DOI: 10.11817/j.issn.1672-7207.2019.05.005

均匀化工艺对Al-4.46Mg合金腐蚀和疲劳性能的影响

王在玲1,邓运来1, 2,伍鹏飞2,孙琳3,戴青松2,叶凌英2

(1. 中南大学 轻合金研究院,湖南 长沙,410083;

2. 中南大学 材料科学与工程学院,湖南 长沙,410083;

3. 中车青岛四方机车车辆股份有限公司,山东 青岛,266111)

摘要:研究480 ℃/20 h,430 ℃/2 h+490 ℃/12 h和500 ℃/16 h这3种均匀化工艺对Al-Mg合金腐蚀性能和疲劳性能的影响;通过晶间腐蚀(IGC)和慢应变速率拉伸(SSRT)腐蚀研究这3种工艺对Al-Mg合金O态板材的腐蚀性能的影响;通过疲劳裂纹扩展速率和Kahn撕裂实验研究这3种工艺对Al-Mg合金O态板材疲劳性能的影响。研究结果表明:与其他2种工艺相比,经430 ℃/2 h+490 ℃/12 h均匀化后得到的板材抗晶间腐蚀性能最佳,腐蚀速率为2.287 8 mg/cm2,应力腐蚀敏感指数ISSRT最小,为0.068;经430 ℃/2 h+490 ℃/12 h均匀化后得到的板材在高应力强度因子范围下抗裂纹扩展性能最佳,其单位面积裂纹形核功与经500 ℃/16 h处理得到的板材的形核功接近。

关键词:Al-Mg合金;均匀化;腐蚀性能;疲劳性能

中图分类号:TG457.14;TG113.25;TG113 文献标志码:A 文章编号:1672-7207(2019)05-1042-07

Effect of homogenization on corrosion and fatigue performance of Al-4.46Mg alloy

WANG Zailing1, DENG Yunlai1, 2, WU Pengfei2, SUN Lin3, DAI Qingsong2, YE Lingying2

(1. Light Alloy Research Institute, Central South University, Changsha 410083, China;

2 School of Materials Science and Engineering, Central South University, Changsha 410083, China;

3. CRRC Qingdao Sifang Co. Ltd, Qingdao 266111, China)

Abstract: The effects of homogenization on corrosion and fatigue performance of Al-Mg alloy were studied after being homogenized using three homogenization technologies, i.e., 480 ℃/20 h, 430 ℃/2 h+490 ℃/12 h and 500 ℃/16 h, the corrosion performance of Al-Mg alloy sheets were tested by intergranular corrosion(IGC) and slow strain rate testing(SSRT), the fatigue performance of Al-Mg alloy sheets were tested by fatigue crack growth rate testing and Kahn tear test. The results show that Al-Mg alloy after homogenization by 430 ℃/2 h+490 ℃/12 h has the best intergranular corrosion resistance, the rate of corrosion is 2.287 8 mg/cm2, and the susceptibility index of slow strain rate test is 0.068. Al-Mg alloy after homogenization by 430 ℃/2 h+490 ℃/12 h has the best crack propagation resistance in the range of high intensity factor, and the unit initiation energy is close to that of the Al-Mg alloy sheets after annealing homogenization through the treatment at 500 ℃ for 16 h.

Key words: Al-Mg alloy; homogenization; corrosion performance; fatigues performance

