文章编号:1004-0609(2008)06-1032-07

形变热处理对Cu-Cr-Zr合金时效组织和性能的影响

钟建伟1,周海涛1,赵仲恺1,李庆波1,周 啸2

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 江西理工大学 材料与化学工程学院,赣州 341000)

摘 要:通过对Cu-1.0Cr-0.2Zr合金固溶处理、冷轧以及随后的时效处理工艺,研究形变及时效过程对材料力学性能、导电性能及其组织结构的影响规律。结果表明:研究合金具有很强的时效强化效应;时效前的预冷变形能显著提高Cu-1.0Cr-0.2Zr合金的力学性能而保持较高的导电性;在最佳的形变热处理工艺条件下其合金的抗拉强度和屈服强度分别达到了527.0和487.0 MPa,伸长率为12.3%,电导率为82.0%IACS。合金力学性能的提高与电学性能的小幅降低主要是由时效过程的固溶体贫化、基体的回复与再结晶以及新相的析出三个因素控制,其中细小弥散均匀分布的析出相是获得高的力学性能和导电性能的重要影响因素。

关键词:Cu-Cr-Zr合金;形变热处理;显微组织;导电性能

中图分类号:TG 146.1 文献标识码:A

Effects of thermo-mechanical heat treatment processing on microstructure and properties of Cu-Cr-Zr alloy

ZHONG Jian-wei1, ZHOU Hai-tao1, ZHAO Zhong-kai1, LI Qing-bo1, ZHOU Xiao2

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. School of Materials and Chemistry Engineering, Jiangxi University of Science and Technology,

Ganzhou 341000, China)

Abstract: The effects of thermo-mechanical heat treatment processing on microstructure and properties of Cu-Cr-Zr alloy were studied. The hot rolled plates were solid solution treated and cold rolled followed by ageing treatments. The different ageing temperatures, ageing times and different reduction ratios of cold-rolled affect the mechanical and electrical properties of the alloy. The results show that the fine chromium and the second phase distributed in matrix were found in matrix. The ageing treatments affect the microstructure, strength and electrical conductivity of the alloy. In optimum treatment, the tensile strength, yield strength, elongation and electrical conductivity are of 527.0 MPa, 487.0 MPa, 14.2% and 82.0% IACS, respectively, which are controlled by recovery, recrystallization and precipitation, moreover, the fine second phase precipitation is the most important factor.

Key words: Cu-Cr-Zr alloy; thermo-mechanical treatment; microstructures; conductivity

