文章编号:1004-0609(2014)10-2490-07

NiTiNb箔片激光焊接工艺及其接头的组织与性能

陆巍巍1,陈玉华1,谢吉林1,王善林1,封小松2

(1. 南昌航空大学 航空制造工程学院,南昌 330063;

2. 上海航天设备制造总厂,上海 200245)

摘 要:采用Nd:YAG激光器实现200 μm厚Ni47Ti44Nb9形状记忆合金箔片的焊接,并对激光工艺参数进行了正交试验。采用光学显微镜观察接头的显微组织,用精密拉伸仪测试了接头强度,并用精密硬度计测试了接头的显微硬度。结果表明:200 μm厚Ni47Ti44Nb9形状记忆合金对接的最优激光工艺参数是平均功率为16.8 W,脉宽为4.4 ms,频率为4.5 Hz,此时,接头的抗拉强度为880 MPa,达到母材强度的95%。水平面呈均匀的鱼鳞纹状。横截面出现了分层现象,焊缝中心为超细等轴晶,热影响区为柱状组织。纵截面为等轴晶与NiTi-βNb伪共晶析出带交替分布,焊缝区的平均硬度大于母材的平均硬度。

关键词:形状记忆合金;激光焊接;正交试验;显微组织

中图分类号:TG456.7 文献标志码:A

Laser welding process of NiTiNb foil and microstructure and properties of welding joint

LU Wei-wei1, CHEN Yu-hua1, XIE Ji-lin1, WANG Shan-lin1, FENG Xiao-song2

(1. School of Aviation Manufacturing and Engineering, Nanchang Hangkong University, Nanchang 330063, China;

2. Shanghai Spaceflight Manufacture (Group) Co., Ltd., Shanghai 200245, China)

Abstract: The welding joint of Ni47Ti44Nb9 shape memory alloy with thickness of 200 μm was achieved by Nd:YAG laser, and the laser process parameters were investigated by orthogonal experiment. The welding joint microstructure was observed by optical microscopy, the strength of extension of the joint was tested by precision stretcher, and the micro-hardness of the welding joint was tested with the precision hardmeter. The results shows that the best laser parameters of jointing Ni47Ti44Nb9 shape memory alloy with thickness of 200 μm are that the average power is 16.8 W, the width of pulse is 4.5 ms and the frequency is 4.5Hz. At this time, the tensile strength is 880 MPa, reaching 95% strength of the base metal. The horizontal surfaces appear uniform scales striate. And there is a phenomenon of layering on the cross-section, the center of the welding joint is ultrafine axis crystal. The heat affected zone is the column structure. The longitudinal section is exchange distribution of equiaxed grains and pseudoeutectic of NiTi-βNb. The average hardness of the welding joint is greater than that of the base metal.

Key words: shape memory alloy; laser welding; orthogonal experiment; microstructure

形状记忆合金由于具有普通材料所没有的超弹性和形状记忆性能而备受关注。NiTi基形状记忆合金自1963年发现以来,人们对其进行了大量的研究和开发,现已广泛应用于航空用管接头、各种驱动器、机器人等零部件中[1]。NiTiNb形状记忆合金中的Nb元素扩大了转变滞后范围,相关的零部件能够在室温下进行储存而成为近年来关注的焦点[2]。NiTi基薄膜制作的血管支架[3]已经应用于临床,Nb元素良好的生物兼容性和耐腐蚀性使得其在医学领域进一步的快速发展[4]。NiTi基合金制作的驱动器在微机电中用途广泛[5]。

