文章编号:1004-0609(2010)05-0820-07

喷射成形Al-9.97Zn-2.65Mg-1.94Cu-0.12%Zr合金均匀化过程中的组织演变

左玉婷,王 锋,熊柏青,张永安,朱宝宏,刘红伟,李志辉

(北京有色金属研究总院 有色金属材料制备加工国家重点实验室,北京 100088)

摘 要:采用光学显微镜、扫描电镜、透射电镜、X射线衍射、差热分析等手段,研究了喷射成形Al-9.97Zn-2.65Mg-1.94Cu-0.12%Zr合金在均匀化过程中微观组织的演变。结果表明:均匀化处理可使合金中的一次析出相明显减少,经470 ℃均匀化处理24 h的Al-9.97Zn-2.65Mg-1.94Cu-0.12%Zr合金的晶粒尺寸没有明显长大,大多数AlZnMgCu四元相回溶到基体中;均匀化态组织除α(Al)外,主要存在3种不同的相,分别为AlZnMgCu四元相、Al9FeNi相以及Al3Zr(L12) 弥散粒子。

关键词:喷射成形;均匀化处理;Al-Zn-Mg-Cu合金

中图分类号:TG 166.3 文献标志码:A

Microstructural evolution of spray formed Al-9.97Zn-2.65Mg-1.94Cu-0.12%Zr alloy during homogenization

ZUO Yu-ting, WANG Feng, XIONG Bai-qing, ZHANG Yong-an, ZHU Bao-hong, LIU Hong-wei, LI Zhi-hui

(State Key Laboratory for Fabrication and Processing of Nonferrous Metals,

General Research Institute For Nonferrous Metals, Beijing 100088, China)

Abstract: Microstructural evolution of spray formed Al-9.97Zn-2.65Mg-1.94Cu-0.12%Zr alloy during homogenization was studied by using optical microscopy, scanning electron microscopy with energy dispersive X-ray spectroscopy, transmission electron microscopy, X-ray diffractometry and differential scanning calorimetry. The results show that the homogenization can decrease the primary precipitates of the alloy obviously, and the coarsening of the grains is not obvious during homogenization treatment at 470 ℃ for 24 h, and most of the AlZnMgCu phases are dissolved into the matrix. After homogenization, the microstructure of the alloy is composed of α(Al), AlZnMgCu phases, Al9FeNi phases and Al3Zr (L12) dispersoids.

Key words: spray-formed; homogenization; Al-Zn-Mg-Cu alloy

7000系铝合金因其优良的性能广泛应用于航空航天领域。随着对材料性能的要求不断提高,7000系铝合金的强度、韧性、疲劳性能、抗剥落腐蚀性能、抗应力腐蚀性能以及淬火敏感性都成为设计合金所要考虑的重要因素[1]。采用喷射成形技术制备的7000系铝合金,克服了传统工艺生产高锌含量铝合金时存在晶粒粗大、宏观偏析显著、铸锭内部容易热裂等缺点,能够得到细小的等轴晶和球状组织,且无明显宏观偏析,最大限度地提高了溶质原子的固溶度。各种研究表明,喷射成形铝合金的力学性能比传统铸造铝合金的力学性能高得多,采用喷射成形技术可制备抗拉强度大于800 MPa的7000铝合金[2-9]。

喷射成形铸锭一般需经热加工及热处理得到最终的产品,其中热处理对性能有着至关重要的影响。热处理工艺主要是固溶处理和时效处理,固溶处理是在晶粒不发生长大和再结晶的条件下,使第一相尽可能的回溶,得到最大的过饱和度;而时效处理是尽可能促使第二相粒子均匀析出,以达到强化的目的[3-6]。目前,国内外对喷射成形7000系铝合金的热处理工艺已进行了许多研究[8-10],针对喷射成形超高强铝合金提出了相应的固溶时效工艺,而对喷射成形超高强铝合金的均匀化热处理研究鲜有报道。研究发现,喷射成形坯锭热挤压后的短时固溶并不能使第二相完全回溶,得不到最大过饱和度,影响时效阶段的第二相析出,限制合金获得其最佳力学性能。因此,有必要研究喷射成形坯锭合理的均匀化工艺,使一次析出相在高温均匀化阶段回溶,并析出Al3Zr(L12)弥散强化粒子,最终经热挤压及固溶时效处理后,得到所需的合金组织。

