DOI:10.19476/j.ysxb.1004.0609.2018.08.05

预孪晶AQ80镁合金热压缩本构方程及热加工图

尹振入1,卢立伟1, 2,刘晓烨1,盛 坤1,刘楚明2

(1. 湖南科技大学 高温耐磨材料及制备技术湖南省国防科技重点实验室,湘潭 411201;

2. 中南大学 材料科学与工程学院,长沙 410083)

摘 要:采用 Gleeble-3500热模拟试验机,对预孪晶AQ80镁合金在变形温度为250~400 ℃、应变速率为1×10-3~ 5 s-1条件下进行热压缩实验。预孪晶AQ80镁合金本构方程的建立通过Arrhenius双曲正弦函数推导而来。基于动态材料模型,建立在应变量为0.1、0.3和0.5下的热加工图。结果表明:预孪晶AQ80镁合金的流变应力随着变形温度升高和应变速率下降而减小,热加工图中耗散峰值(η=48%)区出现在低温低应变速率范围(250~280 ℃, 1×10-3 s-1)。结合热加工图和其对应区域的金相组织进行分析得出:应变量为0.5的失稳区在温度为250~400 ℃、应变速率为0.1~5 s-1范围内;然而,加工安全区在温度为300~400 ℃、应变速率在1×10-3~1×10-2 s-1范围内,组织特征表现为动态再结晶。

关键词: 预孪晶AQ80镁合金;热压缩变形;本构方程;热加工图

文章编号:1004-0609(2018)-08-1523-09 中图分类号:TG376 文献标志码:A

目前,镁及镁合金得到广泛关注,这主要是其拥有良好的性能,如低密度、阻尼减震、高比强度等优点[1-3]。正是由于能减轻重量和节约能源的优点,在航空和汽车领域成为研究焦点[4-5]。但另一方面由于镁合金中滑移变形机制很难在室温下发生塑性变形,极大地限制了镁合金的广泛应用[6-8]。然而,孪生这种变形机制在协调镁合金的塑性变形过程中起到关键作用,最近成为很多学者研究的热点。CHEN等[9]采用预压缩来制备预孪晶AZ31镁合金,然后对其进行热处理,对比没有预孪晶的样品发现在400 ℃保温1 h时,预孪晶镁合金的延伸率有明显的提高。李祎等[10]研究员在室温下对AZ80镁合金进行预压缩,随后将预压缩后的样品在663 K以0.3 s-1应变速率下进行热压缩变形,发现预变形试样比没有预变形的试样的塑性有明显的提升。严红革等[11]对AZ31镁合金板材进行预变形和均匀化处理,将坯料预热至300 ℃在高应变速率下进行轧制变形,发现经过预变形的板材相比没有预变形的板材,晶粒更均匀更细小,平均晶粒为2.3 μm。为了让镁合金得到大规模应用,镁合金塑性变形大多数通过热加工完成,在热加工过程中温度和应变速率等因素对镁合金塑性变形的影响非常大。基于此,对于镁合金热变形行为的研究,建立镁合金流变应力模型,为准确运用有限元数值分析金属塑性成型提供保障。与此同时,热加工图的建立可以获得较优的热加工工艺,为提高镁合金热加工后的产品质量提供帮助。刘海军[12]采用Gleeble-1500D热模拟试验机对含稀土AZ31镁合金进行热压缩实验,热变形温度为250~400 ℃、应变速率为1×10-2~10 s-1,得出该合金的本构方程模型及热加工图,并确定0.03~0.8 s-1、250~325 ℃和1×10-2~0.9 s-1、350~400 ℃两个较优的热加工工艺区域。SHALBAFI等[13]对Mg-10Li-1Zn合金进行热压缩实验,构建热加工图得出当达到试样应变量0.55时,热变形工艺在 548~598 K和1×10-3~1×10-2 s-1范围内,其合金微观组织动态再结晶发生较充分。邱友权等[14]对铸态AZ80A镁合金进行热压缩实验,得出不同热变形条件下的热加工图,并确定了不同应变量下的动态回复区和动态再结晶区。虽然预孪晶对镁合金细化晶粒并提高镁合金塑性有很好的帮助,但对于预孪晶后镁合金的热变形行为及热加工图系统的研究较少。

