多次冲击载荷下TiNiNb合金的反常磨损行为

章建军, 朱金华

(西安交通大学 金属材料强度国家重点实验室, 西安 710049)

摘 要: 在往复冲击载荷下对TiNiNb合金的冲击磨损性能进行研究。 结果表明: 当单位面积冲击能量为1.61J/cm2时, TiNiNb合金表现出通常的耐磨行为, 磨损率始终维持稳定; 但当单位面积冲击能量上升到2.42J/cm2且冲击进行到30万次后, 磨损率曲线发生转折, 转折后的磨损率仅为1.61J/cm2冲击时的1/2.1。 经X射线衍射分析和扫描电镜观察发现, 磨损率下降的主要原因是高能冲击30万次后, 表层组织中出现大量的非晶, 导致通常的磨损机制在很大程度上受到抑制, 使磨损率急剧下降, 并因此使得高能量冲击下的磨损量最终也低于低能量冲击下的磨损量。

关键词: 冲击磨损; TiNiNb形状记忆合金; 非晶 中图分类号: TG115; TG146

文献标识码: A

Abnormal wear behavior of TiNiNb alloy under multiple impact loads

ZHANG Jian-jun, ZHU Jin-hua

(State Key Laboratory for Mechanical Behavior of Materials,Xian Jiaotong University, Xian 710049, China)

Abstract: The impact wear test to TiNiNb alloy was carried out, and an abnormal wear phenomenon was discovered. The TiNiNb alloy exhibits common wear behavior when the energy of per unit area is 1.6J/cm2, and the wear rate keeps invariable all the time. When the energy of per unit area rises to 2.4J/cm2 and the impacting times reach to 30×104, the wear rate curve shows a noticeable decrease, and the decreased wear rate is only 1/2.1 of that under 1.6J/cm2. With the help of X-ray diffractrometry and transmission electron microscopy, it is found that after impacting with the energy of 2.4J/cm2, a lot of amorphous appear in the surface layer of specimen after 30×104 times, the appearance of amorphous restrains strongly the common wear process so that the wear rate and wearing capacity are all lower than those under 1.6J/cm2.

Key words: impact wear; TiNiNb alloy; amorphous

往复多次冲击磨损在工程上较常见, 如内燃机中的汽门/汽门座、 齿轮的啮合面、 矿山机械中的凿岩机活塞/钎具冲击摩擦副、 球磨机衬板/磨球以及铁路中的车轮/道岔等, 这种往复冲击接触负荷造成零件表面磨损, 并常常因此导致零部件整体最终失效, 因此, 研究冲击磨损有较广泛的工程应用背景。 TiNiNb合金是在TiNi形状记忆合金的基础上发展起来的宽相变滞后的形状记忆合金, 用TiNiNb合金制成的构件不需要保存在液氮中, 只需在常温下运输、 存储即可, 应用非常方便[1-3]。 有研究证实TiNi形状记忆合金具有优异的抗磨损性能[4-6], 但对于TiNiNb合金抗磨损性能的研究并不多, 尤其针对往复多次冲击磨损性能的研究目前还未见报道, 因此本文作者对其冲击磨损性能进行了实验研究。

1 实验

形状记忆合金采用真空冶炼制备, 合金成分为(摩尔分数, %)Ti 45%, Ni 46.3%, Nb 8.7%。 材料经850℃, 10h均匀化退火后, 所得合金由β-Nb、 NiTi和β-Nb+NiTi共晶三相组成[7, 8], 共晶组织相互连接成网状分布, 点状β-Nb均匀分布在NiTi基体相上, NiTi基体相为B2型超点阵(完全有序状态排列)。

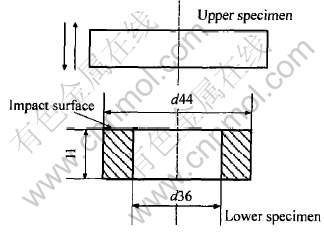

冲击磨损实验在JD-125型冲击磨损实验机上进行。 上试样选用轴承钢, 硬度为HRC61~65。 实验原理及试样形状见图1。 圆盘形上试样固定在做往复直线运动的冲头上, 一面作为冲击面向下。 将TiNiNb合金做成下试样, 固定在底座上, 冲击面向上。 实验时上试样在每一次下行到接近终点时对下试样进行接触冲击, 冲击频率为10次/s。 单位面积冲击能量分别为1.61J/cm2和2.42J/cm2, 实验在空气环境及室温下进行, 每冲击105次取出试样并清洗、 吹干之后称量质量, 以冲击105次的磨损损失质量衡量磨损量, 试样共冲击10×105次, 在正式实验前试样先进行0.4×105次跑合冲击。