时效硬化型Cu-Cr和Cu-Cr-Zr合金及其加入微量稀土元素或其它元素如Mg、Zn、Si等形成的多元微合金化的合金具有高强度、高导电导热性能及其优良的耐磨性,在电阻焊电极、交流电机整流子和集成电路引线框架等方面有广泛用途[1-3]。其中,通过高温固溶处理使合金元素Cr和Zr在铜基体中形成过饱和固溶体,随后的时效处理使过饱和固溶体分解对这类合金的显微组织和性能有很大影响。研究表明[4-5],Cu-Cr-Zr合金的时效析出在强化合金的同时又保持较高的导电性。HOLZWARTH和STAMM [6]研究Cu-0.75 Cr-0.105Zr合金时发现了两种形态沉淀相,一种是0.2~2 μm大小的粗大沉淀相,晶粒间距在几微米,还有一种为细小的弥散沉淀相,大小为2~3 nm,间距30~60 nm。能谱分析确定析出相是Cr、Cu5Zr。HUANG等[7]研究了Cu-0.31Cr-0.21Zr合金,Morris等[8]和BATAWI等[9]采用快速凝固方法制备了Cu-Cr-Zr合金,他们获得了与HOLZWARTH等[6]一致的结果。TANG等[10]研究了Cu-0.65Cr-0.1Zr-0.03Mg合金,观察到细小沉淀相为金属间化合物Heusler相Cr2Cu(Zr,Mg),与基体之间满足N-W关系。在500 ℃细小的弥散相被相对粗大的Cr和Cu4Zr取代。QI等[11]在Cu-0.4Cr-0.2Zr合金中及LIU[12]也得到与TANG 等[10]相似的结论。幕思国等[13]对Cu-0.43Cr-0.17Zr- 0.05Mg-0.05RE合金经过冷轧后,在450 ℃时效4 h,析出相细小且弥散,在不同工艺时效下,铬相存在棒状、六边型和球形3种形态;锆相主要以富锆相存在,并随时效温度升高,迅速长大。当Zr 的含量降低时,该类合金析出相的大小和形态不同,其中BATRA等[14]发现Cu-0.8Cr-0.08Zr中有两种相:一是粗大的未固溶的Cr,二是析出的有序体心Cr。但该类系列合金性能仍未达到σb≥600 MPa,导电率≥80%IACS的理想目标。为此,国内外科技工作者从加入少量合金化元素,改变显微组织结构等方面开展了很多的研究工作[15-16],试图提高力学性能而保持较高的电学性能。廖素三等[15]对Cu-0.5Cr-0.2Zr的时效研究表明,900 ℃固溶1 h,并且450 ℃时效20 h时,合金抗拉强度只有413 MPa,导电率为71%IACS。宋练鹏等[17]研究了Cu-0.4~0.8Cr-0.4Zr-0.1~0.5Mg合金,将其固溶后经过40%冷轧变形,然后在450 ℃时效6 h,由此测得合金的抗拉强度、屈服强度和伸长率分别为486 MPa、443 MPa和9.3%,导电率为84.8% IACS。叶权华等[18]研究了Cu-0.40Cr-0.67Zr-0.021Y合金,经过950 ℃固溶处理1 h后在480 ℃时效及40%变形0.25 h,测得合金显微硬度和导电率分别为HV133和82.83% IACS。可见,这些研究结果并不理想。因此,为更好地满足高强、高导材料方面需求,本文作者针对Cu-1.0Cr-0.2Zr合金,研究形变热处理工艺对其组织与性能的影响,优化形变热处理工艺,使其获得较高的强度和电导率的组合,为今后合理制定该相似合金的形变热处理工艺提供参考。

1 实验

实验合金其主要成分为Cu-1.0Cr-0.2Zr,热轧退火后得到板坯试样。板坯试样的基本处理工艺是,在960 ℃固溶2 ,水中淬火,时效前在室温下进行冷变形。参照先前的一些研究成果[19-21],时效温度范围定为430~530 ℃,冷变形量范围为20%~80%,时效时间先定为4 h。首先在时效温度范围内对时效温度进行优化,然后在优化的时效温度下对时效时间做进一步的优化,最后在优化的时效温度与时效时间上对冷变形量对时效过程的影响进行优化。

时效热处理后板材的样品尺寸及加工按照国家标准进行,标距长40 mm,拉伸速度为2 mm/min。拉伸性能测试在CSS-44100万能电子拉伸实验机上进行。电导率测试先在QJ19单双臂电桥先测出其电阻值然后换算成电导率。金相样品磨面取自板材的轧面,光学金相分析在PLOYMAR MET显微镜上进行。试样研磨抛光后进行化学腐蚀,腐蚀液为FeCl3的盐酸水溶液。采用JEOL 2001高分辨的电子透射电镜对形变热处理过程中最佳性能的合金的微观组织结构进行观察与分析。

2 结果与分析

2.1 固溶—冷变形—时效工艺对合金性能的影响

热轧退火后的板材经过固溶处理―冷变形―时效工艺处理后,在不同时效工艺制度下,合金的力学性能和导电性能如图1~3所示。

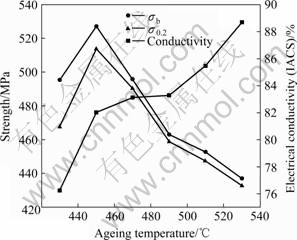

图1 时效温度对Cu-1.0Cr-0.2Zr合金性能的影响

Fig.1 Effects of ageing temperature on properties of Cu-1.0Zr-0.2Zr alloy (ageing for 4 h)

