影响

Fig.1 Effect of hot rolling temperature on Cu-Cr-Zr alloy aged at 450 ℃

2.4 Cu-Cr-Zr合金的TEM组织

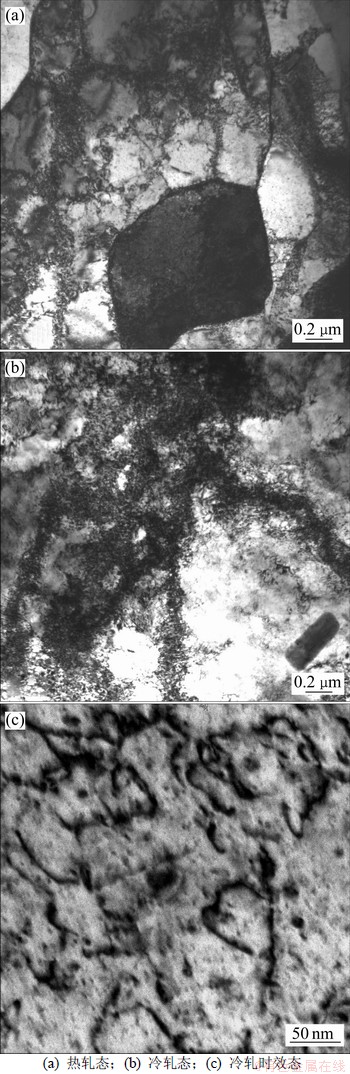

图3(a)所示为Cu-Cr-Zr合金经920 ℃热轧淬火后的TEM显微组织。由图3(a)可见:热轧淬火后合金组织具有变形态与高温回复的双重特征。拉长的晶粒内部为大小不一的位错胞,直径为0.3~0.6 μm,胞壁较为明晰,胞内位错不多,这是热轧时动态回复的结果。随后的冷轧变形大大增加了胞内的位错密度,且位错分布不均匀,胞内位错缠结增多,胞壁变厚,如图3(b)所示。图3(c)所示为合金经时效后的TEM组织。由图3(c)可见:时效后合金内部发生明显的回复,位错不再相互缠结,而是分散地分布在合金内部,部分析出物在位错上不均匀析出。

图2 Cu-Cr-Zr合金在不同状态下的金相组织形貌

Fig.2 Optical microstructures of Cu-Cr-Zr alloy under different conditions

3 分析与讨论

3.1 热轧在线淬火工艺优化合金综合性能的机理

本实验中采用的热轧工艺轧制温度高,轧制速度快,不仅增加了Cr和Zr在Cu中的固溶量,同时也减少了热轧过程中因温度降低而析出的溶质原子数量,所以,热轧后立即淬火可达到在线固溶的目的,这使得Cu-Cr-Zr合金在后续的等温时效过程中显示出强烈的时效硬化反应。此外,变形量较大的热轧可以破碎粗大的铸态晶粒,使其内部形成大量的位错缠结与位错胞组织,通过进一步的动态回复与动态再结晶,这种变形组织又演变为胞壁更窄的位错胞、亚晶以及动态再结晶晶粒组织。这些变形组织通过热轧后的快速淬火保留了下来,一方面细化了合金的亚结构,进而产生类似于细晶强化的亚结构强化;另外,通过动态回复形成的显微组织缺陷密度低,所以,在随后的热处理过程中因储能较低而不易发生再结晶[12-14]。可见:热轧在线淬火工艺可获得细小和均匀的显微组织,为合金后续的冷加工和热处理提供了良好的组织准备。

