文章编号:1004-0609(2013)S1-s0179-05

功率对TiNiNb合金激光微焊接接头成形及组织性能的影响

陈玉华1,戈军委1,陆巍巍1,封小松2

(1. 南昌航空大学 轻合金加工科学与技术国防重点学科实验室,南昌 330063;

2. 上海航天设备制造总厂,上海 200245)

摘 要:为实现0.2 mm厚度TiNiNb形状记忆合金的良好焊接,采用低功率脉冲激光对其进行对接焊试验,研究激光功率对焊缝表面成形、焊接接头横截面形貌和抗拉强度的影响规律以及焊接接头的微观组织结构。结果表明:当激光功率不低于16.8 W时能实现焊透,且焊缝熔宽随着激光功率的增大而增加,但随着激光功率的增大,焊缝表面飞溅比较严重。当激光功率为15.1 W时,焊缝未焊透、焊接接头抗拉强度较低;当激光功率增大到16.8 W以上时,随着激光功率的增大,接头抗拉强度呈现略微减小的趋势。焊接接头中焊缝中心为细小等轴晶,熔池边缘为柱状晶。焊缝上边缘基本不存在热影响区,在焊接接头底部存在约10 μm宽度的热影响区。

关键词:TiNiNb形状记忆合金;激光微焊接;焊缝成形;显微组织;性能;激光功率

中图分类号:TG 456.7 文献标志码:A

Influence of laser power on formation, microstructure and properties of micro laser welded joint of TiNiNb alloy

CHEN Yu-hua1, GE Jun-wei1, LU Wei-wei1, FENG Xiao-song2

(1. National Defense Key Disciplines Laboratory of Light Alloy Processing Science and Technology, Nanchang Hangkong University, Nanchang 330063, China;

2. Shanghai Spaceflight Manufacture (Group) Co., Ltd., Shanghai 200245, China)

Abstract: In order to achieve good welding of 0.2 mm-thick TiNiNb shape memory alloy (SMA) sheet, butt welding was carried out using low power impulse laser. Influences of laser power on the weld formation, cross section morphology, tensile strength and microstructure of the welded joint were studied. The results show that when the laser power is no less than 16.8 W, full penetration welded joint can be got. Weld width increases with the increase of laser power but the welding spatter is serious. When the laser power is 15.1 W, lack of penetration decreases the tensile strength of the welded joint. The tensile strength slightly decreases with the increasing of the laser power when the laser power is greater than 16.8 W. The microstructure of the weld joint consists of fine equiaxed grains in the weld center and columnar crystals on the edge of molten pool. There is almost no heat-affected zone (HAZ) on the weld edge, but there is HAZ with about 10 μm width on the bottom of the welded joint.

Key words: TiNiNb shape memory alloy; micro laser welding; weld formation; microstructure; properties; laser power

TiNiNb宽滞形状记忆合金是在1986年以后发展起来的新型记忆合金,该合金经适当变形后相变滞后可达150 ℃[1-2],无需在液氮中保存,在航空、航天、海军舰艇以及海上石油平台等方面具有广阔的应用前景[3-6]。因而,研究TiNiNb形状记忆合金的焊接技术对于其工程应用具有重要意义。吴冶等[7]研究Ni47Ti44Nb9形状记忆合金的氩弧焊,焊后在适当温度退火处理可显著改善焊缝的显微组织,提高焊缝的力学性能,室温下表现出较高的拉伸强度和伸长率,但氩弧焊焊后热影响区和变形较大,出现显微裂纹,形状记忆性能很差。成志富等[8]研究了2 mm 厚度Ni47Ti44Nb9形状记忆合金丝材的等离子弧搭接焊,焊接接头整体的晶粒较为细小,焊接热影响区为50~60 μm,焊接接头的形状恢复率为母材的89.6%,焊接接头经热处理的抗拉强度为499 MPa。陈庚等[9]研究了1 mm厚度 Ni47Ti44Nb9形状记忆合金的激光焊接,通过分析激光焊接的组织与性能,认为利用激光焊接状记忆合金是一种较理想的焊接方法,焊缝主要是由 TiNi 基体相和β-Nb 相组成的共晶组织,β-Nb 在 TiNi 基体相晶界和晶内分布不均匀, 接头各区域的显微硬度均高于母材的,室温下表现出较高的抗拉强度。DAVID等[10]利用TiNiNb显微组织中包含接近纯NiTi共晶相和Nb相的原理,研究一种关于TiNiNb的新型钎焊技术,当温度高于1 170 ℃时NiTi伪共晶体熔化,形成新的钎焊系统,凝固之后形成有序的NiTi和无序的Nb,熔化的共晶液体Ti质量分数较高,具有很好的润湿效果,并能去除表面的氧化膜,不需要钎剂就能实现焊接。