1 实验

在北京有色金属研究总院自行研制的SF-200喷射成形设备上进行喷射成形实验,制得的实验合金成分(质量分数)如下:9.97%Zn,2.65%Mg,1.94%Cu,0.12%Zr,Al余量。具体的喷射成形工艺参数如下:雾化气体为N2,雾化温度为780~850 ℃,接收距离为400~500 mm,斜喷角为20?~30?,接收盘旋转速度为30~60 r/min,下降速度为1~3 mm/s,雾化压力为0.6~0.8 MPa。将沉积坯件车加工去除表皮,取厚15 mm的圆盘进行实验研究。选择465和470 ℃作为均匀化温度,均匀化时间为24 h,出炉水淬。

用差热分析的方法确定低熔点析出相的熔化温度,差热分析仪型号为NETZSCH STA 409 C/CD。X射线衍射在日本理学DMAX-RB 12 KW旋转阳极衍射仪上进行。组织观察在Axiocert200MAT光学显微镜,HITACHI-S4800型扫描电镜及JEM-2010透射微镜上进行。

2 结果与分析

2.1 沉积态组织

喷射成形Al-9.97Zn-2.65Mg-1.94Cu-0.12%Zr合金(简称Al-Zn-Mg-Cu合金)在扫描电镜下观察到的典型组织如图1所示。由图1可见,晶粒近似球状,尺寸约20~30 ?m,均匀分布;晶界分布着大量一次析出相,

图1 喷射成形Al-Zn-Mg-Cu合金沉积态组织

Fig.1 Micrograph of as-deposited microstructure of spray formed Al-Zn-Mg-Cu alloy

尺寸约1~5 ?m;晶内存在许多尺寸细小的析出相。

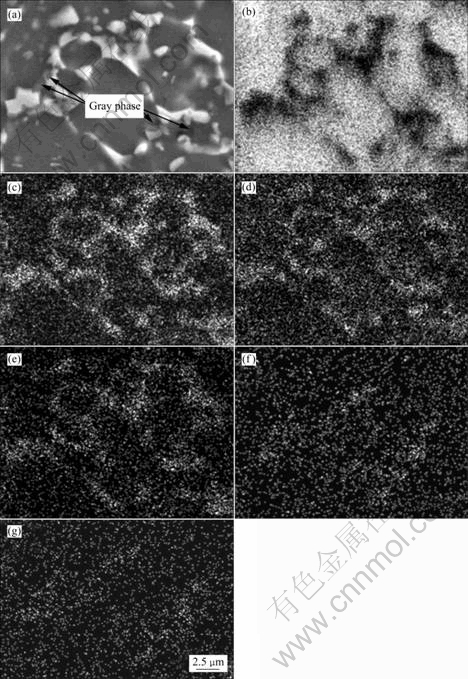

图2所示为喷射成形Al-Zn-Mg-Cu合金沉积态组织的SEM像及元素面扫描分布图。由图2可见,合金沉积态组织中Zn、Mg、Cu合金元素在晶界及白色第二相处都有一定的偏析。Fe和Ni元素在灰色相处偏析,因此,灰色相含Fe和Ni元素。由图2(a)可知,白色相包围着灰色相生长,FeNi相熔点较高,在凝固过程中首先析出。

