文章编号:1004-0609(2013)08-2091-07

2A14铝合金热变形的显微组织及流变行为

刘文胜,郭伦文,马运柱,王 娟,刘东亮

(中南大学 粉末冶金国家重点实验室,长沙 410083)

摘 要:在Gleeble-3500热模拟机上对2A14铝合金进行热压缩实验,研究该合金在变形温度为350~480 ℃、应变速率为0.001~10 s-1条件下热压缩变形的显微组织特征和流变应力行为。采用光学显微镜(OM)和透射电镜(TEM)对变形后的显微组织进行表征。结果表明:随着应变速率的降低和变形温度的升高,合金中拉长的晶粒粗化,发生部分动态再结晶,合金的主要软化机制由动态回复向动态再结晶转变;合金的流变应力随变形温度的升高和应变速率的降低而减小。合金热变形的流变应力行为可用双曲正弦形式的本构方程来描述,也可用Zener-Hollomon参数来描述,其变形激活能为173.375 kJ/mol。

关键词:金属材料;铝合金;热压缩变形;显微组织;本构方程

中图分类号:TG 146.21 文献标志码:A

Microstructure and flow behavior of 2A14 aluminum alloy during hot deformation

LIU Wen-sheng, GUO Lun-wen, MA Yun-zhu, WANG Juan, LIU Dong-liang

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: The flow stress behavior of 2A14 alloy during hot compression deformation was investigated by thermal simulation experiment at the temperature range of 350-480 ℃ and the strain rate range of 0.001-10 s-1 with Gleeble-3500 thermal simulation machine. The deformation microstructures were observed by optical microscopy (OM) and transmission electron microscopy (TEM). The results show that the elongated grains coarsen with decreasing strain rate and increasing temperature. The partial recrystallization takes place in the alloys deformed at high temperature or low strain rate. The main soften mechanism of the alloy transforms from dynamic recovery to dynamic recrystallization. The flow stress reduces with the increasing deformation temperature and decreasing strain rate. The flow stress of the alloy during hot compression deformation can be described by constitutive equation in hyperbolic sine function and can also be described by Zener-Hollomon parameters, and the hot deformation activation energy is 173.375 kJ/mol.

Key words: metallic materials; aluminum alloy; hot compression deformation; microstructure; constitutive equation

2A14铝合金属于Al-Cu-Mg-Si系锻造合金,也被称为高强度锻铝,该合金具有强度高、热塑性好、工作温度较高等优点,主要用于形状复杂的自由锻件和精密模锻件,广泛应用于航空航天及民用交通工具等领域[1-2]。2A14铝合金接头、尾翼、壳体、轮毂等航空锻件形状复杂,具有高肋、薄腹、深腔等成形难点。为了得到性能达标的工件,国内外学者对其热加工工艺和热处理制度展开了较多的研究,而对其在热变形条件下流变应力的行为研究较少。郭鸿镇等[3-4]着重研究2A14铝合金的预处理工艺,利用其超塑性得到高筋薄壁板大型飞机结构件,同时探索其ECAP工艺及晶粒细化效果,为该合金的超塑近净成形技术开发奠定基础;TANNER等[5]研究2A14螺旋桨模锻件热处理工艺,发现在时效温度170 ℃,时效时间12 h条件下,合金具有最好的力学性能和耐腐蚀性能;洪慎章等[6]提出采用等温模锻工艺生产2A14起落架轮毂,能有效提高锻件性能及尺寸精度。

数值仿真技术已广泛应用于铝合金加工生产中,相比于传统的试错法,该技术可有效缩短产品设计生产周期、降低生产成本、提高锻件质量。材料的本构模型是数值仿真的基础,是影响仿真结果准确性的重要因素。为此,本文作者对2A14合金进行高温热压缩实验,研究此类铝合金在压缩变形时的组织特征和流变应力行为,建立本构模型,为该类材料的热加工工艺提供理论与实验依据[7]。

