文章编号:1004-0609(2015)10-2672-08

Al-Zn-Mg-Zr合金铸锭的均匀化

彭勇宜1, 2,樊鹏飞1, 2,潘清林2

(1. 中南大学 物理与电子学院,长沙 410083;

2. 中南大学 材料科学与工程学院 有色金属材料科学与工程教育部重点实验室,长沙 410083)

摘 要:采用差示扫描量热分析确定Al-Zn-Mg-Zr合金均匀化处理温度和过烧温度,采用光学显微镜、扫描电镜、能谱分析和透射电镜研究合金铸锭均匀化过程中显微组织的演化,探索该合金的均匀化热处理工艺,研究铸锭均匀化动力学过程,并利用菲克定理构建均匀化动力学方程。结果表明:铸态Al-Zn-Mg-Zr合金由α(Al)固溶体、固溶了Cu元素的η-MgZn2相和非平衡共晶相T-Mg32(Al, Zn)49组成。随着均匀化温度的升高和时间的延长,非平衡共晶相溶入基体,晶内有弥散Al3Zr粒子析出,该合金的最佳均匀化热处理工艺为470 ℃退火16 h。

关键词:Al-Zn-Mg-Zr合金;铸锭;均匀化;显微组织;动力学

中图分类号:TG113.12 文献标志码:A

Homogenization treatment of Al-Zn-Mg-Zr alloy ingot

PENG Yong-yi1, 2, FAN Peng-fei1 ,2, PAN Qing-lin2

(1. School of Physics and Electronics, Central South University, Changsha 410083, China;

2. Key Laboratory of Nonferrous Materials Science and Engineering, Ministry of Education,

School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The homogenization temperature and overburnt temperature of an Al-Zn-Mg-Zr alloy ingot were confirmed by differential scanning calorimetry, the microstructure evolution of the alloy during homogenization was investigated by optical microscopy(OM), scanning electron microscopy(SEM), energy dispersive X-ray spectrometry(EDX) and transmission electron microscopy(TEM). And the homogenization kinetics equation was derived by the Fick’s law. The results show that the ingot of Al-Zn-Mg-Zr alloy contains a large mount of second solidifying phases, skeletal MgZn2 phase and T-Mg32(Al,Zn)49 phase, which distribute on the boundaries。The second phases are gradually dissolved into the matrix, and the grain boundaries become spare and thin during homogenization with the increase of the temperature and holding time. The results of homogenization kinetic equation and annealing experiments for the Al-Zn-Mg-Zr alloy both show that (470 ℃, 16 h) is the optimal homogenizing treatment process.

Key words: Al-Zn-Mg-Zr alloy; ingot; homogenization; microstructure; kinetics

高速、节能、环保是现代化交通运输业面临的重要课题,而轻量化是实现上述目标的重要途径,Al-Zn-Mg-Zr合金因其具有较好的力学性能、抗腐蚀性能、热稳定性和优良的焊接性能等特点而广泛应用,成为高速列车、地铁列车、轻轨列车和豪华大巴等现代化交通运输工具的关键材料[1-3]。但由于在Al-Zn-Mg-Zr合金中,合金元素含量较高,铸造过程中冷却速度快,在铸造过程中主要合金元素溶解不充分、分布不均匀,易产生严重的枝晶偏析,形成大量的非平衡凝固共晶组织,必须通过均匀化处理消除或降低化学成分和组织不均匀性,提高铸锭的热加工塑性,同时使低熔点第二相充分溶解,为后续固溶和时效处理作准备[4-5]。