因此,本文作者主要构建了预孪晶AQ80镁合金在不同热变形条件下的本构方程和热加工图,为准确运用有限元数值分析预孪晶AQ80镁合金塑性成型与获得较优的热加工工艺提供理论依据。

1 实验

实验材料选用铸态AQ80镁合金,其主要化学成(质量分数,%)为:Al 8.10、Zn 0.46、Mn 0.18、Ag 0.18、 余量Mg。热压缩实验采用d 8 mm×12 mm的圆柱试样,该圆柱试样已对其端面进行变形量为6%的压缩变形。采用Gleeble-3500型热模拟试验机进行等温压缩实验。热变形温度分别为250、300、350、400 ℃;应变速率分别为1×10-3、1×10-2、1×10-1、1、5 s-1;设置最大变形量为70%,热压缩完后立即水冷,观察热压缩前后的金相组织,采用4%(体积分数)的硝酸酒精溶液进行腐蚀。

热压缩前的金相组织如图1所示。从图1中可以看出,经过预压缩后,粗大的晶粒内部出现了大量的呈现长条状且相互平行的孪晶组织。

图1 AQ80镁合金热压缩前的金相组织

Fig. 1 Microstructure of AQ80 Mg alloys before hot compression

2 结果与讨论

2.1 流变应力曲线

图2所示为预孪晶AQ80镁合金在不同实验条件下的真应力-应变曲线。从图2中可以看出,不同应变率下的真应力-应变曲线都呈现大致相同的趋势。在开始变形阶段,应力急剧上升到达一个最高点(峰值应力),这种现象主要原因如下:开始变形阶段位错密度随着应变量的增加而增大,从而积累了大量的位错导致位错积塞,加工硬化在其中占主导地位。随着到应变量继续增大,流变应力的变化趋势与开始阶段明显相反,呈现下降趋势,此时动态回复和动态再结晶的软化效应大于加工硬化的强化作用。最后,当应变进一步的增大,流变应力变化趋势基本趋于水平,说明该阶段已达到稳态流动阶段。此刻由于动态再结晶所导致的晶粒细化使得加工硬化作用有所提升,可以发现流变应力并不是一条光滑的曲线,而是呈现细小的锯齿状,这说明动态再结晶软化作用与热加工硬化相互竞争达到动态平衡。

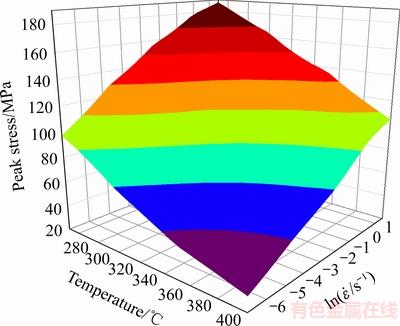

为了更好地说明热变形温度、应变速率和峰值应力的关系,采用如图3所示的三维表面图表示。从图3中可以看出,通过增加热变形温度和降低应变速率,峰值应力呈现下降的趋势。这主要归因于在增加热变形温度时,晶界的移动速度相对提高,同时也促进了位错攀移和湮灭机制的发生,降低应变速率给位错有充足的时间来相互抵消,促进了动态再结晶的形核和晶粒的增长,从而导致峰值应力的降低[13]。当温度为250 ℃时,随着应变速率的增加峰值应力有着明显的提高,结合图2(d)和(e)发现当应变速率为1和5 s-1时,其流变应力曲线最后没有呈现稳态的趋势而出现过早的下降,这说明在较高的应变速率下发生了断裂。这是由于应变速率过大时,位错的密度迅速增加,加上在低温(250 ℃)的情况下,动态在再结晶发生不充分导致软化效果较弱,加工硬化作用非常明显,局部应力超过其塑性变形能力导致试样的断裂。