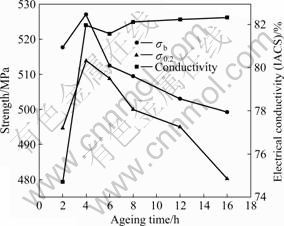

图2 时效时间对Cu-1.0Cr-0.2Zr合金性能的影响

Fig.2 Effects of ageing time on properties of Cu-1.0Cr-0.2Zr alloy(ageing at 450 ℃)

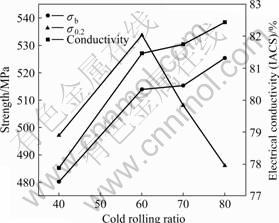

图3 时效前冷轧变形量对Cu-1.0Cr-0.2Zr合金性能的影响

Fig.3 Effects of cold rolling ratio on properties of Cu-1.0Cr-0.2Zr alloy(ageing at 450 ℃ for 4 h)

在960 ℃固溶2 h及时效4 h条件下,不同时效温度对合金力学性能和导电性能的影响如图1所示。由图1可知,在430 ℃以上温度时效时,合金的抗拉强度和屈服强度先提升高,450 ℃时合金的抗拉强度和屈服强度达到峰值,随后随着时效温度的提高合金的抗拉强度和屈服强度又迅速下降,说明合金具有很强的时效强化效果。与此同时,合金电导率随着时效温度的升高而不断上升。

在450 ℃时效温度下,不同时效时间对合金力学性能和导电性能的影响如图2所示。从图中可以看出,合金的力学性能首先升高,时效4 h时达到峰值,随后随着时效时间的延长,力学性能随之不断下降,而电导率随着时效时间的延长而不断增加,但增加趋势不断减缓,最后达到了恒值。由以上分析可见,450 ℃时效4 h是比较好的时效处理制度,在此制度下,合金的抗拉强度和屈服强度达到峰值,合金的电导率保持较高的水平。

在450 ℃时效4 h条件下,时效前的不同冷变形量对合金的力学性能和导电性能的影响如图3所示。在相同的时效工艺条件下,随着冷变形量的增加,合金的强度升高,而电导率达到峰值后下降。这是由于时效前冷变形量的增加促使位错、空位的增殖和晶体界面面积的增大,同时大量位错等缺陷增加了合金的变形储能,析出相析出更为充分,强化效应增加,因而合金的强度增大。当变形量达到80%时,缺陷和界面对电导率的影响超过了溶质原子对电导率的影响,导致电导率下降。但变形量促使合金所增加的位错、空位等缺陷对合金的电导率影响不是很大。时效前冷变形70%时,合金的电导率仍然达到79.87%IACS,保持较高的电导率。

综上所述,综合考虑合金的力学性能与电学性能结合,实验合金最佳的形变热处理工艺是:960 ℃固溶2 h+60%冷变形+450 ℃时效4 h,在此条件下合金抗拉强度和屈服强度分别达到了527.0和487.0 MPa,伸长率为12.3%,电导率为82.0%IACS。Cu-1.0Cr-0.2Zr合金经过合理的热处理规程后其强度较高,电导率保持在80%IACS以上的高水平。