图3 不同处理状态下的Cu-Cr-Zr合金的TEM图像

Fig.3 TEM images of Cu-Cr-Zr alloy under different conditions

3.2 不同固溶温度、热轧温度和时效时间对合金硬度和电导率的影响

在传统的Cu-Cr-Zr合金的制备工艺中,合金经热轧后立即进行固溶淬火处理,固溶温度越低,合金内部剩余的未溶物就越多。这些未溶物多分布在晶界,可稳定晶界,阻碍晶粒长大,进而使得合金晶粒越细小,合金的硬度便越大[15-16];相反,固溶温度越高,合金的再结晶晶粒越大,合金的硬度则越小,故固溶态合金的硬度随着固溶温度的降低而上升。然而,在Cu-Cr-Zr合金的热轧在线淬火制备工艺中,合金的硬度随着热轧温度的升高先增加,达到一定值后开始下降。这是由于合金热轧时温度会有一定程度的下降,因此,热轧时会有析出物的生成,热轧温度越高,溶入到基体中的溶质原子分数越大,生成的析出物的动力越大,析出量便越多,这会导致合金硬度升高;此外,热轧温度越高,溶质原子在基体中的最终溶解度越大,产生的固溶强化作用越强烈。上述2种原因都导致合金硬度随着热轧温度的升高而增大。但是,在热轧过程中,会发生动态回复和再结晶,热轧温度过高,动态回复和再结晶的程度较大,由此导致的合金软化严重,故合金的硬度到达一峰值后,由于回复再结晶导致的软化作用大于析出强化和固溶强化的硬化作用,又开始下降[16]。固溶温度与热轧温度相同时,由于热轧变形不仅破碎了合金中的晶粒,还形成了大量位错胞、亚晶和亚结构[12-14, 16],使合金的硬度增大;此外,由于固溶淬火降温很快,来不及形成弥散细小的析出相。这2种原因都使得经固溶处理后的试样硬度明显小于热轧在线淬火后的试样硬度。

合金的电导率主要取决于基体的电导率,溶入到基体中的固溶原子对电子的散射作用是影响合金基体电导率的主要因素[17]。合金内位错等变形组织对电导率的影响远小于溶质原子的作用,故变形对合金的电导率影响不大[11],2种处理工艺中合金的电导率变化趋势大体是一致的。由于固溶温度和热轧温度越高,溶质原子在基体中的溶解度越大,溶质原子对电子的散射作用越强烈,合金的电导率便越小。但是,Cu-Cr-Zr合金在高温热轧过程中,热轧温度会迅速下降,伴随而来的是溶质原子的部分析出,从而导致热轧淬火态合金的过饱和度低于相同温度下固溶处理的合金的过饱和度[16, 11],故固溶温度与热轧温度相同时,经热轧淬火后的试样的电导率略大于相同温度固溶态的电导率;但是,在此情况下,2种不同处理工艺下合金的电导率相差仅约3%IACS(如表1和2所示),表明热轧在线淬火过程中并未造成溶质原子的大量析 出[11]。由图2(b)可见:在一定的热轧温度和时效温度下,合金的电导率随着时效时间的延长而上升,但上升的速率越来越小,最终趋于平缓。这是由于等温时效过程是时效硬化析出过程,随着时效时间的延长,固溶原子在基体中的原子数分数越小,对合金中电子的散射作用越小,电导率则越大。但随着时效时间的延长,固溶原子在基体中的原子数分数越小,析出动力越来越小,最终电导率上升的速率趋于平缓。随着时效时间的延长,合金内部的析出物会聚集长大,合金的变形组织逐渐发生回复,位错缠结分解,但是,这些都没改变固溶原子在基体的溶解量对合金电导率的影响规律,可见合金内的变形组织和析出相的分布对电导率的影响非常小。