目前,国内外对Al-Zn-Mg系合金的热处理研究多数是针对高强、超高强铝合金,李国峰等[6]对7B50高强铝合金的均匀化进行了研究,讨论了双级均匀化对超高强铝合金的影响。熊创贤等[7]对Al-7.8Zn-1.6Mg-1.8Cu合金铸锭及其均匀化的微结构进行了研究,重点研究了Al3Zr粒子的析出行为。LI等[8]则探讨了均匀化处理对含钪Al-Zn-Mg-Zr合金组织的影响,确定了该合金最佳均匀化处理工艺,ZHENG等[9]通过实验得出了7085铝合金的淬火敏感性随均匀化退火时间的延长而增加的结论。张云崖等[10]指出分级均匀化可促进Al3Zr粒子在Al-Zn-Mg-Cu合金的晶界区域析出,进而影响热轧过程中的动(静)态回复和再结晶过程,提高材料的力学性能。CONG等[11]对均匀化处理对DC铸造7X50铝合金显微组织和力学性能的影响进行了研究,得出预均匀化处理制备的合金板材的抗拉强度和断裂韧性相对常规均匀化处理制备的板材分别提高15 MPa和3.3 MPa·m1/2的相关结论。以上研究均主要针对Cu元素含量较高的7000系高强合金,而对中强可焊铝合金的均匀化热处理工艺研究涉及的较少。

本文作者研究不同均匀化退火制度处理后的中强抗冲撞Al-Zn-Mg-Zr合金显微组织的演变,得出该合金的最佳均匀化热处理工艺,并建立均匀化动力学方程。通过建立数学模型研究了合金组元在均匀化过程中的变化规律,并与实验结果对比,这对于实际生产过程中,快速有效确定合金的均匀化处理工艺具有重要的工程意义。

1 实验

1.1 材料制备

实验采用半连续激冷铜模铸造工艺,其中Al、Zn和Mg以高纯金属形式加入,Cu、Ti、Mn、Zr、Cr分别以Al-48.7%Cu、Al-5%Ti、Al-8.5%Mn、Al-4.5%Zr、和Al-3.7%Cr(质量分数)等中间合金形式加入,制备出50 mm×200 mm×250 mm 的铝合金方锭,其化学成分如表1所列。熔炼选用高纯石墨坩埚井式电阻炉,熔炼温度为750~780 ℃,精炼温度为730~740 ℃, 铸造温度为720~740 ℃,除气剂为C2Cl6。

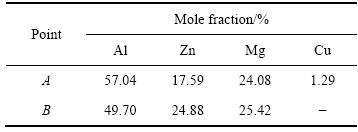

表1 合金化学成分

Table 1 Nominal composition of Al-Zn-Mg-Zr alloy(mass fraction, %)

1.2 实验方法

试验样品从铸锭上经线切割截取,尺寸大小为12 mm×12 mm×8 mm,在440、450、460、470、480和490 ℃下保温12 h,选定最佳处理温度,然后在选定的最佳温度下分别进行4、8、12、16、20和24 h退火处理,确定最佳处理时间。均匀化处理所用设备为SX2-25-10箱式电阻炉,温度误差为±1 ℃。DSC试样取直径6.0 mm、厚度3.5 mm的圆片,从室温加热到700 ℃,升温速率为10 ℃/min。DSC分析在METZSCH DSC 200F3 型同步热分析仪上进行。

将试样置于Polyver-met大型金相显微镜上进行光学金相观察,腐蚀剂为2 mL HF+3 mL HCl+5 mL HNO3+190 mL蒸馏水(Keller 试剂);采用FEI Quanta-200型场发射扫描电镜背散射扫描电子像(Back-scattered scanning electron microscopy,BSEM)观察分析铸态枝晶组织、定性观测枝晶网络溶解程度和未溶相的大小、数量和分布特征,在FEI Quanta-200扫描电镜上配套的EDX设备上进行第二相组成分分析。

2 结果与分析

2.1 合金铸态组织及分析

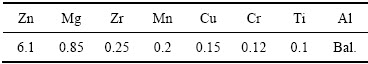

图1所示为添加微量Cu、Cr、Mn、Ti的Al-Zn-Mg-Zr合金的显微组织及主要合金元素Zn、Mg在晶内的分布情况。由图1(a)可知,铸态组织由树枝状α(Al)相和枝晶间的低熔共晶组成,基体α(Al)呈等轴状晶。由图1(b)可知,在晶界处存在粗大的未溶第二相。这些相大部分呈灰色(骨骼状和片状区域),还有小部分颜色稍亮的非平衡相。表2所示为图1(b)中A、B两处的EDS分析结果,结果表明A处主要成分为Al、Zn、Mg,并且含有少量Cu元素;B处成分为Al、Zn、Mg。

