DOI: 10.11817/j.ysxb.1004.0609.2021-36554

Ti-50.8Ni-0.5V形状记忆合金的相变、组织与性能

贺志荣1,王 芳2,叶俊杰1,张坤刚1,杜雨青1

(1. 陕西理工大学 材料科学与工程学院,汉中 723001;

2. 陕西理工大学 图书馆,汉中 723003)

摘 要:利用XRD、示差扫描热分析仪(DSC)、光学显微镜和拉伸试验研究退火态Ti-50.8Ni-0.5V(摩尔分数,%)形状记忆合金的相变行为、组织特征和力学性能。结果表明:400~700 ℃退火态Ti-50.8Ni-0.5V合金室温组成相为母相B2和马氏体B19′。随退火温度升高,该合金冷却/加热时的相变类型由B2→R/R→B2型向B2→R→B19′/B19′→R→B2型向B2→R→B19′/B19′→B2型向B2→B19′/B19′→B2型转变;R相、马氏体相变温度先升高后降低,极大值28.1 ℃、-58.5 ℃分别在400 ℃、500 ℃退火态合金中取得;显微组织由纤维状变为等轴状,再结晶温度在550~600 ℃之间;抗拉强度降低,塑性提高;应力诱发马氏体临界应力σM先降低后升高,极小值325 MPa在450 ℃退火态合金中取得;残余应变先升高后降低再升高,极大值2.55%在450 ℃退火态合金中取得,极小值0.65%在500~650 ℃退火态合金中取得。随形变温度升高,合金由形状记忆效应(SME)向超弹性(SE)转变,SME→SE转变温度可用DSC曲线上马氏体逆相变峰温度tMr+16 ℃估算。随循环次数增加,400 ℃退火态合金的σM稳定,500和600 ℃退火态合金的σM先降低后趋于稳定。

关键词:Ti-Ni-V合金;形状记忆合金;相变;形状记忆效应;超弹性

文章编号:1004-0609(2021)-02-0322-11 中图分类号:TG113.25 文献标志码:A

引文格式:贺志荣, 王 芳, 叶俊杰, 等. Ti-50.8Ni-0.5V形状记忆合金的相变、组织与性能[J]. 中国有色金属学报, 2021, 31(2): 322-332. DOI: 10.11817/j.ysxb.1004.0609.2021-36554

HE Zhi-rong, WANG Fang, YE Jun-jie, et al. Phase transformation, microstructure and properties of Ti-50.8Ni-0.5V shape memory alloy[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(2): 322-332. DOI: 10.11817/j.ysxb.1004.0609.2021-36554

Ti-Ni形状记忆合金(SMA)具有良好的形状记忆效应(SME)和超弹性(SE)[1-3],是集传感和驱动于一体的功能材料,已广泛应用于机械、电子、能源、交通、航空航天及医疗等领域[4-6]。Ti-Ni SMA的SME和SE特性来源于热弹性马氏体(M)相变及其逆相变,并受合金成分、热处理工艺、预变形量、形变温度以及应力-应变循环等因素的影响[7-13]。在Ti-Ni合金中加入第三组元,也可显著改变合金的相变温度、力学性能和恢复特性[14-15];通过热处理可以改变合金的室温相组成、组织形貌及亚结构等,进而改变合金的相变温度和力学特性[16-17];当形变温度(td)低于合金的马氏体相变结束温度tMf时,合金呈现SME;当td高于合金的马氏体逆相变结束温度tAf时,合金呈现SE;当tMf<td<tAf时,合金呈现SME+SE特性[18-19]。因此,可以通过添加合金元素、改变热处理工艺和形变温度来改变Ti-Ni合金的SME和SE特性,从而扩展其应用范围,满足不同应用需求。作者早期研究结果表明,在Ti-Ni二元SMA中加入V可降低相变温度,据此研制了Ti-50.8Ni-0.5V(摩尔分数,%)SMA[20],并系统研究时效工艺对Ti-50.8Ni-0.5V合金相变和形状记忆行为的影响[21]。本文旨在研究退火态Ti-50.8Ni-0.5V形状记忆合金的相变行为、组织特征和力学性能,探讨退火温度、形变温度、应力-应变循环对Ti-50.8Ni-0.5V合金形状记忆行为的影响规律,为开发高性能形状记忆合金及其加工技术提供依据。

