文章编号:1004-0609(2013)05-1301-06

时效工艺对Ti-Ni-V形状记忆合金显微组织和超弹性的影响

贺志荣1,刘曼倩1,王 芳2,张永宏1,王永善1

(1. 陕西理工学院 材料科学与工程学院,汉中 723003;

2. 陕西理工学院 图书馆,汉中 723003)

摘 要:采用TEM和拉伸实验研究经300、400和500 ℃分别时效0.5~100 h后,时效温度和时效时间对Ti-50.8Ni-0.5V(摩尔分数,%)形状记忆合金室温显微组织和超弹性(SE)的影响。结果表明,时效温度对合金析出相形貌和SE特性的影响比时效时间显著。随时效温度的升高,合金中Ti3Ni4析出物形态由颗粒状向针状再向粗片状演变,合金的应力诱发马氏体相变临界应力(σM)降低,SE特性变差。300 ℃时效态合金的σM最大,SE最好;500 ℃时效态合金的σM最小,SE最差。随时效时间的延长,300 ℃时效态合金的SE特性稳定,σM和超弹性能耗降低;400和500 ℃时效态合金的超弹性残余应变增加,SE特性逐渐消失。

关键词:Ti-Ni-V合金;形状记忆合金;时效;显微组织;超弹性

中图分类号:TG113.25 文献标志码:A

Effect of aging process on microstructure and superelasticity of Ti-Ni-V shape memory alloy

HE Zhi-rong1, LIU Man-qian1, WANG Fang2, ZHANG Yong-hong1, WANG Yong-shan1

(1. School of Materials Science and Engineering, Shaanxi University of Technology, Hanzhong 723003, China;

2. Library, Shaanxi University of Technology, Hanzhong 723003, China)

Abstract: The effects of aging temperature and aging time on the microstructure and superelasticity (SE) at room temperature of Ti-50.8Ni-0.5V (mole fraction, %) shape memory alloy aged at 300, 400 and 500 ℃ for 0.5-100 h, respectively, were investigated by TEM and tensile test. The results show that the effects of aging temperature on the precipitate morphology and SE property are more outstanding than those of aging time. With increasing aging temperature, the morphology of Ti3Ni4 precipitates in the alloy changes from the fine particle-shape to the needle-shape and then to the plate-shape; the critical stress for inducing martensitic transformation (σM) decreases; and the SE property becomes poor. The σM is the largest and the SE property is the best for the alloy aged at 300 ℃, and the σM is the smallest and the SE property is the worst for the alloy aged at 500 ℃. With increasing aging time, the SE property is stable, the σM and the superelasticity energy dissipation decrease for the alloy aged at 300 ℃; the residual strain of the superelasticity increases and SE property disappears gradually for the alloy aged at 400 and 500 ℃.

Key words: Ti-Ni-V alloy; shape memory alloy; aging; microstructure; superelasticity

处于母相状态的Ti-Ni形状记忆合金(SMA)具有良好的超弹性(SE),即合金在受到外应力作用时产生远大于其弹性极限应变量的应变,应变在卸载后可自动恢复[1]。SE合金具有恒应力、大应变、非线性阻尼和高弹性模量等特性[2],可用于制作牙齿矫正器、储能器、地震防护装置和耐摩零件等[3-5]。SE由应力诱发马氏体(M)相变及其逆相变过程中的内耗现象引起,在相变过程中材料内部各种界面的滞弹性迁移会吸收大量能量,从而使得应力—应变曲线呈现非线性特性。应力—应变回滞曲线所包围的面积反映合金耗能的大小,面积越大,合金的耗能越高,阻尼特性越好[6-7]。富镍Ti-Ni合金经时效处理后,可析出与母相基体共格的富镍相Ti3Ni4[8-10],该析出相的生成不仅会产生共格应力场,而且会改变合金基体的Ni含量,从而改变合金的相变温度,进而影响合金的SE特性[11]。Ti-50.8Ni-0.5V合金属于富镍Ti-Ni基SMA,具有较低的相变温度,属超弹性型Ti-Ni基SMA[12]。目前,对退火态Ti-50.8Ni-0.5V合金的组织和形变特性已有系统研究[13],而对时效态合金的组织和形变特性尚缺乏研究。为此,本文作者研究时效处理对Ti-50.8Ni-0.5V合金显微组织和超弹性的影响规律,为优化合金的热处理工艺、提高其性能提供依据。