1 实验

实验所用2A14铝合金为西南铝业(集团)有限责任公司提供,合金铸锭的化学成分(质量分数,%)为Cu 4.47,Si 0.63,Mg 0.58,Mn 0.49,Fe 0.22,Al 余量。铸锭经480 ℃、12 h均匀化处理后,线切割加工成尺寸为d 10 mm×15 mm的Rastegaev样品。在Gleeble-3500热模拟试验机上进行等温恒应变速率热压缩实验,实验过程如下:热压缩前在试样两端贴上钽片,并涂抹润滑剂,以减少试样与压头之间的摩擦。以5 ℃/s的升温速率加热到热压缩温度(350、400、450和480 ℃),保温5 min后,分别以0.001、0.01、0.1、1和10 s-1的恒应变速率压缩,总变形量为50%,总应变量为0.7。试验过程中,Gleeble-3500热模拟机自动采集应力、应变和温度等数据,绘制不同条件下的真应力—真应变曲线。变形后立即水淬,以保留热变形组织。

压缩后的试样沿压缩方向对半切开,抛光后经Keller试剂(1 mL HF+1.5 mL HCl+2.5 mL HNO3+95 mL H2O)腐蚀,采用PME3-313uN型倒置式大型金相显微镜观察显微组织。透射电镜(TEM)取样部位与之相同,样品先进行机械减薄,随后通过电解双喷制成观察样品,TEM观察所用电镜为JEM-2100F透射电子显微镜,加速电压为200 kV。

2 结果与分析

2.1 2A14铝合金的热压缩变形显微组织特征

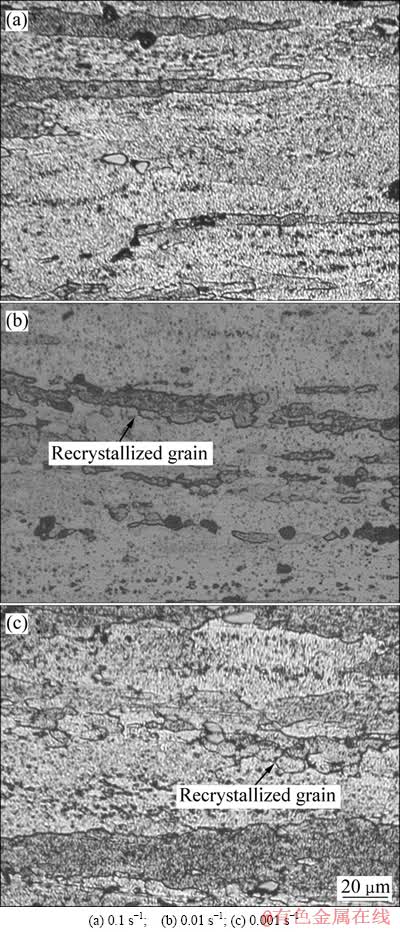

图1所示为450 ℃变形温度下合金分别以0.1、0.01和0.001 s-1应变速率变形后的金相显微组织。从图1可以观察到,2A14合金热压缩变形后的组织中均存在沿垂直于压缩方向拉长的变形晶粒,部分应变速率下合金中出现再结晶晶粒。在应变速率为0.1 s-1条件下,组织中只有拉长的变形晶粒(见图1(a)),表现为典型的动态回复组织;当应变速率减小到0.01 s-1时,拉长的变形晶粒周围出现少量细小的再结晶晶粒(见图1(b)),说明在该条件下发生较小程度的动态再结晶;当应变速率进一步减小到0.001 s-1时,拉长的晶粒周围出现较大尺寸的再结晶晶粒(见图1(c)),说明在该条件下再结晶晶粒发生进一步长大。

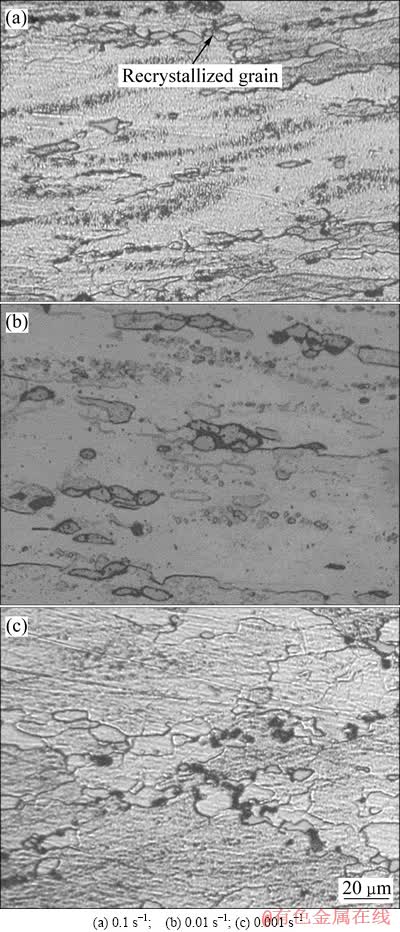

图2所示为480 ℃变形温度下合金同样分别以0.1、0.01和0.001 s-1应变速率变形后的金相显微组织。

图1 变形温度为450 ℃时不同应变速率下合金的金相显微组织

Fig. 1 Optical microstructures of alloys compressed at deformation temperature of 450 ℃ and different strain rates

