文章编号:1004-0609(2010)02-0209-08

2124铝合金的均匀化热处理

李成侣,潘清林,刘晓艳,何运斌,李文斌

(中南大学 材料科学与工程学院,长沙 411083)

摘要:采用光学显微镜、差热分析、扫描电镜、能谱分析、透射电镜和X射线衍射研究2124铝合金铸态与均匀化态的显微组织演化和成分分布。结果表明:2124铝合金的铸态组织枝晶偏析严重,在晶界存在很多低熔点共晶相,合金中元素Cu,Mg和Mn在晶内及晶界分布不均匀;经过均匀化处理后,2124铝合金组织中的非平衡相逐渐溶解,各组元分布趋于均匀;该合金的过烧温度为504 ℃,最佳均匀化制度为(490 ℃,24 h),该制度与均匀化动力学方程得到的结论基本一致。

关键词:2124铝合金;均匀化处理;显微组织;动力学

中图分类号:TG 113.12 文献标识码:A

Homogenizing heat treatment of 2124 aluminum alloy

LI Cheng-lü, PAN Qing-lin, LIU Xiao-yan, HE Yun-bin, LI Wen-bin

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The evolution of the microstructure and the composition distribution of as-cast and homogenized 2124 aluminum alloy were studied by optical microscopy (OM), differential scanning calorimetry (DSC), scanning electron microscopy (SEM), energy dispersive X-ray diffractometry (EDX), transmission electron microscopy (TEM) and X-ray diffractometry (XRD). The results show that serious dendrite segregation exists in the 2124 alloy ingot, and many eutectic phases with low melting-point exist in the grain boundary. Cu, Mg and Mn elements distribute unevenly from the grain boundary to inside of the alloy. The non-equilibrium eutectic phases dissolve after homogenization, and the grain boundary becomes sparse and all elements become more homogenized. The over-burnt temperature is 504 ℃. And the proper homogenizing process of the 2124 alloy is (490 ℃, 24 h), which is corresponding with the results of homogenizing kinetic equation.

Key words: 2124 aluminum alloy; homogenization treatment; microstructure; kinetics

2124铝合金是Al-Cu-Mg 系高强高韧铝合金[1],该合金具有优良的压力加工和机械加工性能,合金厚板的伸长率和断裂韧度都优于常规的2024合金厚板,通常以厚板T351和T851状态使用,广泛应用于航天航空材料[2]。众所周知,金属和合金在凝固时都存在枝晶偏析[3?6],在晶界和晶内各组元分布不均匀,必须通过均匀化处理消除或降低晶体内化学成分和组织的不均匀性[7?10]。均匀化处理能促进合金中低熔点共晶相溶解,使合金铸锭化学成分分布趋于均匀,组织达到或接近平衡状态,改善合金中第二相的形状和分布,提高合金的塑性,并提高合金元素在基体中的固溶度,从而提高合金的强度,最终改善合金的加工性能和最终使用性能 [11?13]。

近年来,国内外主要研究2124铝合金的断裂行为和析出相[14?15],梁忠华[16]研究2124铝合金的铸态组织,并提出该合金的最佳热处理制度。王昌臻等[17?18]研究热处理对2124铝合金热轧厚板组织与性能的影响。本文作者研究2124铝合金铸态和均匀化处理后的显微组织和成分变化,得出最佳均匀化工艺,并导出均匀化动力学方程,对于优化2124铝合金均匀化工艺,指导实际生产具有重要意义。

1 实验

1.1 合金铸锭

实验所用合金铸锭为东北轻合金有限责任公司提供。铸锭尺寸为85 mm×300 mm×500 mm,合金的化学成分如表1所列。

表1 实验合金的化学成分

Table 1 Chemical composition of 2124 alloy (mass fraction, %)

1.2 实验方法

1) 取样与均匀化处理。将合金铸锭采用线切割成12 mm×12 mm×15 mm的小块试样,分别在460、475、490、500、510和520 ℃下进行均匀化处理,处理时间为24 h。在选定的最佳均匀化温度下分别处理12、24、48和72 h。均匀化处理所用设备为程序控温SX2-8-10箱式电阻炉,温度误差±2 ℃。