1 实验

实验材料的名义成分为Ti-50.8Ni-0.5V(摩尔分数,%)。其加工过程如下:以纯度分别为99.7%、99.9%和99.9%的海绵Ti、电解Ni和V粉为原料,采用真空感应炉熔炼;合金铸块经压锻、旋锻、拉拔等多道工序制成直径分别为0.8 mm和5 mm的丝材,每道次变形量为20%。合金的供货状态为拉拔态,时效处理工艺如下:先将合金在800 ℃固溶处理0.5 h后水冷,然后分别在300、400和500 ℃时效0.5~100 h。采用JEM-200CX型透射电子显微镜(TEM)观察不同时效态Ti-50.8Ni-0.5V合金的显微组织形貌,操作电压为160 kV,双喷减薄液的成分为6% HClO4+94% CH3OH(体积分数)。采用带有高低温测试系统的CMT5105型微机控制电子万能试验机测定合金室温(24 ℃)下的力学性能和形状记忆行为。标距为50 mm,加载/卸载速率为2 mm/min。

2 结果及分析

2.1 显微组织

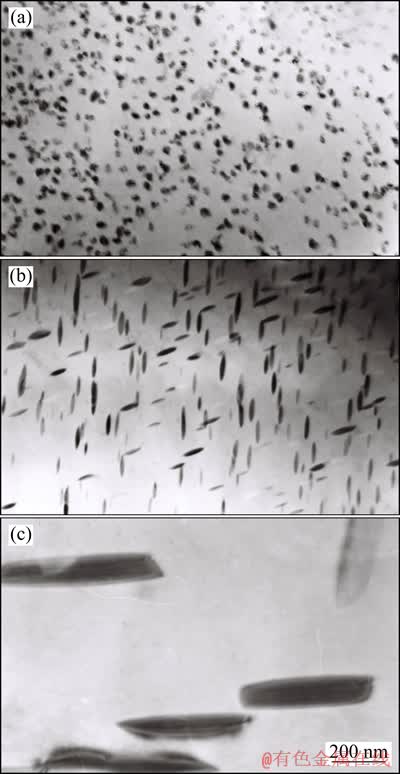

图1所示为Ti-50.8Ni-0.5V合金在800 ℃固溶处理30 min后分别在300、400、500 ℃时效50 h的TEM像。从图1可以看出,该合金经400~500 ℃时效处理后,合金中均有Ti3Ni4析出物出现,但析出物的形貌和弥散度不同。300 ℃时效态合金中析出物呈细小弥散分布的颗粒状(图1(a));随时效温度的升高,颗粒状析出物逐渐长大,弥散度逐渐降低;当时效温度升高至400 ℃时,析出物的形貌转变为针状(图1(b)),随时效温度继续升高至500 ℃时,析出物尺寸进一步长大,呈粗片状,弥散度降低(图1(c))。

图1 不同温度下时效态Ti-50.8Ni-0.5V合金的显微组织

Fig. 1 Microstructures of Ti-50.8Ni-0.5V alloy aged at 300 ℃ (a), 400 ℃ (b) and 500 ℃ (c) for 50 h