从图2中可以看出,在3种变形条件下合金中均出现再结晶晶粒,并且再结晶晶粒的尺寸与体积分数均随应变速率的减小而增大。对比图1与2可以看出,随着变形温度的升高,拉长的变形晶粒变得不明显,晶界变得更清晰;在0.1 s-1应变速率条件下,当变形温度升高到480 ℃时,开始出现再结晶晶粒(见图1(a)与2(a)),说明合金组织开始由动态回复向动态再结晶转变;在0.01 s-1和0.001 s-1应变速率条件下,再结晶晶粒的尺寸和体积分数也随着变形温度的升高而增大(见图1(b)与2(b)、1(c)与2(c))。

图2 变形温度为480 ℃时不同应变速率下合金的金相显微组织

Fig. 2 Optical microstructures of alloys compressed at deformation temperature of 480 ℃ and different strain rates

上述结果表明,应变速率和变形温度是2A14铝合金组织变化的重要影响因素。合金在较高温度下的塑性变形是加工硬化与动态软化的动态平衡过程,其主要软化机制是动态回复和动态再结晶。铝属于高层错能金属,在高温变形过程中易通过攀移和交滑移产生动态回复,但在一定条件下也发生动态再结晶。在热变形过程中,刃位错的攀移和螺位错的交滑移造成异号位错相互吸引而抵消,同号位错相互排斥,形成很多封闭的胞壁。随着变形的进行,位错胞壁多边形化形成规则的边界,构成小角度亚晶[8-9],此时,合金的主要软化机制为动态回复。在相同的应变速率条件下,随变形温度的升高,原子热振动的动能增加,原子间的结合力减弱,位错滑移阻力减小,不断产生新的滑移,位错间的相互抵消和重组作用加强,亚晶通过不断的合并,形成再结晶晶核。随着变形的进行,再结晶晶核长大为完整的再结晶晶粒,此时合金的软化机制由动态回复向动态再结晶转变。而在相同变形温度下,随着应变速率的减小和变形时间延长,位错的攀移和交滑移更加充分,合金组织中的动态回复与再结晶程度也越大。

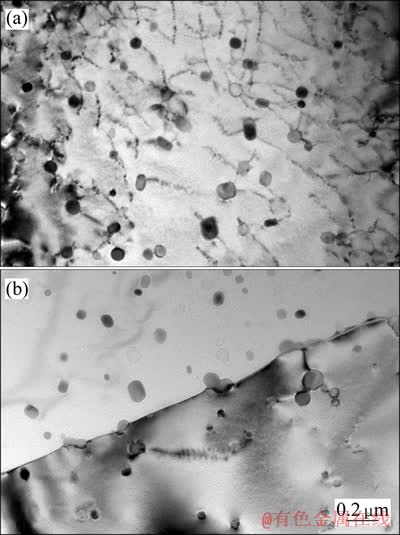

图3 2A14铝合金在TEM下第二相粒子对位错和晶界的钉扎作用

Fig. 3 TEM images showing pinning effect of second phase particles on dislocations(a) and grain boundaries(b) of 2A14 aluminum alloy