图1 铸态Al-Zn-Mg-Zr合金的显微组织

Fig. 1 Microstructures of as-cast Al-Zn-Mg-Zr alloy

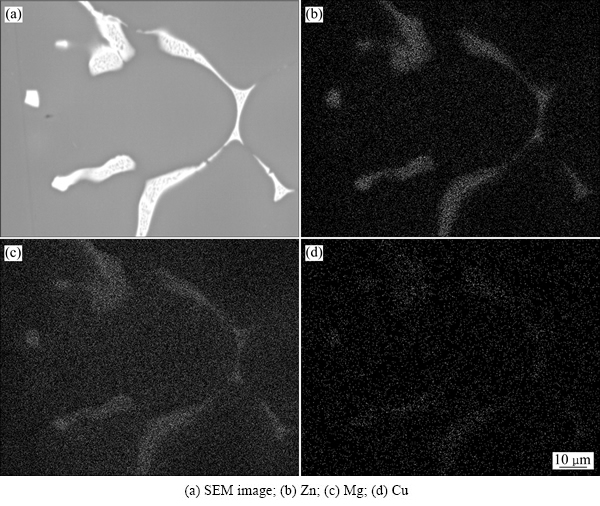

表2 图1(b)中第二相的化学成分

Table 2 Chemical compositions of secondary phases shown in Fig. 1(b)

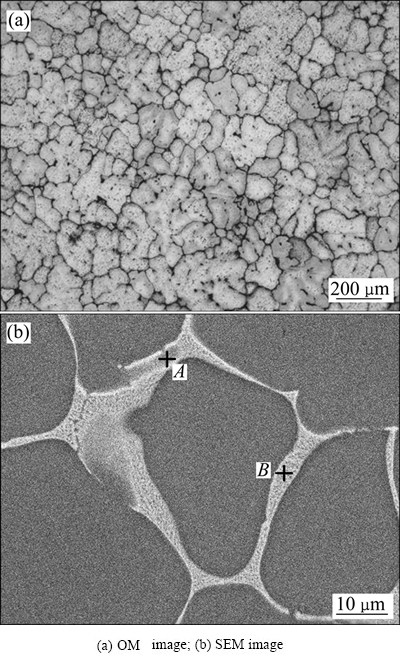

EDS分析中,A处有微量的Cu元素分布,由图2(d)可见,Cu元素的含量很少。对比图2(a)和(d)可以看到,Cu在晶界上分布相对密集。由文献[12-13]可知,当Cu含量低于1.0%(质量分数)时,显微组织不会形成含Cu的第二相结构,Cu几乎完全溶入基体和第二相中。

另外,由于Cu在晶界的富集,所以在晶界上的非平衡共晶相内往往会固溶一定量的Cu,从而形成富Cu的共晶组织,这些组织一般出现在骨骼状和片状区域端头,形貌上和原组织基本相似。面分布图中Zn、Mg元素分布很不均匀,基本聚集在晶界上,表明合金在激冷凝固过程中,大量非平衡相富集在合金晶界处。

图2所示为合金铸锭金相显微组织和元素面扫描分析。由图2可看出,铸锭存在枝晶偏析,晶界上分布着非平衡第二相,主要合金元素Zn、Mg在晶界及第二相粒子上存在着明显的富集现象。为消除枝晶偏析并改善热加工性能,对合金铸锭进行均匀化热处理。

图2 铸态Al-Zn-Mg-Zr合金SEM 像及元素分布

Fig. 2 SEM image(a) and elements distribution((b), (c), (d)) of as-cast Al-Zn-Mg-Zr alloy