综上所述,目前国内外对于TiNiNb新型形状记忆合金焊接技术的研究还较少。本文作者采用低功率脉冲激光对0.2 mm厚度的超薄片状TiNiNb新型形状记忆合金进行激光微焊接技术的探索,研究激光功率对焊缝成形及组织性能的影响规律。

1 实验

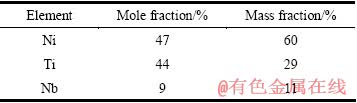

试验采用热轧态TiNiNb形状记忆合金片,其化学成分如表1所列。由于热轧态TiNiNb形状记忆合金片的表面带有致密氧化膜,焊前采用化学腐蚀除去试片表面富集的氧化膜,并打磨成0.2 mm厚的焊接试片。焊接过程采用特制的充气式玻璃保护罩对焊缝整体进行氩气保护。

表1 试验用TiNiNb的化学成分

Table 1 Composition of TiNiNb

试验设备采用Sisma公司生产的SL80型平均功率为80 W的Nd:YAG激光焊接系统及其附属设备,在可控参数中激光功率百分比P为平均输出功率的百分比,可调范围为0~30%;脉冲宽度T可调范围为0.3~9.9 ms;脉冲频率F可调范围为0~15 Hz。焊接速度为0.3 mm/s。

试验过程中,根据前期研究结果,固定脉冲宽度为2.5 ms、脉冲频率为4.5 Hz、分别采用激光功率百分比为19%、21%、23%、25%和27%(对应的激光平均功率为15.1、16.8、18.4、20和21.6 W)进行焊接,观察焊后焊缝表面成形,并制备金相试样,采用Carl Zeiss Jena金相显微镜观察焊缝横截面形貌和微观组织结构,采用INSTRON 5540型电子精密拉伸试验机测试焊接接头的抗拉强度,来研究激光功率对焊缝成形及接头组织性能的影响规律。

2 结果与讨论

2.1 激光功率对焊缝表面成形的影响

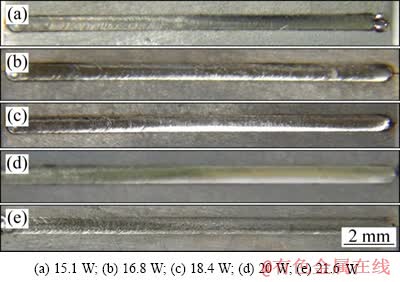

图1所示为不同激光功率时焊缝表面的宏观形貌,从整体上看焊缝表面无氧化,且呈银光色,鱼鳞纹明显。

图1 不同激光功率时焊缝表面的整体形貌

Fig. 1 Overall appearance of weld surface at different laser powers

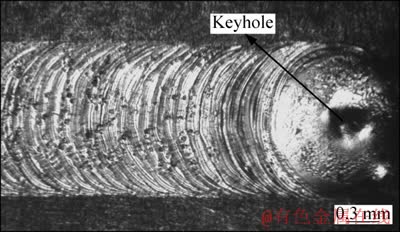

图2所示为图1(e)放大40倍的焊缝宏观照片。从图2可见:即使激光功率增大到21.6 W,焊缝收尾处匙孔效应不明显,但焊缝表面的飞溅较严重。

从图3可见:焊缝表面的金属颗粒突出物随着激光功率的增大逐渐增多,说明在激光微焊接的过程中,焊缝表面上的飞溅现象随着激光功率的增加其效果变得更加明显。在脉冲宽度不变的条件下,增加激光功率导致单位脉冲能量增加,使得激光峰值功率增加。而激光峰值功率密度与激光峰值功率成正比,增加激光功率最终导致焊缝表面峰值功率密度较大,表面温度在极短的时间内升高到沸点,使金属熔化或气化产生的金属蒸汽压力将熔化的金属挤向熔池四周,严重时导致大量金属飞溅。

图2 功率为21.6 W时焊缝结束处的宏观形貌

Fig. 2 Macro-morphology of weld end at laser power of 21.6 W

图3 不同激光功率时焊缝表面的飞溅

Fig. 3 Weld splatter on weld surface at different laser powers

2.2 激光功率对焊缝横截面形貌的影响

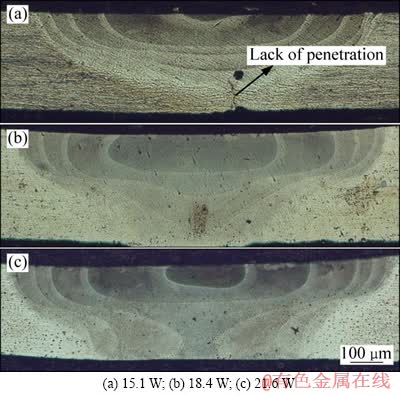

不同激光功率时焊缝横截面形貌如图4所示。P为15.1 W时未焊透、熔深为0.16 mm,P 为16.8、 18.4、20和21.6 W时均焊透,焊缝的熔宽分别为 0.72、0.74、0.79、0.80和0.83 mm,当脉冲宽度和频率不变时,随着激光功率的增加,焊缝熔宽增加。