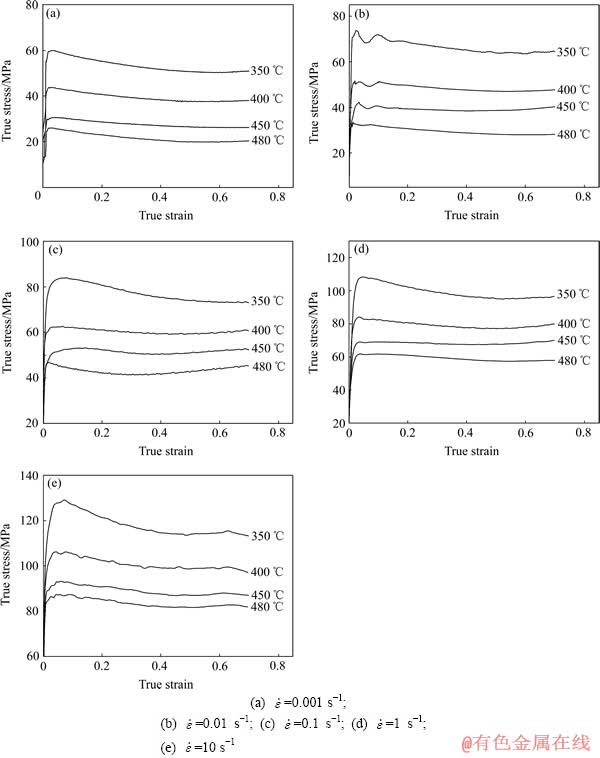

图4 2A14铝合金在不同温度和应变速率条件下压缩变形的真应力—真应变关系曲线

Fig. 4 True stress—true strain curves of 2A14 aluminum alloy during hot compression deformation under condition of different temperatures and strain rates

对比其他体系的铝合金材料[10-12],在本实验中,2A14铝合金的发生动态再结晶需要更低的临界应变速率和更高的临界变形温度,研究发现这与合金组织中存在较多的CuAl2、CuMgAl2等第二相粒子有关[13]。对变形温度为450 ℃、应变速率为0.01 s-1的组织进行了透射电镜观察,如图3所示。从图3中可以看出,合金中均匀分布着细小的第二相粒子,尺寸在0.05~ 0.15 μm之间,这些弥散分布的粒子钉扎在位错和晶界上。在图3(a)中,第二相粒子对位错产生钉扎作用,刃位错的攀移和螺位错的交滑移被延缓,减弱了动态再结晶的亚晶形核;同时,第二相粒子也钉扎在晶界上(见图3(b)),阻碍再结晶晶界的迁移,减慢了再结晶晶粒的长大速度。这些作用都会抑制该条件下的动态再结晶进程,材料发生较少程度的动态再结晶,符合金相组织观察结果(见图1(b))。

2.2 热压缩变形的真应力—真应变关系

图4所示为2A14合金在不同温度和应变速率条件下压缩变形的真应力—真应变关系曲线。由图4可知,在变形初级阶段,合金的真应力随真应变的增加迅速增大,这是由于形变致使合金内部的位错密度迅速增加,而金属内部位错的攀移和交滑移所引起的软化作用不足以补偿变形导致的硬化作用所致。流变应力达到峰值以后,软化作用增强,流变应力有不同程度的减小;最后进入稳态流变阶段,加工硬化与软化作用达到动态平衡,流变应力保持相对平稳,在400 ℃以上,稳态流变阶段更为明显,其实质是在稳态阶段合金内部的位错增殖速率和位错消亡速率达到动态平衡[14]。在相同温度下,随应变速率的增加,材料的流变应力升高,说明2A14合金在该实验条件下具有正的应变速率敏感性;而在相同应变速率下,流变应力随变形温度的升高而降低。这些与合金的动态回复和动态再结晶软化机制有关,符合显微组织观察结果。

在应变速率为0.01 s-1的真应力—真应变曲线上出现一定程度波浪形变化(见图4(b)),呈现不连续动态再结晶特点。在该变形条件下,动态回复引起的软化作用难以同步抵消变形时位错增殖引起的硬化作用,当位错积累到一定程度后引发了动态再结晶形核,而在发生动态再结晶软化后,位错增殖速度不能满足继续进行再结晶的条件,再结晶软化作用减弱,以致不能与新的加工硬化平衡,曲线重新上升。等到位错再度积累到一定程度,使再结晶又占上风时,曲线又重新下降。因此,这种情况下,动态再结晶与加工硬化交替进行,使曲线表现出呈波浪式特征。

2.3 热压缩流变应力本构方程

合金的高温热变形行为可用Sellars和Tegart提出的包含变形激活能Q和变形温度T的双曲线正弦形式的Arrhrnius关系来描述[15-16]:

(1)

(1)

式中: 为合金变形应变速率,s-1;A为结构因子,s-1;

为合金变形应变速率,s-1;A为结构因子,s-1; 为应力水平参数,MPa-1;σ为流变应力;n为应力指数;Q为变形激活能,J/mol;R为摩尔气体常数,J/(mol·K);T为变形温度,K。其中,A、