2.2 显微组织观察与分析

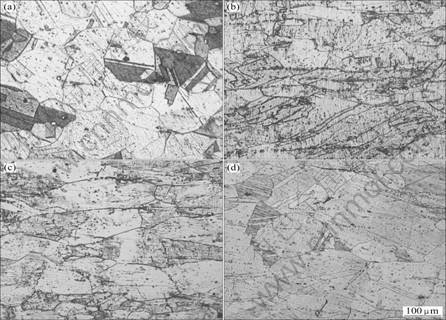

图4所示为Cu-1.0Cr-0.2Zr合金960 ℃固溶处理及不同时效态的金相显微组织。由图4(a)可以看出,960 ℃固溶处理后的金相组织为等轴状再结晶组织,晶粒内部还有较粗大的未溶相。经过60%冷变形后在450 ℃时效4 h,金相组织中可以清晰看到沿着变形方向拉长了的晶粒(见图4(b)),未观察到再结晶组织。这是因为在冷变形量极大的情况下,或当晶界迁移过程受到析出第二相对位错的钉扎作用而阻碍再结晶形核和长大时,金属中只发生极强的特殊回复过程。与此同时,在450 ℃时效4 h时,铜基固溶体中不断脱溶析出大量粒度为几十纳米的粒子,如图6(b)所示。大量细小弥散的析出相分布在基体中并与基质共格,而且尺寸很小,因而位错可以切过析出相。此阶段屈服应力取决于切过析出相所需要的应力,并且共格界面处存在较大的错配度,晶格畸变严重,引起强的内应力场。因此,弥散细小的析出相提高了合金的强度,在450 ℃时效4 h后合金抗拉强度达到了峰值。在450 ℃时效时,随着时效时间的延长,变形组织改组为新的等轴晶粒,新晶粒逐渐长大(图4(c))。随着时效时间的延长,已经形核的析出第二相有充分时间长大,时效过程中还不断有一些新核及新相形成并长大,沉淀相体积含量增加,位错绕过粒子所需应力会小于切割粒子所需应力,奥罗万机制起作用,屈服应力将随粒子间距增加而减少,时效后期合金抗拉强度随时效时间加长而降低。合金随着冷变形程度增加,晶粒内部位错不断增殖,位错密度逐渐增高,储能增多,也提高了再结晶形核率和长大速率,因此再结晶温度降低。在80%冷变形后450 ℃时效4 h时,合金金相组织中发生了再结晶和晶粒长大(图4(d))。再结晶的发生降低了合金的力学性能。而时效过程中合金的电学性能主要由两个过程控制:一是再结晶软化导致基体点阵对电子散射作用减弱,合金的电导率升高[22-23];二是析出粒子的增多和长大,对电子产生附加散射,降低合金的电导率。根据Mathiessen[24]理论,合金中固溶体对电子散射能力远大于析出相对电子的散射能力。因此,随着时效时间的延长和时效温度的升高,沉淀相的不断析出使得基体固溶体不断贫化,合金的电导率随之升高达到较高值。

图4 不同处理态合金的显微组织

Fig.4 Microstructures of Cu-1.0Cr-0.2Zr under different treatment conditions: (a) Solid-solution treated; (b) 60% cold-rolling, ageing at 450 ℃ for 4 h; (c) 60% cold-rolling, aging at 450 ℃ for 6 h; (d) 80% cold-rolling, aging at 450 ℃ for 4 h

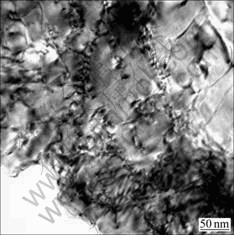

图5所示为Cu-1.0Cr-0.2Zr合金经60%冷变形后在450 ℃时效4 h的位错组态。由图5可看出,合金时效后变形组织仍然存在,位错密度较高,有大量的位错缠结,很多细小的析出相分布在位错线及基体上,这正是合金的强度在时效过程中得到较大提高的原因之一。由于析出相与位错的交互作用,使得析出相倾向于偏聚在位错处,对位错起钉轧与阻碍作用,不利于再结晶的形核和长大,减缓了合金的回复与再结晶过程,使得在450℃时效时析出相仍呈弥散、均匀分布,析出相并没有长大,也未见再结晶的发生。

图5 450 ℃时效4 h的位错形貌

Fig.5 Dislocation morphology of Cu-1.0Cr-0.2Zr alloy after aging at 450 ℃ for 4 h