图1 实验原理及试样形状和尺寸

Fig.1 Schematic diagram and form and size of specimen (Unit: mm)

表面形貌观察在S-2700扫描电子显微镜上进行; 微观组织观察在JEM-200CX透射电子显微镜上进行, X射线衍射在RIGAKU D/MAX-2400 X射线衍射仪上进行。 透射电镜试样由磨损表面切下, 经单面机械减薄, 最后经单面电解抛光得到。

2 结果与分析

2.1 冲击磨损规律

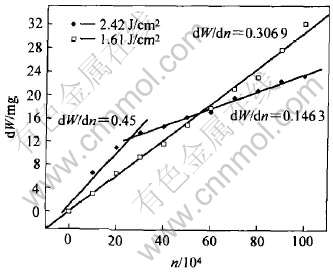

图2所示为两种冲击能量下试样的磨损率曲线。 图中空心点为1.61J/cm2的测量值, 黑色实心点为2.42J/cm2的测量值。 对测得的各点进行线形拟合, 得到平均磨损率曲线。 可见当冲击能量为1.61J/cm2时, 平均磨损率(dW/dn)始终保持稳定, 为0.3069mg/104, 说明此条件下主导磨损机制自始至终未发生改变, 磨损率维持稳定, 属于通常的冲击磨损行为; 当冲击能量提高到2.42J/cm2时, 在冲击3×105次以前, 磨损率随冲击能量的提高而上升, 冲击能量上升1.5倍, 磨损率上升了1.47倍, 基本上磨损率与冲击能量呈线性关系, 符合通常的磨损规律; 而在3×105次以后, 磨损率明显下降, 仅为前期的1/3.08, 为低能量冲击时的1/2.1, 并且在冲击5×105次后, 磨损量也低于1.61J/cm2冲击时的磨损量, 出现了反常磨损行为。 因为磨损发生在材料的表层, 所以这种反常的磨损行为说明在冲击能量提高到某一数值以上时, 经过一定时间的冲击作用, 材料表层的组织和性能发生了变化, 使得原先磨损率较高的磨损机制由于某种原因在相当程度上受到抑制, 磨损率因而大大下降。 这种反常磨损行为显示出其在工程应用中的良好前景, 也给研究材料的耐磨性提供了一个新思路。

图2 磨损率曲线

Fig.2 Curves of wear rate

2.2 磨损表面形貌的观察与讨论

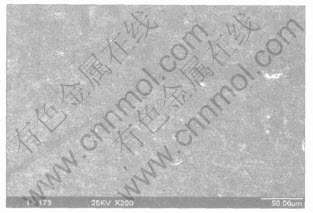

图3和4分别为经低、 高能量冲击后表面磨损形貌的扫描电镜照片。 可见在较低能量冲击下, 磨损表面出现了剥落坑和一些裂纹, 磨损坑大小在10-1mm级, 这种形貌有疲劳磨损和剥层磨损的特征[9, 10], 说明在较低能量冲击下, 磨损机制主要是疲劳磨损和剥层磨损, 这属于通常类型的冲击磨损, 与文献[11]的解释相吻合。 而在较高能量冲击下, 磨损表面形貌出现了反常情形, 此时表面没有出现10-1mm级的剥落坑, 裂纹和其它缺陷更少, 这种磨损形貌和磨损下降现象形成对应, 说明在冲击能量提高到某个值以上时, 通常的磨损机制的确在3×105次后受到很大程度的抑制, 磨损形貌与磨损率形成良好的对应。