为应力水平参数,MPa-1;σ为流变应力;n为应力指数;Q为变形激活能,J/mol;R为摩尔气体常数,J/(mol·K);T为变形温度,K。其中,A、 、n、Q值为待求的参数值。

、n、Q值为待求的参数值。

在高应力条件下( >1.2):

>1.2):

(2)

(2)

在低应力条件下( <0.8):

<0.8):

(3)

(3)

式中: ;

; ;

; 。

。

对式(2)和(3)两边取对数可得

(4)

(4)

(5)

(5)

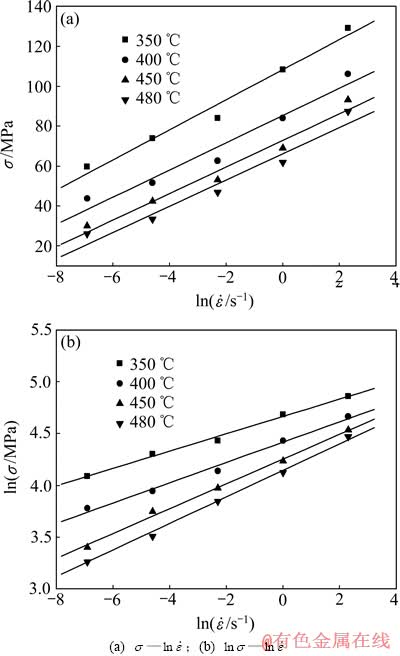

由式(4)和(5)可知,取不同变形条件下的真实峰值应力,分别绘制 和

和 的关系图,如图5所示;用最小二乘法线性回归,图5(a)和(b)中直线的线性相关系数分别大于0.977和0.996,得到β=0.145 MPa-1,n=8.621,所以,α =β/n=0.016 89 MPa-1。

的关系图,如图5所示;用最小二乘法线性回归,图5(a)和(b)中直线的线性相关系数分别大于0.977和0.996,得到β=0.145 MPa-1,n=8.621,所以,α =β/n=0.016 89 MPa-1。

假设合金的变形激活能Q与温度T无关,在式(1)两边取对数可得:

(6)

(6)

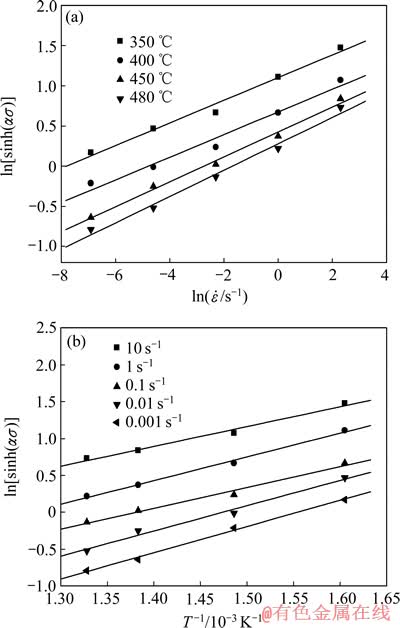

将2A14合金在不同温度下的峰值应力、应变速率以及上述求得的 值代入式(6),通过线性拟合得到

值代入式(6),通过线性拟合得到 —

— 和

和 —

— 关系曲线,如图6所示。由图6中所示直线的斜率可以计算出n=6.645,变形激活能 Q=173.375 kJ/mol。

关系曲线,如图6所示。由图6中所示直线的斜率可以计算出n=6.645,变形激活能 Q=173.375 kJ/mol。

求得材料的热变形激活能Q值后,热变形条件和流变应力的关系可通过材料的温度补偿应变速率因子Zener-Hollomon参数来描述[17],由式(1)可得

(7)

(7)

通过对式(7)变形可得

(8)

(8)

(9)

(9)

根据双曲正弦函数的定义,可得σ与Z参数的关系:

(10)

(10)

对式(7)两边取对数可得

(11)

(11)

