DOI: 10.11817/j.ysxb.1004.0609.2020-35813

Cu-Cr-Zr合金的高温热变形行为

丁宗业1,贾淑果1, 2, 3,宁向梅1, 2,刘 平1,赵培峰1, 2,宋克兴1, 2

(1. 河南科技大学 材料科学与工程学院,洛阳 471023;

2. 河南科技大学 河南省有色金属共性技术河南省协同创新中心,洛阳 471023;

3. 河南科技大学 河南省有色金属材料科学与加工技术重点实验室,洛阳 471023)

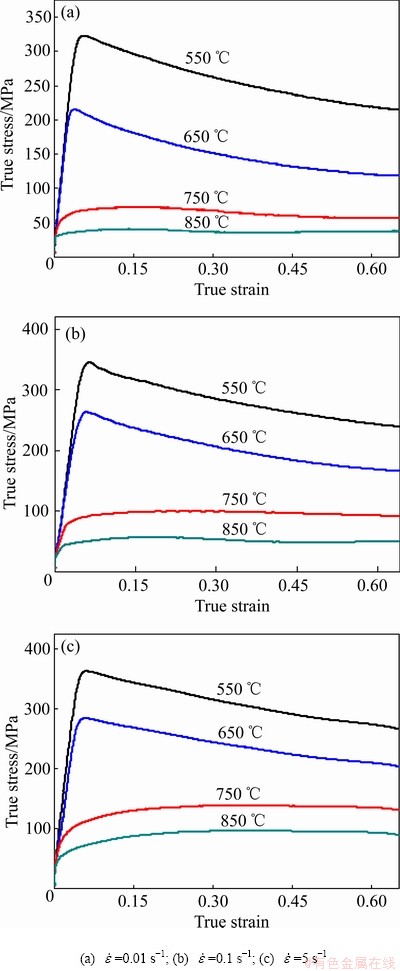

摘 要:利用Gleeble-1500型热模拟试验机对Cu-0.6Cr-0.03Zr合金进行高温热压缩变形,研究了合金在550~ 750 ℃变形温度、0.01~5 s-1应变速率条件下的热压缩变形行为,建立Cu-0.6Cr-0.03Zr合金的热变形本构方程及热加工图。结果表明:Cu-0.6Cr-0.03Zr合金的流变应力随变形温度的升高而减小,随应变速率的增大而增大;Cu-0.6Cr-0.03Zr合金的流变行为可用包含Zener-Hollomon参数的Arrhenius双曲正弦模型来描述,合金的热变形激活能为572.05 kJ/mol;Cu-0.6Cr-0.03Zr合金在高温热压缩变形时存在3个安全加工区,合金最佳热变形参数为变形温度770~800 ℃、应变速率0.01~0.05 s-1、功率耗散效率因子32%~40%。

关键词:Cu-Cr-Zr合金;热变形行为;本构方程;热加工图

文章编号:1004-0609(2020)-08-1811-07 中图分类号:TG146.1 文献标志码:A

Cu-Cr-Zr时效析出强化型合金具有优良的导电导热性、良好的抗腐蚀性、较高的强度及疲劳强度,因此被广泛应用于集成电路引线框架、连铸机结晶器内衬、电力机车架空导线等领域[1-5]。目前,关于Cu-Cr-Zr合金的研究主要集中在合金元素对时效性能与组织影响、合金熔炼技术等方面,关于该合金热变形行为的相对较少。然而,金属在热加工过程中,热变形温度和应变速率直接影响金属加工硬化和动态软化过程,通过流变应力的变化可表征金属在热加工过程中的塑性变形行为[6-10]。因此,开展Cu-Cr-Zr合金热变形过程中流变应力的演变可为该合金的热加工流程提供重要的理论指导。 基于动态材料模型的热加工图是材料流变失稳图和功率耗散图的叠加,可用来描述材料加工失稳区和安全加工区,优化材料的热加工工艺。动态材料模型认为热加工材料是非线性功率耗散体,材料在热加工过程中单位时间体积内所吸收的功率P转换成塑性变形所消耗的功率G和组织变化所消耗的功率J两部分,其关系可用式(1)来描述 [11]:

(1)

(1)

式中:m为应变速率敏感因子。当热变形材料处于理想线性耗散状态时,m=1,J达到最大(Jmax= )。

)。

功率耗散效率因子η反映材料功率耗散特征,可用应变速率敏感因子(m)表示[12]:

(2)

(2)

