DOI:10.19476/j.ysxb.1004.0609.2018.05.04

铝锶合金高温塑性变形行为及本构方程

万帆,运新兵,毕胜,裴久杨

(大连交通大学 连续挤压工程研究中心,大连 116028)

摘 要:采用Gleeble-1500型热模拟试验机进行高温压缩实验,结合连续挤压工艺制定热压缩实验方案,研究铝锶合金高温塑性变形行为,分析变形温度、应变速率对铝锶合金热变形过程中流变应力和Al4Sr相形态的影响,并采用线性回归的方法建立铝锶合金高温下的本构方程。结果表明:铝锶合金的热塑性变形软化机制以动态回复为主;在热变形过程中流变应力随变形温度的升高而减小,随应变速率的增大而增大;变形温度为400 ℃时Al4Sr相破裂严重,而当温度为500 ℃时Al4Sr相具有韧性而易于弯曲;可用包含Zener-Hollomon参数的Arrhenius双曲正弦模型描述其热变形行为。

关键词:铝锶合金;高温塑性变形;流变应力;显微组织;本构方程

文章编号:1004-0609(2018)-05-0888-09 中图分类号:TG301;TG146.2 文献标志码:A

Al-Sr合金是变质型细化剂[1],主要用于亚共晶和共晶铸造铝硅合金的变质处理,被广泛用于汽车和摩托车铝合金轮毂的生产中。英国、日本、美国等国从20世纪80年代初就提出Sr细化合金,认为Sr是最理想的铝合金细化剂[2-3]。Sr细化一般以Al-Sr中间合金的形式加入,且Sr的含量在5%~10%(质量分数)范围内,常见的有Al5Sr和Al10Sr。Al-Sr合金在变质处理时具有有效变质时间长、重熔性好、无过变质现象、添加时无烟雾、不腐蚀设备、易于控制和无污染等优点[4-6]。随着铝系合金的应用领域不断扩大,人们对其后续的深加工和最终产品的质量要求不断提高,为改善铝系合金的组织与性能,这就需要对其进行细化处理。在工业生产中,变质剂往往以线材的形式加入到熔体中,以提高细化效果和降低成本,Al-Sr合金的细化性能取决于Al4Sr相的相貌和尺寸[7]。目前,大量研究主要集中在添加铝锶中间合金变质后铸造铝硅合金力学性能的改变,而对铝锶中间合金基础性研究几乎没有。

Al-Sr合金的加工方式主要有半连续铸造-挤压法,而采用连铸连挤方法生产铝锶线材相对较少。连续挤压法具有工艺简单、材料利用率高、生产效率高、节能环保等优点[8-9],使其在铝锶合金线材的生产中具有明显的优势和巨大的潜力。然而铝锶合金变形温度高、铸态铝锶合金孔隙度大,因此,铝锶合金连续挤压在塑性变形机理和工艺参数等方面还有待进一步研究。

金属材料的热变形行为是材料重要特性之一,是制定材料热加工工艺的重要依据,它同时受变形温度、应变速率、变形程度以及变形体内显微组织的综合影响。材料本构方程模型是有限元塑性成形数值模拟的理论基础,其计算精度是有限元理论计算的关键,并且直接影响计算结果准确性和计算速度[10-12],对于分析评价金属材料成形性能特征和成形工艺有着指导意义[13-14]。寇林媛等[15]研究了7150铝合金高温热压缩变形流变应力行为及其显微组织演化规律,结果表明,在变形温度低于450 ℃时合金主要软化机制是动态回复,在变形温度较高且应变速率较低时合金主要软化机制为动态再结晶。陈修梵等[16]研究了7050铝合金热压缩变形的流变行为及显微组织演变,发现高变形温度和低应变速率下,晶内位错密度下降,晶界变得平直而清晰,流变应力减小。贾乐等[17]研究了7085铝合金的高温压缩流变应力及软化行为,建立应变量与本构方程参数之间的关系,发现合金流变行为差异及动态回复再结晶与第二相粒子相关。本文作者以热压缩实验为基础,研究了铝锶合金在不同变形条件下的热变形行为和显微组织演化,并建立描述铝锶合金流变特性的本构方程,为制定合理的铝锶合金成形工艺提供理论依据,以改善产品的显微组织和性能。