2.2 均匀化退火温度的确定

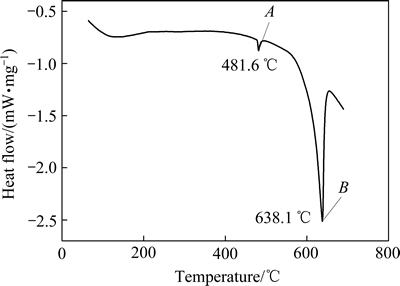

为确定合金的均匀化退火温度,对截取铸态合金先进行了DSC测试和分析。图3所示为Al-Zn-Mg-Zr 合金铸态的DSC 曲线。由图3可知,铸锭在481.6 ℃和638.1 ℃两处出现吸热峰,638.1 ℃为合金熔化终了温度,481.6 ℃为合金组织中低熔点非平衡共晶相熔化温度,可知合金的均匀化退火温度应在481.6 ℃以下。因此,选取450、460、470和480 ℃作为均匀化退火温度进行试验。

2.3 均匀化态合金的组织及分析

2.3.1 不同均匀化处理温度下合金的金相显微组织

图3 铸态Al-Zn-Mg-Zr合金DSC曲线

Fig. 3 DSC curve of as-cast Al-Zn-Mg-Zr alloy

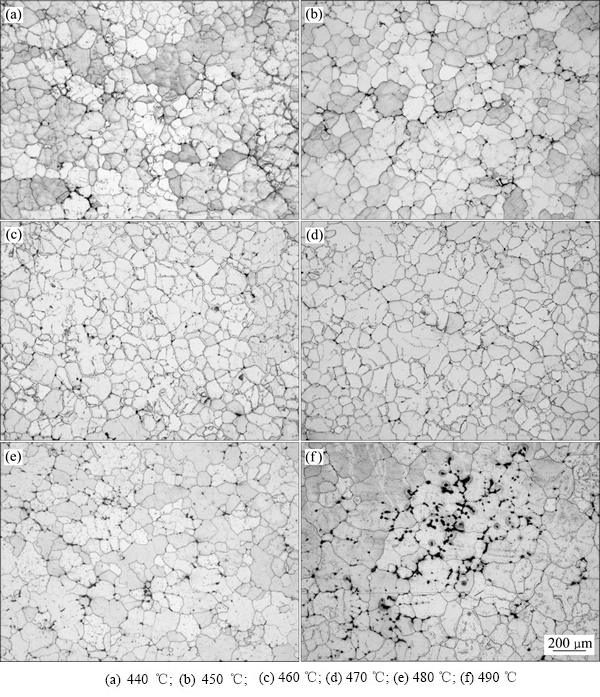

图4 Al-Zn-Mg-Zr合金在不同温度均匀化处理16 h后的金相组织

Fig. 4 Optical microstructures of Al-Zn-Mg-Zr alloy homogenized at different temperatures for 16 h

图4所示为合金在不同温度下进行均匀化退火处理16 h的金相组织。从图4可以看出,随着均匀化温度的升高,合金组织中的非平衡共晶数量较铸态的逐渐减少,网状晶界化合物不再连续,晶界变得稀疏,经460~470 ℃保温16 h均匀化处理后,合金中的枝晶网络变稀,非平衡共晶组织和枝晶偏析基本消除(见图4(c)和(d)));当均匀化温度进一步升高到480 ℃时,合金中开始出现三角晶界和少量复熔球,出现轻微的过烧组织(见图4(e));合金经490 ℃均匀化后,出现大量晶界复熔物和三角晶界,合金呈现严重过烧(见图4(f))。因此,该合金适宜的均匀化温度为470 ℃。