Al-4.46Mg合金属于5系铝合金,其成分与5083铝合金接近,具有中等强度、良好的塑性、抗蚀性及焊接性、较高的疲劳极限,常被应用于模具制造业、造船业、运输业,是制作模具、船板、船外壳、燃料储存罐的重要材料[1-4]。高镁铝合金在熔铸过程中易产生偏析,轧制前必须进行均匀化处理,通过均匀化热处理最大限度地消除晶间偏析、一次析出相及铸锭组织中的残留相,提高合金元素在基体中的固溶度和铸锭的热塑性,进而提高合金的综合性能[5-8]。目前,5083铝合金在船舶上的应用越来越广泛,铝合金船板可有效减轻船舶质量,提高稳定性,增大航速[9],但船舶长期处于极其恶劣的海洋腐蚀环境中,容易发生由腐蚀引起的断裂,这种断裂常造成巨大的损失,因此,船舶对铝合金耐蚀性有较高的要求。同时,随着我国高速列车技术的发展,5083铝合金以其优良的综合性能应用于高速列车的车体、外墙和车底安装座等处,人们针对高速列车用金属材料的疲劳性能的研究正逐步开展[10]。5系铝合金是一种热处理不可强化合金,其主要强化手段是通过Mg原子的固溶强化以及加工硬化。当Mg质量分数大于3%,在100 ℃以上进行稳定化退火,β相(Al3Mg2)沿晶界析出,合金从而对应力腐蚀(SCC)十分敏感[11],耐晶间腐蚀能力也较弱,目前,大量研究主要集中在合金成分、稳定化处理工艺对Al-Mg合金综合性能的影响方面,如:杨磊等[12]研究了添加Zn对5083铝合金组织和腐蚀性能的影响,通过在合金中添加Zn,在晶界形成τ相(Mg32(Al,Zn)49),从而抑制β相的析出,降低SCC敏感性;周庆波等[13]研究了化学成分对 5083 铝合金性能的影响,通过控制5083铝合金中的Mg与Mn质量分数在中上限,可提高材料的综合性能,如强度、塑性及耐蚀性等; 罗兵辉等[14]研究了退火温度对淬火后冷轧5083铝合金组织及腐蚀性能的影响;DAVENPORT等[15]利用TEM,ATM和SSRT 等方法研究了5182铝合金经敏化处理后的应力腐烛和晶间腐烛性能,发现该合金的抗蚀性与敏化处理的时间和温度有密切关系;MIYAKE等[16]通过添加Sc和Zr改善合金的微观组织与成形性能,从而可以优化热处理条件,提高机械性能;POPOVIC等[17]通过添加微量元素、调整成分、优化工艺来改善 5000系铝合金的耐 SCC 性能。近年来,虽然国内外学者对铝合金的疲劳性能进行了大量研究,但主要是研究铝合金的高周疲劳与低周疲劳性能,如彭金波等[18]对5083-H111轧制铝合金的低周疲劳性能进行了研究;梁凌宇等[11]研究了厚度对5083铝合金薄板超高周弯曲疲劳性能的影响,而对相关均匀化工艺对Al-Mg合金的抗疲劳裂纹扩展性能等研究很少。为此,本文作者主要研究铸锭经480 ℃/20 h,430 ℃/2 h+490 ℃/12 h和500 ℃/16 h这3种均匀化工艺制度处理后,对再经过热轧、退火后所得到的O态板材腐蚀性能和疲劳性能的影响。通过将晶间腐蚀、慢应变速率拉伸腐蚀、疲劳裂纹扩展速率与Kahn撕裂实验结果进行对比,得到适用于Al-4.46Mg合金O态板材制备的最佳均匀化工艺制度,为提高板材综合性能提供依据。

1 实验材料和方法

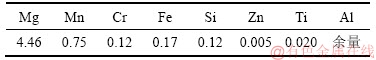

实验材料为自制的Al-Mg合金铸锭,成分如表1所示,对铸态Al-Mg合金进行如下均匀化处理:A工艺为480 ℃/20 h,B工艺为430 ℃/2 h+490 ℃/12 h,C工艺为500 ℃/16 h,锯切、铣面,再经420 ℃/2 h热轧,轧制后得到厚度为4 mm的H态5083板材,在380 ℃下退火2 h,得到厚度为4 mm的O态5083板材。从3种板材上取样,分别进行晶间腐蚀、慢应变慢速率拉伸腐蚀、疲劳裂纹扩展速率和Kahn撕裂实验。

表1 Al-Mg合金铸锭成分(质量分数)

