DOI: 10.11817/j.issn.1672-7207.2020.11.009

激光送粉增材制造Fe-Mn-Si基形状记忆合金组织与性能

姚聪,李瑞迪,袁铁锤,牛朋达

(中南大学 粉末冶金国家重点实验室,湖南 长沙,410083)

摘要:为了探索简单高效且能制备出具有复杂形状、优异性能的Fe-Mn-Si基形状记忆合金的新工艺,采用激光同轴送粉沉积工艺制备Fe-Mn-Si基形状记忆合金,并研究其组织结构、机械性能和形状记忆性能。研究结果表明:沉积态Fe-Mn-Si基形状记忆合金由γ-奥氏体和ε-马氏体组成,且母相奥氏体基体内有大量层错存在。沉积态Fe-Mn-Si基形状记忆合金室温下的名义屈服强度为508 MPa,拉伸强度为1 030 MPa,伸长率达31%,最大可回复变形量为3.6%,其形状记忆性能优于传统固溶态变形加工Fe-Mn-Si基形状记忆合金的形状记忆性能。因此,采用激光增材制造技术制备Fe-Mn-Si基形状记忆合金具有广阔的前景。

关键词:激光同轴送粉沉积;铁锰硅;形状记忆合金;形状记忆性能

中图分类号:TG142.1 文献标志码:A 开放科学(资源服务)标识码(OSID)

文章编号:1672-7207(2020)11-3081-07

Microstructure and properties of Fe-Mn-Si based shape memory alloy by powder feeding laser additive manufacturing

YAO Cong, LI Ruidi, YUAN Tiechui, NIU Pengda

(State key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: In order to explore new simple and efficient process for preparing Fe-Mn-Si based shape memory alloy with complex shape and excellent performance, Fe-Mn-Si base shape memory alloy was prepared by laser melting deposition and its microstructure, mechanical and shape memory property were studied. The results show that the as-deposited sample is composed of γ-austenite and ε-martensite, and the matrix contains a large number of stacking faults. The nominal yield strength, tensile strength, elongation of as-deposited alloy at room temperature are 508 MPa, 1 030 MPa and 31%, respectively. Consequently, the maximum recoverable strain of printed Fe-Mn-Si based shape memory alloy is 3.6%, which is higher than that of traditionally deformation processed alloy. Therefore, additively manufactured Fe-Mn-Si based shape memory alloy possesses broad prospect.

Key words: laser melting deposition; Fe-Mn-Si; shape memory alloy; shape memory property

1982年,SATO等[1]通过研究发现单晶Fe-30Mn-1Si合金具有与Ni-Ti合金相近的可恢复变形量(高达9%),这一发现引起了大量研究者开发商业吸引力更高、成本更低、加工性能更好的铁基形状记忆合金的兴趣。然而,有研究[2-4]表明,固溶处理后的变形加工多晶Fe-Mn-Si基合金可恢复应变较低,其中,Fe-28Mn-6Si-5Cr,Fe-20Mn-5Si-8Cr-5Ni和Fe-16Mn-5Si-12Cr-5Ni合金具有良好的耐蚀性和形状记忆性能,但可恢复变形量均小于2.5%[3],并不能满足工程应用的要求。因此,科研工作者为提升Fe-Mn-Si基合金的形状记忆性能进行了大量的研究工作[5-9]。

目前,研究者常用热机械处理[5-6]、时效处理[7-9]来提高Fe-Mn-Si基形状记忆性能。热机械处理主要分为奥氏体形变热处理(马氏体逆转变温度以上变形处理)和“训练”处理(室温下变形+退火的数次循环),可以有效地提高合金的形状记忆效应。例如,Fe-28Mn-6Si-5Cr合金经奥氏体形变处理后可恢复变形量从2.5%提高到3.8%[5];“训练”处理后的Fe-30Mn-6Si-5Cr合金可恢复变形量提高到5.4%[6]。然而,热机械处理过程中预变形量的引入,会降低生产效率,增加成本,且不适用于复杂形状工件的制备。时效处理主要是通过析出沉淀相(如NbC[7],VC[8],TiC[9])来强化基体,从而提高合金的形状记忆性能。但时效处理处理需要长时间的热处理来实现沉淀相的析出,从而增加了生产周期和成本,降低了生产效率。此外,铸造加上退火处理可以显著提高合金形状记忆效应(达6%~9%),但铸造态Fe-Mn-Si基形状记忆合金存在屈服强度和回复应力低的问题,在实际应用中受到限制。因此,寻找一种免“训练”并且能制备出具有复杂形状、优异性能的Fe-Mn-Si基形状记忆合金的新工艺是很有必要的。