2) 微观组织观察。分别采用POLYVER-MET金相显微镜和飞利浦Sirion200场发射扫描电镜观察铸锭枝晶组织、定性观测枝晶网络溶解程度和残留相的大小、数量和分布特征,金相试样采用Kellers试剂腐蚀,采用面扫描和线扫描分析晶界和晶内的化学成分分布;合金中的第二相分别采用飞利浦Tecnai-G220透射电镜和日本理学G/max 2500 X射线衍射仪进行观察与分析。第二相组成分析采用Sirion200扫描电镜上配套的EDX设备进行;DSC分析在SDT-Q600热分析仪上进行。

2 结果与分析

2.1 铸态合金组织及分析

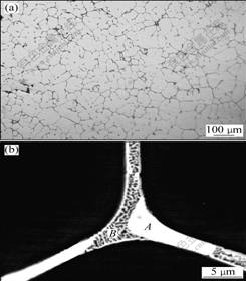

图1所示为铸态2124合金的微观组织。从图1(a)中可以看出,铸态组织由少量树枝状α(Al)和枝晶间低熔点共晶组成,基体α(Al)呈等轴状。由图1(b)可以看出,在晶界处存在粗大的未溶第二相。这些相大部分呈灰色,还有小部分颜色较亮的非平衡相。经EDX能谱分析(见表2)可知,该平衡相主要为Al2CuMg和溶解了Mn的Al2Cu相。

图1 铸态2124合金的微观组织

Fig.1 Microstructures of as-cast 2124 alloy

表2 图1中第二相的化学成分

Table 2 Chemical compositions of secondary phases shown in Fig.1(mole fraction, %)

图2所示为铸态合金的SEM像与合金中主要合金元素Cu、Mg、Mn在晶内及晶界的面扫描分布。从图2可以看出,合金中主要元素Cu和Mg在晶界存在不同程度的富集现象,其成分偏析程度由大到小的顺序依次为Cu、Mg、Mn,元素含量由晶界向晶内逐渐降低。

图2 铸态2124合金的SEM像及元素面扫描分布

Fig.2 SEM image and elements mapping distribution of as-cast 2124 alloy: (a) Microstructure; (b) Cu; (c) Mg; (d) Mn

由以上实验结果可知,2124铸态合金中存在严重的元素偏析,必须对其进行均匀化处理。均匀化退火是基于原子的扩散运动,均匀化过程中,扩散系数与温度的关系可用Arrhenius方程表示如下

式中:D为与温度基本无关的系数;Q为扩散激活能;R为摩尔气体常数;T为绝对温度。从式(1)可以看出,温度越高,扩散系数越大,原子扩散速度越快,偏析越容易消除。因此,为了加速均匀化过程,应尽可能提高均匀化温度。然而,为了防止合金过烧,必须先确定合金的过烧温度。

2.2 铸态合金的DSC分析

图3所示为2124合金铸态的DSC曲线。由图3可知,铸锭在504.0和639.6 ℃处出现吸热峰。其中,639.6 ℃是合金的熔点;504.0 ℃是该合金组织中非平衡低熔点共晶相的熔化温度。由此可以确定该合金铸锭的均匀化温度不能超过504.0 ℃。