功率耗散效率因子η随应变量、变形温度和应变速率的变化而改变,依据其相互关系可得到功率耗散图。若构建材料热加工图,还需建立材料的热变形加工流变失稳图。根据不可逆热力学极值原理,PRASAD等[13]推导出材料塑性变形时连续失稳判据,可用无量纲参数 来表示:

来表示:

<0 (3)

<0 (3)

根据流变失稳参数 、变形温度和应变速率的关系可绘制材料流变失稳图,其中阴影区为流变失稳区。将功率耗散图与流变失稳区叠加得到材料热加工图,通过图中变形参数可描述材料的流变行为,为热加工工艺参数选择提供理论依据。本文作者对Cu-0.6Cr-0.03Zr合金进行热压缩变形,研究该合金的流变行为,计算合金热变形激活能,建立热变形本构方程和加工图,为热加工工艺的优化提供理论依据。

、变形温度和应变速率的关系可绘制材料流变失稳图,其中阴影区为流变失稳区。将功率耗散图与流变失稳区叠加得到材料热加工图,通过图中变形参数可描述材料的流变行为,为热加工工艺参数选择提供理论依据。本文作者对Cu-0.6Cr-0.03Zr合金进行热压缩变形,研究该合金的流变行为,计算合金热变形激活能,建立热变形本构方程和加工图,为热加工工艺的优化提供理论依据。

1 实验

实验材料为Cu-0.6Cr-0.03Zr(质量分数,%)合金。采用纯铜、纯铬和海绵锆为原料,真空熔炼、浇铸成型。对铸锭进行固溶(920 ℃,1 h)和时效(450 ℃,4 h)处理,然后加工出尺寸为d 10 mm×12 mm的热压缩试样。 在Gleeble-1500型热模拟机上进行热压缩试验,变形温度分别为550、650、750、850 ℃,应变速率分别为0.01、0.1、1、5 s-1,试样压缩量为60%;试样以10 ℃/s的速度加热至850 ℃,保温5 min,然后以5 ℃/s的速度冷却至设定的变形温度(550、650和750 ℃)。变形结束后立即对试样进行水淬以保留热变形组织。采用OLYMPUSPMG3型金相显微镜进行变形组织观察。

2 结果与分析

2.1 合金的真应力-应变曲线

图1所示为Cu-0.6Cr-0.03Zr合金在不同变形温度、不同应变速率下的真应力-真应变曲线。 HAMEDA等[8]对时效析出强化型铜合金在较低温度下的热变形行为进行研究,认为剪切带处的析出相动态粗化软化机制对流变应力的降低起主导作用。从图1可看出,在变形温度为550 ℃和650 ℃时,合金的流变应力随应变量的增加而迅速升高至最高值,随后逐渐减小,这是加工硬化、动态回复与析出相动态粗化相互作用的结果。随应变量增加,位错密度增加,流变应力急剧增加;当流变应力达到峰值时,析出相颗粒粗化,产生局部软化区,使合金的流变应力递减。在变形温度为750 ℃ 和850 ℃时,流变应力随应变量的增加而升高至最高值,随后逐渐下降至稳态值,这是加工硬化与动态再结晶共同作用的结果。当应变速率一定时,流变应力随变形温度降低而增大;当变形温度一定时,流变应力随应变速率降低而减小。

图1 合金在不同应变速率下的真应力-真应变曲线

Fig. 1 True stress-true strain curves at various strain rates

2.2 本构方程

材料在热变形过程中,流变应力σ主要取决于应变速率 和变形温度T,可用SELLARS等[14]提出的双曲正弦方程描述:

和变形温度T,可用SELLARS等[14]提出的双曲正弦方程描述:

(

( <0.8) (4)

<0.8) (4)

(

( >1.2) (5)

>1.2) (5)

(6)

(6)

式中: 、

、 、n、A为常数,与材料有关且主要取决于材料的化学组成;

、n、A为常数,与材料有关且主要取决于材料的化学组成; 为应力水平参数(mm-2·N-1);A为结构因子(s-1);n为应力指数;Q为热变形激活能;T为绝对温度;

为应力水平参数(mm-2·N-1);A为结构因子(s-1);n为应力指数;Q为热变形激活能;T为绝对温度; 为应变速率;R为摩尔气体常数。式(4)适用于低应力水平,式(5)适用于高应力水平。对式(4)、式(5)和式(6)两端求导分别得到式(7)、式(8)和式(9),依据不同应变速率下的峰值应力,可绘制