激光增材制造是一种快速、高效、节省原料的近净成形工艺,通过该工艺可制备具有复杂形状的工件,并且工件成分均匀、机械性能优越[10]。目前,关于增材制造Fe-Mn-Si基形状记忆合金的研究较少,因此,本文研究了增材制造对Fe-Mn-Si基形状记忆合金组织结构、力学和形状记忆性能的影响,以便为实际应用提供理论指导。

1 实验材料与方法

1.1 实验材料

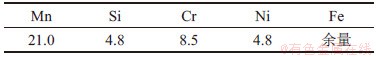

采用气雾化工艺制备Fe-Mn-Si基合金粉末,预合金粉末球形度高、氧含量低、流动性较好,适用于激光同轴送粉成形工艺。合金的成分如表1所示。图1所示为气雾化制备的Fe-Mn-Si基预合金粉末粒径分布图。从图1可以看出,粉末的粒度主要为65~160 μm,平均粒度为102 μm。

表1 Fe-Mn-Si基合金粉末化学组成(质量分数)

Table 1 Chemical composition of Fe-Mn-Si based alloy powder %

图1 Fe-Mn-Si基预合金粉末粒径分布

Fig. 1 Particle size distribution of Fe-Mn-Si based alloy powder

1.2 实验设备与方法

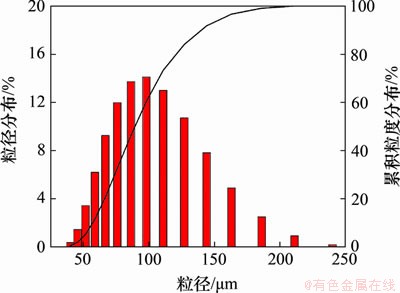

实验所用的激光同轴送粉沉积设备为南京中科煜辰LDM8060,所用基板为喷砂处理的304不锈钢。沉积过程如图2所示,整个沉积过程在氩气气氛中进行,成形腔内氧气和水的体积分数均低于50×10-6。沉积参数如表2所示。

图2 沉积过程示意图

Fig. 2 Schematic of deposition process

1.3 实验表征与设备

沉积态试样的物相组成采用α-Cu靶材的XRD(日本株式会社D/max 2550 VB)分析,扫描角为30°~100°,扫描速度为8 (°)/min。粉末粒径分布采用激光粒度分析仪(Mastersizer 300,英国)测定。金相样品经砂纸打磨到6.5 μm,采用氧化铝悬浮液抛光后,用1 g FeCl3+20 mL HCl+60 mL H2O混合溶液进行腐蚀,时间为10 s。腐蚀后的样品在光学显微镜(MeF3A,德国莱卡)下观察。打印样品和拉伸试样的微观组织采用场发射电子显微镜(FEI NanoLAB,600i)进行观察。沉积态合金试样的马氏体相变温度采用差示扫描量热仪(DSC8000,珀金埃尔)测试,测试条件为先降温(室温~-30 ℃)后升温(-30~200 ℃),升降温速率均为10 ℃/min。