1 实验

实验材料为轮带式铸造生产的铸态Al10Sr合金,实验在Gleeble-1500型热模拟试验机上进行。将铸态坯料加工成直径8 mm×15 mm圆柱形试样,在圆柱试样两端浅槽内添加润滑剂。实验温度分别为200、300、400和500 ℃,应变速率选取0.01、0.1和1 s-1,总压缩变形量为60%。实验前在热模拟实验机上以5 ℃/s的速率将试样加热到变形温度,保温3 min后进行压缩实验。压缩变形后,将试样迅速冷却至室温以保留高温变形组织。试样均选取中心横截面处组织,之后用OLYMPUS-BX41M型金相显微镜和VEGA-TSCAN型扫描电镜观察组织。实验中计算机处理系统自动控制实验参数并采集实验数据。

2 结果与讨论

2.1 热压缩流变应力曲线分析

2.1.1 变形温度对流变应力的影响

图1所示为不同应变速率下铝锶合金的真实应力-应变曲线。由图1可以看出,Al-Sr合金高温塑性变形时流变应力呈明显的阶段性。在起始阶段,流变应力随着应变的增加迅速升高,曲线斜率很大。在第二阶段,随着变形量的进一步增加,曲线斜率逐渐减小,流变应力到达峰值。在最终阶段,达到峰值后出现了两种情况:当变形温度为200和300 ℃时,流变应力不随变形程度的增加而改变,即进入了稳态变形阶段[18];当变形温度为400和500 ℃时,流变应力先下降减小而后趋于稳定不变。这是因为变形起始阶段,晶粒内部位错密度急剧增加,相互缠结交割,材料产生加工硬化作用,应力急剧增大;随着变形的进行,位错继续增加,加工硬化持续增强,但是由于螺位错的交滑移和刃型位错的攀移所引起的软化作用也增强,流变应力逐渐达到最大值[19-20]。当变形温度较低时(200和300 ℃),合金热变形达到一定程度时,合金中的加工硬化作用和位错相互销毁的动态软化达到平衡,流变应力到达峰值后就直接趋于稳定;当变形温度较高时(400和500 ℃),热激活作用增加,各种缺陷运动势能垒下降[21],合金显微组织动态演化产生的软化作用大于加工硬化作用,这就使得位错密度降低,材料流变应力下降,最终材料的硬化作用和软化作用达到动态平衡,流变应力趋于稳定。

图1 不同应变速率下铝锶合金的真实应力-应变曲线

Fig. 1 Curves of true stress-strain for Al-Sr alloy under different strain rates

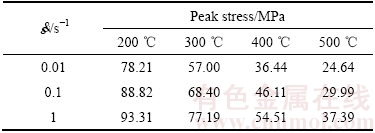

表1所列为不同条件下铝锶合金热压缩峰值应力。从图1和表1可以看出,在同一应变速率下,流变应力随变形温度的增加而减小。这是因为变形温度升高时,原子热振动增强,原子扩散能力增加,原子热激活能增强,位错的交滑移和攀移所引起的软化作用也增强,异号位错相互抵消,位错密度降低,金属内部畸变能降低,从而提高了合金塑性,降低了金属强度,流变应力相应降低。

表1 不同变形条件下合金的峰值应力

Table 1 Peak stress under different deformation conditions

2.1.2 应变速率对流变应力的影响

图2所示为变形温度400 ℃时铝锶合金的真实应力-应变曲线,在同一变形温度条件下,流变应力随应变速率的增加而增加。随着应变速率的增加,一方面单位应变的变形时间缩短,位错增殖数目增加,位错运动速度加快,位错运动受阻,位错相互交割的几率增大,促使临界剪切应力大幅提高,流变应力增加。另一方面应变速率的增加,很多区域的位错来不及相互抵消,软化程度降低,导致流变应力峰值和稳态流变应力值都增加。

图2 变形温度400 ℃时铝锶合金的真实应力-应变曲线

Fig. 2 Curves of true stress-strain for Al-Sr alloy at deformation temperature of 400 ℃

2.2 高温塑性变形过程中显微组织演变

2.2.1 变形温度对显微组织的影响

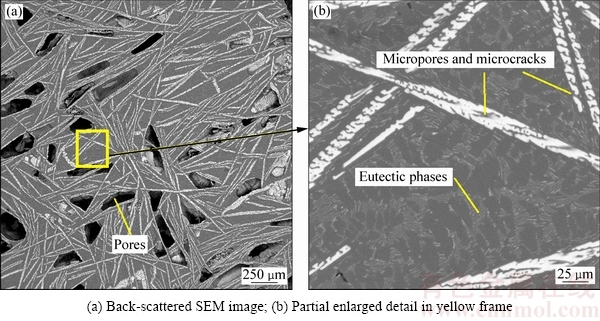

图3所示为铸态Al10Sr坯料的显微组织。从背散射电子图像可以看出,铝锶合金是由铝基体和第二相Al4Sr(强化颗粒)组成。基体中呈长针状分布的粒子即为Al4Sr相,初生Al4Sr相粒子相互交叉,分布不均匀,Al4Sr相粒子的平均长度为500~600 μm。铸态铝锶合金基体中存在大量宏观孔洞(见图3(a)),长针状Al4Sr相是由许多不规则颗粒沿着特定方向排列组成,几乎所有析出的Al4Sr粒子上具有不规则形状的微孔或微裂纹(见图3(b))。由此可以知道,轮带式铸造生产的铝锶合金缺陷很多。