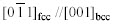

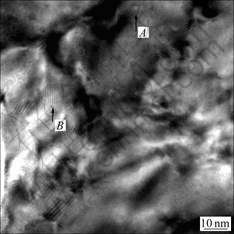

图6所示为Cu-1.0Cr-0.2Zr合金450 ℃时效4 h后在铜基体上析出相的衍射斑点及其弱斑点的暗场像。从衍射谱中可以看到一套亮斑点和两套弱斑点(图6(a)中的箭头A、B),亮斑点为铜基体的衍射斑点,而弱斑点则为析出相的衍射斑点,图中箭头A所指为析出相的衍射斑点,而箭头B所指的额外反射是由于二次衍射造成的。额外衍射斑点的出现,可能是由于在时效过程中Zr原子发生扩散,逐渐形成了有序的原子排列,即形成了超点阵。对于部分共格或非共格粒子而言,一般容易出现二次衍射,因此二次衍射的出现从侧面证明这种弥散分布的粒子是嵌于基体内部的沉Cu matrix.淀相。对电子衍射花样标定的结果表明,晶内沉淀相为与Fe3Al相似晶格的Heusler相CrCu2(Zr,Mg),此时,析出相与基体有着严格的N-W位向关系:(111)fcc//(110)bcc, ,

, 。

。

图6 450 ℃时效4 h的析出相衍射斑点及其暗场像

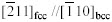

Fig.6 TEM micrographs of Cu-1.0Cr-0.2Zr alloy after ageing at 450 ℃ for 4 h: (a) Selected electron diffraction pattern of alloy, showing distinct reflection of precipitated phases; (b) DF micrograph,showing fine precipitates with size of 10-30 nm dispersing in

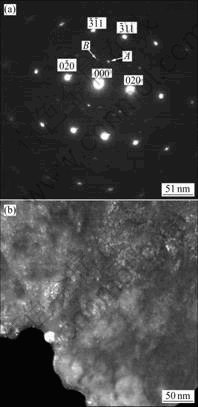

图6(b) 所示为析出相的暗场(DF)像,暗场像中亮斑点为析出相。由此可以看出,450 ℃时效4 h时,固溶体基体上的细小析出相均匀分布,密度较大。图7所示为450℃时效4 h的析出相形貌。可以看出,合金中存在两种不同析出沉淀相,这与当前这类合金的时效析出相研究结果相一致[6, 3, 25]。根据这些文献资料,可判断第一种析出相是球状沉淀相Cr粒子(图7中A),第二种析出相是弥散细小的铜锆化合物析出相(图7中B)。图7中的平行波纹图(Morié patterns)是由析出相与基体的双衍射所造成的。当电子束连续通过两层重叠的晶体,而析出相与基体的晶面间距非常接近,晶格不匹配形成了一种周期间距的波纹图,称为摩尔条纹,其间距取决于析出相与基体两晶体的晶面间距和相对配置,间隔距离为1.25 ~1.45 nm。细小弥散的析出相对合金起到弥散强化的作用,使得强度得到了很大的提高。而析出相从铜基体中析出,使得基体中的固溶体贫化,减少了电子散射作用,提高了合金的电导率。

图7 450 ℃时效4 h的析出相形貌

Fig.7 Precipitation morphology in alloy after aging at 450 ℃ for 4 h

3 结论

1) Cu-1.0Cr-0.2Zr合金具有很强的时效强化效果。随时效温度升高和时效时间的延长,析出相长大,合金强度随之下降;而导电性能随时效过程中固溶体的不断贫化使得电子散射减少,电导率随之升高并保持在一个平台的水平。

2) 形变热处理能提高Cu-1.0Cr-0.2Zr合金的力学性能和导电性能。合金在960 ℃固溶2 h后经60%预冷变形和450 ℃时效4 h,合金的抗拉强度、屈服强度和伸长率分别达到了527.0 MPa、487.0 MPa和12.3%,合金的相对电导率为82.0%IACS。

3) Cu-1.0Cr-0.2Zr合金60%冷变形450 ℃时效4 h后,合金获得两种细小弥散分布的析出相。析出物对位错的钉扎,减缓了变形回复及随后的再结晶的过程。弥散细小的析出相是合金强化的重要机制。

致谢:

论文透射电镜实验得到了中国科学院上海硅酸盐研究所冯景伟老师的帮助,深表谢意。

REFERENCES

[1] KALININ G, MATERA R. Comparative analysis of copper alloys for the heat sink of plasma facing components in ITER[J]. Journal of Nuclear Materials, 1998, 258/263: 345-350.