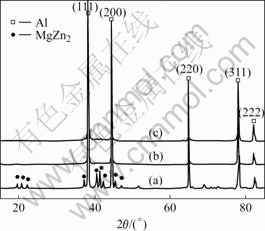

图3所示为喷射成形Al-Zn-Mg-Cu合金沉积态及均匀化态组织的XRD谱。由图3(a)可知,合金沉积态组织主要由α(Al)固溶体和MgZn2相组成。由于含FeNi的灰色相数量过少,XRD谱中没有出现其衍射峰。为了消除偏析,使一次析出相大量回溶,优化合金的性能,需对沉积态坯锭进行均匀化处理。

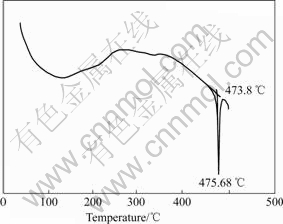

图4所示为喷射成形Al-Zn-Mg-Cu合金沉积态组织的DSC曲线。由图4可见,喷射成形Al-Zn-Mg-Cu合金在475.68 ℃有较大的吸热峰,该峰对应的喷射成形Al-9.97Zn-2.65Mg-1.94Cu-0.12%Zr合金中析出相的开始熔化温度为473.8 ℃,因此,均匀化的温度不宜超过此温度。本研究采用的两种均匀化工艺如下:均匀化温度分别为465和470 ℃,均匀化时间均为24 h。

2.2 均匀化态组织

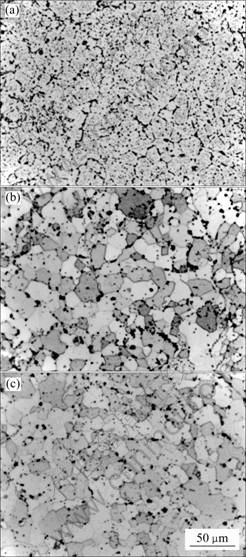

在均匀化处理过程中,析出相中的合金元素扩散进入基体,AlZnMgCu一次析出相逐渐溶解。图5(a)~(c)所示分别为喷射成形Al-Zn-Mg-Cu合金沉积态、465 ℃均匀化24 h、470 ℃均匀化24 h的金相照片。由图5可知,沉积态合金经过均匀化后,晶界显著变细,趋于光滑,晶粒尺寸没有明显变化,未发生显著长大。

图6所示为喷射成形Al-Zn-Mg-Cu合金在465和470 ℃均匀化24 h的SEM像。由图6(a)可见,沉积

图2 喷射成形Al-Zn-Mg-Cu合金沉积态组织的SEM像和元素面扫描分布图

Fig.2 SEM image and elemental maps of as-deposited microstructure of spray formed Al-Zn-Mg-Cu alloy: (a) SEM image; (b) Al; (c) Zn; (d) Mg; (e) Cu; (f) Fe, (g) Ni

态合金经465 ℃均匀化处理24 h后,低熔点一次析出相大量溶解,晶界连续析出相断开,残留少量1~5 ?m的第二相。从图6(b)可见,沉积态合金在470 ℃均匀化24 h后,一次析出相基本溶解,还残留少数孤立粗大的析出相,第二相形状趋于球状。采用Axio Vision软件对一次析出相面积分数进行计算,结果表明:沉积态中一次析出相的面积分数为8.47%;在465 ℃均匀化24 h后,一次析出相的面积分数下降至2.04%;在470 ℃均匀化24 h,一次析出相的面积分数为1.19%。由图3(b)、(c) 所示均匀化态合金的XRD谱可见,由于一次析出相大量减少,MgZn2相的衍射峰也消失了,且未见文献[11-12]中提到的Al2CuMg相的衍射峰。

图7所示为喷射成形Al-Zn-Mg-Cu合金在465 ℃均匀化处理24 h后在SEM下观察到的典型残留析出相。表1所列为图7中各析出相的能谱分析结果。由图7可知,残留析出相主要为白色粗大相(如图7中箭头1、2所指)以及少量尺寸约1 ?m的灰色相(如图7中箭头3、4和5所指)。由EDS成分分析结果可知,粗大相1和2为AlZnMgCu四元相;灰色相3、4和5