2.2 本构方程的建立

本构方程的建立可以让流变应力与热变形温度以及应变速率之间的关系变得更加直观。本构方程的类型很多,现在应用最广泛的本构方程模型是由SELLARS等[15]提出的Arrhenius 型公式,其公式有3种表现形式。通常应力较低的情况下可以表示为指数关系:

(1)

(1)

当应力较高时,可表示为幂指数关系:

(2)

(2)

式(3)适用所有应力值

(3)

(3)

式中:A、A1、A2、n1、n、 和

和 都是与温度无关的常数;R为摩尔气体常数(8.314 J/(mol·K));Q为变形激活能(kJ/mol);T为绝对温度(K);

都是与温度无关的常数;R为摩尔气体常数(8.314 J/(mol·K));Q为变形激活能(kJ/mol);T为绝对温度(K); 为应变速率(s-1);

为应变速率(s-1); 为流变应力(MPa)。

为流变应力(MPa)。

通常 。当温度恒定时,根据式(1)和(2)可以得出

。当温度恒定时,根据式(1)和(2)可以得出 和

和 的表达式分别为

的表达式分别为

(4)

(4)

(5)

(5)

可以得出 和

和 的值分别为曲线

的值分别为曲线 -

- 和

和 -

- 的斜率。

的斜率。 取不同热加工条件下的峰值应力并绘制曲线

取不同热加工条件下的峰值应力并绘制曲线 -

- 和

和 -

- ,然后分别对每个温度下的曲线进行线性拟合,得出的结果如图4所示。图4(a)和(b)中每个温度下的直线都是经过一次线性拟合后的结果。

,然后分别对每个温度下的曲线进行线性拟合,得出的结果如图4所示。图4(a)和(b)中每个温度下的直线都是经过一次线性拟合后的结果。 取图4(a)中应力相对较低的两条直线斜率的平均值为7.2922,

取图4(a)中应力相对较低的两条直线斜率的平均值为7.2922, 取图4(b)中应力相对较高的两条直线斜率的平均值为0.09121,进而得出

取图4(b)中应力相对较高的两条直线斜率的平均值为0.09121,进而得出 = 0.012507。

= 0.012507。

图2 不同变形条件下预孪晶AQ80镁合金的真应力-应变曲线

Fig. 2 True stress-strain curves of pre-twin AQ80 magnesium alloy under different temperatures and strain rates

图3 不同应变速率和热变形温度下的峰值应力

Fig. 3 Representation of peak stress at different strain rates and deformation temperatures

图4 峰值应力与应变速率的关系

Fig. 4 Relationships between peak stress and strain rate

假定变形激活能Q与温度T不存在函数关系,对式(3)进行两边取自然对数再进行偏微分可得到Q的表达式为

(6)

(6)

根据式(6)取不同实验条件下的峰值应力为流变应力,绘制出 -

- 和

和 -1/T曲线并对其进行线性回归,如图5所示。从图5中分别求出图5(a)和(b)中4条线性拟合直线斜率的平均值得出的结果分别为6.1596和2.8737,则计算出变形激活能的值为147.1652 kJ/mol。

-1/T曲线并对其进行线性回归,如图5所示。从图5中分别求出图5(a)和(b)中4条线性拟合直线斜率的平均值得出的结果分别为6.1596和2.8737,则计算出变形激活能的值为147.1652 kJ/mol。

图5  与应变速率和温度的关系

与应变速率和温度的关系

Fig. 5 Relationships between  and

and  (a), T -1(b)

(a), T -1(b)

根据ZENER等[16]提出用Z参数来描述变形温度和应变速率对流变应力的影响,其表达式为

(7)

(7)

式中:Z为温度补偿的应变速率因子式中;n为应力指数; 为应力水平参数;A为结构因子。对式(7)两边取对数可得

为应力水平参数;A为结构因子。对式(7)两边取对数可得

(8)