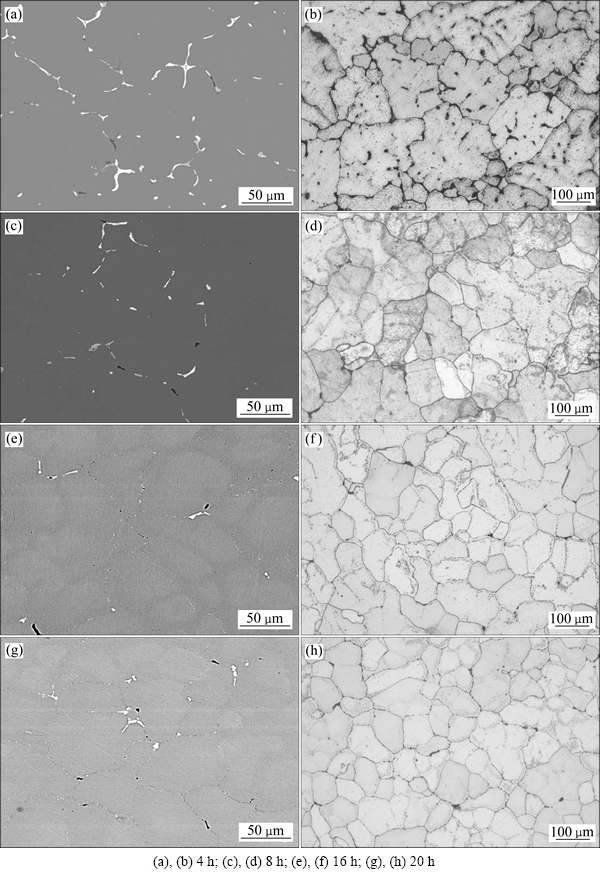

2.3.2 不同均匀化处理时间合金的SEM像和金相组织

图5所示为合金在470 ℃条件下经不同均匀化退火时间处理后的BSEM像和金相组织。从图5可以看出,随着均匀化时间的延长,晶界上粗大的共晶组织和枝晶逐渐溶解。合金在470 ℃均匀化处理4 h时,枝晶网溶解不充分,晶界上粗大的非平衡相有所减少;当均匀化时间达到16 h时,合金组织中网状共晶体基本溶解,且枝晶网络变稀。此后,再延长均匀化处理时间,枝晶网溶解和残留相减少的效果也不明显(见图5(g)和(h)),可见(470 ℃, 16 h)为该合金最适宜的均匀化热处理工艺。

图5 Al-Zn-Mg-Zr合金经470 ℃均匀化处理不同时间后的BSEM像及金相组织

Fig. 5 BSEM images((a), (c), (e), (g)) and optical microstructures((b), (d), (f), (h)) of Al-Zn-Mg-Zr alloy homogenized at 470 ℃ for different times

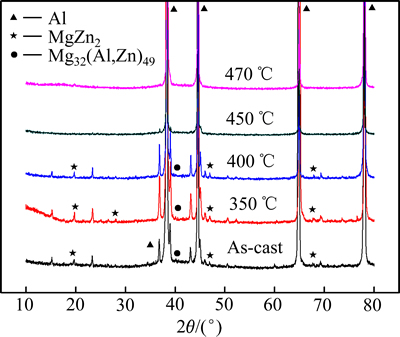

2.4 均匀化态合金的XRD物相分析

图6所示为Al-Zn-Mg-Zr合金铸态及不同温度下均匀化处理16 h的XRD谱。由图6可知,铸态合金由α(Al)固溶体、固溶了Cu元素的η-MgZn2相和非平衡共晶相T-Mg32(Al, Zn)49组成。铸锭经350 ℃、16 h均匀化后,过饱和固溶体分解,合金中析出较多的η相;当均匀化温度超过400 ℃时,合金组织中η相的含量随着均匀化温度的升高开始减少,析出相又回溶到α(Al)基体中;经(470 ℃, 16 h)均匀化处理后,η相和T相完全回溶入α(Al)基体中。

图6 Al-Zn-Mg-Zr合金在不同温度下均匀化处理16 h的XRD谱

Fig. 6 XRD patterns of Al-Zn-Mg-Zr alloy homogenized at different temperatures for 16 h