为应变速率;R为摩尔气体常数。式(4)适用于低应力水平,式(5)适用于高应力水平。对式(4)、式(5)和式(6)两端求导分别得到式(7)、式(8)和式(9),依据不同应变速率下的峰值应力,可绘制 –

– 、

、 –

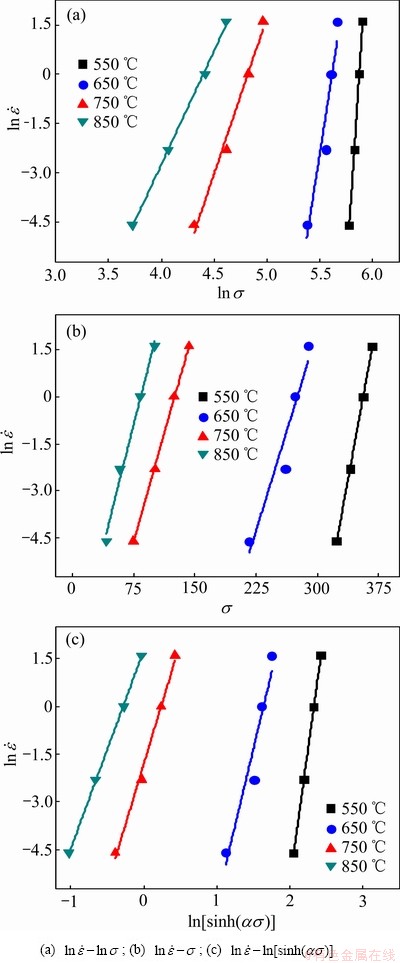

– 曲线,如图2(a)和(b)所示。

曲线,如图2(a)和(b)所示。

图2 Cu-0.6Cr-0.03Zr合金峰值应力与应变速率的关系

Fig. 2 Relationship between flow stress and strain rate

(7)

(7)

(8)

(8)

(9)

(9)

n为 –

– 曲线斜率的平均值,β为

曲线斜率的平均值,β为 –

– 曲线斜率的平均值,采用最最小二乘法线性回归可得到n和β的值,由

曲线斜率的平均值,采用最最小二乘法线性回归可得到n和β的值,由 可得

可得 =0.0085,将

=0.0085,将 代入式(8)可得到

代入式(8)可得到 –

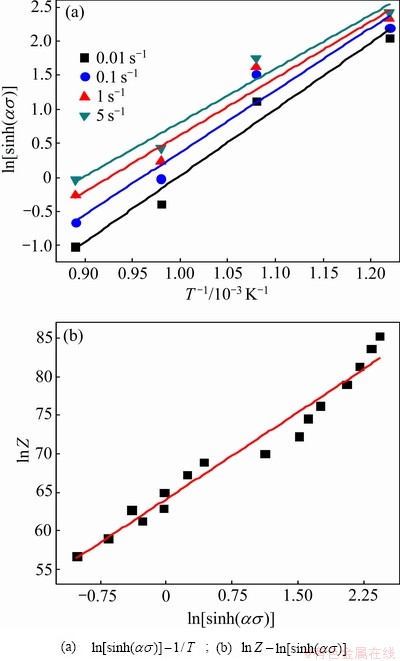

– 曲线如图2(c)所示。对式(6)求偏导得到式(10),可绘制出

曲线如图2(c)所示。对式(6)求偏导得到式(10),可绘制出 –1/T曲线,如图3(a)所示。设S为曲线

–1/T曲线,如图3(a)所示。设S为曲线 –1/T斜率的平均值,n为曲线

–1/T斜率的平均值,n为曲线 –

– 斜率的平均值,可求得S=8.783、n=7.834,由式(10)可得Q=RnS=572.05 kJ/mol。

斜率的平均值,可求得S=8.783、n=7.834,由式(10)可得Q=RnS=572.05 kJ/mol。

(10)

(10)

ZENER等[15]提出用应变速率因子Zener- Hollomon参数Z描述热变形条件:

(11)

(11)

(12)

(12)

对式(11)两端求导可得到式(12),利用应变速率 与变形温度T值,得到对应

与变形温度T值,得到对应 值,可绘制

值,可绘制 –

– 曲线,如图3(b)所示,其斜率的自然对数即

曲线,如图3(b)所示,其斜率的自然对数即 为48.37676。

为48.37676。

图3 峰值应力、变形温度与参数Z之间的关系

Fig. 3 Relationships between peak stress, deformation temperature and parameter Z