Table 1 Chemical composition of Al-Mg alloy %

晶间腐蚀实验按照腐蚀深度观察和质量损失测定2种方法进行。分别参照GB/T 7998—2005与GB/T 26491—2011,按金相试样制备方法对腐蚀后试样进行磨制和抛光,通过金相显微镜放大200倍进行观察,得到最大腐蚀深度;根据GB/T 26491—2011对经过腐蚀和洗刷的试样称质量,直至相继2次称的质量差值小于0.5 mg为止,计算单位面积的质量损失。

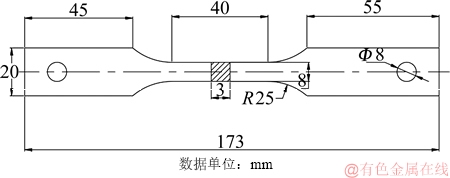

慢应变速率拉伸实验沿板材轧制方向取样,试样尺寸见图1,实验按GB/T 15970.4—2000进行。介质采用硅油与质量分数为3.5%的NaCl溶液,应变速率为10-6/s,实验温度为50 ℃,得到相应的应力-应变曲线。为了表征5083铝合金在质量分数为3.5% NaCl溶液中的应力腐蚀敏感性,定义应力腐蚀敏感指数ISSRT,其计算式为

图1 慢速率拉伸试样尺寸

Fig. 1 Size of slow strain rate test specimen

(1)

(1)

式中: 为铝合金在环境介质中的断裂强度,MPa;

为铝合金在环境介质中的断裂强度,MPa; 为铝合金在惰性介质中的断裂强度,MPa;

为铝合金在惰性介质中的断裂强度,MPa; 为铝合金在环境介质中的断裂伸长率,%;

为铝合金在环境介质中的断裂伸长率,%; 为铝合金在惰性介质中的断裂伸长率,%。

为铝合金在惰性介质中的断裂伸长率,%。

疲劳裂纹扩展速率实验在高频疲劳实验机上进行,试样尺寸如图2所示,沿板材轧制和垂直轧制方向预制缺口试样,按GB/T 6398—2000进行,载荷波形为正弦波,应力比R=0.1,载荷频率为10 Hz。

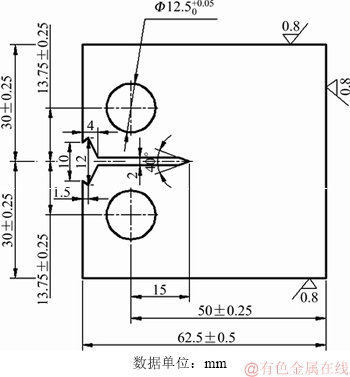

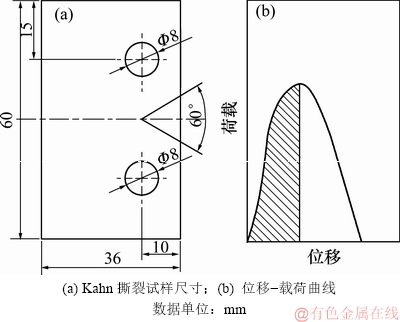

Kahn撕裂试样尺寸如图3所示,实验从平行于轧制方向取样,在慢速率实验机上进行。Kahn撕裂实验主要用于表征铝合金的断裂韧性缺口敏感性。通过Kahn撕裂实验的单位面积裂纹形核功UIE表征合金断裂韧性。

图2 疲劳裂纹扩展试样尺寸

Fig. 2 Size of fatigue crack propagation rate specimen

图3 Kahn撕裂试样尺寸

Fig. 3 Size of Kahn tear specimen and curve of displacement-load

UIE可以根据载荷位移曲线裂纹扩展前所消耗的能量W与试样截面积A之比获得:

(2)

(2)