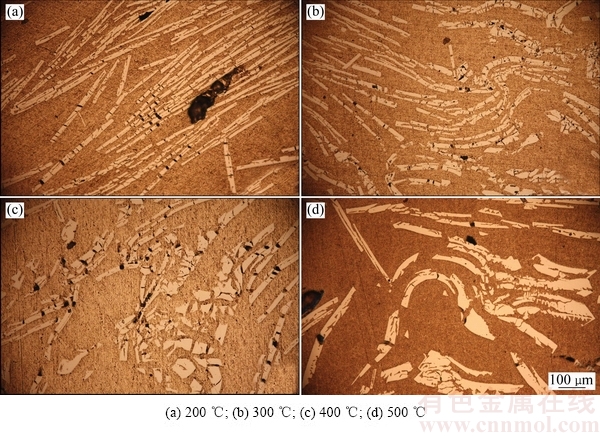

图4所示为应变速率为0.01 s-1时不同变形温度下合金的金相显微组织。在高温塑性变形过程中,变形温度对于第二相Al4Sr颗粒的细化效率起着重要作用,在热压缩后,Al4Sr相破裂(破裂包括原有序排列的Al4Sr颗粒变得无序排列以及Al4Sr颗粒的破碎)并造成强化粒子分布的不均匀。

当变形温度200 ℃时,Al4Sr相破碎甚少,部分发生断裂,呈粗大长针状并错乱不均匀分布,变形主要发生在基体上;当变形温度为300 ℃时,部分Al4Sr相发生破裂,尺寸减小,原来长针状的Al4Sr相变成具有一定的曲线流线形;当变形温度为400 ℃时,Al4Sr相破碎严重并呈板块状,尺寸细小,部分Al4Sr相堆积在一起;当变形温度500 ℃时,Al4Sr相板块状,但尺寸要比400 ℃时要大的多,部分形貌以弯曲线的形式分布在基体中。在较低温度下(200 ℃和300 ℃),由于压缩过程中产生位错饱和,超过粒子的抗拉强度导致在显微组织中形成了微裂纹,在张力作用下,材料发生塑性变形,通过空隙聚集产生的微裂纹阻碍了裂纹的生长[22];在400 ℃时,高温下合金塑性变形软化作用增强,加工硬化作用减弱,材料易于变形,第二相颗粒形貌尺寸变化较大;在较高温度下(500 ℃),Al4Sr相粒子易于弯曲,变得有韧性而不易破碎,这是因为此时温度超过了其脆韧转变温度(BDTT),颗粒变得具有延展性[23]。

图3 铸态Al10Sr坯料的显微组织

Fig. 3 Microstructures of cast Al10Sr billet

图4 不同变形温度下铝锶合金的金相组织

Fig. 4 Metallographs of Al-Sr alloy under different deformation temperatures

2.2.2 应变速率对铝锶合金显微组织的影响

图5所示为变形温度400 ℃时不同应变速率下铝锶合金的显微组织。从金相图可以看出,当应变速率为0.01 s-1和0.1 s-1时Al4Sr相破裂严重并呈板块状,尺寸较小,Al4Sr相在基体相中的分布不均匀,部分堆积在一起。当应变速率为1 s-1时,Al4Sr相发生断裂,但是宏观来看仍然呈长杆状。这是因为在较低变形速率下,合金塑性变形时变形抗力小,材料软化作用增强,材料易于成形,Al4Sr相易于破碎呈块状;在较高变形速率下,材料变形时间短,加工硬化作用强,塑性变形抗力大,变形主要以基体的变形为主,Al4Sr相变化不大。