吴冶等[6]研究NiTiNb的氩弧焊,发现接头为脆性断裂。ZHAO等[7]研究NiTi/NiTiNb的真空钎焊钎焊,发现叠层复合钎焊的减震效果较好。韩立军等[8]研究NiTiNb的精密脉冲电阻对焊,研究结果表明接头组织细小、强度较高。陈玉华等[9]研究200 μm厚321不锈钢箔片的激光焊,并对焊接参数进行正交优化,发现激光功率、脉宽、频率对接头的强度影响较大。张春生等[10]研究了不同方法获得的NiTiNb合金,发现(Ti,Nb)2Ni呈偏聚态分布,并随着C和O含量的增加而增加,(Ti,Nb)2Ni的数量、形态、分布对合金的塑性影响很大。WANG等[11]采用快却冷的方法制备了400 nm~1.5 μm的超微晶薄带,认为基体中的黑色颗粒是C和O 化物,而非Ti2Ni相。但是第二相在激光焊接后的变化尚不明确。GONG等[12]研究了200 μm厚的NiTi合金激光焊,发现接头强度能到轧制母材的97%,焊缝中心为细小的等轴晶,焊缝边缘为柱状晶组织。FALVO等[13]发现NiTi合金激光焊接接头应变小于5%时,焊接接头对应变回复影响是可以忽略的。但是激光焊接冷却速度较大,较大的冷却速度对记忆合金的相变有很大影响[14]。姚伟等[15]研究了钛合金的激光焊,发现接头为“网篮状”马氏体组织,接头各区域硬度均高于母材。激光热作用导致焊接接头的产生的孪晶马氏体与第二相都会影响焊接接头的力学性能和形状记忆性能[16]。

氩弧焊、钎焊的热输入量较大,不适合箔片焊接。电阻焊对构件的接头和结构形式有严格要求,同样不适合200 μm厚箔片的焊接。形状记忆合金接头要想具有较好的形状记忆性能,就要求合适的晶粒大小和较小的热影响区。而激光焊能量密度高、热影响区小,是焊接薄片状记忆合金理想的焊接方法。但是NiTiNb这种材料的激光焊接研究还较少,特别是Nb元素在焊缝中的分布及其对接头性能的影响尚不明确。因此,本文作者采用正交实验的方法研究激光焊接工艺参数,并分析接头的显微组织和力学性能。

1 实验

1.1 实验条件

本试验材料选用300 μm厚热轧态未去除氧化膜的Ni47Ti44Nb9(摩尔分数,%)箔片。先用线切割加工成20 mm×25 mm的焊接试样,再按照JB/T 7901—1999《金属材料实验室均匀腐蚀全浸试验方法》的要求,放入V(HF):V(HNO3):V(H2O)=1:3:5的混合溶液中浸泡,取出后用丙酮冲洗并吹干,厚度控制在(0.2±0.01) mm。激光焊接设备是Sisma公司生产的SL80型Nd:YAG激光焊接系统,激光波长1.06 μm,最大激光功率80 W。采用专用工装进行装夹,采用玻璃保护箱整体氩气保护焊接。保护气流量为8 L/min。接头形式为I形对接,焊缝垂直于轧制纤维方向。焊前将试样两端对齐并且用小能量激光点焊定位。

拉伸标准参照ASTM 2516-07,使用INSTRON5540型电子精密拉伸实验机进行拉伸试验,拉伸试验时室温为10 ℃。每个焊接参数加工3个拉伸试样,取拉伸平均值。使用401MVD数字显微硬度计测量焊接接头的显微硬度变化。测量点间距为50 μm,加载载荷约为2 N,加载时间为10 s。使用MR5000倒置显微镜观察金相组织,使用Quanta 2000型环境扫描电子显微镜进行显微组织观察,二次电子图像分辨率为 3.0 nm。