2.2 形变特性

2.2.1 拉伸性能

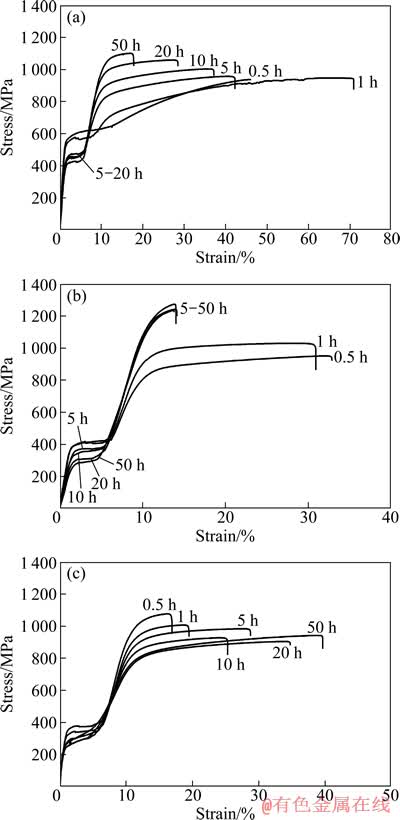

Ti-50.8Ni-0.5V合金在300、400和500 ℃时效不同时间后,在室温(24 ℃)下的拉伸应力—应变曲线如图2所示。由图2可见,时效温度和时效时间(tag)对合金的应力—应变曲线有较大影响。300~500 ℃时效态合金时效不同时间后,应力—应变曲线上均出现了典型的应力诱发M相变平台,应力—应变曲线均经历了母相的弹性变形、应力诱发M相变、M弹性变形、塑性变形和断裂5个阶段。所不同的是,合金在时效过程中由于时效温度和tag的不同,析出了大小不同、形貌各异的Ti3Ni4相[14],因而对合金的力学性能产生了不同的影响。合金在300 ℃短时间时效后具有较好的塑性,比如1 h时效态合金的断裂伸长率可达70%,随tag的延长,合金的塑性逐渐减弱,应力诱发M临界应力逐渐降低,抗拉强度有所提高(图2(a))。400 ℃时效0.5~1 h后,合金的塑性较好,其断裂伸长率可达33%,随tag的延长,合金的塑性趋于稳定(其断裂伸长率保持在14%左右)(图2(b))。与300和400 ℃时效态合金不同的是,500 ℃时效态合金的塑性随tag的延长而提高,由时效0.5 h时的16%增大至时效50 h时的39%,合金的抗拉强度随tag的延长而降低(图2(c))。

图2 时效工艺对Ti-50.8Ni-0.5V合金拉伸性能的影响

Fig. 2 Effect of aging process on tensile properties of Ti-50.8Ni-0.5V alloy aged at 300 ℃ (a), 400 ℃ (b) and 500 ℃ (c) (test at 24 ℃)

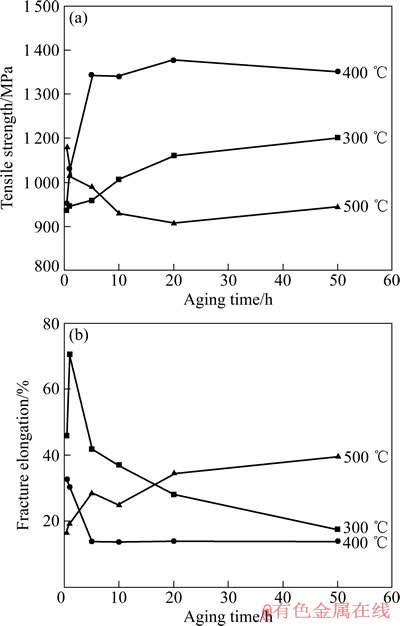

图3所示为时效工艺对Ti-50.8Ni-0.5V合金抗拉强度(σb)(图3(a))和断裂伸长率(δk)(图3(b))的影响。由图3(a)可知,随tag的延长,300和400 ℃时效态合金在tag=0.5~5 h时,σb逐渐升高,tag=5~50 h时,σb基本保持不变;而500 ℃时效态合金在tag=0.5~5 h时,σb逐渐降低,tag=5~50 h时,σb也基本保持不变。当tag≥10 h时,σb400>σb300>σb500。从图3(b)可以看出,随tag的延长,300 ℃时效态合金的δk先增大后降低;400 ℃时效态合金的δk先降低后趋于稳定值;500 ℃时效态合金的δk先增大后趋于稳定值。

图3 时效工艺对Ti-50.8Ni-0.5V合金抗拉强度和断裂伸长率的影响

Fig. 3 Effect of aging process on tensile strength (a) and fracture elongation (b) of Ti-50.8Ni-0.5V alloy