图5 不同应变速率下铝锶合金的金相组织

Fig. 5 Metallographs of Al-Sr alloy under different deformation rates

由上述分析可知,铝锶合金热变形主要以铝基体变形为主,伴随的是粗大的第二相Al4Sr相发生破裂。铝合金属于高层错能金属,其热变形主要恢复机制为动态回复[24];铝合金热变形的实质是位错的运动、增殖和销毁[21]。铝基体在热变形过程中,原子扩散、位错运动及相互销毁的难易程度都决定了其软化机制作用的大小,但与此同时晶界迁移也会影响合金的显微结构的演变。GOURDET等[25]研究发现对于高层错能金属,在热压缩过程中有晶界迁移现象。晶界迁移数量越多、迁移速率越快越容易影响合金显微结构演变。李俊杰等[26]采用相场法,研究了不同体积及不同尺寸的第二相颗粒对晶粒组织演化及其生长动力学的影响,研究认为第二相颗粒体积分数越大,单个第二相颗粒尺寸越大,对晶界钉扎作用越强,而当体积分数一定时,第二相颗粒尺寸越小,总的钉扎效果越强,最终系统的晶粒尺寸越小。当变形温度较低(200和300 ℃)和应变速率较高(1 s-1)时,第二相颗粒Al4Sr相发生断裂,破碎程度小,对基体晶粒晶界的钉扎作用强,在热变形过程中,位错钉扎、晶界迁移都会受到制约,恢复软化机制减弱,塑性变形抗力大;当变形温度较高(400和500 ℃)和应变速率较低(0.1和0.01 s-1)时,Al4Sr相破裂严重,铝基体原子扩散、位错运动和晶界迁移都有一定程度的增强,恢复软化机制能力增大,流变应力变小;变形温度为500 ℃时,第二相颗粒尺寸虽比400 ℃时大,但温度对合金恢复软化机制的影响远大于第二相颗粒的作用,从弯曲状的Al4Sr相可以看出,故流变应力小。

综上所述,铝锶合金热塑性变形工艺参数和显微组织演变之间的关系错综复杂,在应变速率和变形温度的双重影响下,合金的应力、应变会发生变化,其显微组织也会发生变化。显微组织演变不仅受变形温度、应变速率等外在因素的影响,而且还取决于合金基体中第二相颗粒尺寸大小。

3 本构方程的建立

本构方程是表征金属塑性变形时流变应力和应变之间的关系[27-28]。Al-Sr合金在热变形过程中对变形温度和应变速率都很敏感。材料的本构模型有很多种,不存在普遍使用的构造方法,而大多数模型属于经验或半经验模型,本文作者依据Arrhenius方程中双曲正弦模型进行建立[29-31]:

(1)

(1)

式中: 为应变速率,s-1;Q为变形激活能,J/mol,与材料有关;σ为流变应力,MPa;n为应力指数;T为热力学温度,K;R为摩尔气体常数,8.314 J/(mol·K);A和α为与材料有关的常数。在金属材料热变形过程中,该式可以在任何应力范围内描述其流变应力的变化规律。通常在低应力水平和高应力水平条件下,Arrhenius方程中的双曲正弦函数可以简化成指数函数或者幂指数函数形式。

为应变速率,s-1;Q为变形激活能,J/mol,与材料有关;σ为流变应力,MPa;n为应力指数;T为热力学温度,K;R为摩尔气体常数,8.314 J/(mol·K);A和α为与材料有关的常数。在金属材料热变形过程中,该式可以在任何应力范围内描述其流变应力的变化规律。通常在低应力水平和高应力水平条件下,Arrhenius方程中的双曲正弦函数可以简化成指数函数或者幂指数函数形式。

(2)

(2)

(3)

(3)

式中:β=αn1,先对式(1)、(2)和(3)取自然对数,分别得到:

(4)

(4)

(5)

(5)

(6)

(6)

对式(5)和(6)求偏微分可得: ,

, 。

。

因此可以看出:n1和β分别是到 和

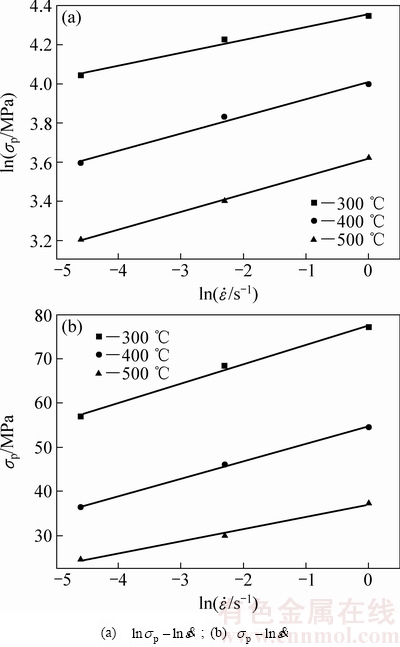

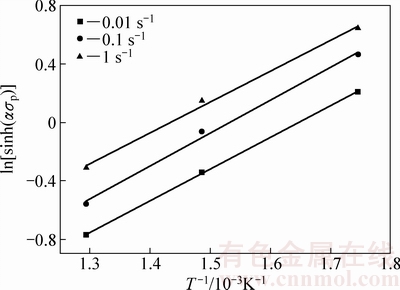

和 曲线方程斜率的倒数,运用Origin软件处理不同温度下的应力峰值和对应的应变速率,如图6所示。β值取高应力水平[32],即变形温度为300 ℃时的β值,则β=0.22802;n1值取低应力水平,即变形温度为400和500 ℃时的平均值,则n1=12.54962。所以α=β/n1=0.01817。