其中:W根据载荷-位移曲线上裂纹扩展前的面积计算,如图3(b)中的阴影部分;b为缺口尖端至对边的距离;t为试样厚度。

2 结果与分析

2.1 晶间腐蚀

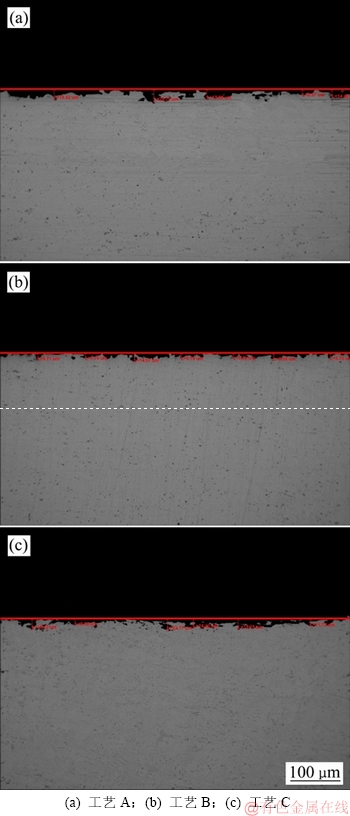

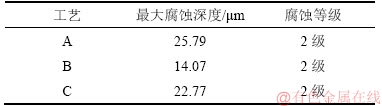

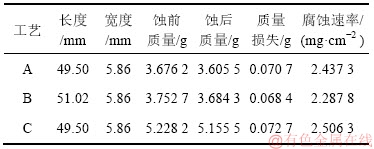

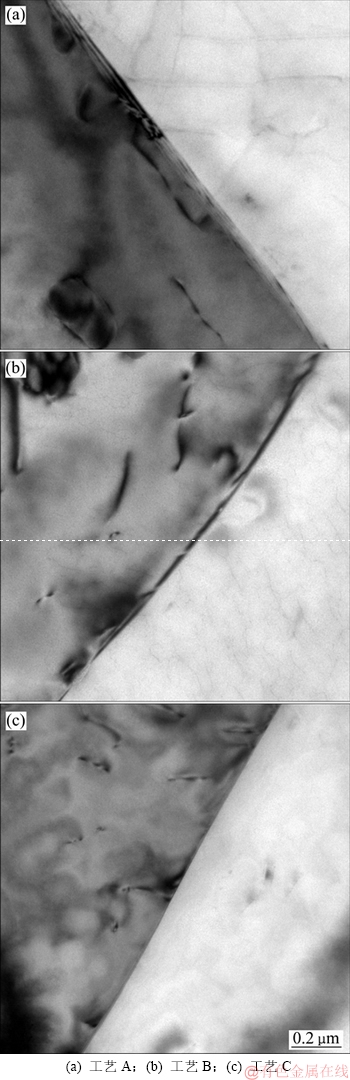

经3种工艺处理后的晶间腐蚀显微组织如图4所示,最大腐蚀深度与腐蚀等级见表2,试样腐蚀前后的质量变化及质量损失见表3。由图4与表3可知:经这3种工艺制度处理完后的材料,其晶间腐蚀最大深度都较小,都达到了二级标准,质量损失也较小,这说明经3种工艺处理后的试样的抗晶间腐蚀性能都较好。这3种均匀化制度下Al-Mg合金透射电镜照片如图5所示。从图5可见:晶界上出现的高镁β相不连续,且较少,这种结构是抗晶间腐蚀的,晶界呈不连续分布的β相,在无β相出现的地方腐蚀停止;经430 ℃/2 h+490 ℃/12 h双级均匀化工艺处理后的材料其晶间腐蚀最大腐蚀深度与单位面积质量损失分别为33.4 μm与2.287 8 mg/cm2,都比其他2种工艺处理后试样的小,这表明经过430 ℃/2 h+490 ℃/12 h双级均匀化工艺处理后的材料的抗晶间腐蚀性能更佳。

图4 3种均匀化制度下的晶间腐蚀的金相显微组织

Fig. 4 Micrographs of phase with three homogenization processes after intergranular corrosion