1 实验

实验材料是直径为0.8 mm的Ti-50.8Ni-0.5V (摩尔分数,%)合金丝材,其加工过程是,以纯度分别为99.7%,99.9%和99.9%的海绵Ti,电解Ni和V粉为原料,采用真空感应炉熔炼,合金铸块经压锻、旋锻、拉拔等多道工序制成丝材,每道次变形量为20%。退火处理工艺为:350~800 ℃保温30 min空冷。用Rigaku Ultima IV型X射线衍射仪(XRD)分析不同热处理态合金的室温相组成,扫描速率为0.1 (°)/s,靶材为Cu Kα。用Shimadzu DSC-50型示差扫描量热仪(DSC)分析合金的相变行为,冷却/加热温度范围为-150~100 ℃,冷却/加热速率为10 ℃/min。用XJL-300型金相显微镜分析不同热 处理态Ti-50.8Ni-0.5V合金的显微组织,腐蚀剂为V(HF):V(HNO3):V(H2O)=1:4:5。用带有高低温测试系统的CMT5105型微机控制电子万能试验机测定合金在室温下的应力-应变循环特性,标距为50 mm,加载/卸载速率为2 mm/min。

2 实验结果

2.1 相组成

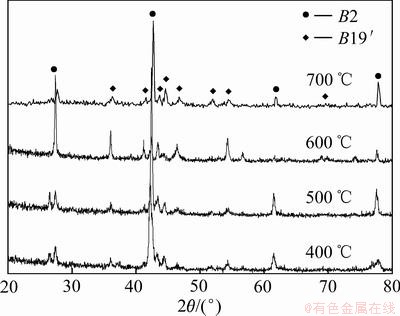

图1所示为400~700 ℃退火态Ti-50.8Ni-0.5V合金室温XRD谱。由图1可知,该合金室温下主要由母相B2和马氏体B19′相组成,以母相为主。由于SME与B19′相对应,SE与B2相对应[19],故Ti-50.8Ni-0.5V合金室温下将主要呈现SE特性。

2.2 相变行为

2.2.1 相变类型

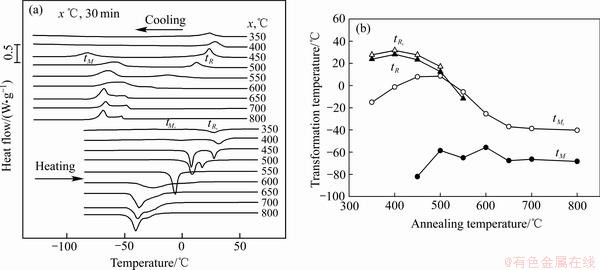

350~800 ℃退火态Ti-50.8Ni-0.5V合金的相变类型如图2(a)所示。图2(a)中,冷却曲线上的R和M分别代表R相和马氏体M的正相变峰,加热曲线上的Rr和Mr分别代表R和M相变的逆相变峰。可以看出,冷却/加热时,350~400 ℃退火态合金的相变类型为B2→R/R→B2(B2—母相,CsCl型结构;R—R相,菱方结构)一阶段可逆相变,M相变峰在测试温度范围内未检测出;450~500 ℃退火态合金的相变类型为B2→R→B19′/B19′→R→B2(B19′—马氏体,单斜结构)两阶段可逆相变;550 ℃退火态合金发生B2→R→B19′/B19′→B2型相变;600 ℃以上温度退火态合金发生B2→B19′/B19′→B2型相变[13],R相变峰未出现。随退火温度(tan)升高,R、M相变峰均先移向高温后移向低温。当tan超过600℃后,合金的R、M相变峰重合。