3.3 热轧温度对时效后合金的硬度和电导率的影响

对于成分相同的Cu-Cr-Zr合金,热轧温度越低,变形抗力越大,塑性越差,热轧变形越困难;热轧温度越高,热轧淬火后获得的过饱和度越高,时效过程中析出的第二相粒子越多,合金的时效硬度峰值便越高。但热轧温度过高时,溶入到基体中的溶质原子分数越大,时效析出时不能完全析出,导致合金的电导率偏低[12]。故热轧生产工艺中,热轧温度的选择尤为重要。Cu-Cr-Zr合金在实际应用中希望得到硬度和电导率的良好匹配。例如,热轧温度为960 ℃时,合金时效15 min后便达到硬度峰值188,电导率却偏低。此外,较高的热轧温度易导致过快的时效析出速率,在实际生产过程中不易控制,不但容易发生过时效,而且峰时效时间太短也可导致合金的性能不均匀[11, 18-19]。过高的热轧温度导致生产线设备损耗大,能耗也高。综合考虑本实验结果中合金硬度和电导率的变化规律及材料的实际生产要求与条件,采用920 ℃热轧在线淬火能更好地满足实际生产的要求,结合后续的形变热处理,可以制备出综合性能良好的Cu-Cr-Zr合金板带材。

4 结论

(1) Cu-Cr-Zr合金热轧在线淬火工艺达到了在线固溶的目的,缩短工艺流程,使生产工艺变得连续,可用于Cu-Cr-Zr合金板带的生产。

(2) 热轧在线淬火获得了细小均匀的再结晶晶粒和位错胞组织,为后续的形变热处理做好组织准备。

(3) 920 ℃可作为Cu-Cr-Zr合金合适的热轧在线淬火温度。经920 ℃热轧淬火结合后续的冷轧和时效处理后,合金可获得良好的综合性能,其硬度和电导率分别可达180和80.1%IACS。

参考文献:

[1] ZHU Dachuan, SONG Mingzhao, CHEN Jiazhao. Electrical conductivity of Cu-Li alloys[J]. Journal of Central South University of Technology: English Edition, 2004, 11(3): 252-254.

[2] 尹志民, 张生龙. 高强高导铜合金研究热点及发展趋势[J]. 矿冶工程, 2002, 22(2): 1-9.

YIN Zhimin, ZHANG Shenglong. Hot spots and developing tendency on high-strength and high-conductivity copper alloys[J]. Mining and Metallurgical Engineering, 2002, 22(2): 1-9.

[3] 刘平. 高性能铜合金的热处理及其加工技术[J]. 金属热处理, 2005, 30(Z1): 1-7.

LIU Ping. Heat treatment and machining technique of copper alloy with high property[J]. Heat Treatment of Metals, 2005, 30(Z1): 1-7.

[4] 周倩, 李雷, 李强, 等. 新型高强高导接触导线用Cu-Cr-Zr系合金研究进展[J]. 有色金属加工, 2008, 37(6): 4-8.

ZHOU Qian, LI Lei, LI Qiang, et al. Review on the new Cu-Cr-Zr alloy for high-strength and high-conductivity wire[J]. Nonferrous Metals Processing, 2008, 37(6): 4-8.

[5] 方善峰, 汪明朴, 程建奕, 等. 高强高导Cu-Cr-Zr系合金材料的研究进展[J]. 材料导报, 2009, 17(9): 21-24.

FANG Shanfeng, WANG Mingpu, CHEN Jianyi, et al. Recent developments in high strength and high conductivity Cu-Cr-Zr alloys[J]. Materials Review, 2009, 17(9): 21-24.

[6] 钟建伟, 周海涛, 赵仲恺, 等. 形变热处理对Cu-Cr-Zr合金时效组织和性能的影响[J]. 中国有色金属学报, 2008, 18(6): 1032-1038.

ZHONG Jianwei, ZHOU Haitao, ZHAO Zhongkai, et al. Effects of thermo-mechanical heat treatment processing on microstructure and properties of Cu-Cr-Zr alloy[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(6): 1032-1038.

[7] LIU Ping, KANG Buxi, CAO Xingguo, et al. Aging precipitation and recrystallization of rapidly solidified Cu-Cr-Zr- Mg alloy[J]. Materials Science and Engineering, 1999, 265(1/2): 262-267.

[8] 李华清, 汤玉琼, 汪明朴. 热轧生产工艺对C70250合金力学性能和导电性能的影响[J]. 中国有色金属学报, 2010, 20(1): 62-66.