(8)

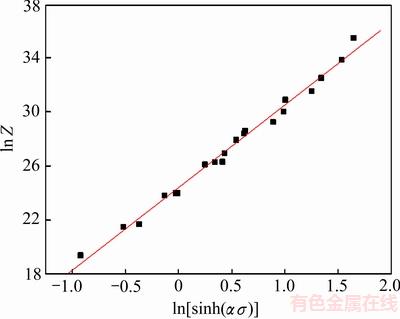

根据式(8)绘出 -

- 曲线图并进行线性回归处理,如图6所示。

曲线图并进行线性回归处理,如图6所示。

图6  与

与 的关系

的关系

Fig. 6 Relationship between  and

and

根据式(8)可知图6线性拟合的斜率即为n值,n=6.11532,截距为ln A,则A=3.94578×1010值。将求出的各参数代入式(3)得预孪晶AQ80镁合金热压缩的本构方程为

(9)

(9)

2.3 预孪晶AQ80镁合金热加工图及分析

热加工图是由功率耗散图和失稳图两部分叠加而成,是基于动态材料模型理论而构建。动态材料模型通常表达了材料在热加工的过程中总能量耗散(P)包括两个部分:一部分是由塑性变形引起的能量耗散(G),另一部分是由动态回复和动态再结晶引起的微观组织变化所耗散的能量(J)。可将其表示为[17]

(10)

(10)

功率耗散图由功率耗散因子( )随温度和应变速率的变化而构成。功率耗散因子(

)随温度和应变速率的变化而构成。功率耗散因子( )是在材料成形阶段微观组织演变所耗散的能量与线性耗散能量(Jmax)的比值,其表达式为[18]

)是在材料成形阶段微观组织演变所耗散的能量与线性耗散能量(Jmax)的比值,其表达式为[18]

(11)

(11)

式中:m为应变速率敏感指数, 。在功率耗散图中并不是

。在功率耗散图中并不是 值越高,材料的加工性能越好,往往需要结合失稳图来判断,失稳判断的公式为[13]

值越高,材料的加工性能越好,往往需要结合失稳图来判断,失稳判断的公式为[13]

<0 (12)

<0 (12)

则根据失稳判断公式得出 和m<0时失稳,因m<0时此失稳判断公式无意义。基于上述热加工图构建原理,构建应变量为0.1、0.3、0.5下的热加工图,如图7所示。

和m<0时失稳,因m<0时此失稳判断公式无意义。基于上述热加工图构建原理,构建应变量为0.1、0.3、0.5下的热加工图,如图7所示。

图7中等高线数值代表材料在加工过程中的功率耗散大小,而阴影部分代表材料容易出现失稳的区域。

图7 预孪晶AQ80镁合金不同应变量下的热加工图

Fig. 7 Processing maps for pre-twin AQ80 Mg alloy at different true strains

从图7中可以看出,不同的应变量,对加工图的影响非常明显。在应变量为0.1时(见图7(a)),失稳区表现在低温低应变速率(250~340 ℃,1×10-3~1×10-1 s-1),此时变形量低,低温低应变速率导致的加工硬化占主导地位,塑性变形很难完成不易加工。当变形量为0.3时(见图7(b)),失稳区域有所增大,表现在3个区域:低温低应变速率(250~300 ℃,1×10-3~1×10-1 s-1)、低温高应变速率(250~300 ℃,1~5 s-1)以及高温高应变速率(300~400 ℃,1~5 s-1)。当应变量进一步增大到0.5时,此应变量处于流变应力曲线的稳定阶段,发现失稳区域(见图7(c))有所减小,几乎都出现在高应变速率只有少部分出现在低应变速率(0.1 s-1)且涵盖所有温度。图7(c)中右上角虽然是空白区域,但出现了负的耗散系数(-0.063)也属于失稳区。这说明较高的应变量,在高应变速率的情况下加工失稳区更容易发生。