图3 铸态2124合金的DSC曲线

Fig.3 DSC curves of as-cast 2124 alloy

2.3 均匀化态合金的组织及分析

2.3.1 不同均匀化处理温度的组织

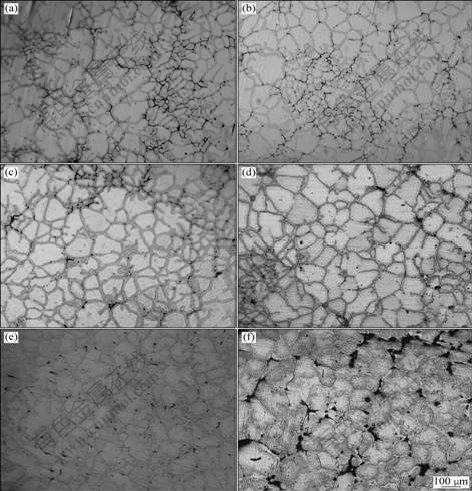

图4所示为合金在不同均匀化温度下进行均匀化的金相组织。从图4可以看出,随着均匀化温度的升高,合金组织中的非平衡低熔点共晶相逐渐溶解,晶界变得稀疏,并且晶界上的残留相由连续分布转变为不连续分布。经490~500 ℃ 保温24 h均匀化处理后,合金中的枝晶网络变稀,非溶相和枝晶偏析基本消除;当均匀化温度进一步升高到510 ℃时,合金中开始出现三角晶界和少量复熔球,出现轻微的过烧组织;合金经520 ℃均匀化后,出现大量晶界复熔物和三角晶界,合金处于严重过烧状态。因此,该合金适宜的均匀化温度为490~500 ℃。但考虑到工业生产中的各种影响因素(大尺寸铸锭和炉温波动等),在满足合金性能要求的前提下,建议合金均匀化温度为490~495 ℃。

图4 2124合金在不同温度均匀化处理后的金相组织

Fig.4 Optical microstructures of 2124 alloy homogenized at different temperatures: (a) 460 ℃; (b) 475 ℃; (c) 490 ℃; (d) 500 ℃; (e) 510 ℃; (f) 520 ℃

2.3.2 不同均匀化处理时间的组织

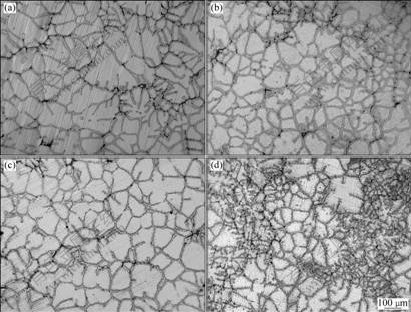

图5所示为合金在490 ℃不同时间下均匀化处理的金相组织。从图5可以看出,随着均匀化时间的延长,晶界上粗大的共晶组织和枝晶逐渐溶解。合金在490 ℃均匀化处理12 h时,枝晶网溶解不充分,晶界上粗大的非平衡相有所减少;当均匀化时间达到24 h时,合金组织中网状共晶体基本溶解,且枝晶网络变稀(见图5(b));此后再延长均匀化时间,尽管枝晶网溶解充分,残留相较少,但效果也不很明显(见图5(c)和(d))。考虑到生产周期,2124合金适宜的均匀化时间定为24 h为宜。

图5 2124合金不同均匀化时间的OM像

Fig.5 OM images of 2124 alloy homogenized at 490 ℃ for different times: (a) 12 h; (b) 24 h; (c) 48 h; (d) 72 h

通过以上实验分析可知,2124合金适宜的均匀化制度为(490~495 ℃,24 h)。

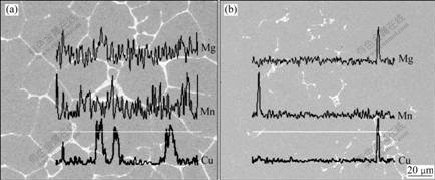

2.3.3 均匀化前后合金元素的成分分布

图6所示为合金铸锭经均匀化处理前后主要合金元素的线扫描分析结果。由图6可见,铸态合金的主要元素Cu、Mg、Mn在合金内分布不均匀,尤其是在晶界上存在明显的富集现象,其中Cu的偏析程度最大,Mg的次之,Mn的偏析程度最小;铸锭经(490 ℃,24 h)均匀化处理后,合金元素扩散,枝晶偏析消除,从晶界至晶内的分布也趋于平稳,只是晶界仍存在少量元素分布偏聚现象。

图6 2124合金的线扫描分析曲线

Fig.6 Line scanning curves of 2124 alloy: (a) As-cast; (b) As-homogenized

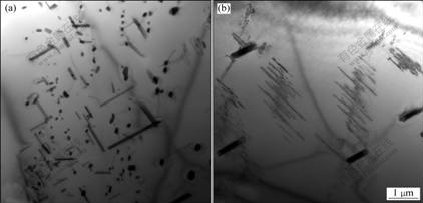

2.3.4 合金的TEM像

图7所示为2124合金铸态和均匀化态的TEM像。由图7可看出,铸态合金主要由α(Al)、片状θ(Al2Cu)和针状S(Al2CuMg)平衡相以及多边形块状Al6Mn结晶相等组成,并且针状S(Al2CuMg)相存在一定程度的偏聚现象。