图1 退火态Ti-50.8Ni-0.5V合金的相组成

Fig. 1 Phase composition of annealed Ti-50.8Ni-0.5V alloy

2.2.2 相变温度

为准确、直观确定合金的相变温度,本研究用DSC冷却曲线上的R相变峰温度tR和M相变峰温度tM分别表示R、M正相变温度,用DSC加热曲线上的R逆相变峰温度tRr和M逆相变峰温度tMr分别表示R、M逆相变温度。tan对350~800 ℃退火态Ti-50.8Ni-0.5V合金tR、tRr、tM、tMr温度的影响如图2(b)所示。由图2(b)可以看出,随tan升高,合金的R相变温度tR、tRr先升高后降低,400 ℃退火态合金的tR和tRr达到极大值28.1 ℃和31.7 ℃;合金的M相变温度tM和tMr先升高后降低,极大值-58.5 ℃和8.7 ℃在500 ℃退火态合金中取得。350 ℃和600 ℃以上温度退火态合金的tMr温度普遍较低,表明经这些温度退火的Ti-50.8Ni-0.5V合金将具有良好的低温超弹性。

图2 退火温度对Ti-50.8Ni-0.5V合金相变类型和相变温度的影响

Fig. 2 Effect of annealing temperature on transformation type(a) and transformation temperature(b) of Ti-50.8Ni-0.5V alloy

2.3 显微组织特征

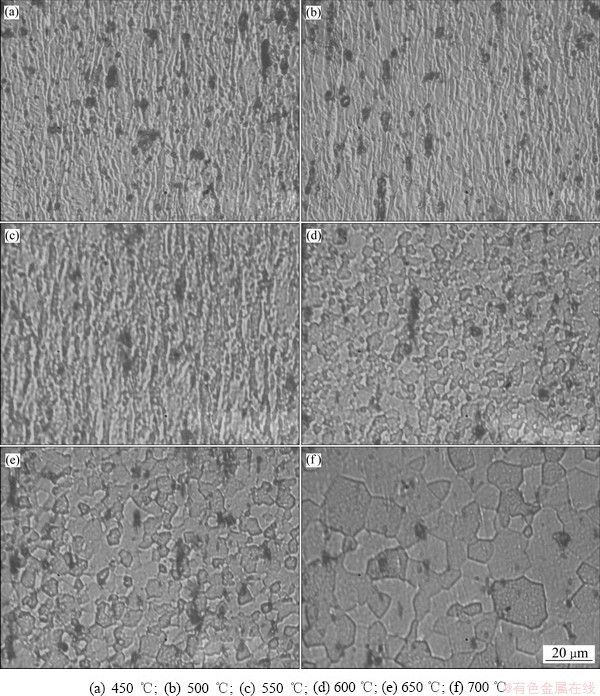

图3所示为450~700 ℃退火态Ti-50.8Ni-0.5V合金的显微组织。由图3可以看出,退火温度低于550 ℃时,合金的显微组织形态呈纤维状,随tan升高,纤维密度降低,连续性变差,逐渐向等轴晶粒过度;当tan升至600 ℃时,合金组织由纤维晶粒转变为细小等轴晶粒,可见该合金形变后加热退火时的再结晶温度在550~600 ℃之间。形变合金加热时纤维状组织演变成等轴状的热力学驱动力是形变储存能的释放。形变纤维状组织中点缺陷和位错密度高,晶格畸变度大,形变储存能高;当退火温度达到再结晶温度时,首先在晶格畸变度大的区域产生新的无畸变晶粒核心,使该区域的形变储存能得到释放,然后逐渐消耗周围的变形基体而长大,直到形变纤维组织完全改组为新的、无畸变的细等轴晶为止。随着tan继续升高,大晶粒通过吞并小晶粒而长大,显微组织由细晶粒变为粗晶粒。细晶粒变为粗晶粒的热力学驱动力是晶粒长大前后界面能之差。细晶粒单位体积界面积大、界面能高,细晶粗化后,单位体积界面积减少,界面能降低,因此,细晶粗化是能量降低过程。