将上述所得参数值代入式(6),可得到Cu-0.6Cr-0.03Zr合金的高温热变形流变应力本构方程:

2.3 热加工图

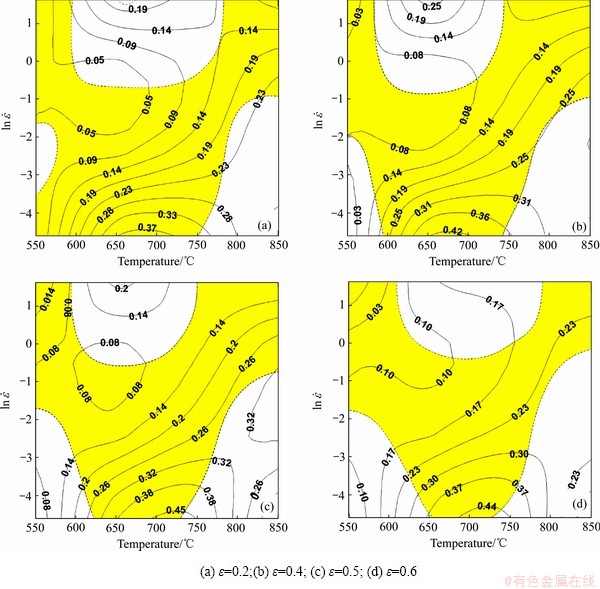

将Cu-0.6Cr-0.03Zr合金不同变形条件下的应变速率敏感因子m代入式(2)和式(3)中,求出相对应的功率耗散效率因子η和流变失稳参数 ,然后绘制功率耗散图和流变失稳图;将功率耗散图与流变失稳图叠加得到合金在应变量分别为0.2、0.4、0.5和0.6时的热加工图,如图4所示,等值轮廓线上的数值是功率耗散效率因子η,白色区域为安全加工区,黄色阴影区为流变失稳区。从图4可知,当应变速率小于5 s-1、变形温度小于750 ℃时,功率耗散效率因子随变形温度的升高或应变速率的降低而增加,不存在功率耗率效率因子急剧变化区。在不同应变量下该合金失稳区相似,说明变形量对加工图影响不大。合金在热压缩变形时存在3个安全加工区域,变形温度为550~575 ℃、应变速率为0.03~0.22 s-1的区域、变形温度为600~750 ℃、应变速率为1~5 s-1的区域和变形温度为775~850 ℃、应变速率为0.01~0.37 s-1的区域。功率耗散效率因子越高,材料能量状态越低,易发生动态再结晶,有利于材料的热变形。

,然后绘制功率耗散图和流变失稳图;将功率耗散图与流变失稳图叠加得到合金在应变量分别为0.2、0.4、0.5和0.6时的热加工图,如图4所示,等值轮廓线上的数值是功率耗散效率因子η,白色区域为安全加工区,黄色阴影区为流变失稳区。从图4可知,当应变速率小于5 s-1、变形温度小于750 ℃时,功率耗散效率因子随变形温度的升高或应变速率的降低而增加,不存在功率耗率效率因子急剧变化区。在不同应变量下该合金失稳区相似,说明变形量对加工图影响不大。合金在热压缩变形时存在3个安全加工区域,变形温度为550~575 ℃、应变速率为0.03~0.22 s-1的区域、变形温度为600~750 ℃、应变速率为1~5 s-1的区域和变形温度为775~850 ℃、应变速率为0.01~0.37 s-1的区域。功率耗散效率因子越高,材料能量状态越低,易发生动态再结晶,有利于材料的热变形。