1.2 正交实验设计

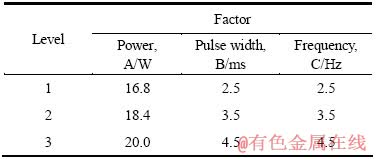

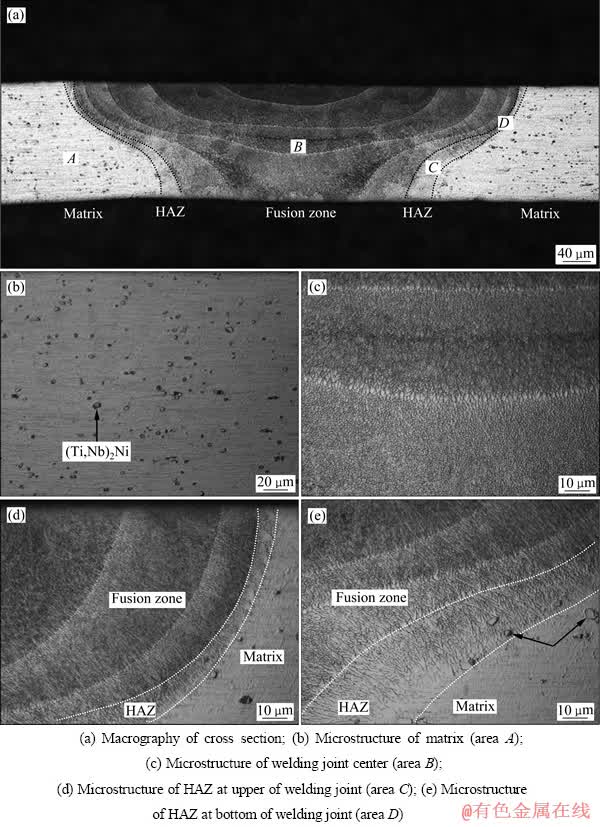

根据预实验的结果,选取平均功率、脉宽和频率3个因素,每个因素各取三水平。选用L9(34)的正交实验表。正交实验设计方案如表1所列。激光光斑直径选取d 200 μm,焊接速度为0.3 m/min。

表1 正交试验因素与水平

Table 1 Factor and level of orthogonal experiment

2 结果与分析

2.1 正交实验结果

表2 正交试验结果分析

Table 2 Result analysis of orthogonal experiment

从正交优化结果(表2)可以看出,最高抗拉强度为880 MPa,最低抗拉强度为708 MPa。空白列为误差列,误差列的极差小于功率和脉宽的极差,说明实验误差可以接受。由于K1A>K2A>K3A、K3B>K1B>K2B、K3C>K2C>K1C, 所以最优工艺参数为A1B3C3,即平均功率为16.8 W,脉宽为4.5 ms,频率为4.5 Hz。从极差R1>R2>R3可以看出,功率是影响抗拉强度的最主要因素,其次是脉宽,再次是频率。通过最优工程平均分析,A1的效应为47(838-791),B3的效应为17(808-791),C3的效应为26(817-791)。μo=791+47+17+ 26=881,与最优方案的抗拉强度相当,这从另一角度说明所选方案是最优参数。从 、

、 、

、 的变化趋势来看,功率越小,强度越高,因此,在确保焊透的基础上进一步减小功率可能得到更高的强度。频率试验指标的平均值随着功率的增加而增加,说明在确保焊透的基础上进一步提高频率也可以提高强度,这和焊接基本理论相符。减小热输入可以减小接头的组织受热影响的区域和时间,减小热影响区宽度和变形,防止晶粒过分粗化,增加深宽比,从而在一定程度上提高接头的强度。增加频率可以增加熔池的搅动,减小宏观偏析,使熔池化学成分更加均匀,焊缝成型更加平整光滑,这也有利于提高接头强度。

的变化趋势来看,功率越小,强度越高,因此,在确保焊透的基础上进一步减小功率可能得到更高的强度。频率试验指标的平均值随着功率的增加而增加,说明在确保焊透的基础上进一步提高频率也可以提高强度,这和焊接基本理论相符。减小热输入可以减小接头的组织受热影响的区域和时间,减小热影响区宽度和变形,防止晶粒过分粗化,增加深宽比,从而在一定程度上提高接头的强度。增加频率可以增加熔池的搅动,减小宏观偏析,使熔池化学成分更加均匀,焊缝成型更加平整光滑,这也有利于提高接头强度。