图8所示为应变量为0.5时失稳区不同加工条件下的金相组织。从图8(a)可以看出,在低温高应变速率(250 ℃,1 s-1)出现大量被拉长的晶粒且大多数沿压缩方向45°角倾斜,伴随大量的孪晶并在孪晶与晶粒的交界处附有裂纹。由于高应变速率累积了大量的位错,使得位错滑移没有充分的时间去开启,且低温位错攀移难以实现,导致应力集中。此时孪晶附近会形成细小再结晶晶粒并协调晶粒转动发生塑性变形,但温度较低时动态再结晶软化能力较弱,局部的变形量超过其塑性变形能力,在应力集中部分导致裂纹的产生。高温高应变速率(400 ℃,5 s-1)时孪晶基本消失,晶粒有所长大(见图8(b)),说明温度的升高位错运动更活跃,动态再结晶能力有所增强,但应变速率过快再结晶晶粒没有时间充分发生,晶粒仍不均匀局部出现了孔洞和裂纹的扩张,说明高应变速率下失稳非常严重。图8(c)中出现了少量的孔洞,晶粒非常不均匀且大晶粒周围出现了很多细小的动态再结晶晶粒,晶粒不均匀程度过大导致组织不稳定,不适宜加工。

图8 不同变形条件下失稳区的金相组织

Fig. 8 Metallographic structures in instability region under different conditions

图7(c)中加工安全区范围较广,为了更好地确定加工安全区的热加工工艺参数范围,需结合其金相组织进一步分析。图9所示为热加工安全区不同变形条件下的微观组织。功率耗散峰值区域(250~280 ℃, 1×10-3 s-1)对应的微观组织如图9(a)所示,从图9(a)中可以看出,孪晶周围出现了很多细小的再结晶晶粒,这是由于温度过低可开启的滑移系较少,此时孪晶将会对再结晶形核以及协调晶粒长大对晶粒择优取向有重要作用,同时应变速率过低给动态再结晶形核留有充分时间,只因温度过低提供形核能力有限,导致晶粒细化效果不明显,虽然此时功率耗散值最大,但大多数功率由孪晶再结晶形核所消耗。随着温度升高到400 ℃(见图9(b)),呈现细小的再结晶晶粒,此时已观察不到孪晶,说明低应变速率下温度越高,孪晶提供的形核点已完全转化为细小的再结晶晶粒。图9(c)应变速率提高到1×10-2 s-1时,晶界附近有第二相析出且晶粒大小相对均匀,当温度升高到400 ℃时(见图9(d)),晶粒进一步细化,说明第二相有抑制动态再结晶晶粒长大的作用。综上所述,较合适的热变形区在温度300~400 ℃、应变速率1×10-3 ~1×10-2 s-1范围内。

图9 不同变形条件下安全区的金相组织

Fig. 9 Metallographic in safe region under different conditions

3 结论

1) 预孪晶AQ80镁合金的流变应力受应变速率和温度的影响较大,流变应力随着温度升高和应变速率下降而减小,温度对流变应力呈负相关,应变速率对流变应力呈正相关。

2) 在变形温度250~400 ℃,应变速率1×10-3~ 5 s-1条件下,预孪晶AQ80镁合金流变应力本构方程为

。

。

3) 结合热加工图和微观组织得出预孪晶AQ80镁合金较合适的热加工工艺范围在应变速率1×10-3~1×10-2 s-1,温度为300~400 ℃。

REFERNCES

[1] 刘 筱, 朱必武, 李落星, 唐昌平. 挤压态AZ31镁合金热变形过程中的孪生和织构演变[J]. 中国有色金属学报, 2016, 26(2): 288-295.

LIU Xiao, ZHU Bi-wu, LI Luo-xing, TANG Chang-ping. Twinning and texture evolution in extruded AZ31 magnesium alloy during hot deformation[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(2): 288-295.