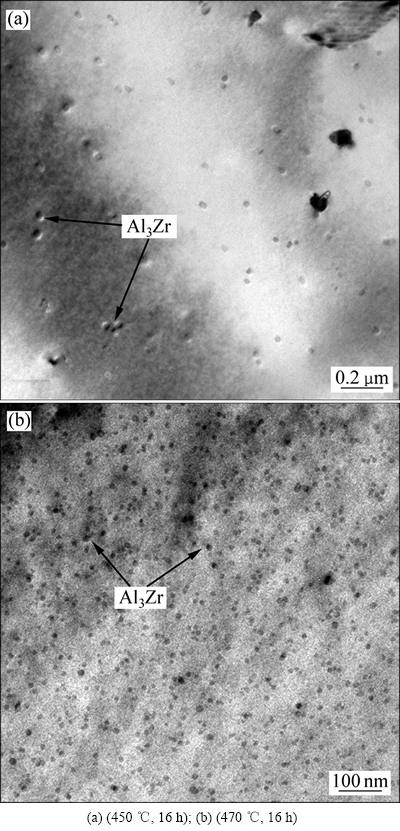

2.5 均匀化态合金的TEM像

图7所示为均匀化态合金的TEM像。由图7(a)可知,在450 ℃下均匀化保温16 h,合金中析出了尺寸为10~20 nm的Al3Zr粒子。微量Zr元素能抑制铝合金的再结晶,提高其再结晶温度。在室温下,Zr在合金中主要以过饱和固溶体形式存在,且十分稳定,在250 ℃时,Al3Zr 粒子的析出时间长达1000 h[14]。Al3Zr粒子对再结晶的抑制作用取决于析出的Al3Zr粒子的尺寸大小、分布间距和体积分数。通过均匀化热处理,可以获得具有再结晶抑制作用的细小弥散分布的球形Al3Zr粒子。ROBSON等[15]研究Al-Zn-Mg-Cu合金中Zn、Mg、Cu等主要合金元素对Al3Zr析出动力学过程的影响,发现Zn、Mg、Cu等合金元素的添加可以大大缩短Al3Zr粒子析出的孕育期,促使Al3Zr粒子细化。本合金中的Zn、Mg、Cu 总含量比ROBSON等[15]研究合金中的总含量高3%,Al3Zr粒子析出的孕育期更短。470 ℃条件下均匀化退火,Al3Zr粒子的孕育期为4 h,在此温度下保温16 h析出了大量的Al3Zr粒子(见图7(b))。

图7 均匀化退火的Al-Zn-Mg-Zr合金TEM像

Fig. 7 TEM images of homogenized Al-Zn-Mg-Zr alloy at different conditions

2.6 均匀化动力学分析

合金中主要元素Zn和Mg沿枝晶间呈周期性变化。HILLERT[16]研究表明,在具有偏析的铸态组织中,枝晶部分的合金元素含量比基体内部的合金元素含量高很多,各合金组元的浓度沿枝晶间分布大都呈周期性变化。因此,研究合金组元在均匀化过程中的变化规律,只需研究相邻枝晶间合金组元的扩散规律即可。

LI等[8]和JIANG等[17]认为,均匀化过程中合金元素的分布状态c(x)可用余弦函数的傅氏级数分量逼近,表达式为

(1)

(1)

(2)

(2)

式中:L为枝晶间距; 为晶界与晶内元素的浓度差;

为晶界与晶内元素的浓度差; 为完全均匀化后合金元素平均含量;x为元素所在处与晶界的距离。

为完全均匀化后合金元素平均含量;x为元素所在处与晶界的距离。

式(2)逼近的分布状态的每一个基波分量均随加热时间按一定速度独立衰减,基波衰减函数A(t)可以表示为

(3)

(3)

式中:D为合金元素在基体中的扩散系数;t为时间。且扩散系数D与温度T的关系为

(4)

(4)

式中:D0为常数;Q为激活能;R为普适气体常数;T为均匀化热力学温度。

在均匀化退火过程中,当合金元素浓度差衰减到1/100时,认为均匀化结束,即当

(5)

(5)

对式(5)取自然对数,则有

(6)

(6)

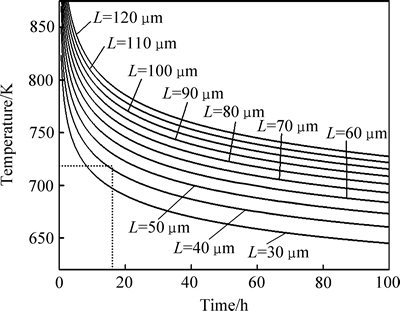

式(6)即为均匀化动力学方程。将铸锭原始组织参量代入便可做出铸锭加热转变动力学曲线。此合金中,Zn与Mg的扩散速度相当,热激活能非常接近,本文作者考虑Mg元素的扩散。据文献[18],D0(Mg)= 1.2×10-4 m2/s,Q(Mg)=130 kJ/mol,R=8.31 J/(mol·K),将各参量代入式(6)绘出不同参数时Mg元素的均匀化动力学曲线(见图8)。从图8可以看出,随着均匀化温度的升高,均匀化时间大大缩短。