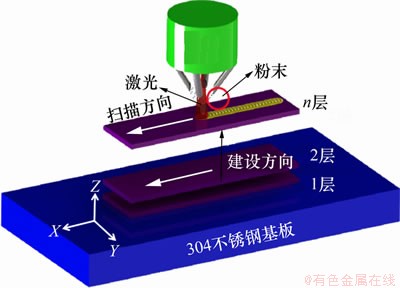

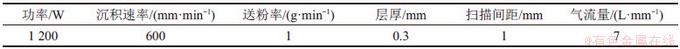

表2 沉积参数

Table 2 Parameters of deposited process

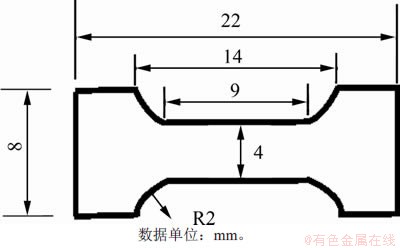

拉伸试样的力学性能采用电子直接万能拉伸试验机(MTS system,美国)测试,拉伸速率为1 mm/min。拉伸样品尺寸如图3所示。

图3 拉伸试样示意图

Fig. 3 Schematic map of tensile test sample

采用弯曲法测试形状记忆效应,测量原理示意图[11]如图4所示。

图4 弯曲法测形状记忆效应原理示意图

Fig. 4 Schematic map of shape memory effect measurement by bending method

将长×宽×厚为60 mm×2 mm×1 mm的长条试样置于直径D分别为32.0,19.0,13.2和9.0 mm的弯曲模具U型压块上进行180°弯曲,从而获得不同的预变形量(3%,5%,7%,10%)。预变形量由式(1)得出:

(1)

(1)

式中,ε为预变形量,d为试样厚度。

对试样进行卸载,测量卸载前后试样角的变化θe,在400 ℃下保温15 min后样品充分回复,测量回复前后角度变化θr,则形状回复率η为

(2)

(2)

2 实验结果与讨论

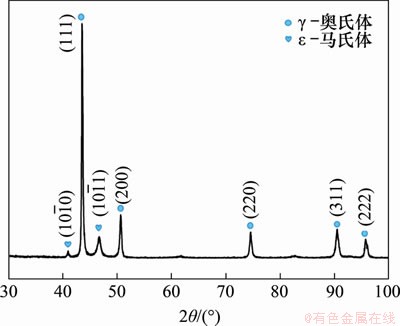

2.1 沉积态Fe-Mn-Si基合金物相分析

图5所示为沉积态Fe-Mn-Si基形状记忆合金试样的XRD衍射图。从图5可见:XRD衍射图上同时出现FCC和HCP相的特征衍射峰,表明合金在室温下由γ-奥氏体和ε-马氏体组成。但是DSC测试结果表明:合金的马氏体转变温度(Ms)低于室温,由此可以推断ε-马氏体的形成可能与残余应力有关。由于成形过程冷却速度较快(103 K/s),沉积态试样会经历循环加热和冷却的温度变化,加上基板的约束作用,试样内部会产生较大的残余应力,残余应力作为应力诱发马氏体相变的驱动力,促进ε-马氏体的形成[12]。

图5 沉积态Fe-Mn-Si基形状记忆合金XRD图谱

Fig. 5 XRD pattern of as-deposited Fe-Mn-Si based shape memory alloy

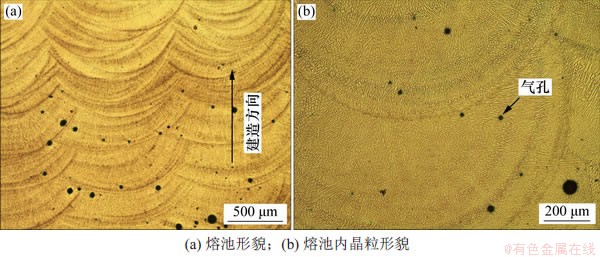

2.2 沉积态Fe-Mn-Si基合金微观组织分析

图6所示为Fe-Mn-Si基合金沿建造方向(Y-Z向)样品的金相照片。从图6(a)可以清晰地看到:因高斯热源作用而呈半圆形的熔池,熔池的宽度为1.0~1.1 mm,深度为300~500 μm,熔池尺寸的变化与沉积层反复重熔和凝固有关[13]。从图6(b)还可以发现:等轴晶主要分布在熔池内,而柱状晶沿着熔池边界向熔池内部外延生长,这意味着熔池内部出现了柱状晶到等轴晶的转变(CET)。熔池内部晶粒形貌的改变与熔池内凝固速度R和温度梯度G有关。当高能量激光束熔化粉末形成新的熔池时,熔池边界形成较大的温度梯度,凝固速度低,G/R1/2较大,柱状晶沿着温度梯度方向外延生长。随着凝固过程的进行,熔池内部温度梯度逐渐减小,凝固速度增大,G/R1/2减小,熔池内形成了等轴晶。在熔池内还观察到不同尺寸的球形气孔,而且气孔主要分布在熔池底部,因为不稳定的熔池在高的能量密度下容易产生球化、液体的飞溅等,导致气体难以从熔池内部逸出去,从而产生气孔[14]。

图6 Fe-Mn-Si基形状记忆合金建造方向(Y-Z向)金相形貌

Fig. 6 OM images of sample along building direction(Y-Z) of Fe-Mn-Si alloy based shape memory alloy