图3 低冲击能量下表面磨损形貌

Fig.3 Wear surface topography under lower impact energy

图4 高冲击能量下表面的磨损形貌

Fig.4 Wear surface topography under higher impact energy

2.3 表层组织观察与讨论

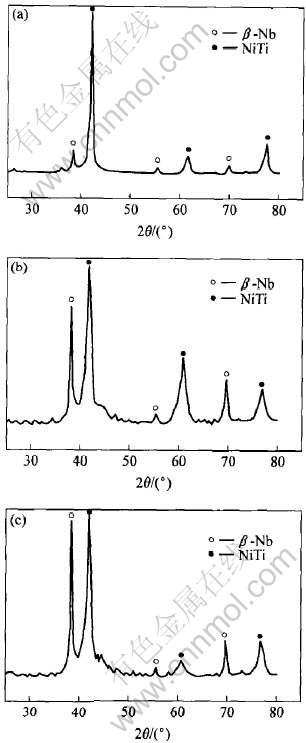

试样冲击前和在高、 低能量冲击后表层的X射线衍射谱见图5。 可见在两种能量冲击作用下谱线在约37°~47°范围内呈现非晶衍射的馒头峰特征(图5(b)、 5(c)), 在非晶衍射峰上还叠加了晶体衍射峰, 由图中非晶与晶体衍射峰重叠现象可以推断材料表层是由晶体和非晶混合构成, 也可能是X射线穿透深度较非晶分布深度大, 使晶体衍射出现。图中未见明显的形变诱发而生成的马氏体相谱线, 说明表层组织中最主要的变化是非晶的生成而非马氏体相变。 图中显示高能量冲击下的NiTi相的晶体衍射最弱, 说明高能量冲击后的表面晶体量显著减少, 非晶相的量相对较多。 β-Nb的最强衍射强度在3个图中相差不大, 说明β-Nb在冲击前后并无明显变化。

图5 TiNiNb表层材料在冲击前、低能冲击后和高能冲击后的X射线衍射谱

Fig.5 XRD patterns of surface materials before impacting(a), after impacting with lower energy(b) and after impacting with higher energy(c)

两者虽然在X射线衍射谱上相差无几,但利用TEM观察两种试样的表层组织则发现有很大区别。 图6和图7显示低能量冲击后表层典型的组织中既有形变碎化晶体, 也有粗大晶体与非晶的混合组织, 说明表层组织不均匀,有部分材料产生形变强化,而相当部分材料未得到强化。 表层组织的不均匀导致力学性能和形变都不均匀, 而粗糙的磨损形貌更加剧了这种不均匀性, 因此, 即使部分高性能区域对裂纹的形核及扩展有较好的抗力, 裂纹仍可借助低性能区域实现形核并扩展, 一旦微裂纹达到一定尺寸, 即使是高性能区也无法阻止其进一步扩展, 直至形成磨屑, 高性能材料也作为磨屑的一部分从基体剥落, 所以磨损过程并不会因为部分材料得到强化而受到抑制, 剥层磨损和疲劳磨损可持续进行下去, 磨损率自始至终维持稳定。

图6 低冲击能量后表面组织有单纯晶体存在

Fig.6 Pure crystals in surface impacted with lower energy

图7 低冲击能量后表面有部分晶体-非晶混合组织

Fig.7 Crystals-amorphous mixed structure in surface impacted with lower energy

图8所示为高能量冲击后的表面组织。 X射线衍射花样显示表层主要是非晶相, 而晶体组织较少出现, 这与低能量冲击后的表层组织有很大区别, 也说明此时表层组织在一定能量的冲击下大部分转化为非晶, 可以认为表面形成了一个较完整的非晶层, 组织均匀性良好, 这种均匀的表层组织和图4所示平整的磨损表面在冲击加载中可以更加均匀地分配载荷和变形, 使得裂纹形成的倾向下降, 有利于减少磨损, 磨损量的减少反过来又有利于磨损表面的平整优化。

图8 高能量冲击后表面组织中存在大量非晶相

Fig.8 Many amorphous structure in surface impacted with higher energy

非晶组织具有很好的力学性能, 这无疑是耐磨性提高的一个重要因素。 此外由于非晶的弹性极限接近屈服强度[12, 13], 弹性变形量比晶体大得多, 弹性变形量大意味着冲击时可以承受更大的变形而不致发生塑性变形及随变形出现的开裂, 因此在非晶中生成裂纹及使裂纹在其中扩展无疑都比在晶体材料中困难得多, 所以表面附着这样一层组织对冲击磨损具有很强的抑制作用。

非晶的形成目前主要有形变诱发机制和熔化机制[14-16], 不论以那种机制形成非晶, 都可以在原晶体转化为非晶时消除积聚在晶体内部的形变能和各种晶体缺陷, 如位错、 空位等, 随着材料内部存储的能量和各种缺陷的消失, 裂纹产生及扩展过程都将在很大程度上受到抑制, 因而可以极大地抑制通常的冲击磨损发生, 使磨损率下降。

实验结果还证实, 往复多次冲击加载条件下材料表面形成非晶层要求冲击能量超过某一阈值, 在阈值之上冲击一定次数有可能出现非晶层; 而在这个数值之下即使冲击时间延长也无法形成稳定的非晶层。 有文献报道[15], 由于形变诱发形成非晶时需要外力提供很大能量, 非晶形成的几率和数量都随外加能量的提高而提高, 因此可以合理地推论, 在本实验条件下, 当冲击能量小于某个阈值, 非晶的形成量就始终低于其磨损损失量, 因此始终无法形成非晶层, 而只能有少许非晶存在。 当冲击能量大于阈值时, 非晶的生成量大于同期的磨损损失量, 最终经一定时间的积累, 在表面形成一个较为完整且均匀的非晶层。