2.2.2 超弹性

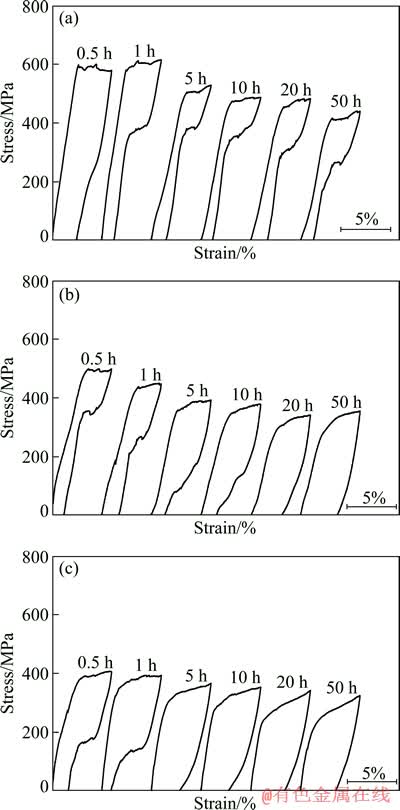

时效工艺对Ti-50.8Ni-0.5V合金室温(24 ℃)SE特性的影响如图4所示。由图4可知,随时效温度的升高和时效时间(tag)的延长,合金的应力诱发M相临界应力(即平台应力)降低。300 ℃时效态合金的应力—应变回滞曲线始终保持SE特性,随tag的延长,合金应力—应变回滞曲线所包围的面积减小,即合金超弹性能耗降低;合金的残余应变先快速减小后趋于稳定(图4(a))。随tag的延长,400 ℃时效态合金的应力—应变曲线逐渐由SE特性转变为形状记忆效应(SME)特性,且合金的应力诱发M临界应力显著降低(图4(b)),这是由于随tag的延长,合金的M逆相变温度升高,M逆相变温度高于实验温度的合金表现为SE特性,M逆相变温度低于实验温度的合金表现为SME特性。图4(c)所示为500 ℃时效态合金在不同时间的应力—应变回滞曲线。由图4(c)可见,随tag的延长,500 ℃时效合金也表现出和400 ℃时效态合金相同的由SE特性向SME特性的转变,所不同的是,合金由SE特性转变为SME特性的时间变短,且合金的应力诱发M临界应力进一步降低。

图4 时效工艺对Ti-50.8Ni-0.5V合金超弹性的影响

Fig. 4 Effect of aging process on superelasticity of Ti-50.8Ni-0.5V alloy aged at 300 ℃ (a), 400 ℃ (b) and 500 ℃ (c) (test at 24 ℃)

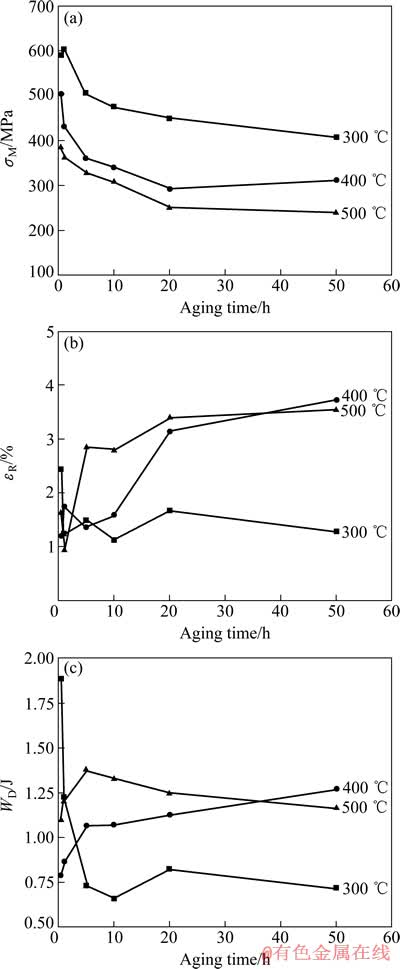

图5 时效工艺对Ti-50.8Ni-0.5V合金临界应力(σM)、残余应变(εR)和循环耗能(WD)的影响

Fig. 5 Effect of aging process on critical stress for inducing critical stress (σM) (a), residual strain (εR) (b) and cyclic energy dissipation (WD) (c) of Ti-50.8Ni-0.5V alloy