[2] ZHU S Z, LUO T J, ZHANG T A, LIU Y T, YANG Y S. Effects of extrusion and heat treatments on microstructure and mechanical properties of Mg-8Zn-1Al-0.5Cu-0.5Mn alloy[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(1): 73-81.

[3] ASGARI M, FERESHTEH-SANIEE F. Production of AZ80/Al composite rods employing non-equal channel lateral extrusion[J]. The Chinese Journal of Nonferrous Metals, 2016, 26: 1276-1283.

[4] MAHALLAWY N E, AHMED D A, AKDESIR M, PALKOWSKI H. Effect of Zn addition on the microstructure and mechanical properties of cast, rolled and extruded Mg-6Sn-xZn alloys[J]. Materials Science and Engineering A, 2017, 680: 47-53.

[5] TANG L L, ZHAOY H, ISLAMGALIEV R K, TSAOC Y A, VALIEV R Z, LAVERNIA E J, ZHU Y T. Enhanced strength and ductility of AZ80 Mg alloys by spray forming and ECAP[J]. Materials Science and Engineering A, 2016, 670: 280-291.

[6] 王忠堂, 马 康, 梁海成, 张士宏. AZ31镁合金板材双向循环弯曲的孪晶组织及织构[J]. 稀有金属材料与工程, 2016, 45(10): 2746-2751.

WANG Zhong-tang, MA Kang, LIANG Hai-cheng, ZHANG Shi-hong. Twin and texture of AZ31 magnesium alloy sheet deformed by bidirectional cyclic bending technology[J]. Rare Metal Materials and Engineering, 2016, 45(10): 2746-2751.

[7] 宋广胜, 陈强强, 徐 勇, 李 娟, 张士宏. AZ31镁合金变路径压缩过程中解孪晶行为分析[J]. 稀有金属材料与工程, 2016, 43(10): 2561-2567.

SONG Guang-sheng, CHEN Qiang-qiang, XU Yong, LI Juan, ZHANG Shi-hong. Untwining behavior of AZ31 Mg alloy multi-path compressions[J]. Rare Metal Materials and Engineering, 2016, 45(10): 2561-2567.

[8] ZHANG W G, YE Y C, HE L J, LI P J, ZHANG H S. Dynamic mechanical response and microstructural evolution of extruded Mg AZ31B plate over a wide range of strain rates[J]. Journal of Alloys and Compounds, 2017, 696: 1067-1079.

[9] CHEN Hong-bo, LIU Tian-mo, LU Li-wei, HE Jie-jun, ZHAI Yan-bo. Influence of pre-strain and heat treatment on subsequent deformation behavior of extruded AZ31 Mg alloy[J]. Transaction of Nonferrous Metals Society of China, 2015, 25(11): 3604-3610.

[10] 李 祎, 蒋莉萍, 肖振宇. 预变形对AZ80镁合金组织与力学性能的影响[J]. 铝加工, 2016(6): 12-16.

LI Wei, JIANG Li-ping, XIAO Zhen-yu. Effect of pre-deformation on microstructures and mechanical properties of AZ80 magnesium alloys[J]. Aluminium Fabrication, 2016(6): 12-16.

[11] 严红革, 田 津, 朱素琴, 陈吉华, 苏 斌, 吴远志. 预处理对高应变速率轧制镁合金板材组织均匀性和力 学性能的影响[J]. 湖南大学学报(自然科学版), 2011, 38(9): 55-58.

YAN Hong-ge, TIAN Jin, ZHU Su-qin, CHEN Ji-hua, SU Bin, WU yuan-zhi. Effect of pre-treatment on the microstructural homogeneity and mechanical properties of magnesium alloy sheets produced by high strain rate rolling[J]. Journal of Hunan University (Natural Sciences), 2011, 38(9): 55-58.

[12] 刘海军. 含稀土AZ31镁合金热压缩变形行为及加工图[J]. 特种铸造及有色合金, 2017, 37(1): 15-17.