[2] SPAIC S, KRIZMAN A, MARINKOVIC V. The metallographical structure and property of copper alloys aging hardening by adding minor alloy element[J]. Meta of Western Germany, 1985, 39(1): 43-48.

[3] 邬震泰. 半导体器件引线框架材料的现状与发展[J]. 材料科学与工程, 2001, 19(3):127-130.

WU Zhen-tai. Current status and development of lead frame materials used in semiconductor devices [J]. Materials Science and Engineering, 2001, 19(3): 127-130.

[4] TU J P, QI W X, YANG Y Z, LIU F, ZHANG J T, GAN G Y, WANG N Y, ZHANG X B, LIU MS. Effect of aging treatment on the electrical sliding wear behavior of Cu-Cr-Zr alloy[J]. Wear, 2002, 249: 1021-1027.

[5] DAVIS J W, KALININ G M. Material properties and design requirements for copper alloys used in ITER[J]. Journal of Nuclear Materials, 1998, 258/263: 323-328.

[6] HOLZWARTH U, STAMM H. The precipitation behavior of ITER-grade Cu-Cr-Zr alloy after simulating the thermal cycle of hot isostatic pressing[J]. Journal of Nuclear Materials, 2000, 279: 31-45.

[7] HUANG F X, MA J S. Analysis of phases in a Cu-Cr-Zr alloy[J]. Scripta Materialia, 2003, 48: 97-102.

[8] MORRIS M A, MORRIS D G, KULKARNI U D. Microstructure and properties of Cu-Cr-Zr alloy[J]. Journal of Nuclear Materials, 2001, 299: 91-100.

[9] BATAWI E, MORRIS D, MORRIS M A. Effect of small alloying additions on behavior of rapidly solidified Cu-Cr alloys[J]. Materials Science Technology, 1990, 6: 892-899.

[10] TANG N Y, TAPLIN D M, DUNLOP G L. Precipitation and aging in high-conductivity Cu-Cr alloys with additions of zirconium and magnesium[J]. Materials Science Technology, 1985(1): 270-275.

[11] QI Wei-xiao, TU Jiang-ping, LIU Fu. Microstructure and tribological behavior of a peak aged Cu-Cr-Zr[J]. Mater Sci Eng A, 2003, A343: 89-96.

[12] LIU Ping, SU Juan-hua, DONG Qi-ming. Microstructure and properties of Cu-Cr-Zr alloy after rapidly solidified aging and solid solution aging[J]. J Mater Sci Technol, 2005, 21(4): 475-478.

[13] 幕思国, 曹兴民, 汤玉琼, 向朝建, 杨春秀, 郭富安, 唐谟堂. 时效态Cu-Cr-Zr-Mg-RE合金的组织与性能[J]. 中国有色金属学报, 2007, 17(7): 1112-1118.

MU Si-guo, CAO Xing-min, TANG Yu-qiong, XIANG Chao-jian, YANG Chun-xiu, GUO Fu-an, TANG Mo-tang. Microstructure and properties of aging Cu-Cr-Zr-Mg-RE alloy[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(7): 1112-1118.

[14] BATRA I S, DEY G K, KULKARNI U D, BANERJEE S. Microstructure and properties of a Cu-Cr-Zr alloy[J].Journal of Nuclear Materials, 2001, 299: 91-100.

[15] 廖素三, 尹志民, 蒋 牵, 姜 锋, 宋练鹏, 汪明朴. 热处理对Cu-Cr(-Zr)合金力学性能和导电性能的影响[J]. 中国有色金属学报, 2000, 10(5): 684-687.