图3 喷射成形Al-Zn-Mg-Cu合金沉积态及均匀化态组织的XRD谱

Fig.3 XRD patterns of spray formed Al-Zn-Mg-Cu alloy: (a) As-deposited; (b) Homogenized at 465℃for 24 h; (c) Homogenized at 470 ℃ for 24 h

图4 喷射成形Al-Zn-Mg-Cu合金沉积态组织的DSC曲线

Fig.4 DSC curve of as-deposited microstructure of spray formed Al-Zn-Mg-Cu alloy

表1 喷射成形Al-Zn-Mg-Cu合金在465 ℃均匀化24 h后析出相的EDS分析结果

Table 1 EDS analysis results of spray formed Al-Zn-Mg-Cu alloy homogenized at 465 ℃for 24 h

图5 喷射成形Al-Zn-Mg-Cu合金的金相照片

Fig.5 OM micrographs of spray formed Al-Zn-Mg-Cu alloy: (a) As-deposited; (b) Homogenized at 465 ℃ for 24 h; (c) Homogenized at 470 ℃ for 24 h

为含Fe和Ni相,因此,残余一次相为白色AlZnMgCu四元相和灰色含Fe和Ni相。析出相的具体结构有待进一步分析确定。

均匀化处理基于原子的扩散运动,根据扩散第一定律,单位时间通过单位面积的扩散质量(J)正比于垂直该界面x方向上该物质的浓度梯度,即

扩散系数D与温度的关系为

图6 喷射成形Al-Zn-Mg-Cu合金的SEM像

Fig.6 SEM images of spray-formed Al-Zn-Mg-Cu alloy homogenized for 24 h: (a) At 465 ℃; (b) At 470 ℃

这表明均匀化温度稍有升高将使扩散过程大大加速[13]。由图5(a)和(b)可知,均匀化温度提高至470 ℃时,加速了各合金元素的扩散过程,使沉积态合金中的一次析出相进一步回溶,经过470 ℃均匀化24 h,组织中残留的析出相已很少,且残留析出相趋于球化。

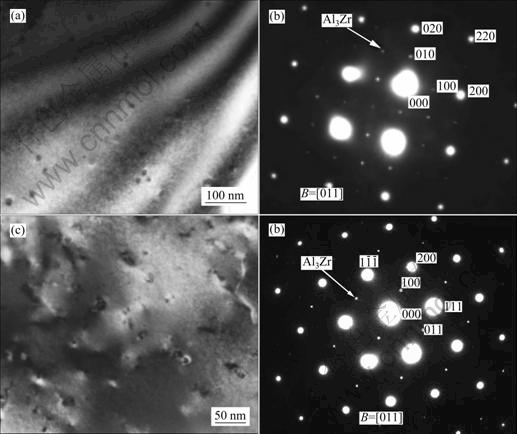

图8所示为喷射成形Al-Zn-Mg-Cu合金在470 ℃均匀化处理24 h后第二相的TEM像及选区衍射花样。

图7 在465 ℃均匀化2 4 h的喷射成形Al-Zn-Mg-Cu合金的SEM像

Fig.7 SEM image of spray formed Al-Zn-Mg-Cu alloy homogenized at 465 ℃for 24 h

图8 在470 ℃均匀化24 h的喷射成形Al-Zn-Mg-Cu合金的TEM像及选区衍射花样

Fig.8 TEM micrographs of spray formed Al-Zn-Mg-Cu alloy homogenized at 470 ℃ for 24 h: (a) Bright-field image of MgZn2 phase; (b) SADP (selected area diffraction pattern) of MgZn2 phase as shown in Fig. 8(a); (c) Bright-field image of Al9FeNi phase; (d) SADP of Al9FeNi phase as shown in Fig. 8(c)