2.2 焊接接头显微组织分析

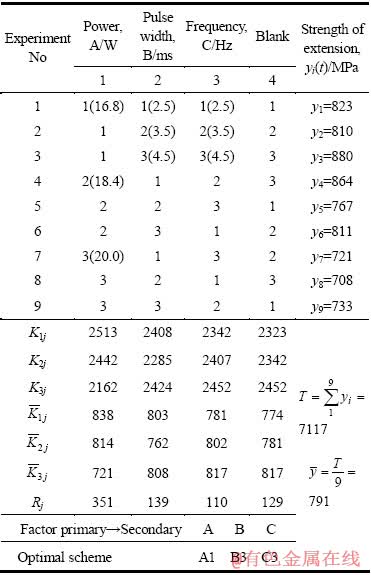

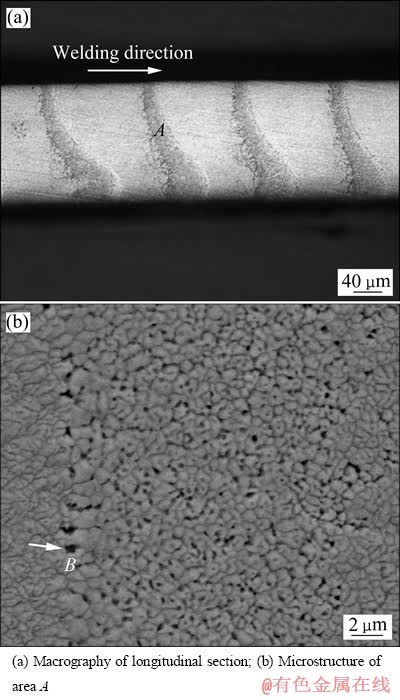

焊接接头水平面的组织形貌如图1所示。从图1(a)中可以看出,焊缝宽窄均匀,呈鱼鳞纹状。鱼鳞纹的法线方向与热流方向一致。单一轮廓线为圆弧形,中间宽两边窄,圆弧弯曲方向与焊接方向相反。接头表面无裂纹、气孔、咬边等肉眼可见缺陷。接头包括热影响区、焊缝区和母材3部分。焊缝热影响区如图1(b)和(d)所示。热影响区的晶粒比焊缝区的晶粒粗大,但仍然为细小晶粒。热影响区内可以发现未熔化的(Ti,Nb)2Ni相。(Ti,Nb)2Ni相硬而脆,可能造成位错塞积和应力集中,对焊缝强度有不利影响。焊缝区形貌如图1(c)为所示,晶粒尺寸细小,晶粒形貌为等轴晶。母材与热影响区存在脆硬的(Ti,Nb)2Ni颗粒。热轧后母材的织构组织在激光热作用下消失。Nb元素的熔点比Ni和Ti的熔点要高很多,凝固时成为异质形核核心。由于冷却速度很快,新形成的晶粒来不及长大便形成了细小的等轴晶。