图4 Cu-0.6Cr-0.03Zr合金在不同应变量下的热加工图

Fig. 4 Processing maps of Cu-0.6Cr-0.03Zr alloy at different true strains

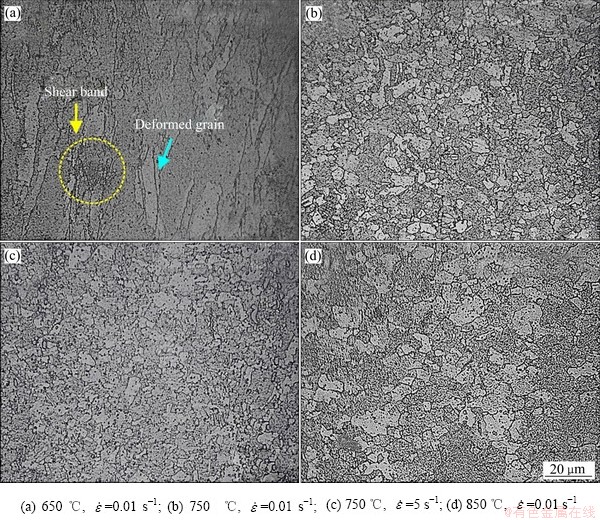

图5 合金在不同温度下的热压缩显微组织

Fig. 5 Microstructures of alloy heat compressed at different temperatures

图5所示为Cu-0.6Cr-0.03Zr合金在不同变形温度和不同应变速率下热压缩后的显微组织。从图5可看出,当变形温度较低时,合金中存在剪切带,晶粒呈拉长状,无动态再结晶晶粒(见图5(a))。当变形温度升高至750 ℃以上时,发生了完全动态再结晶,晶粒为等轴状,如图5(b)~(d)所示。同时,在相同热变形温度下,动态再结晶晶粒尺寸随应变速率增加而减小;而在相同应变速率条件下,动态再结晶晶粒尺寸随温度增加而增大。同时,应兼顾较高的功率耗散因子。因此,综上分析可知,Cu-0.6Cr-0.03Zr合金相对较佳的安全热加工参数:变形温度为770~800 ℃、应变速率为0.01~0.05 s-1,功率耗散效率因子为32%~40%。

3 结论

1) 在变形温度为550 ℃和650 ℃时,Cu-0.6Cr-0.03Zr合金动态软化机制主要为动态回复与析出相动态粗化;当变形温度为750 ℃和850 ℃时,动态再结晶软化机制起主导作用。

2) Cu-0.6Cr-0.03Zr合金高温热变形激活能为572.05 kJ/mol,流变应力本构方程为 。 3) Cu-0.6Cr-0.03Zr合金在高温热变形时存在3个安全加工区域。相对较佳的热加工参数:变形温度为770~800 ℃、应变速率为0.01~0.05 s-1,功率耗散效率因子为32%~40%。

。 3) Cu-0.6Cr-0.03Zr合金在高温热变形时存在3个安全加工区域。相对较佳的热加工参数:变形温度为770~800 ℃、应变速率为0.01~0.05 s-1,功率耗散效率因子为32%~40%。

REFERENCES

[1] PAN Zhen-ya, CHEN Jiang-biao, LI Jin-fu. Microstructure and properties of rare earth-containing Cu-Cr-Zr alloy[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(4): 1206-1214.

[2] 丁宗业, 贾淑果, 宁向梅, 宋克兴, 刘 平. 高强高导Cu-Cr-Zr合金时效性能[J]. 中国有色金属学报, 2017, 27(12): 2420-2425.

DING Zong-ye, JIA Shu-guo, NING Xiang-mei, SONG Ke-xing, LIU Ping. Aging properties of high-strength and high-conductivity Cu-Cr-Zr alloy[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(12): 2420-2425.

[3] ABIB K, LARBI H F, RABAHI L, ALILI B, BRADAI D. DSC analysis of commercial Cu-Cr-Zr alloy processed by equal channel angular pressing[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(3): 838-843.

[4] 贾淑果, 刘 平, 宋克兴, 陈讲彪, 陈小红, 田保红, 任凤章. Cu-Cr-Zr原位复合材料的组织与性能[J]. 中国有色金属学报, 2010, 20(7): 1334-1338.

JIA Shu-guo, LIU Ping, SONG Ke-xing, CHEN Jiang-biao, CHEN Xiao-hong, TIAN Bao-hong, REN Feng-zhang. Microstructures and properties of Cu-Cr-Zr in-situ composites[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(7): 1334-1338.

[5] 钟江伟, 张 鸿, 陈彦旭. 稀土元素La、Ce含量对Cu-0.4Cr-0.2Zr-0.15Mg合金组织和性能的影响[J]. 中国有色金属学报, 2016, 26(5): 1092-1099.

ZHONG Jiang-wei, ZHANG Hong, CHEN Yan-xu. Effects of Ce and La contents in rare earth elements on microstructure and properties of Cu-0.4Cr-0.2Zr-0.15Mg alloy[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(5): 1092-1099.

[6] 贾亚娟, 朱 晨, 李赛毅. 基于最大应变速率失稳准则预测铝合金板成形极限曲线[J]. 中国有色金属学报, 2019, 29(6): 1143-1149.