LIU Hai-jun. Hot compression deformation behavior and processing map of as-cast RE-Mg AZ31 alloy[J]. Special Casting and Nonferrous Alloys, 2017, 37(1): 15-17.

[13] SHALBAFI M, ROUMINA R, MAHMUDI R. Hot deformation of the extruded Mg-10Li-1Zn alloy: Constitutive analysis and processing maps[J]. Journal of Alloys and Compounds, 2017, 696: 1269-1277.

[14] 邱友权, 袁 琳, 单德彬. 铸态AZ80A镁合金热加工图及高温变形行为研究[J]. 精密成形工程, 2015, 7(1): 16-21.

QIU You-quan, YUAN Lin, SHAN De-bin. Hot processing maps and hot deformation behavior of As-cast AZ80A magnesium alloy[J]. Journal of Netshape Forming Engineering, 2015, 7(1): 16-21.

[15] SELLARS C M, MCTEGAR W J. On the mechanism of hot deformation[J]. Acta Metallurgica, 1966, 14(9): 1136-1138.

[16] ZENER C, HOLLOMON J. Effect of strain rate upon plastic flow of steel[J]. Journal of Applied Physics, 1944, 15: 22-23.

[17] ZHANG Y, LIU P, TIAN B H, LIU Y, LI R Q, XU Q Q. Hot deformation behavior and processing map of Cu-Ni-Si-P alloy[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(8): 2341-2347.

[18] BASINSKI Z S. Thermally activated glide in face-centred cubic metals and its application to the theory of strain hardening[J]. Philosophical Magazine, 1959, 4(40): 393-432.

Constitutive equation and processing map of hot deformation for pre-twin AQ80 magnesium alloy

YIN Zhen-ru1, LU Li-wei1, 2, LIU Xiao-ye1, SHENG Kun1, LIU Chu-ming2

(1. Hunan Provincial Key Defense Laboratory of High Temperature Wear-resisting Materials and Preparation Technology, Hunan University of Science and Technology, Xiangtan 411201, China;

2. School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The hot compression tests of pre-twin AQ80 magnesium alloy were conducted at temperature of 250-400 ℃ and strain rates of 1×10-3 to 5 s-1 by using the Gleeble-3500 hot-simulator. The constitutive equation of pre-twin AQ80 magnesium alloy was constructed by Arrhenius hyperbolic sine function. According to dynamic materials model, the hot processing maps of pre-twin AQ80 magnesium alloy were established for strain of 0.1, 0.3 and 0.5. The results show that the flow stress of pre-twin AQ80 magnesium alloy decreases with the decrease of strain rate and the increase of temperature. The processing maps exhibit one peak η value (48%) region at temperature of 250-280 ℃ and the strain rate of 1×10-3 s-1. Combining with analysis of hot processing map and the corresponding microstructure at each domain, the instability regions were identified to be at the temperature range of 250-400 ℃ and strain rate of 0.1-5 s-1 for billets deformed to strains of 0.5, while the microstructures characteristic mainly show dynamic recrystallization at the temperature of 300-400 ℃ and strain rate of 1×10-3-1×10-2 s-1, which were indicated as safe regions.

Key words: pre-twin AQ80 magnesium alloy; hot compression deformation; constitutive equation; hot processing map

Foundation item: Project(51505143) supported by the National Natural Science Foundation of China; Project(17B089) supported by the Scientific Research Fund of Hunan Provincial Education Department, China; Projects(2016T90759, 2014M562128) supported by China Postdoctoral Science Foundation

Received date: 2017-06-05; Accepted date: 2017-09-15

Corresponding author: LU Li-wei; Tel: +86-731-58290782; E-mail: cqulqyz@126.com

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51505143);湖南省教育厅优秀青年基金资助项目(17B089);中国博士后科学基金资助项目(2016T90759,2014M562128)

收稿日期:2017-06-05;修订日期:2017-09-15

通信作者:卢立伟,副教授,博士;电话:0731-58290782;E-mail: cqulqyz@126.com