图7 2124合金的TEM组织

Fig.7 TEM images of 2124 alloy: (a) As-cast; (b) As-homogenized

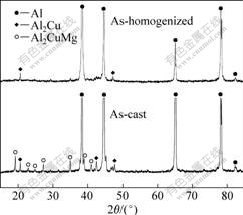

2.3.5 合金的XRD物相分析

图8所示为2124合金铸态和均匀化态的XRD谱。

图8 2124合金铸锭均匀化前后的XRD谱

Fig.8 XRD patterns of 2124 alloy before and after homogenization

由图8可看出,铸态合金主要由α(Al)、S(Al

2CuMg)和θ(Al

2Cu)平衡相组成。合金铸锭经(490 ℃,24 h)均匀化处理后,S(Al

2CuMg)相完全回溶到α(Al)基体中,θ(Al

2Cu)相也基本回溶,只是有极少量残留,这与选取的均匀化温度(490 ℃)偏低有关。对比图8和7可知,合金经均匀化处理后,在透射电镜下可以看到的Al

6Mn相,而在XRD谱中看不到,主要原因是Mn的添加量较少,析出的Al

6Mn粒子质量分数不足基体质量的5%,因而在XRD谱的结果中看不到Al

6Mn相。

2.3.6 均匀化动力学分析

由前面的图6(a)可以看出,合金中主要元素Cu、Mg和Mn沿枝晶间呈周期性变化。HILLERT等[19]研究表明,在具有偏析的铸态组织中,固溶体内部的合金元素含量比枝晶部分的含量低很多,各合金组元的浓度沿枝晶间分布大都呈周期性变化,这与本实验结果相符。因此研究合金组元在均匀化过程中的变化规律,只需研究相邻枝晶间合金组元的扩散规律即可。

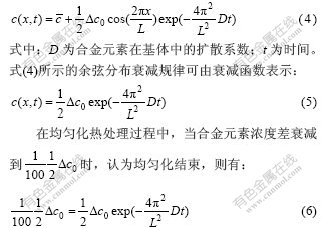

SHEWMAN[20]认为,均匀化过程中合金元素的分布状态可用余弦函数的傅氏级数分量逼近,表达式为

式中:L为枝晶间距;Δc0为晶界与晶内元素含量差; 为完全均匀化后合金元素平均含量;x为元素所在处与晶界的距离。

为完全均匀化后合金元素平均含量;x为元素所在处与晶界的距离。

式(3)逼近的分布状态的每一个基波分量均随加热时间按一定速度独立衰减,基波衰减函数可描述为

而扩散系数D与温度T的关系:

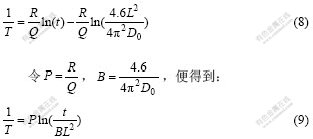

将式(7)代入式(6),整理后得:

式(9)即为均匀化动力学方程。只要给出铸锭原始组织参量便可做出铸锭加热转变动力学曲线。由于在相同温度下,Mg和Mn合金元素的扩散比Cu元素要快,所以主要考虑Cu元素的扩散。在本实验中,D0(Cu)= 0.084 cm2/s,Q(Cu)=136.8 kJ/mol,R=8.31 J/(mol?K),将各参量代入式(8)便可绘出不同参数时Cu元素的均匀化动力学曲线(见图9)。从图9可以看出,随着均匀化温度的升高,均匀化时间大大缩短。

图9 不同参数时Cu元素的均匀化动力学曲线

Fig.9 Homogenization kinetic curves of Cu element at different parameters

根据定量金相可以知道,铸态枝晶平均间距L约为44 μm,由以上分析可知,理想的均匀化温度为490 ℃,查动力学曲线可知在此温度下的均匀化时间为 22 h,这与实验结果(490 ℃,24 h)基本吻合。经均匀化退火后,合金组织枝晶偏析基本消除,晶界上的残留相也基本溶解。但合金经均匀化处理后晶界仍存在少量的Cu和Mg偏聚,这可能是由于合金中这些元素含量较高引起的。