LIAO Su-san, YIN Zhi-min, JIANG Qian, JIANG Feng, SONG Lian-peng, WANG Ming-pu. Effect of heat treatment on mechanical properties and electrical conductivity of Cu-Cr(-Zr) alloy[J]. The Chinese Journal of Nonferrous Metals, 2000, 10(5): 684-687.

[16] BATRA I S, DEY G K, KULKARNI U D, BANERJEE S. Precipitation in a Cu-Cr-Zr alloy[J]. Materials Science and Engineering A, 2002, 356: 32-36.

[17] 宋练鹏, 尹志民, 李娜娜, 张 伟. 不同处理工艺对Cu-Cr-Zr-Mg合金组织与性能的影响[J]. 稀有金属, 2004, 28(1): 122-125.

SONG Lian-peng, YIN Zhi-min, LI Na-na, ZHANG Wei. Influence of different treatment on microstructures and properties of Cu-Cr-Zr-Mg alloy[J]. Chinese Journal of Rare Metals, 2004, 28(1): 22-125.

[18] 叶权华, 刘 平, 刘 勇, 田保红. 时效对Cu-Cr-Zr-Y合金显微硬度及导电率的影响[J]. 有色金属, 2007, 59(1): 14-16.

YE Quan-hua, LIU Ping, LIU Yong, TIAN Bao-hong. Influence of aging on microhardness and electrical conductivity of Cu-Cr-Zr-Y alloy[J]. Nonferrous Metals, 2007, 59(1): 14-16

[19] 行如意, 康布喜, 苏娟华, 田保红, 刘 平. 时效参数和变形量对Cu-Cr-Zr-Mg合金组织和性能的影响[J]. 热加工工艺, 2004(3): 1-5.

XING Ru-yi, KANG Bu-xi, SU Juan-hua, TIAN Bao-hong, LIU Ping. Study on microstructure and property of Cu-Cr-Zr-Mg alloy after aging and cold deformation[J]. Hot Working Technology, 2004(3): 1-5.

[20] 李 伟, 刘 平, 苏娟华, 刘 勇, 康布熙, 田保红. 时效与形变对Cu-Cr-Zr合金性能的影响[J]. 特种铸造及有色合金, 2004(6): 25-26.

LI Wei, LIU Ping, SU Juan-hua, LIU Yong, KANG Bu-xi, TIAN Bao-hong. Effects of ageing and deformation on properties of the Cu-Cr-Zr alloy[J]. Special Casting and Nonferrous Alloys, 2004(6): 25-26.

[21] 张生龙. Cu-Cr-Zr和Cu-Zn-Cr-Zr合金时效特性研究[D]. 长沙: 中南大学, 2002.

ZHANG Sheng-long. Aging properties study of Cu-Cr-Zr and Cu-Zn-Cr-Zr alloy[D]. Changsha: Central South University, 2002.

[22] 田 莳, 李秀臣, 刘正堂. 合金的物理性能[M]. 北京: 航空工业出版社, 1994: 36.

TIAN Shi, LI Xiu-chen, LIU Zheng-tang. Physical property of metals[M]. Beijing: Aviation Industry Press, 1994: 36.

[23] GORELIK S S. Recrystallization of metal and alloy[M]. Beijing: China Machine Industry Press, 1985: 369-390.

[24] 方俊鑫, 陈 栋. 固体物理[M]. 北京: 高等教育出版社, 1981: 156.

FANG Jun-xing, CHEN Dong. Solid state physics[M]. Beijing: Higher Education Press, 1981: 156.

[25] ZENG K J, H?M?L?INEN M, LILIUS K. Phase relationships in Cu-rich corner of the Cu-Cr-Zr phase diagram[J]. Scripta Metallurgica et Materialia, 1995, 32(12): 2009-2014.

收稿日期:2007-09-30,修订日期:2007-12-27

通讯作者:周海涛,教授,博士;电话:0731-2655250;E-mail: htzhou62@yahoo.com.cn

(编辑 何学锋)