表2 晶间腐蚀深度与等级

Table 2 Depth and degree of intergranular corrosion

表3 3种工艺制度下的腐蚀速率

Table 3 Corrosion rates at three homogenization processes

2.2 慢应变速率拉伸腐蚀

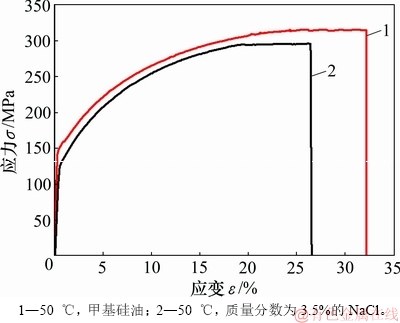

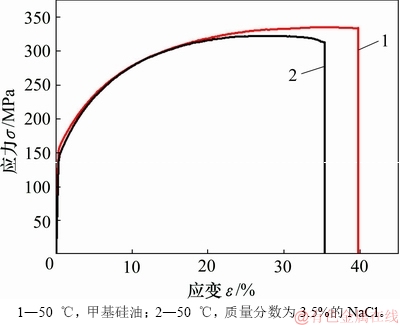

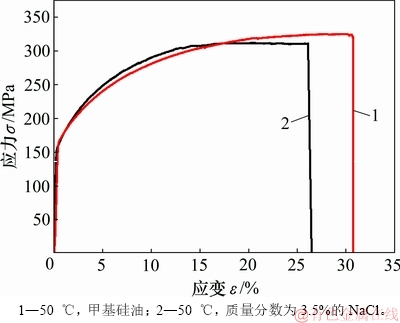

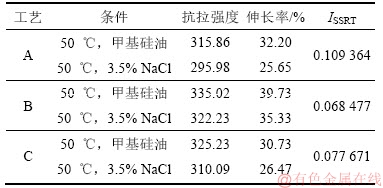

经A,B和C这3种工艺处理后得到Al-Mg合金O态板材试样的慢应变速率拉伸实验的应力-应变曲线与相应的应力腐蚀敏感指数(ISSRT)如图6~8和表4所示。

从图6~8可知:这3种工艺制度下的慢速率拉伸应力-应变曲线形状基本相同,都存在弹性变形阶段和塑性变形阶段,试样在质量分数为3.5%的NaCl腐蚀介质中伸长率明显比惰性介质硅油中的伸长率低, 其抗拉强度与惰性介质硅油中的抗拉强度也有不同程度降低,这说明5083铝合金在质量分数为3.5%的NaCl 溶液中具有应力腐蚀敏感性。

由表4可知:这3种工艺制度下相对应的O态板材的断裂强度及应变损失与应力敏感指数都不同;经A工艺处理后的试样,其应力腐蚀敏感指数ISSRT最大,抗拉强度最小,伸长率也较小,具有较高的应力敏感性; 经B工艺处理后的试样得应力腐蚀敏感指数ISSRT最小,抗拉强度与伸长率都较大,应力敏感性较小。