3 结论

1) 铸态2124合金组织中存在严重的元素偏析,偏析程度大小为Cu、Mg、Mn。在晶界上有许多粗大的Al2CuMg和溶解少量Mn的Al2Cu非平衡相。

2) 2124合金铸锭均匀化过烧温度为504 ℃。适宜的实验均匀化温度为490~500 ℃。考虑到工业生产中各种影响因素的影响,建议合金生产均匀化制度以(490~495 ℃,24 h)为宜。

3) 铸态合金主要由基体α(Al)和片状θ(Al2Cu)、针状S(Al2CuMg)相以及多边形块状Al6Mn相等组成。经(490 ℃,24 h)均匀化处理后,合金铸锭中大部分平衡相溶解,晶界变得稀薄,各合金元素分布趋于均匀。

4) 在主要合金元素Cu、Mg和Mn中,Cu的扩散系数最小,偏析最严重,对均匀化过程起控制作用。合金的均匀化动力学方程为 ,由此得到的均匀化制度为(490 ℃,22 h),与实验结果基本吻合。

,由此得到的均匀化制度为(490 ℃,22 h),与实验结果基本吻合。

REFERENCES

[1] 王祝堂, 田荣璋. 铝合金及其加工手册[M]. 长沙: 中南大学出版社, 2000: 64?67.

WANG Zhu-tang, TIAN Rong-zhang. Manual for aluminum alloy and its processing[M]. Changsha: Central South University Press, 2000: 64?67.

[2] 林 钢, 林慧国, 赵玉涛. 铝合金应用手册[M]. 北京: 机械工业出版社, 2006: 484.

LIN Gang, LIN Hui-guo, ZHAO Yu-tao. Aluminum alloy application manual[M]. Beijing: China Machine, 2006: 484.

[3] 刘晓涛, 董 杰, 崔建中, 赵 刚.高强铝合金均匀化热处理[J]. 中国有色金属学报, 2003, 13(4): 909?913.

LIU Xiao-tao, DONG Jie, CUI Jian-zhong, ZHAO Gang. Homogenizing treatment of high strength aluminum alloy cast under electric magnetic field[J]. The Chinese Journal of Nonferrous Metal, 2003, 13(4): 909?913.

[4] WANG Tao, YIN Zhi-min, SUN Qiang. Effect of homogenization treatment on microstructure and hot workability of high strength 7B04 aluminum alloy[J]. Trans Nonferrous Met Soc China, 2007, 17(2): 335?339.

[5] LI Nian-kui, CUI Jian-zhong. Microstructural evolution of high strength 7B04 ingot during homogenization treatment[J]. Trans Nonferrous Met Soc China, 2008, 12(5): 769?773.

[6] 蒋春丽, 姜 峰, 许栩达, 文 康. Al-Cu-Mg-Sc-Zr合金均匀化制度的研究[J]. 材料热处理技术, 2008, 37(4): 10?12.

JIANG Chun-li, JIANG Feng, XU Xu-da, WEN Kang. Study on homogenization treatment of Al-Cu-Mg-Sc-Zr alloy[J]. Material & Heat Treatment, 2008, 37(4): 10?12

[7] FAN Xi-gang, JIANG Da-ming, MENG Qing-chang, LI Zhong. The microstructural evolution of an Al-Zn-Mg-Cu alloy during homogenization[J]. Materials Letters, 2006, 60(12): 1475?1479.

[8] TOTIK Y, SADELER R, KAYMAZ I. The effect of homogenization on cold deformations of AA2014 and AA6063 alloys[J]. Materials Processing Technology, 2004, 147: 60?64.

[9] 仲志国, 左秀荣, 翁永刚. 变形铝合金均匀化热处理的应用现状与研究进展[J]. 轻合金加工技术, 2006, 34(1): 10?14.