图9 喷射成形Al-Zn-Mg-Cu合金均匀化态组织中Al3Zr 弥散相的TEM像及选区衍射花样

Fig.9 TEM images and SADP of Al3Zr dispersoids in spray formed Al-Zn-Mg-Cu alloy homogenized at 470 ℃ for 24 h: (a) Al3Zr dispersoids with B=[001] close to Al zone axis; (b) SADP of Al3Zr dispersoids as shown in Fig. 9(a); (c) Al3Zr dispersoids with B=[011] close to Al zone axis; (d) SADP of Al3Zr dispersoids as shown in Fig. 9(c)

对衍射花样进行标定, 确定图8(a)中第二相为MgZn2结构相,但其EDS分析结果显示,该相中固溶进了部分Al、Cu原子,因此,确定该相为MgZn2结构的AlZnMgCu四元相。图8(b)中第二相为Al9FeNi相。由图1可知,在沉积态组织中就可观察到灰色的Al9FeNi相,因此,可以确定Al9FeNi相是在合金凝固过程中形成的。由于FeNi相熔点较高,在470 ℃均匀化24 h后没有发生明显变化。在TEM下观察未发现Al2CuMg相,结合图3(b)和(c)所示均匀化态合金的XRD谱可知,喷射成形Al-Zn-Mg-Cu合金在470 ℃均匀化处理24 h后,低熔点相(大量)溶解、部分粗化,未发生文献[12, 14]中提到的低熔点相向Al2CuMg相的转变。

在7xxx超高强铝合金中Zr元素是一个重要的微量元素,具有细化晶粒、抑制再结晶以及提高合金抗应力腐蚀性能的作用,并通过弥散析出的、与基体共格的Al3Zr(L12)粒子提高合金的强度[10, 15]。由于喷射成形冷速较快,凝固过程中Zr元素固溶在Al基体中,均匀化处理对超高强铝合金的另一个重要作用就是弥散析出的纳米级Al3Zr(L12)粒子[16]。

图9所示为喷射成形Al-Zn-Mg-Cu合金均匀化态组织中Al3Zr弥散相的TEM像及选区电子衍射花样。由图9可知,在明场相中可以观察到粒径约20~30 nm的球状粒子弥散分布,衍射花样中在Al基体衍射斑点的1/2位置处有较强的斑点,经标定为与基体呈共格关系的Al3Zr(L12)的衍射斑点。图9(a)中B为[001]晶带轴,图9(b)中B为[011]晶带轴。

3 结论

1) 喷射成形Al-9.97Zn-2.65Mg-1.94Cu-0.12%Zr合金沉积态组织主要由α(Al)与MgZn2结构的AlZnMgCu四元相组成,沉积态组织中还含有少量的Al9FeNi相。

2) 喷射成形Al-9.97Zn-2.65Mg-1.94Cu-0.12%Zr合金沉积坯锭经470 ℃均匀化处理24 h后,一次析出相大量溶解、部分粗化,除α(Al)之外,还残留少量MgZn2结构的AlZnMgCu四元相、Al9FeNi相及Al3Zr(L12)弥散粒子。

REFERENCES

[1] THOMPSON D S. Metallurgical factors affecting[J]. Metallurgical Transactions A, 1975, 6: 671-691.

[2] GRANT P S. Spray forming[J]. Progress in Materials Science, 1995, 39: 397-545.

[3] 李先聚, 杨 杰, 张 豪, 张 捷, 张 荻. 喷射成形7055铝合金的显微组织和力学性能[J]. 中国有色金属学报, 2007, 17(12): 1987-1992.

LI Xian-ju, YANG Jie, ZHANG Hao, ZHANG Jie, ZHANG Di. Microstructure and mechanical properties of 7055 Al alloys by spray forming[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(12): 1987-1992.

[4] 韦 强, 熊柏青, 张永安, 朱宝宏, 石力开. 喷射成形Al-Zn-Mg-Cu系高强铝合金的组织与性能[J]. 中国有色金属学报, 2001, 11(2): 279-283.