曲线方程斜率的倒数,运用Origin软件处理不同温度下的应力峰值和对应的应变速率,如图6所示。β值取高应力水平[32],即变形温度为300 ℃时的β值,则β=0.22802;n1值取低应力水平,即变形温度为400和500 ℃时的平均值,则n1=12.54962。所以α=β/n1=0.01817。

图6 不同温度下铝锶合金峰值应力与应变速率之间的关系

Fig. 6 Relationship between peak stress and strain rate of Al-Sr alloy at different temperatures

铝锶合金连续挤压过程中没有发生相变,假定在一定范围内热变形激活能Q与变形温度T无关[33],对式(4)求偏微分可得到如下方程:

(7)

(7)

(8)

(8)

式中:n值和Q值可以通过图7和图8中直线的斜率平均值求得,则变形激活能Q=179165 J/mol。

图7  关系图

关系图

Fig. 7 Relationship between  and

and  at different temperatures

at different temperatures

图8  关系图

关系图

Fig. 8 Relationship between  and T-1 at different strain rates

and T-1 at different strain rates

金属材料高温塑性变形行为是材料内部微观变形机理和显微组织演化的综合表现。Zener和Hollomon研究[34]指出,材料热变形行为受变形激活能Q影响,所以应力应变之间的关系又可以由Z参数来表示:

(9)

(9)

将Z参数方程代入式(1)中,两边取自然对数得:

(10)

(10)

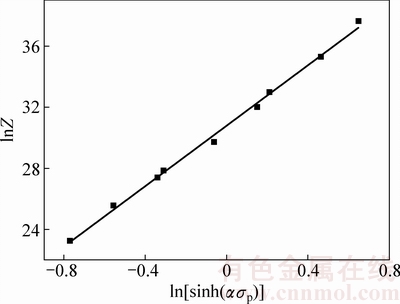

对得到lnZ- 数据进行线性回归,得到如图9的关系曲线,即A=2.456×1013,n=9.8872。

数据进行线性回归,得到如图9的关系曲线,即A=2.456×1013,n=9.8872。

图9  关系曲线

关系曲线

Fig. 9 Relationship between lnZ and

将求得的A、α、n及Q代入式(1),得到Al-Sr合金Arrhenius流变应力本构方程,该方程可用来模拟Al10Sr合金一般加载条件下(变形温度300~500 ℃时)的热成形过程,其表达式为

(11)

(11)

4 结论

1) 铝锶合金热变形流变应力随着变形温度的降低和应变速率的升高而增加,说明变形温度和应变速率是影响其变形工艺的主要因素。在整个变形过程,材料经历了从加工硬化阶段逐渐过渡到稳态变形阶段。

2) 当变形温度较低(200和300 ℃)和应变速率较高(1 s-1)时,合金中Al4Sr相主要呈长针状,其形貌和尺寸没有明显变化;变形温度较高时(400和500 ℃)和变形速率较低(0.01和0.1 s-1)时,Al4Sr相破碎严重,呈板块状;变形温度为500 ℃时,温度超过了第二相颗粒脆韧转变温度(BDTT),Al4Sr相具有延展性而易发生弯曲变形。

3) 铝锶合金恢复软化机制主要是动态回复,原子扩散、位错钉扎、晶界迁移以及第二相颗粒尺寸对硬化和软化行为有显著的影响。

4) 依据热模拟压缩实验结果,采用Arrhenius方程中双曲正弦模型来描述铝锶合金应力与应变之间的关系,利用Origin软件进行线性回归,建立其本构方程。

REFERENCES

[1] 任 峻, 陶钦贵, 马 颖. Al-Ti-B合金晶粒细化剂及细化机理的发展与现状[J]. 铸造技术, 2007, 28(1): 69-73.

REN Jun, TAO Qin-gui, MA Ying. Development and situation of refinement mechanism and grain refinement of Al-Ti-B alloy[J]. Foundry Technology, 2007, 28(1): 69-73.