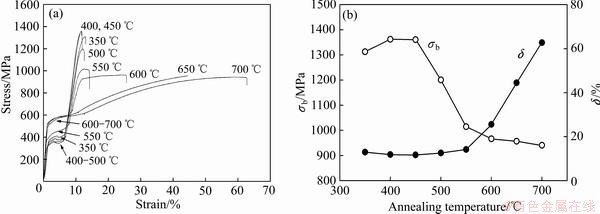

2.4 力学性能

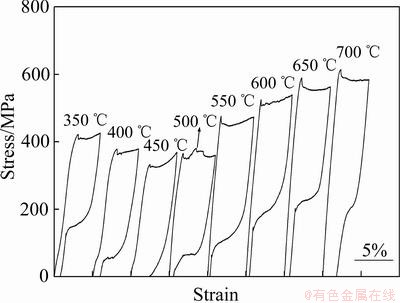

350~700 ℃退火态Ti-50.8Ni-0.5V合金室温拉伸曲线如图4(a)所示,由图4(a)可见,该合金拉伸时经历了母相的弹性变形、应力诱发M相变、应力诱发M的弹性变形、塑性变形和断裂5个典型阶 段。350~550 ℃退火态合金的抗拉强度高于600~700 ℃退火态合金的,塑性则低于后者。tan对Ti-50.8Ni-0.5V合金抗拉强度σb和断裂伸长率δ的影响如图4(b)所示。由图4(b)知,随tan升高,σb降低,δ升高。350~450 ℃退火态合金的σb较大,约为1350 MPa,700 ℃退火态合金的σb降至940 MPa。350~550 ℃退火态合金的δ较小,为11%~15%;当tan高于550 ℃后,随tan升高,δ迅速升高,在700 ℃时,δ高达63%。

此外,由图4(a)还可以看出,350~550 ℃退火态合金的应力诱发M相变应力点低于600~700 ℃退火态合金,原因在于350~550 ℃退火态合金的M逆相变温度高于600~700 ℃退火态合金(见图2)。M逆相变温度较高时,合金室温组织(母相+马氏体M)中,M份额较多,拉伸试验时,除发生应力诱发母相→M相变外,还发生M再取向,由于前者所需应力较高,后者所需应力较低,平均后使应力-应变曲线上的应力诱发M相变应力点变低。反之,M逆相变温度较低时,合金室温组织中,M份额较少甚至全为母相,拉伸试验时应力诱发M相变应力点变高。

图3 不同退火温度时Ti-50.8Ni-0.5V合金的显微组织

Fig. 3 Microstructures of Ti-50.8Ni-0.5V alloy at different annealing temperatures

图4 不同退火温度时Ti-50.8Ni-0.5V合金拉伸曲线和抗拉强度σb、伸长率δ

Fig. 4 Tensile curve (a) and tensile strength σb, elongation δ (b) of Ti-50.8Ni-0.5V alloy at different annealing temperatures