图5 3种均匀化制度下Al-Mg合金透射电镜照片

Fig. 5 TEM images of Al-Mg alloy at three homogenization processes

图6 A工艺下的慢应变速率拉伸实验应力-应变曲线

Fig.6 Stress-strain curves at slow strain rate test under condition A

图7 B工艺下的慢应变速率拉伸实验应力-应变曲线

Fig. 7 Stress-strain curve at slow strain rate test under condition B

图8 C工艺下的慢应变速率拉伸实验应力-应变曲线

Fig. 8 Stress-strain curves at slow strain rate test under condition C

表4 3种工艺制度下的应力敏感指数ISSRT

Table 4 Index of slow strain rate test under three conditions

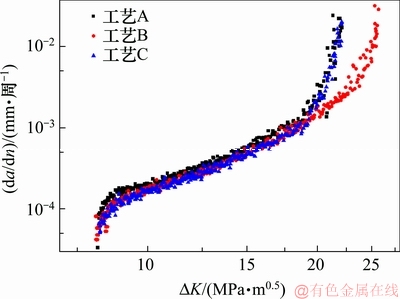

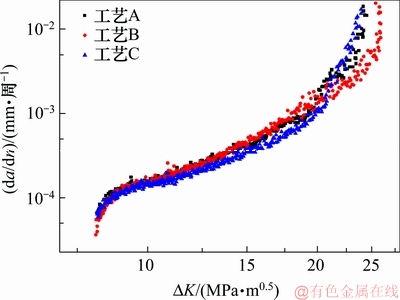

2.3 疲劳裂纹扩展曲线

对3种工艺制度下Al-Mg合金O态板材进行裂纹扩展速率实验,轧制方向与垂直轧制方向的裂纹扩展速率da/dN随应力强度因子△K变化的裂纹扩展速率曲线分别如图9和图10所示。从图9和图10可见:在整个疲劳过程中,无论是轧制方向还是垂直轧制方向,当△K较小时,在较小应力强度因子范围内,曲线之间的偏差较小,这3种工艺制度下的裂纹扩展速率da/dN相差不大;随着△K不断增大,在较高的应力强度因子范围下,这3种工艺制度下的裂纹扩展速率曲线开始出现偏差,经A工艺与C工艺处理后,材料的疲劳裂纹扩展速率增长较快,且与经B工艺处理后的裂纹扩展速率差距越来越大,明显比经B工艺处理后的裂纹扩展速率大,由此可知经过B工艺处理后的材料其的抗裂纹扩展性能比经其他2种工艺处理后的材料的抗裂纹扩展性能优。

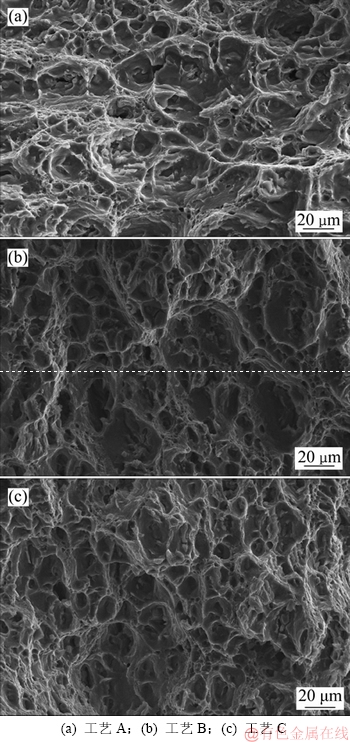

2.4 Kahn撕裂

这3种工艺制度下的Al-Mg合金O态板材断口扫描如图11所示。

图9 轧制方向的疲劳裂纹扩展速率曲线

Fig. 9 Fatigue crack propagation rate curves along rolling direction

图10 垂直于轧制方向的疲劳裂纹扩展速率曲线

Fig. 10 Fatigue crack growth rate curves along transverse direction

图11 Kahn撕裂断口形貌

Fig. 11 Fracture morphologies of Kahn tear testing

由Kahn撕裂实验结果可知:A,B和C工艺处理后的O态板材的UIE分别为174.29,212.53和216.54 N/mm,经B工艺与C工艺处理后得到的O态板材的UIE 接近,比经A工艺处理后材料的UIE高19.51%。同时,可以根据撕裂断口上韧性断裂和脆性断裂的所占比例直观地判断出经不同均匀化工艺处理后材料的韧性。从图11可以看出经这3种工艺处理后的材料主要断裂方式为韧性断裂,图11(b)与11(c)中未溶的微小粒子较少,韧窝中还有许多小韧窝,韧窝数量较多,Kahn撕裂所得到的UIE与撕裂断口都表明经过工艺B和C处理后,材料的断裂韧性较好。

3 结论

1) 经480 ℃/20 h,430 ℃/2 h+490 ℃/12 h和500 ℃/16 h这3种均匀化工艺处理后,材料的晶界上的β相较少,且呈不连续分布,为抗晶间腐蚀结构;经430 ℃/2 h+490 ℃/12 h双级均匀化处理后得到的O态板材其晶间腐蚀最大深度为14.07 μm,晶间腐蚀等级为二级,质量损失为2.287 8 mg/cm2,相对480 ℃/20 h和500 ℃/16 h工艺处理后的材料耐晶间腐蚀性能更好。