采用Image J相图软件测量大量的铸态枝晶平均间距,并定量统计得出铸态枝晶平均间距约为52 μm,由以上分析可知,理想的均匀化温度为470 ℃,查动力学曲线可知,此温度下的均匀化时间为16 h,这与前述实验得出的该合金最佳的均匀化制度(470 ℃, 16 h)相吻合。

图8 不同枝晶间距时Mg元素的均匀化动力学曲线

Fig. 8 Homogenization kinetic curves of Mg element at different dendrite arm spacing

3 结论

1) 铸态Al-Zn-Mg-Zr合金组织中存在严重的元素偏析,偏析程度大小为Zn、Mg、Cu。铸态Al-Zn-Mg-Zr合金主要由α(Al)固溶体和固溶了Cu元素的η-MgZn2相和非平衡共晶相T-Mg32(Al, Zn)49组成。

2) Al-Zn-Mg-Zr合金铸锭均匀化过烧温度为 481.6 ℃。在350 ℃以下均匀化,铸锭过饱和固溶体分解,平衡相η-MgZn2增加,枝晶没有消除;当均匀化温度超过400 ℃后,合金中的非平衡相逐渐溶解,经(470 ℃, 16 h)均匀化处理后,合金铸锭中大部分非平衡相溶解,晶界变得稀薄,各合金元素分布趋于均匀。

3) 通过均匀化动力学方程和曲线分析得到的理想均匀化制度是(470 ℃, 16 h),这与实验获得的最佳均匀化制度基本吻合。

REFERENCES

[1] LI Bo, PAN Qing-lin, ZHANG Zhi-ye, LI Chen. Characterization of flow behavior and microstructura1 evolution of A1-Zn-Mg-Sc-Zr alloy using processing maps[J]. Materials Science and Engineering A, 2012, 556: 844-848.

[2] 王正安, 汪明朴, 李 周, 杨文超, 肖从文. 轨道交通车辆大型材用7005 铝合金的热处理特性[J]. 中国有色金属学报, 2010, 20(6): 54-56.

WANG Zheng-an, WANG Ming-pu, LI Zhou, YANG Wen-chao, XIAO Cong-wen. Heat treatment characteristic of 7005 Al alloy employed in railway trains[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(6): 54-56.

[3] DEV S, STUART A A, KUMAAR R C R D, MURTY B S, RAO K P. Effect of scandium additions on microstructure and mechanical properties of A1-Zn-Mg alloy welds[J]. Materials Science and Engineering A, 2007, 467: 132-138.

[4] ZOU Liang, PAN Qing-lin, HE Yun-bin, WANG Chang-zhen, LIANG Wen-jie. Effect of minor Sc and Zr addition on microstructures and mechanical properties of A1-Zn-Mg-Cu alloys[J]. Transactions of Nonferrous Metals Society of China, 2007, 17(2): 340-345.

[5] DENG Ying, YIN Zhi-min, CONG Fu-guan. Intermetallic phase evolution of 7050 aluminum alloy during homogenization[J]. Intermetallics, 2012, 26: 114-121.

[6] 李国峰, 张新明, 朱航飞, 李鹏辉. 7B50高强铝合金的均匀化[J]. 中国有色金属学报, 2008, 18(5): 764-770.

LI Guo-feng, ZHANG Xin-ming, ZHU Hang-fei, LI Peng-hui. Homogenizing treatment of 7850 high strength aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(5): 764-770.

[7] 熊创贤, 万 里, 邓运来, 张新明. Al-7.8Zn-1.6Mg-1.8Cu合金铸锭及其均匀化的微结构研究[J]. 中南大学学报(自然科学版), 2010, 41(2): 465-471.