ZHONG Zhi-guo, ZUO Xiu-rong, WENG Yong-gang. The application situation and the study development of the wrought aluminum alloy’s homogenization[J]. Light Alloy Fabrication Technology, 2006, 34(1): 10?14.

[10] EIVANI A R, AHMED H, ZHOU J, DUSZCZYK J. Evolution of grain boundary phases during the homogenization of AA7020 aluminum alloy[J]. Metallurgical and Materials Transaction A, 2009, 40(3): 717?728.

[11] 李松瑞, 周善初. 金属热处理[M]. 长沙: 中南大学出版社, 2003: 17?23.

LI Song-rui, ZHOU Shan-chu. Metal heat treatment[M]. Changsha: Central South University Press, 2003: 17?23.

[12] 夏卿坤, 刘志义, 余日成, 李云涛. 均匀化退火对Al-Cu-Mg-Ag系合金组织和性能的影响[J]. 材料热处理, 2006, 35(14): 8?10.

XIA Qing-kun, LIU Zhi-yi, YU Ri-cheng, LI Yun-tao. Effect of homogenizing annealing on microstructure and properties in Al-Cu-Mg-Ag alloy[J]. Material & Heat Treatment, 2006, 35(14): 8?10.

[13] SUKUMARAN K, RAVIKUMAR K K, PILLAI S G K, RAJAN T P D, RAVI M. Study on squeeze casting of 2124 Al alloy and 2124-10%SiCp metal matrix composite[J]. Mater Sci Eng A, 2008, 490: 235?~241.

[14] SMITH G W. Precipitation kinetics in solutionized aluminum alloy 2124: Determination by scanning and isothermal calorimetry[J]. Thermochimica Acta, 1998, 317: 7?23.

[15] MCHUGH K M, LIN Y, ZHOU Y, JOHNSON S B. Microstructure evolution during spray rolling and heat treatment of 2124 Al[J]. Mater Sci Eng A, 2008, 477: 26?34.

[16] 梁忠华. 2124铝合金铸态及厚板的组织分析[J]. 黑龙江大学自然科学学报, 1995, 12(2): 72?76.

LIANG Zhong-hua. Microscopical structures analysis of cast constitution and plant in 2124 aluminum alloy[J]. Journal of Natural Science of Heilongjiang University, 1995, 12(2): 72?76.

[17] 王昌臻, 潘清林, 何运斌. 2124铝合金热轧厚板的热处理制度[J]. 中南大学学报: 自然科学版, 2007, 38(3): 386?393.

WANG Chang-zhen, PAN Qing-lin, HE Yun-bin. Heat treatment of thick hot-rolled plate of 2124 alloy[J]. Journal of Central South University: Science and Technology, 2007, 38(3): 386?393.

[18] 王昌臻, 潘清林, 何运斌, 邹 亮, 尹志明, 聂 波, 何振波. 热处理对2124铝合金热轧厚板组织与性能的影响[J]. 矿业工程, 2007, 27(1): 68?71.

WANG Chang-zhen, PAN Qin-lin, HE Yun-bin, ZOU Liang, YIN Zhi-ming, NIE Bo, HE Zhen-bo. Effect of heat treatment on microstructure and tensile properties of the thick hot-rolled plate of 2124 aluminum alloy[J]. Mining and Metallurgical Engineering, 2007, 27(1): 68?71.

[19] 刘国勋. 金属学原理[M]. 北京: 冶金工业出版社, 1999: 283.

LIU Guo-xun. Fundentals of metallurgy[M]. Beijing: Metallurgical Industry Press, 1999: 283.

[20] 刘晓涛, 崔建忠. 铝合金均匀化扩散动力学研究[J]. 材料导报, 2004, 18(6): 102?104.

LIU Xiao-tao, CUI Jian-zhong. Study on the diffusion kinetics of aluminum alloy cast during homogenizing penetration[J]. Materials Review, 2004, 18(6): 102?104.

基金项目:国防科技资助项目(JGPT-SD-031)

收稿日期:2008-11-14;修订日期:2009-12-04

通信作者:潘清林,教授,博士;电话:0731-88830933;E-mail:pql@mail.csu.edu.cn

(编辑 龙怀中)