2) 经430 ℃/2 h+490 ℃/12 h双级均匀化工艺处理后的板材在腐蚀介质和惰性介质中的抗拉强度都最高,分别为335.02 MPa和320.23 MPa;该工艺处理后的应力腐蚀敏感指数也最小,为0.068 477,低于480 ℃/20 h工艺制度下的0.109 364和500 ℃/16 h工艺制度下的0.077 671,说明经过双级均匀化处理后的材料应力敏感性小,抗应力腐蚀性能好。

3) 在较小应力强度因子范围内用加载力较小情况下,这3种工艺下板材的疲劳裂纹扩展速率差别不大。随着应力强度因子增大,经过430 ℃/2 h+490 ℃/12 h双级均匀化工艺处理后的板材在较大加载力下,裂纹的扩展速率明显比经480 ℃/20 h和500 ℃/16 h工艺制度处理后材料的低,抗疲劳裂纹扩展性能较好。

4) 经430 ℃/2 h+490 ℃/12 h双级均匀化工艺处理后的板材的单位面积裂纹形核功为212.53 N/mm,与经500 ℃/16 h工艺处理后材料的UIE接近,比经480 ℃/20 h工艺处理后材料的UIE高。撕裂断口中韧窝数量与尺寸也表明经过430 ℃/2 h+490 ℃/12 h双级均匀化处理后的材料断裂韧性更好。

5) 双级均匀化处理后合金腐蚀性能与疲劳性能等均比经单级均匀化处理的优,且从加热温度、保温时间等综合考量,双级均匀化处理的能耗也明显低于单级处理的能耗。

参考文献:

[1] LI Huizhong, WANG Haijun, LIANG Xiaopeng, et al. Effect of Sc and Nd on the microstructure and mechanical properties of Al-Mg-Mn alloy[J]. Journal of Materials Engineering and Performance, 2012, 21(1): 83-88.

[2] JONES R H, BAER D R, DANIELSON M J, et al. Role of Mg in the stress corrosion cracking of an Al-Mg alloy[J]. Metallurgical & Materials Transactions A, 2001, 32(7): 1699- 1711.

[3] SEARIES J L, GOUMA P I, BUCHHEIT R G. Stress corrosion cracking of sensitized AA5083(Al-4.5Mg-1.0Mn)[J]. Metallurgical & Materials Transactions A, 2001, 32(11): 2859- 2867.

[4] POPOVIC M, ROMHANJI E. Stress corrosion cracking susceptibility of Al-Mg alloy sheet with high Mg content[J]. Journal of Materials Processing Technology, 2002, 125(2): 275- 280.

[5] 蒋海春, 叶凌英, 张新明, 等. 5059 高镁铝合金均匀化热处理工艺[J]. 中南大学学报(自然科学版), 2014, 45(12): 4139- 4141.

JIANG Haichun, YE Lingying, ZHANG Xinming, et al. Homogenizationheat treatment process of 5059 high Mg containing aluminum alloy[J]. Journal of Central South University(Science and Technology), 2014, 45(12): 4139-4141.

[6] 陈星霖, 罗兵辉, 刘成. 时效温度和镁含量对高镁铝合金微观组织和腐蚀性能的影响[J]. 材料科学与工程学报, 2009, 27(4): 548-552.

CHEN Xinglin, LUO Binghui, LIU Cheng. Effects of aging temperature and Mg content on the microstructure and corrosive properties of a high-Mg aluminum alloy[J]. Journal of Materials Science and Engineering, 2009, 27(4): 548-552.

[7] HUSKINS E L, CAO B, RAMESH K T. Strengthening mechanisms in an Al-Mg alloy[J]. Materials Science & Engineering A, 2010, 527(6): 1292-1298.

[8] LI Yin, HUNG Yuanchuan, DU Zhiyong, et al. The effect of homogenization on the corrosion behavior of Al-Mg alloy[J]. Physics of Metals & Metallography, 2018, 119(4): 339-346.