JIA Ya-juan, ZHU Chen, LI Sai-yi. Prediction of forming limit curve of aluminum alloy sheet based on maximum strain-rate necking criterion [J]. The Chinese Journal of Nonferrous Metals, 2019, 29(6): 1143-1149.

[7] HAMEDAN S S, ABDI M, SHEIBANI S. Comparative study on hot rolling of Cu-Cr and Cu-Cr-CNT nanocomposites[J]. Transactions of Nonferrous Metals Society of China, 2018, 28(10): 2044-2052.

[8] HAMEDA A A, BLAZ L. Microstructure of hot-deformed Cu-3.45wt%Ti alloy[J]. Materials Science and Engineering A, 1998, 254: 83-89.

[9] HUANG X S, SUZUKI K, CHINO Y. Different annealing behaviours of warm rolled Mg-3Al-1Zn sheets with dynamic recrystallized microstructure and deformation microstructure[J]. Materials Science and Engineering A, 2013, 560: 232-240.

[10] LI Kai, YANG Ping. Strain-induced α-to-β phase transformation during hot compression in Ti-5Al-5Mo-5V- 1Cr-1Fe alloy[J]. Transactions of Nonferrous Metals Society of China, 2019, 29(2): 296-304.

[11] PRASAD Y V R K, SASIDHARA S. Hot working guide: A compendium of processing maps[M]. Ohio: American Society for Metals International 1997: 23-29.

[12] BOZZINI B, CERRI E. Numerical reliability of hot working processing maps[J]. Materials Science and Engineering A, 2002, 328(1/2): 344-347.

[13] PRASAD Y V R K, SESHSCHARYULU T. Modeling of hot deformation for microstructure control[J]. International Materials Reviews, 1998, 43(6): 243-258.

[14] SELLARS C M. Modeling microstructural development during hot rolling[J]. Materials Science Technology, 1990, 16(11): 1072-1078.

[15] ZENER C, HOLLOMON J H. Effect of strain-rate upon the plastic flow of steel[J]. J Appl Phys, 1944, 15(1): 22-27.

Hot deformation behavior of Cu-Cr-Zr alloy

DING Zong-ye1, JIA Shu-guo1, 2, 3, NING Xiang-mei1, 2, LIU Ping1, ZHAO Pei-feng1, 2, SONG Ke-xing1, 2

(1. School of Materials Science and Engineering, Henan University of Science and Technology, Luoyang 471023, China;

2. Henan Province Collaborative Innovation Center of Nonferrous Metals, Henan University of Science and Technology, Luoyang 471023, China;

3. Henan Key Laboratory of Non-ferrous Materials Science and Processing Technology, Henan University of Science and Technology, Luoyang 471023, China)

Abstract: The deformation behavior of Cu-0.6Cr-0.03Zr alloy was investigated by compression test on Gleeble-1500 hot-simulation machine in the temperature range of 550-750 ℃ and the strain rate range of 0.01-5 s-1. The hot deformation constitutive equation and processing map were established. The results show that the flow stress decreases with increasing the deformation temperature and increases with increasing the strain rate. The flow stress behavior is expressed by hyperbolic sine equation containing Zener-Hollomon parameter, and the hot deformation activation energy is calculated as 572.05 kJ/mol under the present experimental condition. There are three safe processing zones for high temperature deformation of the alloy. The optimum domain for hot working occurs at 770-800 ℃ and 0.01-0.05 s-1, with the efficiency of power dissipation of 32%-40%.

Key words: Cu-Cr-Zr alloy; hot deformation behavior; constitutive equation; processing map

Foundation item: Project(50571035) supported by the National Natural Science Foundation of China; Project (2017YFB0306405) supported by the National Basic Research Development Program of China; Project(14IRTSTHN007) supported by the Program for Innovative Research Team (in Science and Technology) in University of Henan Province, China; Project(IRT1234) supported by the Program for Changjiang Scholars and Innovative Research Team in University, China

Received date: 2019-08-03; Accepted date: 2019-12-25

Corresponding author: JIA Shu-guo; Tel: +86-379-64231269; E-mail: sgjia@haust.edu.cn

(编辑 李艳红)

基金项目: 国家自然科学基金资助项目(50571035);国家重点研发计划资助项目(2017YFB0306405);河南省高校科技创新团队支持计划(14IRTSTHN007);长江学者和创新团队发展计划(IRT1234)

收稿日期:2019-08-03;修订日期:2019-12-25

通信作者:贾淑果,教授,博士;电话:0379-64231269;E-mail:sgjia@haust.edu.cn