图5所示为时效工艺对Ti-50.8Ni-0.5V合金应力诱发M临界应力σM(图5(a))、残余应变εR(图5(b))和单次循环能耗WD(图5(c))的影响。由图5(a)可知,随tag的延长,不同时效温度合金的σM均呈降低趋势,且σM300>σM400>σM500。图5(b)表明,随tag的延长,300 ℃时效态合金的εR先降低后趋于稳定,400和500 ℃时效态合金的εR先增大后趋于稳定。从图5(c)可以看出,随tag的延长,300 ℃时效态合金的WD先减小后趋于稳定,400和500 ℃时效态合金的WD先增大后趋于稳定,这是由于300 ℃时效态合金始终呈现SE特性,卸载后应力诱发M可逆转变为母相,而400和500 ℃时效态合金呈现由SE向SME的转变,呈现SME特性的合金在卸载后M只有通过加热才能逆转变为母相。

3 讨论

时效温度对Ti-50.8Ni-0.5V合金显微组织的影响比时效时间的影响显著。当时效温度较低时,原子扩散能较低,扩散速率较小,析出物细小弥散。随时效温度升高,原子扩散能增强,扩散速率增大,溶质原子聚集长大,析出物尺寸增加,弥散度降低。随tag的延长,原子扩散充分,析出物生长时间长,尺寸粗化。

随tag的延长,300和400 ℃时效态Ti-50.8Ni-0.5V合金在tag=0.5~5 h时,σb逐渐增大,这是由于在时效过程中合金组织中逐渐析出细小的Ti3Ni4相,这些细小的颗粒弥散分布于基体中,可起到强化基体的作用,从而使合金的σb增大,δk减小。而合金在500 ℃时效后,由于时效温度较高,合金中的析出物逐渐长大,弥散度降低,对基体的强化能力减弱,因此,合金的σb减小,δk增大。

合金的应力诱发M临界应力σM和残余应变εR是反映SMA的SE特性的两个重要指标。通常,合金的σM越大,合金所能提供的恒定应力越大,εR越小,合金的SE特性越好。当Ti-50.8Ni-0.5V合金在300 ℃时效0.5 h时,由于合金的M相变开始温度较低[15],合金发生应力诱发M相变所需临界应力较大,且此时合金中析出相较少,对基体的强化作用较弱,因此,合金在发生应力诱发M相变之前已经发生了塑性变形,卸载后应变有部分残余,不能完全恢复,εR较大。随tag的延长,合金中细小弥散的析出物增多,强化了基体,使得应力诱发M相变之前的塑性变形量减小,在卸载后可恢复应变增大,SE性能增强。随时效温度升高,合金中的析出物长大速率加快,随tag的延长,合金中析出物逐渐长大,弥散度降低,对基体的强化作用减弱,同时由于富镍相的析出使得合金中的Ni含量降低,相变温度升高,合金表现出由SE向SME的转变。

4 结论

1) 时效温度对合金析出相和SE特性的影响比时效时间的影响显著。

2) 随时效温度的升高,合金中Ti3Ni4析出物形态由颗粒状向针状再向粗片状演变;合金的σM减小,SE性能变差;300 ℃时效态合金的σM最大,SE特性最好;500 ℃时效态合金的σM最小,SE特性最差。

3) 随时效时间的延长,300 ℃时效态合金的SE特性稳定,σM和超弹性能耗降低;400和500 ℃时效态合金的超弹性残余应变增加,SE特性逐渐消失。

4) 随时效时间的延长,300和400 ℃时效态合金的σb先增大后趋于稳定,500 ℃时效态合金的σb先降低后趋于稳定;300 ℃时效态合金的δk先升高后降低;400 ℃时效态合金的δk先降低后趋于稳定;500 ℃时效态合金的δk先增大后趋于稳定。

REFERENCES

[1] OTSUKA K, WAYMAN C M. Shape memory materials[M]. Cambridge: Cambridge University Press, 1998: 49-97.