[9] 刘晓涛, 董杰, 崔建忠, 等. 高强铝合金均匀化热处理[J]. 中国有色金属学报, 2003, 13(4): 909-913.

LIU Xiaotao, DONG Jie, CUI Jianzhong, et al. Homogenizing treatment of high strength aluminium alloy cast under electric magnetic field[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(4): 909-913.

[10] CARROLL M C, BUCHHEIT R G, DAEHN G S, et al. Optimum trace copper levels for SCC resistance in a Zn-modified Al-5083 alloy[J]. Materials Science Forum, 2002, 396/397/398/399/400/401/402: 1443-1448.

[11] 梁凌宇, 王弘, 董轩成. 厚度对5083铝合金薄板超高周弯曲疲劳性能的影响[J]. 机械工程材料, 2016, 40(3): 85-88.

LIANG Lingyu, WANG Hong, DONG Xuancheng. Effect of thickness on very high cycle bending fatigue properties of 5082 aluminum alloy sheet[J]. Materials for Mechanical Engineering, 2016, 40(3): 85-88.

[12] 杨磊, 罗兵辉, 柏振海, 等. 添加 Zn 对 5083铝合金组织和腐蚀性能的影响[J]. 中南大学学报(自然科学版), 2012, 43(12): 4666-4668.

YANG Lei, LUO Binghui, BAI Zhenhai, et al. Effect of Zn on microstructure and corrosion ropery of 5083 alloy[J]. Journal of Central South University(Science and Technology), 2012, 43(12): 4666-4668.

[13] 周庆波, 张宏伟, 刘科研, 等. 化学成分对5083铝合金性能的影响[J]. 轻合金加工技术, 2007, 35(10): 33-34.

ZHOU Qingbo, ZHANG Hongwei, LIU Keyan, et al. Effect of chemical components on properties of 5083 aluminium alloy[J]. Light Alloy Fabrication Technology, 2007, 35(10): 33-34.

[14] 罗兵辉, 单毅敏, 柏振海. 退火温度对淬火后冷轧5083铝合金组织及腐蚀性能的影响[J]. 中南大学学报(自然科学版), 2007, 38(5): 802-806.

LUO Binghui, SHAN Yimin, BAI Zhenhai, et al. Effect of annealing temperature on microstructure and corrosive properties of cold-rolled 5083 aluminum alloy after quenching[J]. Journal of Central South University(Science and Technology), 2007, 38(5): 802-806.

[15] DAVENPORT A J, YUAN Y, AMBAT R, et al. Intergranular corrosion and stress corrosion cracking of sensitized AA5182[J]. Materials Science Forum, 2006, 519/520/521: 641-646.

[16] MIYAKE Y, SATO Y, TERANISHI R, et al. Effect of heat treatments on the microstructure and formability of Al-Mg-Mn- Sc-Zr alloy[J]. Micron, 2017, 101: 151-155.

[17] POPOVIC M, ROMHANJI E. Stress corrosion cracking susceptibility of Al-Mg alloy sheet with high Mg content[J]. Materials Processing Technology, 2002, 125(2): 275-280.

[18] 彭金波, 康国政, 刘宇杰, 等. 5083-H111轧制铝合金的低周疲劳行为[J]. 机械工程材料, 2015, 39(1): 39-40.

PENG Jinbo, KANG Guozheng, LIU Yujie, et al. Low cycle fatigue behavior of 5083-H111 rolled aluminum alloy[J]. Materials for Mechanical Engineering, 2015, 39(1): 39-40.

(编辑 陈灿华)

收稿日期:2018-04-10;修回日期:2018-06-05

基金项目(Foundation item):国家重点研发计划项目(2016YFB0300901);国家自然科学基金资助项目(51375503) (Project(2016YFB0300901) supported by the Major State Research Program of China; Project(51375503) supported by the National Natural Science Foundation of China)

通信作者:叶凌英,博士,副教授,从事有色金属材料加工研究;E-mail:lingyingye@csu.edu.cn