图1 焊接接头水平面形貌

Fig. 1 Horizontal plane morphologies of welded joint

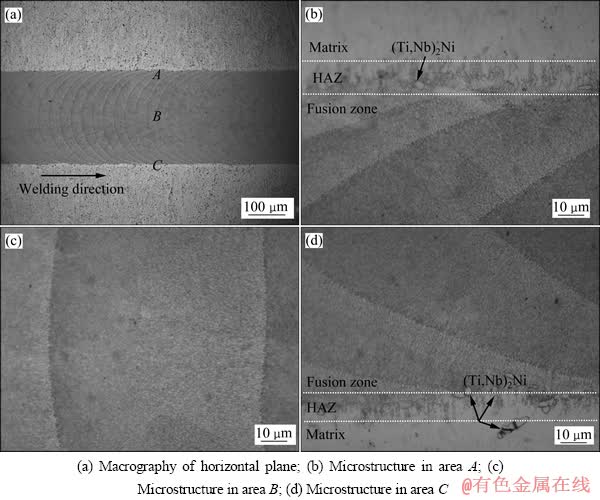

焊接接头横截面形貌如图2所示。从图2(a)可以看出,接头可以分为母材、热影响区和焊缝区。焊缝区组织出现了分层现象,呈“菊花”形貌。分层结构在焊缝上部和下部的拐角处有一个变窄的过程。分层结构的出现可能与激光脉冲作用和熔池的波动有关。热影响区上部宽下部窄,说明上部热量散失快而下部热量散失较慢。由于本研究中所用的激光器功率较小,等离子体仅由金属离子蒸气组成,自由电子的功能还不足以使保护气体雪崩式电离,少量的等离子体贴附于焊件表面或匙孔内部。一方面,根据流体力学,贴近焊缝底部的等离子体流动速度较慢,导致底部热量散失较慢;另一方面,从熔合线的形貌可以看出,上部的熔合线弯向焊缝,下部的熔合线背向焊缝,底部热影响区通过热传导积累的热量多于顶部,使底部热影响区经历了一个较高的峰值温度,形成了较宽的热影响区。图2(b)所示为热轧后母材的形貌。由图2(b)可以看到明显的纤维状织构和弥散分布的第二相颗粒,母材由NiTi基体和NiTi-βNb伪共晶组织组成,其中NiTi基体中固溶有少量的Nb元素,弥散分布的颗粒为(Ti,Nb)2Ni。而(Ti,Nb)2Ni为一脆硬相,轧制时由大块状碎裂成小颗粒弥散分布于基体中,对母材的韧性有一定的影响。焊缝中心处的组织如图2(c)所示,焊缝中心部位为细小等轴晶,晶粒大小在纳米级别。细小的等轴晶可以提高接头的强度和韧性。从图2(c)中可以看出,分层结构的帯状部分为外延竞争生长的树枝状组织。带状区域组织较为粗大,晶粒以前一个脉冲冷却后的凝固组织为基底而形核,在脉冲激光热作用下长大而出现了带状组织。这种粗大的晶粒会降低焊接接头的强度。由图2(d)和(e)可以看出,母材熔化之后,热影响区仍然存在(Ti,Nb)2Ni颗粒,但是熔合区以内,热轧态组织完全消失。焊缝热影响区和靠近热影响区的部位为树枝晶,枝晶的长大方向和热流方向一致。

图2 焊接接头横截面形貌

Fig. 2 Cross section morphologies of welded joint

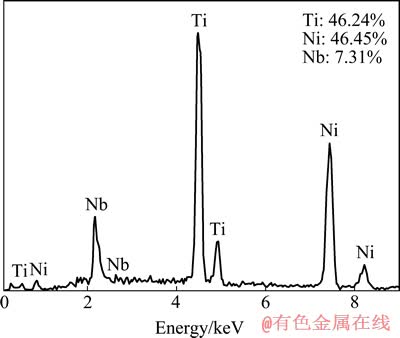

焊缝纵截面的形貌如图3所示。由图3可以看出,焊缝由一个深色和浅色的区域组成。深色带呈一定的弧度弯向焊缝移动反方向。焊缝金属熔化后在溶液重力、金属蒸汽反作用力和表面张力的共同作用下处于一个动态平衡的状态,且随着工作台的移动,金属溶液往后流动,形成一个弧线形,能够防止焊缝金属烧穿和凹陷。两个深色带之间形成了一个上大下小的细晶区。对图3中深色区域进行放大如图3(b)所示,细晶区域在晶界弥散析出了第二相。这种析出相的形成是由于激光的脉冲作用形成的。对图3(b)中的黑色区域B进行能谱分析,发现该区域的成分为Ti 46.24%、Ni 46.45%、Nb 7.31%(摩尔分数),结合NiTiNb的三元相图可知,黑色析出物为NiTi-βNb伪共晶化合物。