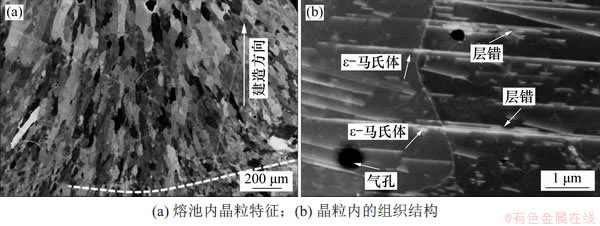

图7(a)所示为熔池内的晶粒微观形貌图。从图7(a)可以看出:在熔池底部有一层细小等轴晶区,晶粒粒径小于10 μm。柱状晶沿着熔池边界向熔池内部外延生长,晶粒粒径相对较大。当熔池形成时,熔池底部熔液的冷却速度最快,并且以先前的沉积层为形核点,形成大量的晶核并迅速长大形成细小的等轴晶区。随着熔池内部的冷却速度变慢以及结晶潜热的释放,熔液的过冷度减小形核困难,只有沿着温度梯度的方向的晶粒择优生长,从而形成相对较大的柱状晶。图7(b)所示为奥氏体晶粒内的组织特征。从图7(b)看出:沉积态合金基体中分布着层错和ε-马氏体,细的带状组织为层错,而粗的带状组织是ε-马氏体,马氏体能穿过晶界向相邻晶粒内生长[15]。层错的形成取决于合金层错能,层错能越小,层错形成的概率越大。因此,Fe-Mn-Si基形状记忆合金的层错能较低[16],在快速冷却的过程中,基体中会形成大量的层错,层错在热应力场的作用下会扩展重叠转变为ε-马氏体。

图7 沉积态Fe-Mn-Si基形状记忆合金的组织特征

Fig. 7 Microstructure characteristic of as-deposited Fe-Mn-Si alloy based shape memory alloy

2.3 沉积态合金力学性能和形状记忆效应分析

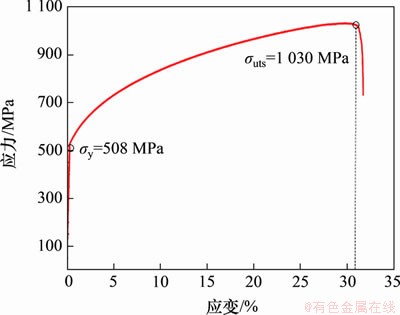

图8所示为沉积态试样的拉伸应力-应变曲线。可见:沉积态试样在室温下名义屈服强度为508 MPa,拉伸强度为1 030 MPa,伸长率达到31%,这说明沉积态合金兼具高强度和高塑性。沉积态Fe-Mn-Si基形状记忆合金屈服强度的提高主要受到2个方面的影响,一方面,沉积过程中快速冷却导致的晶粒细化,晶粒尺寸减小,屈服强度提高;另一方面,根据前面对沉积态合金微观组织和相组成分析可知,在拉伸变形之前基体中存在预存ε-马氏体,能够作为强化相抑制不可逆变形,从而提高基体发生塑性变形所需要的应力[17]。沉积态合金内细小的奥氏体基体塑性较好,同时,较硬的马氏体能阻碍位错的运动而提高强度。此外,变形应力可以作为马氏体相变的驱动力,合金在变形过程不断发生马氏体相变,从而保证了沉积态合金具有高强度和高塑性。

图8 沉积态合金应力-应变曲线

Fig. 8 Tensile stress-strain curves of as-deposited alloy

图9所示为沉积态合金在不同预变形量下的回复率。从图9可以看出,随着预变形量不断增大,合金的形状回复率降低。当变形量为3%时,形状回复率最大为73.4%,而变形量为10%时,回复率仅为36%,沉积态Fe-Mn-Si基合金所测得的最大可回复变形量为3.6%,相对于未经特殊处理的变形加工合金的可回复变形量(2%~3%)有所提高。从图7可以看出,大量的层错分布在基体中,而层错相当于只有两层原子的细小ε-马氏体,可以作为ε-马氏体长大的核胚[18]。因此,当合金受到外力时,大量马氏体由层错扩展而形成,应力诱发马氏体相变得到有效促进。另外,当变形量较小时,由于基体的屈服强度较高,位错滑移得到一定的抑制,形变主要由马氏体相变承担。因此,在较小的预变形量条件下,形变可恢复率较高。当变形量增大时,位错滑移产生不可恢复塑性变形也随之增大,而且随着应力增大,基体内位错密度增大,在加热回复过程中,位错会阻碍马氏体向奥氏体的逆转变,从而抑制形状回复。