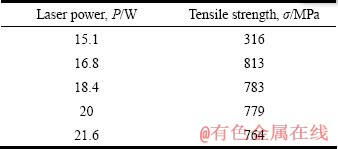

2.3 激光功率对接头抗拉强度的影响

测试不同激光功率下焊接接头的抗拉强度,结果如表2所列。从表2中可知,在其他工艺参数不变,当激光功率较小时,焊缝根部未焊透,导致接头抗拉强度较低;当激光功率增大到可以使得焊接接头完全焊透以上时,随着激光功率的增大,接头抗拉强度呈现略微减小的趋势,分析其原因是激光功率过大,焊缝表面产生严重飞溅和气化,使得焊缝区域凹陷、有效厚度减小、承载能力降低。

图4 不同激光功率时焊缝的横截面形貌

Fig. 4 Cross section morphologies of weld at different laser powers

表2 不同激光功率时焊接接头的抗拉强度

Table 2 Tensile strength of welded joint at different laser powers

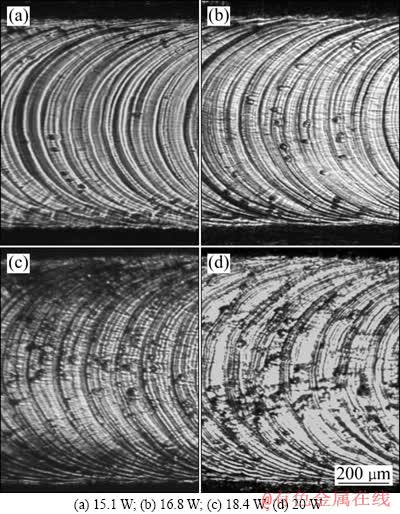

2.4 TiNiNb合金激光微焊接接头的显微组织

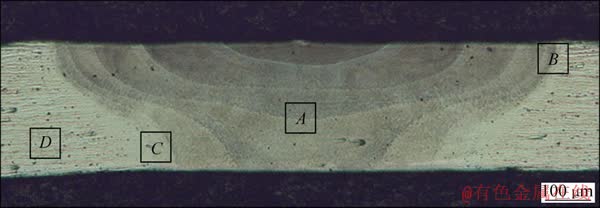

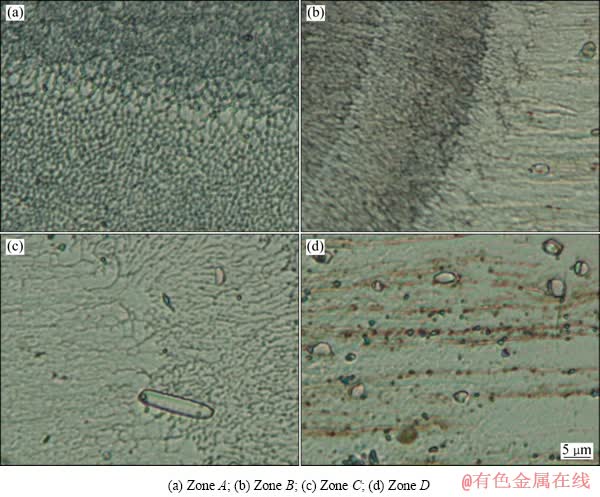

图5和图6所示分别为0.2 mm厚度TiNiNb记忆合金激光焊典型接头的横截面宏观形貌、分区以及各区的显微组织。图6(a)为焊缝中心区显微组织,从图中可看出,焊缝中心为分布不同大小的细小等轴晶,并且晶粒呈一定的分布规律。图6(b)是焊缝上边缘的组织图,图中几乎看不到热影响区,但能看到在每个脉冲能量下熔池的晶粒长大情况,焊缝上端边沿的热影响区几乎不存在。但是,在焊缝的底部能看到大约10 μm的热影响区,并且熔池边缘出现明显的柱状晶。如图6(c)所示。图6(d)所示为TiNINb沿轧制方向的母材垂直截面,从图中可以看出,母材中存在大量的织构和少量沉淀相。