LI Huaqing, TANG Yuqiong, WANG Mingpu. Effects of hot rolling process on mechanical and electrical properties of C70250 alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(1): 62-66.

[9] XIA Chengdong, ZHANG Wan, KANG Zhanyuan, et al. High strength and high electrical conductivity Cu-Cr system alloys manufactured by hot rolling-quenching process and thermo- mechanical treatment[J]. Material Science and Engineering A, 2012, 538: 295-301.

[10] 林亮华, 刘志义, 韩向楠, 等. 大变形量Al-Zn-Mg-Cu合金的热轧板再结晶行为[J]. 中南大学学报: 自然科学版, 2011, 42(10): 2990-2995.

LIN Lianghua, LIU Zhiyi, HAN Xiangnan, et al. Recrystallization behavior of hot-rolled Al-Zn-Mg-Cu alloy after great deformation[J]. Journal of Central South University: Science and Technology, 2011, 42(10): 2990-2995.

[11] 周明哲, 易丹青, 王斌, 等. 固溶处理对2E12铝合金组织及疲劳断裂行为的影响[J]. 中南大学学报: 自然科学版, 2012, 43(1): 67-73.

ZHOU Mingzhe, YI Danqing, WANG Bin, et al. Effect of solution treatment on fatigue behavior of 2E12 aluminum alloy[J]. Journal of Central South University: Science and Technology, 2012, 43(1): 67-73.

[12] LIU Ping, SU Juanhua, DONG Qiming, et al. Optimization of aging treatment in lead frame copper alloy by intelligent technique[J]. Materials Letters, 2005, 59(26): 3337-3342.

[13] Panigrahi S K, Jayaganthan R. Effect of annealing on thermal stability, precipitate evolution, and mechanical properties of cryorolled Al 7075 alloy[J]. Metallurgical and Materials Transactions A, 2011, 42(10): 3208-3217.

[14] Habibi A, Ketabchi M. Enhanced properties of nano-grained pure copper by equal channel angular rolling and post-annealing[J]. Materials and Design, 2011, 34: 483-487.

[15] 向朝建, 郭富安, 杨春秀, 等. C194合金热轧工艺及其对性能影响[J]. 稀有金属材料与工程, 2009, 38(A01): 239-243.

XIANG Chaojian, GUO Fuan, YANG Chunxiu, et al. Hot rolling process and its influence on the mechanical properties of C194 alloy[J]. Rare Metal Materials and Engineering, 2009, 38(A01): 239-243.

[16] 贾淑果, 刘平, 宋克兴, 等. Cu-Cr-Zr 原位复合材料的组织与性能[J]. 中国有色金属学报, 2010, 20(7): 1134-1138.

JIA Shuguo, LIU Ping, SONG Kexing, et al. Microstructures and properties of Cu-Cr-Zr in-situ composites[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(7): 1134-1138.

[17] 夏承东, 汪明朴, 徐根应, 等. 形变热处理对低浓度CuCr合金性能的影响[J]. 功能材料, 2011, 5(32): 872-876.

XIA Chengdong, WANG Mingpu, XU Genying, et al. Effect of thermo-mechanical treatment on properties of dilute CuCr alloys[J]. Functional Materials, 2011, 5(32): 872-876.

[18] Suzuki H, Kanno M, Kitano H. High-temperature embrittleness of Cu-Cr alloy[J]. Journal of the Japan Institute of Metals, 1970, 34(5): 497-501.

[19] Murayama M, Belyakov A, Hara T, et al. Development of a high-strength high-conductivity Cu-Ni-P alloy[J]. Journal of Electronic Materials, 2006, 35(10): 1787-1792.

(编辑 何运斌)

收稿日期:2012-03-29;修回日期:2012-09-07

基金项目:安徽省科技攻关计划项目(08010201026)

通信作者:汪明朴(1952-),男,安徽安庆人,教授,从事高性能有色金属制备及性能研究;电话:0731-88830264;E-mail: wangmp@csu.edu.cn