2.3 焊接接头力学性能分析

图3 焊缝的纵截面形貌

Fig. 3 Longitudinal section morphologies of welded joint

图4 NiTi-βNb伪共晶(B处)能谱

Fig. 4 EDS of NiTi-βNb pseudoeutectic (area B) shown in Fig. 3(b)

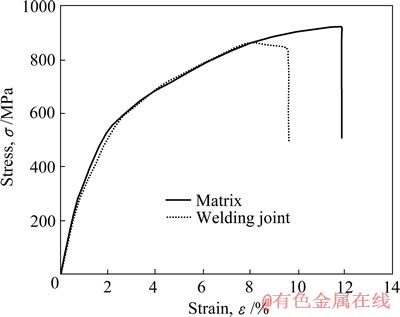

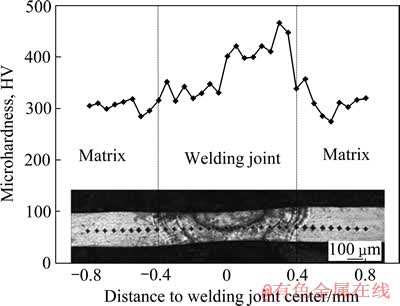

母材和焊接接头的应力-应变曲线如图5所示。母材的抗拉强度为923 MPa,焊接接头的抗拉强度为880 MPa,焊接接头的抗拉强度达到母材的95%。母材和焊接接头在线弹性阶段的弹性模量相当,说明焊接接头对记忆合金的弹性影响不大。母材和焊接接头都没有出现屈服平台,都没有出现应力诱发马氏体,这是因为母材和焊缝都没有通过热处理获得形状记忆功能。母材的平均硬度为307HV,焊缝的平均硬度为374HV,可见焊缝的平均硬度高于母材的平均硬度。

图5 基体和焊接接头应力-应变曲线

Fig. 5 Stress-strain curves of matrix and welding joint

图6 焊接接头显微硬度

Fig. 6 Microhardness of welding joint

由于焊缝晶粒细小,根据Hall-Petch原理,焊缝的硬度高于母材的。硬度的不均匀性是由局部晶粒度不一致、成分的不均匀性和第二相所导致的。

3 结论

1) 200 μm厚Ni47Ti44Nb9形状记忆合金对接焊时,最优激光工艺参数是平均功率为16.8 W,脉宽为4.4 ms,频率为4.5 Hz,此时接头的抗拉强度为880 MPa,达到母材强度的95%。

2) 水平面呈均匀的鱼鳞纹状。横截面出现了分层现象,焊缝中心为超细等轴晶,热影响区为柱状组织,Nb元素由母材中的带状变成网状分布于焊缝晶界。纵截面为等轴晶NiTi-βNb伪共晶析出带交替分布。

3) 母材和焊缝线弹性阶段弹性模量相同,未出现应力诱发马氏体导致的屈服平台,焊缝区的平均硬度高于母材的。

REFERENCES

[1] OTSUKA K, WAYMAN C M. Shape memory materials[M]. Cambridge: Cambridge University Press, 1999: 76.

[2] HE X M, RONG L J, YAN D S, LI Y Y. TiNiNb wide hysteresis shape memory alloy with low niobium content[J]. Materials Science and Engineering A, 2004, 371(1): 193-197.

[3] SUGAWARA T, HIROTA K, WATANABE M, TAKASHI M, EIJI M, SATOSHI T, TAKAYUKI S. Shape memory thin film actuator for holding a fine blood vessel[J]. Sensors and Actuators A: Physical, 2006, 130: 461-467.

[4] BANSIDDHI A, DUNAND D C. Shape-Memory NiTi-Nb foams[J]. Journal of Materials Research, 2009, 24(6): 2107-2117.

[5] PEQUEGNAT A, DALY M, WANG J, ZHOU Y, KHAN M I. Dynamic actuation of a novel laser-processed NiTi linear actuator[J]. Smart Materials and Structures, 2012, 21(9): 094004.