WEI Qiang, XIONG Bai-qing, ZHANG Yong-an, ZHU Bao-hong, SHI Li-kai. Structure and property of high strength Al-Zn-Mg-Cu alloy by spray forming[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(2): 279-283.

[5] WANG F, XIONG B Q, ZHANG Y A, ZHU B H, LIU H W, HE X Q. Effect of heat treatment on the microstructure and mechanical properties of the spray-deposited Al-10.8Zn-2.8Mg-

1.9Cu alloy[J]. Mater Sci Eng A, 2008, 486: 648-652.

[6] WANG F, XIONG B Q, ZHANG Y A, ZHANG Z H, WANG Z X, ZHU B H, LIU H W. Microstructure and mechanical properties of spray-deposited Al-Zn-Mg-Cu alloy[J]. Materials and Design, 2007, 28: 1154-1158.

[7] SHARMA M M. Microstructural and mechanical characterization of various modified 7XXX series spray formed alloys[J]. Materials Characterization, 2008, 59: 91-99.

[8] 熊柏青, 张永安, 石力开. 喷射成形技术制备高性能铝合金材料[J]. 材料导报, 2000, 14(12): 50-55.

XIONG Bai-qing, ZHANG Yong-an, SHI Li-kai. High-property aluminum alloys prepared by spray-forming process[J]. Materials Review, 2000, 14(12): 50-55.

[9] 张永安, 熊柏青, 石力开. 快速凝固7000系超高强铝合金的研究现状[J]. 材料导报, 2005, 19(10): 91-93.

ZHANG Yong-an, XIONG Bai-qing, SHI Li-kai. Research of rapidly solidified ultra-high strength aluminum alloys[J]. Materials Review, 2005, 19(10): 91-93.

[10] POLMEAR I J. Light alloys[M]. London: Edward Arnold , 1981: 54-58.

[11] 高凤华, 李念奎, 丛福官, 田 妮, 赵 刚. 7050合金半连续铸锭中结晶相及其均匀化处理[J]. 稀有金属, 2008, 32(3): 274-278.

GAO Feng-hua, LI Nian-kui, CONG Fu-guan, TIAN Ni, ZHAO Gang. Constituent and homogenizing treatment of semi-continuous casting ingot of 7050 aluminum alloy[J]. Chinese Journal of Rare Metals, 2008, 32(3): 274-278.

[12] FAN X G, JIANG D M, MENG Q C, LI Z. The microstructural evolution of an Al-Zn-Mg-Cu alloy during homogenization[J]. Materials Letters, 2006, 60: 1475-1479.

[13] 张士林, 任颂赞. 简明铝合金手册[M]. 上海: 上海科学技术文献出版社, 2000: 339-340.

ZHANG Shi-lin, REN Song-zan. Concise Aluminum Alloy Manual[M]. Shanghai: Shanghai Scientific and Technological Literature Publishing House, 2000: 339-340

[14] LI Nian-kui, CUI Jian-zhong. Microstructural evolution of high strength 7B04 ingot during homogenization treatment[J]. Trans Nonferrous Met Soc China, 2008, 18(4): 769-773.

[15] SHARMA M M. Hardening mechanisms of spray formed Al-Zn-Mg-Cu alloys with scandium and other elemental additions[J]. Journal of Alloy and Compounds. 2006, 416: 135-142.

[16] SENKOV O N, SHAGIEV S M R. Precipitation of Al3(Sc, Zr) particles in an Al-Zn-Mg-Cu-Sc-Zr alloy during conventional solution heat treatment and its effect on tensile properties[J]. Acta Materialia, 2008, 56: 3723-3738.

(编辑 何学锋)

基金项目:国家重点基础研究发展计划资助项目(2005CB623704)

收稿日期:2009-07-28;修订日期:2009-11-26

通信作者:王 锋,高级工程师;电话:010-82241161;E-mail: wangfeng@grinm.com