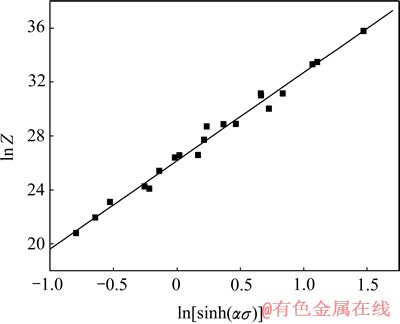

将不同变形温度下的应变速率 和求得的激活能Q代入式(7)可得不同的Z值,又将不同温度下的峰值应力代入式(11),运用线性回归方法得到

和求得的激活能Q代入式(7)可得不同的Z值,又将不同温度下的峰值应力代入式(11),运用线性回归方法得到 与

与 的关系曲线如图7所示,其关系式为

的关系曲线如图7所示,其关系式为 =26.155+6.552

=26.155+6.552 ,得到结构因子A= 2.285 45×1011 s-1。

,得到结构因子A= 2.285 45×1011 s-1。

图5 2A14铝合金应变速率与流变应力的关系

Fig. 5 Relationships between strain rate and flow stress of 2A14 aluminium alloy

图6 2A14铝合金应变速率和热变形温度与流变应力的关系

Fig. 6 Relationships between strain rate (a) and hot deformation temperature (b) and flow stress of 2A14 aluminium alloy

综上所述,将所得的结构因子A、应力指数n、应力水平参数α和激活能Q代入式(1)和式(10),可得2A14合金的流变应力本构方程为

该方程适用于应变速率为0.001~10 s-1,变形温度为350~480 ℃,总变形量为50%的2A14铝合金的流变应力行为。

图7 2A14铝合金流变应力与Z参数的关系

Fig. 7 Relations between stress and Z parameter of 2A14 aluminium alloy

3 结论

1) 2A14合金的热变形组织特征为动态回复并伴随部分动态再结晶;随着应变速率的减小和热变形温度的升高,合金中的主要软化机制逐步由动态回复转变为动态再结晶。同时,该合金中弥散分布的第二相粒子对位错和晶界的钉扎作用,一定程度上抑制动态再结晶的形核与长大。

2) 2A14铝合金的流变应力在变形初期随着应变的增加而迅速增大至峰值,在后期表现出明显的稳态流变特征;合金的流变应力随应变速率的增大而增大,随变形温度的升高而减小。

3) 用线性回归方法求得2A14铝合金高温变形的4个特征常数:结构因子A=2.285 45×1011 s-1,应力水平参数 = 0.016 89 MPa-1,应力指数n=6.645,变形激活能Q=173.375 kJ/mol。合金的应变速率和流变应力满足以下本构方程:

= 0.016 89 MPa-1,应力指数n=6.645,变形激活能Q=173.375 kJ/mol。合金的应变速率和流变应力满足以下本构方程:

REFERENCES

[1] 潘复生, 张丁非. 铝合金及应用[M]. 北京: 化学工业出版社, 2006: 305-306.

PAN Fu-sheng, ZHANG Ding-fei. Aluminum alloy and its application[M]. Beijing: Chemical Industry Press, 2006: 305-306.

[2] 王乐安. 特种合金及其锻造[M]. 北京: 国防工业出版社, 2009: 272-273.

WANG Le-an. Special alloy and its forging[M]. Beijing: National Defense Industry Press, 2009: 272-273.

[3] 段春燕, 郭鸿镇, 姚泽坤, 张 维, 虢迎光, 王宝善. LD10热轧棒材的预处理工艺及超塑性[J]. 热加工工艺, 2007(7): 11-13.

DUAN Chun-yan, GUO Hong-zhen, YAO Ze-kun, ZHANG Wei, GUO Ying-guang, WANG Bao-shan. Pretreatment technologies and superplasticity of LD10 hot-rolled bars[J]. Hot Working Technology, 2007(7): 11-13.

[4] 袁士翀, 郭鸿镇, 王晓燕, 杨守良, 姚泽坤. LD10合金ECAP工艺参数的研究[J]. 金属铸锻焊技术, 2008, 37(2): 68-73.

YUAN Shi-chong, GUO Hong-zhen, WANG Xiao-yan, YANG Shou-liang, Yao Ze-kun. Study of ECAP processing parameter for LD10 alloy[J]. Casting Forging Welding, 2008, 37(2): 68-73.

[5] TANNER D A, ROBINSON J S. Reducing residual stress in 2014 aluminium alloy die forgings[J]. Materials and Design, 2008, 29(7): 1489-1496.

[6] 洪慎章, 曾振鹏. 起落架轮毂等温模锻工艺[J]. 航空制造技术, 2002(2): 59-61.

HONG Shen-zhang, ZENG Zhen-peng. Isothermal die forging process of landing gear hub[J]. Aeronautical Manufacturing Technology, 2002(2): 59-61.