[2] 陈鸿国. 铝-锶合金长效变质剂的应用[J]. 轻合金加工技术, 1992, 20(2): 13-16.

CHEN Hong-guo. Application of long-acting modifier Al-Sr alloy[J]. Light Alloy Fabrication Technology, 1992, 20(2): 13-16.

[3] 王顺成, 陈彦博, 温景林. 变质剂Al-Sr中间合金的制备及其变质效果[J]. 轻合金加工技术, 2003, 31(1): 4-6.

WANG Shun-cheng, CHEN Yan-bo, WEN Jing-lin. Research on preparation of Al-Sr master alloy and the modification effect[J]. Light Alloy Fabrication Technology, 2003, 31(1): 4-6.

[4] 赵淑荣. 变质处理对ZL101合金力学性能的影响[D]. 昆明: 昆明理工大学, 2012: 9-10.

ZHAO Shu-rong. The influence of modification on mechanical properties of ZL101 alloy[D]. Kunming: Kunming University of Science and Technology, 2012: 9-10.

[5] 程仁菊, 潘复生, 王维青. Al-Sr中间合金制备及应用的发展现状[J]. 轻合金加工技术, 2006, 34(7): 5-11.

CHENG Ren-ju, PAN Fu-sheng, WANG Wei-qing. Development status of preparation and application of Al-Sr master alloy[J]. Light Alloy Fabrication Technology, 2006, 34(7): 5-11.

[6] 高泽生. 铝-锶合金长效变质剂的生产[J]. 轻合金加工技术, 1992, 20(1): 16-19.

GAO Ze-sheng. Production of long-acting modifer Al-Sr alloy[J]. Light Alloy Fabrication Technology, 1992, 20(1): 16-19.

[7] 廖成伟, 陈建春, 潘春旭. Al-Sr 中间合金中Al4Sr相微结构及其对变质性能的影响[C]//2011中国材料研讨会论文摘要集, 2011: 805-814.

LIAO Cheng-wei, CHEN Jian-chun, PAN Chun-xu. Microstructure of Al4Sr phase in Al-Sr master alloy and its effect on modification properties[C]//2011 Chinese Materials Conference, 2011: 805-814.

[8] 宋宝韫, 樊志新, 陈吉光, 刘元文, 贾春博. 铜、铝连续挤压技术特点及工业应用[J]. 稀有金属, 2004, 28(1): 257-261.

SONG Bao-yun, FAN Zhi-xin, CHEN Ji-guang, LIU Yuan-wen, JIA Chun-bo. Features of copper and aluminum continuous extrusion process and industrial application[J]. Chinese Journal of Rare Metals, 2004, 28(1): 257-261.

[9] 樊志新, 陈 莉, 孙海洋. 连续挤压技术的发展与应用[J]. 中国材料进展, 2013, 32(5): 276-282.

FAN Zhi-xin, CHEN Li, SUN Hai-yang. Development and application of continuous extrusion technology[J]. Materials China, 2013, 32(5): 276-282.

[10] 张文玉, 刘先兰, 陈振华. 异步轧制AZ31镁合金板材室温冲压性能研究[J]. 塑性工程学报, 2007, 14(4): 6-10.

ZHANG Wen-yu, LIU Xian-lan, CHEN Zhen-hua. Research on drawability of AZ31 magnesium alloy sheet processed by differential speed rolling at room temperature[J]. Journal of Plasticity Engineering, 2007, 14(4): 6-10.

[11] 黄光胜, 徐 伟, 黄光杰, 刘天模, 汪凌云, 潘复生. 镁合金板材冲压性能与冲压工艺研究进展[J]. 材料导报, 2006, 20(11): 73-76.

HUANG Guang-sheng, XU Wei, HUANG Guang-jie, LIU Tian-mo, WANG Ling-yun, PAN Fu-sheng. The development of stamping properties and stamping technology of magnesium alloy sheet[J]. Materials Review, 2006, 20(11): 73-76.

[12] 于彦东, 李彩霞. 镁合金AZ31B板材热拉深成形工艺参数优化[J]. 中国有色金属学报, 2006, 16(5): 786-792.

YU Yan-dong, LI Cai-xia. Optimization of processing parameters for magnesium alloy AZ31B sheets in thermal deep-drawing process[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(5): 786-792.

[13] 苌群峰, 李大永, 彭颖红, 曾小勤. AZ31镁合金板材温热冲压数值模拟与实验研究[J]. 中国有色金属学报, 2006, 16(4): 580-585.

CHANG Qun-feng, LI Da-yong, PENG Ying-hong, CENG Xiao-qin. Numerical simulation and experimental study of warm deep drawing of AZ31 magnesium alloy sheet[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(4): 580-585.