图5 焊接接头横截面宏观形貌及其分区

Fig. 5 Cross section morphology and partitions of welded joint

图6 图5中不同区域的显微组织

Fig. 6 Microstructures of different zones in Fig. 5

3 结论

1) 采用低功率脉冲激光可以实现0.2 mm厚度TiNiNb合金的良好焊接。焊缝表面成形较好。当激光功率不低于16.8 W时能实现焊透,且随着激光功率的增加,焊缝熔宽增加,但焊缝表面的飞溅比较严重。

2) 当激光功率为15.1 W时,由于焊缝根部未焊透,焊接接头抗拉强度较低;当激光功率增大到16.8 W以上、焊接接头均焊透时,随着激光功率的增大,接头抗拉强度呈现略微减小的趋势。在试验条件下,激光功率为16.8 W时接头强度最高,为813 MPa。

3) TiNiNb合金激光微焊接接头中焊缝中心为细小等轴晶,焊缝上边缘基本不存在热影响区,在焊缝底部存在约10 μm的热影响区,并且熔池边缘出现明显的柱状晶。

REFERENCES

[1] 蔡 伟, 张春生, 赵连城. 热变形对Ni-Ti-Nb宽滞后记忆合金显微组织和力学性能的影响[J]. 中国有色金属学报, 1994, 4(4): 69-72.

CAI Wei, ZHANG Chun-sheng, ZHAO Lian-cheng. Influence of thermal deformation on the microstructure and mechanical property of Ni-Ti-Nb wide hysteresis shape memory alloy[J]. The Chinese Journal of Nonferrous Metals, 1994, 4(4): 69-72.

[2] Moochul Shin. Seismic retrofit and repair of reinforced concrete bridge columns using shape momory alloy spirals[M]. Urbana, Illino, 2012.

[3] 张春生, 蔡 伟, 王永前, 等. Ni-Ti-Nb宽滞后形状记忆合金的显微组织和力学性能[J]. 中国有色金属学报, 1994, 4(3): 82-85.

ZHANG Chun-sheng, CAI Wei, WANG Yong-qian, et al. Microstructure and mechanical property of Ni-Ti-Nb wide hysteresis shape memory alloy[J]. The Chinese Journal of Nonferrous Metals, 1994, 4(3): 82-85.

[4] CHEN Y, JIANG H C, LIU S W, RONG L J, ZHAO X Q. The effect of Mo additions to high damping Ti-Ni-Nb shape memory alloys[J]. Materials Science and Engineering A, 2009, 512: 26-31.

[5] HE X M, RONG L J, YAN D S, LI Y Y. TiNiNb wide hysteresis shape memory alloy with low niobium content[J]. Materials Science and Engineering A, 2004(371): 193-197.

[6] LIU Wei, ZHAO Xin-qing. Mechanical properties and transformation behavior of NiTiNb shape memory alloys[J]. Chinese Journal of Aeronautics, 2009, 22: 540-543.

[7] 吴 冶, 孟祥龙, 蔡 伟, 赵连城. Ni47Ti44Nb9 合金丝氩弧焊接头的显微组织和力学行为[J]. 材料科学与工艺, 2005, 13(5): 312-319.

WU Ye, MENG Xiang-long, Cai Wei, ZHAO Lian-cheng. Microstructure and mechanical behaviors of TiNiNb wide hysteresis shape memory alloy wire argon arc welding joint[J]. Materials Science & Technology, 2005, 13(5): 312-319.

[8] 成志富, 张益坤. TiNiNb形状记忆合金丝材等离子焊接工艺研究[C]//全国荷电粒子源、粒子束学术会议论文集, 哈尔滨: 全国粒子源、粒子束会议组委会, 2008: 285-289.

CHENG Zhi-fu, ZHANG Yi-kun. Study on the plasma welding process of TiNiNb shape memory alloy wire[C]//Proceedings of Source of Charged Particle Beams and Particle Beam Academic Meeting, 2008: 285-289.

[9] 陈 庚, 赵兴科, 陈 俐, 王 蔚, 黄继华, 张 华. TiNiNb合金激光焊接接头的组织与性能[J]. 热加工工艺, 2008, 37(17): 99-101.

CHEN Geng, ZHAO Xing-ke, CHEN Li, et al. Microstructure and properties of laser welded joint of TiNiNb wide hysteresis shape memory alloy[J]. Hot Working Technology, 2008, 37(17): 99-101.

[10] DAVID S, GRUMMON, LOW Ke-bin. A new method for brazing nitinol based on the quasibinary TiNi-Nb system[J]. American Institute of Aeronautics and Astronautics, 2007, 48: 1-7.

(编辑 邓履翔)

基金项目:上海航天科技创新基金资助项目(SAST201209);南昌航空大学卧龙之星培养计划项目(201302)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:陈玉华,副教授,博士;电话:0791-83863023;E-mail:ch.yu.hu@163.com