[6] 吴 冶, 孟祥龙, 蔡 伟, 赵连城. Ni47Ti44Nb9 合金丝氩弧焊接头的显微组织和力学行为[J]. 材料科学与工艺, 2005, 13(3): 312-315.

WU Ye, MENG Xiang-long, CAI Wei, ZHAO Lian-cheng. Microstructure and mechanical behaviors of TiNiNb wide hysteresis shape memory alloy wire argon arc welding joint[J]. Materials Science and Technology, 2005, 13(3): 312-315.

[7] ZHAO X K, LAN L, SUN H B, HUANG J H, ZHANG H. Preparation of NiTi/NiTiNb laminated alloys by vacuum brazing[J]. Advanced Materials Research, 2010, 97: 1653-1656.

[8] 韩立军, 赵熹华, 赵 蕾, 张 甫. TiNiNb 形状记忆合金丝精密脉冲电阻对焊工艺分析[J]. 材料科学与工艺, 1999, 7(3): 76-79.

HAN Li-jun, ZHAO Xi-hua, ZHAO Lei, ZHANG Fu. Analysis of welding parameters of precise pulse resistance butt welding on TiNiNb shape memory alloys[J]. Materials Science and Technology, 1999, 7(3): 76-79.

[9] 陈玉华, 柯黎明, 徐世龙, 邢 丽. 超薄不锈钢片的微激光焊接工艺研究[J]. 材料工程, 2008(11): 28-31.

CHEN Yu-hua, KE Li-ming, XU Shi-long, XING Li. Study on the micro laser welding parameter of ultrathin stainless steel sheet[J]. Journal of Materials Engineering, 2008(11): 28-31.

[10] 张春生, 蔡 伟, 王永前, 赵连城. Ni-Ti-Nb 宽滞后记忆合金的显微组织和力学性能[J]. 中国有色金属学报, 1994, 4(3): 82-85.

ZHANG Chun-sheng, CAI Wei, WANG Yong-qian, ZHAO Lian-cheng. Microstructure and mechanics properties of wide hysteresis shape memory alloy[J]. The Chinese Journal of Nonferrous Metals, 1994, 4(3): 82-85.

[11] WANG E M, YANG G L, ZHAO W B. Microstructure and evolution of fine grained NiTiNb alloys[J]. Materials Review, 2009, 23(11S): 524-526.

[12] GONG W H, CHEN Y H, KE L M. Microstructure and properties of laser micro welded joint of TiNi shape memory alloy[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(9): 2044-2048.

[13] FALVO A, FURGIUELE F M, MALETTA C. Laser welding of a NiTi alloy: Mechanical and shape memory behaviour[J]. Materials Science and Engineering A, 2005, 412(1): 235-240.

[14] ZHANG Y, JIANG S, ZHAO Y, TANG M. Influence of cooling rate on phase transformation and microstructure of Ti-50.9% Ni shape memory alloy[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(11): 2685-2690.

[15] 姚 伟, 巩水利, 陈 俐. 钛合金激光焊接接头的组织和力学性能[J]. 焊接学报, 2006, 27(2): 69-72.

YAO Wei, GONG Shui-li, CHEN Li. Microstructure and mechanical properties of laser welded joint of titanium alloy[J]. Transactions of the China Welding Institution, 2006, 27(2): 69-72.

[16] JIANG Shu-yong, ZHAO Ya-nan, ZHANG Yan-qiu, HU Li, LIANG Yu-long. Effect of solution treatment and aging on microstructural evolution and mechanical behavior of NiTi shape memory alloy[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(12): 3658-3667.

(编辑 李艳红)

基金项目:上海航天科技创新基金资助项目(SAST201209);江西省科技计划项目(20133BBE50021)

收稿日期:2014-03-28;修订日期:2014-06-13

通信作者:陈玉华,教授,博士;电话:0791-83863023;E-mail: ch.yu.hu@163.com