[2] HUMBEECK J V. Damping capacity of thermo elasticmartensite in shape memory alloys[J]. J Alloys Compound, 2003, 355: 58-64.

[3] KIREEVA I V, CHUMLYAKOV Y I, ZAKHAROVA E G, KARAMAN I. Shape memory and superelasticity in single-phase nickel titanium single crystals[J]. J de Phys TV, 2004, 115: 175-179.

[4] SEYYED AGHAMIRI S M, NILI AHMADABADI M, RAYGAN S, HARIRIAN I, AHMAD AKHONDI M S. The mechanical and thermal behaviors of heat-treated Ni-rich NiTi orthodontic archwires[J]. JMEPEG, 2009, 18: 843-847.

[5] HUMBEECK J V. Preface to the viewpoint set on: Shape memory alloys[J]. Scripta Mater, 2004, 50: 179-180.

[6] MIYAZAKI S, IMAI T, IGO Y. Effect of cyclic deformation on pseudoelasticity characteristics of Ti-Ni alloy[J]. Metall Trans, 1986, 17: 115-120.

[7] COLUZZI COLUZZI B, BISCARINI A, CAMPANELLA R, MAZZOLAI G, TROTTA L, MAZZOLAI F M. Effect of thermal cycling through the martensitic transition on the internal friction and Young’s modulus of a Ni50.8Ti49.2 alloy[J]. J Alloys Compound, 2000, 310: 300-305.

[8] 赵连城, 蔡 伟, 郑玉峰. 合金的形状记忆效应与超弹性[M]. 北京: 国防工业出版社, 2002: 23-30.

ZHAO Lian-cheng, CAI Wei, ZHENG Yu-feng. Shape memory effect and superelasticity in alloys[M]. Beijing: National Defense Industry Press, 2002: 23-30.

[9] YONEYAMA T, DOI H, KOBAYASHI E, HAMANAKA H. Effect of heat treatment with the mould on the super-elastic property of Ti-Ni alloy castings for dental application[J]. J Mater Sci: Mater in Medicine, 2002, 13: 947-951.

[10] KIM J I, MIYAZAKI S. Effect of low-temperature aging on the R-phase transformation of a Ti-50.9at%Ni alloy[J]. Mater Sci Forum, 2002, 394/395: 225-228.

[11] KIM J I, MIYAZAKI S. Comparison of shape memory characterterstics of a Ti-50.9at. pct Ni alloy aged at 473 and 673 K[J]. Metall Mater Trans A, 2005, 36: 3301-3310.

[12] 贺志荣, 王 芳, 王永善, 夏鹏举, 杨 波. V和Cr对Ti-Ni超弹性合金相变和形变特性的影响[J]. 金属学报, 2007, 43(12): 1293-1296.

HE Zhi-rong, WANG Fang, WANG Yong-shan, XIA Peng-ju, YANG Bo. Effects of V and Cr on transformation and deformation characteristics of Ti-Ni superelastic alloy[J]. Acta Metall Sin, 2007, 43(12): 1293-1296.

[13] HE Z, LIU M. Effects of annealing and deforming temperature on microstructure and deformation characteristics of Ti-Ni-V shape memory alloy[J]. Mater Sci Eng B, 2012, 177(12): 986-991.

[14] CAO S, NISHIDA M, SCHRYVERS D. Quantitative three-dimensional analysis of Ni4Ti3 precipitate morphology and distribution in polycrystalline Ni-Ti[J]. Acta Mater, 2011, 59: 1780-1789.

[15] HE Z, LIU M. Effect of heat treatment on transformation behavior of Ti-Ni-V shape memory alloy[J]. Mater Sci Eng A, 2011, 528(22/23): 6993-6997.

(编辑 陈卫萍)

基金项目:陕西省科技计划项目(2011KTDZ01-03-06);陕西省教育厅科研计划项目(12JK0436)

收稿日期:2012-07-21;修订日期:2012-09-23

通信作者:贺志荣,教授,博士;电话:0916-2291079;E-mail:hezhirong01@163.com