[14] 刘祖岩, 刘 刚, 梁书锦. AZ31镁合金应力-应变关系的测定与四维描述[J]. 稀有金属材料与工程, 2007, 36(3): 304-307.

LIU Zu-yan, LIU Gang, LIANG Shu-jin. Measurement of the stress-strain relationship of AZ31 magnesium alloy and its four-dimensional description[J]. Rare Metal Materials & Engineering, 2007, 36(9): 304-307.

[15] 寇琳媛, 金能萍, 张 辉, 韩 逸, 吴文祥, 李落星. 7150铝合金高温热压缩变形流变应力行为[J]. 中国有色金属学报, 2010, 20(1): 43-48.

KOU Lin-yuan, JIN Neng-ping, ZHANG Hui, HAN Yi, WU Wen-xiang, LI Luo-xing. Flow stress behavior of 7150 aluminum alloy during hot compression deformation at elevated temperature[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(1): 43-48.

[16] 陈修梵, 彭小燕, 张慧颖, 肖 丹, 王恒玉, 徐国富. 7050铝合金热压缩变形的流变行为及微观组织演变[J]. 特种铸造及有色合金, 2015, 35(12): 1237-1242.

CHEN Xiu-fan, PENG Xiao-yan, ZHANG Hui-ying, XIAO Dan, WANG Heng-yu, XU Guo-fu. Characterization of flow behavior and microstructural evolution of 7050 aluminum alloy during hot compression process[J]. Special Casting & Nonferrous Alloys, 2015, 35(12): 1237-1242.

[17] 贾 乐, 陈康华, 陈送义, 彭国胜, 董鹏轩, 金狂浩. 7085铝合金的高温压缩流变应力及软化行为[J]. 粉末冶金材料科学与工程, 2012, 17(4): 423-429.

JIA Le, CHEN Kang-hua, CHEN Song-yi, PENG Guo-sheng, DONG Peng-xuan, JIN Kuang-hao. Flow stress and softening behavior of 7085 aluminum alloy during compression deformation at elevated temperature[J]. Materials Science & Engineering of Powder Metallurgy, 2012, 17(4): 423-429.

[18] 张红钢, 张 辉, 刘婉容, 林启权, 林高用, 彭大暑. C194铜合金热压缩变形流变应力[J]. 湘潭大学自科学报, 2003, 25(3): 82-86.

ZHANG Hong-gang, ZHANG Hui, LIU Wan-rong, LIN Qi-quan, LIN Gao-yong, PENG Da-shu. Rheologic stress of C194 copper alloy under hot compression deformation[J]. Natural Science Journal of Xiangtan University, 2003, 25(3): 82-86.

[19] 翁舒楚. 7150铝合金热变形过程中动态组织演变规律研究[D]. 长沙: 湖南大学, 2012: 20-21.

WENG Shu-chu. Study on the dynamic microstructural evolution of the 7150 aluminum alloy during hot deformation[D]. Changsha: Hunan University, 2012: 20-21.

[20] 丁汉林. AZ91镁合金高温变形行为的实验研究与数值模拟[D]. 上海: 上海交通大学, 2007: 62-63.

DING Han-lin. Experimental study and numerical simulation of hot deformation behaviors of AZ91 alloy[D]. Shanghai: Shanghai Jiao Tong University, 2007: 62-63.

[21] 肖 罡, 李落星, 刘志文, 叶 拓. 6013铝合金的热变形行为及热加工图[J]. 材料热处理学报, 2014, 35(10): 23-28.

XIAO Gang, LI Luo-xing, LIU Zhi-wen, YE Tuo. Hot deformation behavior and processing map of 6013 aluminum alloy[J]. Transactions of Materials and Heat Treatment, 2014, 35(10): 23-28.

[22] TAVIGHI K, EMAMY M, EMAMI A R. Effects of extrusion temperature on the microstructure and tensile properties of Al-16wt%Al4Sr metal matrix composite[J]. Materials & Design, 2013, 46(4): 598-604.

[23] KHANTHA M, POPE D P, VITEK V. Dislocation generation instability and the brittle-to-ductile transition[J]. Materials Science and Engineering A, 1995, s192/193(94): 435-442.

[24] 王 冠, 卞东伟, 寇琳媛, 易 杰, 刘志文, 李落星. 多尺度铝合金变形组织演变模型研究进展[J]. 精密成形工程, 2017(1): 10-16.