图9 沉积态合金在不同预变形量下的形状回复率

Fig. 9 Shape recovery rates of as-deposited alloy under different pre-deformation

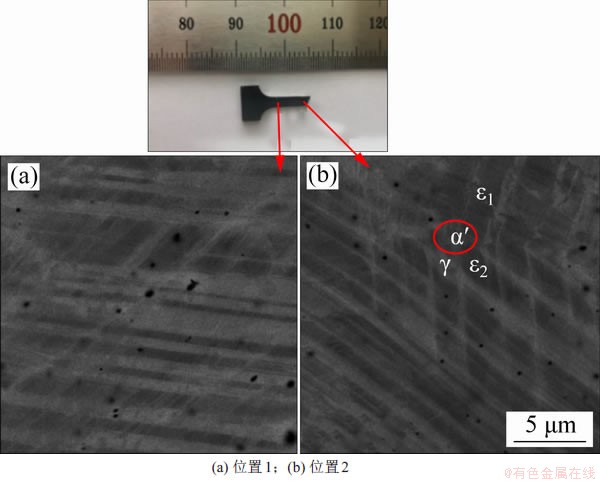

图10所示为沉积态合金试样在室温下拉伸变形后(拉伸变形量为31%)的微观组织形貌。如图10(a)所示,奥氏体晶粒内部产生的应力诱发马氏体具有不同的尺寸,较小的马氏体在应力的作用下不断扩展为较宽的板条状马氏体,较宽的马氏体彼此碰撞从而产生不可恢复的塑性变形。另外,不同位向的马氏体彼此之间会在晶粒内部发生较为严重的碰撞而产生α′马氏体,如图10(b)所示,这种马氏体会损害合金的形状记忆效应。当变形量较大时,位错滑移带来的不可恢复变形也增加。因此,随着变形量增大,由位错滑移以及马氏体相互碰撞产生的不可恢复变形增加,合金的形状记忆效应会大幅度下降。

图10 室温下经31%变形量拉伸后试样不同位置的微观结构

Fig. 10 Microstructure of samples at different positions after tensile test with 31% deformation strain at room temperature

3 结论

1) 激光同轴送粉熔化成形的Fe-Mn-Si-Cr-Ni形状记忆合金由γ-奥氏体和ε-马氏体组成,其中,ε-马氏体由打印过程中试样内部产生的残余应力作为驱动力诱发而形成。

2) 沉积态合金的屈服强度为508 MPa,拉伸强度为1 030 MPa,伸长率达31%。沉积态合金较高的室温名义屈服强度与晶粒细化以及预存马氏体对基体强化有关。变形过程中,应力诱发马氏体相变提高了合金的强度和塑性。

3) 沉积态的Fe-Mn-Si基形状记忆合金形状回复率随着预变形量的增大而减小,最大可回复变形量为3.6%。形状回复率随着变形量增大而减小,主要是因为变形量增大时,基体内由位错滑移以及ε-马氏体碰撞导致的不可恢复变形量增多。

参考文献:

[1] SATO A, CHISHIMA E, SOMA K, et al. Shape memory effect in  transformation in Fe-30Mn-1Si alloy single crystals[J]. Acta Metallurgica, 1982, 30(6): 1177-1183.

transformation in Fe-30Mn-1Si alloy single crystals[J]. Acta Metallurgica, 1982, 30(6): 1177-1183.

[2] ROBINSON J S, MCCORMICK P G. Factors influencing shape memory behaviour in an Fe-Mn-Si alloy[J]. Scripta Metallurgica, 1989, 23(11): 1975-1978.

[3] OTSUKA H, YAMADA H, MARUYAMA T, et al. Effects of alloying additions on Fe-Mn-Si shape memory alloys[J]. ISIJ International, 1990, 30(8): 674-679.

[4] REYHANI M M, MCCORMICK P G. Mechanical and shape memory behaviour in an Fe-Mn-Si-Cr-Ni alloy[J]. Materials Science and Engineering: A, 1993, 160(1): 57-61.