3 结论

1) TiNiNb合金在单位面积冲击能量为1.61J/cm2的冲击作用下磨损率始终稳定。 在2.42J/cm2冲击能量冲击下, 磨损率在冲击30×104次后急剧下降, 并且低于1.61J/cm2时的冲击磨损率, 冲击5×105次后的磨损量也低于1.61J/cm2时冲击的磨损量, 显示出很好的抗多次冲击磨损特性。

2) 1.61J/cm2冲击能量冲击下的磨损机制主要是剥层磨损和疲劳磨损; 在2.42J/cm2冲击能量冲击下, TiNINb合金表层形成大量的非晶, 强烈抑制了剥层磨损和疲劳磨损, 致使磨损率下降, 磨损表面较1.61J/cm2时冲击更加平滑。

3) 实验结果表明, 多次冲击条件下材料表面能否获得非晶层取决于冲击能量值而不是冲击次数, 只有达到某一阈值, 材料表面才可能出现非晶层。

REFERENCES

[1]Melton K N, Proft J L, Duerig T W. Wide hysteresis shape memory alloys based on the Ni-Ti-Nb system[A]. Proc Int Meeting on Advanced Materials[C]. Tokyo: Materials Research Society, 1989. 165-170.

[2]Zhao L C, Duerig T W, Justi S, et al. Study of niobium-rich precipitates in a Ni-Ti-Nb shape memory alloy[J]. Scripta Metall Mater, 1990, 24: 221-225.

[3]Piao M, Miyazaki S, Otsuka K. Characteristics of deformation and transformation in Ti44Ni47Nb9 shape memory alloy[J]. Mater Trans, 1992, 33: 341-353.

[4]Liang Y N, Li S Z, Jin Y B, et al. Wear behavior of a TiNi alloy[J]. Wear, 1996, 198(1/2): 236-241.

[5]Li D Y. A new type of wear-resistant material: pseudo-elastic TiNi alloy[J]. Wear, 1998, 221(2): 116-123.

[6]Lin H C, Liao H M, He J L, et al. Wear characteristics of TiNi shape memory alloys[J]. Metall Mater Trans A, 1997, 28A: 1871-1877.

[7]Zhang C S, Wang Y Q, Chai W, et al. The study of constitutional phases in aNi47Ti44Nb9 shape memory alloy[J]. Materials Chemistry and Physics, 1991, 28: 43-50.

[8]杨冠军, 郝士明. 一种新型形状记忆合金的相组成[J]. 稀有金属材料与工程, 1995, 24(6): 31-35.

YANG Guan-jun, HAO Shi-ming. Constitutional phase in a new shape memory alloy[J]. Rare Metal Materials and Engineering, 1995, 24(6): 31-35.

[9]李建明. 磨损金属学[M]. 北京: 冶金工业出版社, 1990. 186-190.

LI Jian-ming. Wear Metallorgraphy[M]. Beijing: Metallurgical Industry Press, 1990. 186-190.

[10]刘家浚. 材料磨损原理及其耐磨性[M]. 北京: 清华大学出版社, 1993. 144-153.

LIU Jia-jun. Materials Wear Mechanisms and Wear Resistance[M]. Beijing: Tsinghua University Press, 1993. 144-153.

[11]Engel P A. Impact Wear of Materials[M]. Amsterdam: Elesevies, 1976. 9-17.

[12]孙军, 张国军, 刘刚. 大块非晶合金力学性能研究进展[J]. 西安交通大学学报, 2001, 35(6): 640-645.

SUN Jun, ZHANG Guo-jun, LIU Gang. Research progress in mechanical properties of bulk amorphous alloys[J]. Journal of Xian Jiao Tong University, 2001, 35(6): 640-645.

[13]Inoue A. Stabilization and high strain-rate superplasticity of metallic supercooled liquid[J]. Mater Sci Eng A,1999, A267: 171-183.

[14]Wang Y, Lei T Q, Gao C Q. An observation of a filiform wear product in bearing steel, 52100[J]. Wear, 1989, 134: 231-234.

[15]Huang J Y, Yasuda H, Mori H. Deformation-induced amorphization in ball-milled silicon[J]. Philosophical Magazine Letters, 1999, 79: 305-314.

[16]Huang J Y. HRTEM and EELS studies of defects structure and amorphous-like graphite induced by ball-milling[J]. Acta Mater, 1999, 47: 1801-1808.

(编辑陈爱华)

基金项目: 国家自然科学基金资助项目(50071045, 50471036)

收稿日期: 2005-05-31; 修订日期: 2005-11-08

作者简介: 章建军(1969-), 男, 博士研究生

通讯作者: 章建军,电话:029-82674870; 传真:029-2663453; E-mail: zhjj69@sohu.com