WANG Guan, BIAN Dong-wei, KOU Lin-yuan, YI Jie, LIU Zhi-wen, LI Luo-xing. Research progress in multi-scale modelling of microstructure evolution during hot deformation of aluminum alloy[J]. Journal of Netshape Forming Engineering, 2017(1): 10-16.

[25] GOURDET S, MONTHEILLET F. Effects of dynamic grain boundary migration during the hot compression of high stacking fault energy metals[J]. Acta Materialia, 2002, 50(11): 2801-2812.

[26] 李俊杰, 王锦程, 杨根仓. 含第二相颗粒的晶粒长大过程相场法[J]. 稀有金属材料与工程, 2008, 37(10): 1746-1750.

LI Jun-jie, WANG Jin-cheng, YANG Gen-cang. Phase-field simulation of grain growth in systems containing second-phase particles[J]. Rare Metal Materials and Engineering, 2008, 37(10): 1746-1750.

[27] HUANG J S, HUANG L, LIU B, ZHANG Y H, ZHANG W, HE X Y, LIU Y. Simulation of hot compression of Ti-Al alloy[J]. Intermetallics, 2007, 15(5/6): 700-705.

[28] ZENG Z, JONSSON S, ZHANG Y. Constitutive equations for pure titanium at elevated temperatures[J]. Materials Science and Engineering A, 2009, 505(1): 116-119.

[29] SELLARS C M, MCTEGART W J. On the mechanism of hot deformation[J]. Acta Metallurgica, 1966, 14(9): 1136-1138.

[30] WHITTENBERGER J D. The influence of grain size and composition on slow plastic flow in FeAl between 1100 and 1400 K[J]. Materials Science & Engineering, 1986, 77(1/2): 103-113.

[31] IMBERT C A C, MCQUEEN H J. Peak strength, strain hardening and dynamic restoration of A2 and M2 tool steels in hot deformation[J]. Materials Science and Engineering A, 2001, 313(1/2): 88-103.

[32] 李 亮, 彭富昌. 高纯钛热变形的本构模型及微观组织演变[J]. 功能材料, 2014, 45(S2): 76-80.

LI Liang, PENG Fu-chang. Investigation on constitutive model and microstructure evolution of high purity titanium during hot deformation[J]. Journal of Functional Materials, 2014, 45(S2): 76-80.

[33] 戚运莲. Ti600高温钛合金的热变形行为及加工图研究[D]. 西安: 西北工业大学, 2007: 18-30.

QI Yun-lian. Study on hot deformation behavior and processing map of high temperature titanium alloy Ti600[D]. Xi’an: Northwestern Polytechnical University, 2007: 18-30.

[34] ZENER C, HOLLOMON J H. Effect of strain rate upon plastic flow of steel[J]. Journal of Applied Physics, 1944, 15(1): 22-32.

Pyroplastic deformation behavior and constitutive equation of Al-Sr alloy

WAN Fan, YUN Xin-bing, BI Sheng, PEI Jiu-yang

(Engineering Research Center of Continuous Extrusion, Dalian Jiaotong University, Dalian 116028, China)

Abstract: The pyroplastic deformation experiment of Al-Sr alloy was studied on the Gleeble-1500 thermal-mechanical simulator, which was based on the continuous extrusion process. The pyroplastic deformation behavior of Al-Sr alloy was systematically studied the effects of deformation temperature and strain rate on the flow stress and Al4Sr phase of Al-Sr alloy during hot deformation were analyzed, and the constitutive equation of Al-Sr alloy by linear regression analysis was established. The results show that the main softening mechanism of the Al-Sr alloy under the pyroplastic deformation is dynamic recovery; and the rheological stress decreases with increasing the temperature, and increases with increasing the strain rate. When the deformation temperature was 400 ℃, the Al4Sr phase break seriously; once the deformation temperature was 500 ℃, the particles become ductile and flexible. The thermal deformation behavior can be described by the Arrhenius hyperbolic sine equation with Zener-Hollomon parameters.

Key words: Al-Sr alloy; pyroplastic deformation; rheological stress; microstructure; constitutive equation

Foundation item: Project(LR2015011) supported by Universities Excellent Talent Support Plan of Liaoning Province, China

Received date: 2017-05-10; Accepted date: 2017-07-28

Corresponding author: YUN Xin-bing; Tel: +86-411-84109416; E-mail: yunxb@djtu.edu.cn

(编辑 龙怀中)

基金项目:辽宁省高等学校优秀人才支持计划资助项目(LR2015011)

收稿日期:2017-05-10;修订日期:2017-07-28

通信作者:运新兵,教授,博士;电话:0411-84109416;E-mail:yunxb@djtu.edu.cn