XIONG Chuang-xian, WAN Li, DENG Yun-lai, ZHANG Xin-ming. Investigation of microstructures in as-cast and homogenizedAl-7.8Zn-1.6Mg-1.8Cu aluminum alloy[J]. Journal of Central South University (Science and Technology), 2010, 41(2): 465-471.

[8] LI Bo, PAN Qing-lin, SHI Yun-jia, LI Chen, YIN Zhi-min. Microstructural evolution of Al-Zn-Mg-Zr alloy with trace amount of Sc during homogenization treatment[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(12): 3568-3574.

[9] ZHENG Yu-lin, LI Cheng-bo, LIU Sheng-dan, DENG Yun-lai, ZHANG Xin-ming. Effect of homogenization time on quench sensitivity of 7085 aluminum alloy[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(7): 2275-2281.

[10] 张云崖, 邓运来, 万 里, 张新明. Al3Zr析出相对Al-Zn-Mg-Cu合金板组织、织构与性能的影响[J]. 中国有色金属学报, 2012, 22(2): 358-364.

ZHANG Yun-ya, DENG Yun-lai, WAN Li, ZHANG Xin-ming. Effects of precipitation of Al3Zr particles on microstructures, textures and properties of Al-Zn-Mg-Cu alloy hot-rolled plate[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(2): 358-364.

[11] CONG Fu-guan, ZHAO Gang, JIANG Feng, TIAN Ni, LI Rui-feng. Effect of homogenization treatment on microstructure and mechanical properties of DC cast 7X50 aluminum alloy[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(4): 1027-1034.

[12] 王祝堂, 田荣璋. 铝合金及其加工手册[M]. 2版. 长沙: 中南大学出版社, 2000: 16-18.

WANG Zhu-tang, TIAN Rong-zhang. Aluminum alloy and its processing handbook[M]. 2nd ed. Changsha: Central South University Press, 2000: 16-18.

[13] 李 晨, 潘清林, 彭 虹, 李 波, 尹志民. 含钪铝锌镁合金铸锭和均匀化显微组织研究[J]. 热加工工艺, 2012, 41(24): 91-94.

LI Chen, PAN Qing-lin, PENG Hong, LI Bo, YIN Zhi-min. Investigation on microstructure of as-cast and homogenized Al-Zn-Mg-Sc alloys[J]. Hot Working Technology, 2012, 41(24): 91-94.

[14] 戴晓元, 夏长清, 彭小敏. 7×××铝合金退火过程中二次Al3(Sc, Zr)粒子的析出行为[J]. 中国有色金属学报, 2010, 20(3): 451-455.

DAI Xiao-yuan, XIA Chang-qing, PENG Xiao-min. Precipitation behavior of Al3(Sc, Zr) secondary particles in 7××× aluminum alloys during annealing[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(3): 451-455.

[15] ROBSON J D, PRANGNELL P B. Modelling Al3Zr dispersoid precipitation in multicomponent aluminium alloys[J]. Materials Science and Engineering A, 2003, 352: 240-250.

[16] HILLERT A. 合金扩散和热力学[M]. 北京: 冶金工业出版社, 1999.

HILLERT A. Diffusion and thermodynamics of alloy[M]. Beijing: Metallurgical Industry Press, 1999.

[17] JIANG Hai-chun, YE Ling-ying, ZHANG Xin-ming, GU Gang, ZHANG Pan, WU Yu-long. Intermetallic phase evolution of 5059 aluminum alloy during homogenization[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(12): 3553-3560.

[18] 张伟彬. 多元A1合金扩散系数研究及扩散行为模拟[D]. 长沙: 中南大学, 2012: 22-24.

ZHANG Wei-bin. Investigation of diffusion coefficient and simulation of diffusion behavior in the multi-Al alloys[D]. Changsha: Central South University, 2012: 22-24.

(编辑 李艳红)

基金项目:湖南省科技计划资助项目(2014FJ3092)

收稿日期:2015-02-09;修订日期:2015-06-19

通信作者:潘清林,教授,博士;电话:0731-88830933;E-mail: pql@mail.csu.edu.cn