[7] 李雪松, 陈 军, 张鸿冰. 6082铝合金热变形的本构模型[J]. 中国有色金属学报, 2008, 18(10): 1769-1774.

LI Xue-song, CHEN Jun, ZHANG Hong-bing. Constitutive model for hot deformation of 6082 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(10): 1769-1774.

[8] 崔忠祈, 刘北兴. 金属学与热处理原理[M]. 哈尔滨: 哈尔滨工业大学出版社, 2004: 164-166.

CUI Zhong-qi, LIU Bei-xing. Metallography and heat treatment principles[M]. Harbin: Harbin Institute of Technology Press, 2004: 164-166.

[9] ZHANG Hui, JIN Neng-ping, CHEN Jiang-hua. Hot deformation behavior of Al-Zn-Mg-Cu-Zr aluminum alloys during compression at elevated temperature[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(3): 437-442.

[10] 刘晓艳, 潘清林, 何运斌, 李文斌, 梁文杰, 尹志民. Al-Cu-Mg-Ag合金热压缩变形的流变应力行为和显微组织[J]. 中国有色金属学报, 2009, 19(2): 201-207.

LIU Xiao-yan, PAN Qing-lin, HE Yun-bin, LI Wen-bin, LIANG Wen-jie, YIN Zhi-min. Flow stress behavior and microstructure of Al-Cu-Mg-Ag alloy during hot compression deformation[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(2): 201-207.

[11] 寇琳媛, 金能萍, 张 辉, 韩 逸, 吴文祥, 李落星. 7150铝合金高温热压缩变形流变应力行为[J]. 中国有色金属学报, 2010, 20(1): 43-48.

KOU Lin-yuan, JIN Neng-ping, ZHANG Hui, HAN Yi, WU Wen-xiang, LI Luo-xing. Flow stress behavior of 7150 aluminum alloy during hot compression deformation at elevated temperature[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(1): 43-48.

[12] 何振波, 李慧中, 梁霄鹏, 尹志民. Al Zn Mg Sc Zr合金的热变形行为及加工图[J]. 中国有色金属学报, 2011, 21(6): 1220-1228.

HE Zhen bo, LI Hui zhong, LIANG Xiao peng, YIN Zhi min. Hot deformation behavior and processing map of Al Zn Mg Sc Zr alloy[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(6): 1220-1228.

[13] ZHANG Xin-ming, SONG Min, ZHOU Zhuo-ping, ZENG Su-min. Microstructures and mechanical properties of 2014aluminium alloy forgings made by a new process[J]. Transactions of Nonferrous Metals Society of China, 2000, 10(2): 139-143.

[14] 黄裕金, 陈志国, 舒 军, 刘瑶琼, 周 娴. 2E12铝合金的高温塑性变形流变应力行为[J]. 中国有色金属学报, 2010, 20(11): 2094-2100.

HUANG Yu-jin, CHEN Zhi-guo, SHU Jun, LIU Yao-qiong, ZHOU Xian. Flow stress behavior of 2E12 aluminum alloy during hot plastic deformation at high temperature[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(11): 2094-2100.

[15] JIA Yan-dong, CAO Fu-yang, NING Zhi-liang, SUN Xiao-bing, SUN Jian-fei. Hot deformation behavior of spray formed Al-22Si-5Fe-3Cu-1Mg alloy[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(S2): s299-s303.

[16] 范 曦, 潘清林, 李建湘, 杨志兵, 刘晓艳, 覃银江. Al-Mn-Mg-Cu-Ni合金热压缩变形的流变行为和组织[J]. 中国有色金属学报, 2010, 20(11): 420-426.

FAN Xi, PAN Qing-lin, LI Jian-xiang, YANG Zhi-bin, LIU Xiao-yan, QIN Yin-jiang. Flow behavior and microstructure of Al-Mn-Mg-Cu-Ni alloy during hot compression deformation[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(11): 420-426.

[17] ZENER C, HOLLOMON J H. Effect of strain rate upon the plastic flow of steel[J]. Journal of Applied Geophysics, 1944, 15(1): 22-32.

(编辑 李艳红)

基金项目:国家高技术研究发展计划重点资助项目(2009AA034300);国家教育部“长江学者特聘教授”奖励计划(T20011119)

收稿日期:2012-10-12;修订日期:2013-02-25

通信作者:马运柱,教授,博士;电话:0731-88877285;E-mail: zhuzipm@mail.csu.edu.cn