[5] BARUJ A, TROIANI H E. The effect of pre-rolling Fe-Mn-Si-based shape memory alloys: mechanical properties and transmission electron microcopy examination[J]. Materials Science and Engineering: A, 2008, 481/482: 574-577.

[6] LIN H C, LIN K M, WU S K, et al. Effects of thermo-mechanical training on a Fe59Mn30Si6Cr5 shape memory alloy[J]. Materials Science and Engineering: A, 2006, 438/439/440: 791-795.

[7] DONG Z Z, KAJIWARA S, KIKUCHI T, et al. Effect of pre-deformation at room temperature on shape memory properties of stainless type Fe-15Mn-5Si-9Cr-5Ni-(0.5-1.5)NbC alloys[J]. Acta Materialia, 2005, 53(15): 4009-4018.

[8] LAI M J, LI Y J, LILLPOPP L, et al. On the origin of the improvement of shape memory effect by precipitating VC in Fe-Mn-Si-based shape memory alloys[J]. Acta Materialia, 2018, 155: 222-235.

[9] STANFORD N, DUNNE D P. Effect of second-phase particles on shape memory in Fe-Mn-Si-based alloys[J]. Materials Science and Engineering: A, 2007, 454/455: 407-415.

[10] LUO Shuncun, GAO Piao, YU Hanchen, et al. Selective laser melting of an equiatomic AlCrCuFeNi high-entropy alloy: processability, non-equilibrium microstructure and mechanical behavior[J]. Journal of Alloys and Compounds, 2019, 771: 387-397.

[11] WEN Y H, YAN M, LI N. Effects of carbon addition and aging on the shape memory effect of Fe-Mn-Si-Cr-Ni alloys[J]. Scripta Materialia, 2004, 50(4): 441-444.

[12] JU Heng, LIN Chengxin, LIU Zhijie, et al. Study of in situ formation of Fe-Mn-Si shape memory alloy welding seam by laser welding with filler powder[J]. Optics & Laser Technology, 2018, 104: 65-72.

[13] TAN Z E, PANG J H L, KAMINSKI J, et al. Characterisation of porosity, density, and microstructure of directed energy deposited stainless steel AISI 316L[J]. Additive Manufacturing, 2019, 25: 286-296.

[14] 李瑞迪. 金属粉末选择性激光熔化成形的关键基础问题研究[D]. 武汉: 华中科技大学材料科学与工程学院, 2010: 18-26.

LI Ruidi. Research on key basic problems of metal powder selective laser melting[D]. Wuhan: Huazhong University of Science and Technology. School of Materials Science and Engineering, 2010: 18-26.

[15] WANG Meimei, LI Zhiming, RAABE D. In-situ SEM observation of phase transformation and twinning mechanisms in an interstitial high-entropy alloy[J]. Acta Materialia, 2018, 147: 236-246.

[16] PENG Huabei, WANG Gaixia, WANG Shanling, et al. Key criterion for achieving giant recovery strains in polycrystalline Fe-Mn-Si based shape memory alloys[J]. Materials Science and Engineering: A, 2018, 712: 37-49.

[17] 杨军, 邓龙江, 王昕, 等. 快速凝固对Fe-Mn-Si系形状记忆合金组织和性能的影响[J]. 功能材料, 2011, 42(4): 711-717.

YANG Jun, DENG Longjiang, WANG Xin, et al. The influence of rapidly solidification on the structure and property of the Fe-Mn-Si base shape memory alloy[J]. Journal of Functional Materials, 2011, 42(4): 711-717.

[18] ESQUIVEL I, GIORDANA M F, DRUKER A V. Effect of heat treatment on the microstructure and shape memory behaviour of Fe-Mn-Si-Ni-Cr alloys[J]. Materials Characterization, 2019, 155: 109-111.

(编辑 赵俊)

收稿日期: 2020 -08 -28; 修回日期: 2020 -10 -19

基金项目(Foundation item):国家自然科学基金资助项目(51871249);湖南省自然科学基金资助项目(2020JJ2046) (Project(51871249) supported by the National Natural Science Foundation of China; Project(2020JJ2046) supported by the Natural Science Foundation of Hunan Province)

通信作者:李瑞迪,研究员,博士生导师,从事激光增材制造粉末材料研究;E-mail:liruidi@csu.edu.cn