2.5 形状记忆行为

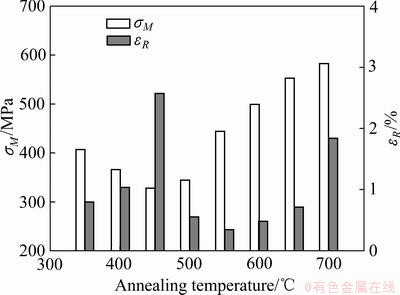

2.5.1 退火温度对形状记忆行为的影响

SMA的超弹性常用加载/卸载应力-应变曲线的平台应力即应力诱发马氏体临界应力(σM)和残余应变量(εR)评价,σM越高表明SMA的恒弹性应力越大,εR越小说明SMA的超弹性恢复越好。tan对Ti-50.8Ni-0.5V合金室温加载/卸载应力-应变曲线和σM、εR的影响如图5所示。由图5知,室温下,不同温度退火态合金加载/卸载时呈现不同程度非线性超弹性。图6所示为退火温度对应力诱发马氏体临界应力和残余应力的影响。由图6可以看出,随tan升高,合金的σM先降低后升高,极小值 325 MPa和极大值582 MPa分别在450 ℃和700 ℃退火态合金中取得;εR先升高后降低再升高,极大值2.55%和1.84%分别在450 ℃和700 ℃退火态合金中取得,极小值0.65%在500~650 ℃退火态合金中取得。此外,实验表明,试样加载-卸载后加热时,650 ℃以下温度退火态合金的εR完全恢复,650 ℃以上温度退火态合金的εR未完全恢复。因此,要使Ti-50.8Ni-0.5V合金在室温下获得优异SE(即高σM低εR),tan应取500~600 ℃。

图5 不同退火温度时Ti-50.8Ni-0.5V合金加载/卸载应力-应变曲线

Fig. 5 Loading/unloading stress-strain curves of Ti-50.8Ni-0.5V alloy at different annealing temperatures

图6 不同退火温度时应力诱发Ti-50.8Ni-0.5V合金马氏体临界应力σM和残余应变εR

Fig. 6 Critical stress of stress inducing martensite σM and residual strain εR of Ti-50.8Ni-0.5V alloy at different annealing temperatures (test at 20 ℃)

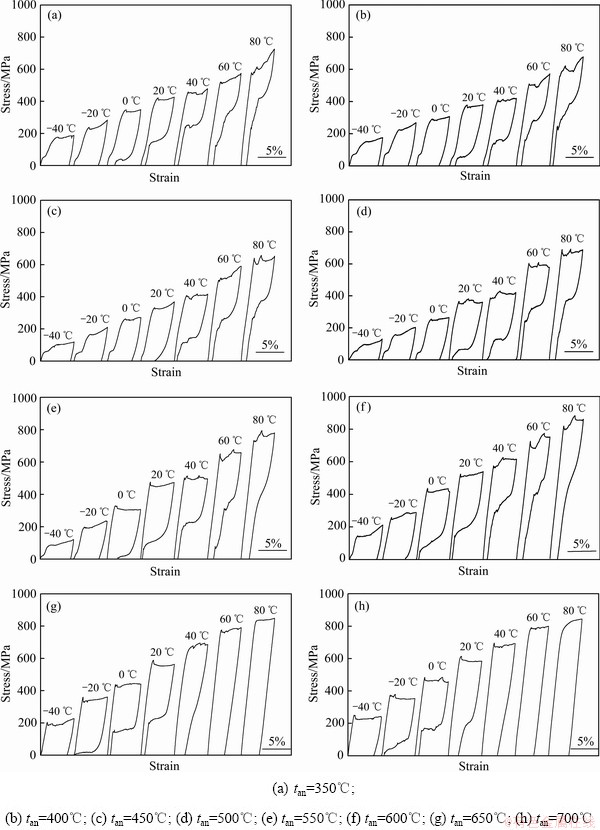

2.5.2 形变温度对形状记忆行为的影响

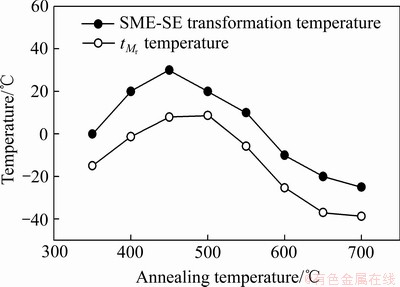

形变温度(td)对350~700 ℃退火态Ti-50.8Ni- 0.5V合金加载/卸载应力-应变曲线的影响如图7所示。由图7可以看出,随td升高,不同温度退火态合金均发生由SME向SE转变,而SME→SE转变温度受退火温度的影响,如图8所示。由图8可看出,随tan升高,SME→SE转变温度先升高后降低。具体来说,350、400、450、500、550、600、650和700 ℃退火态Ti-50.8Ni-0.5V合金分别在0、20、30、20、10、-10、-20和-25 ℃及其以上温度下呈现SE。最高SME→SE转变温度30 ℃在450 ℃退火态合金中取得,最低SME→SE转变温度-25 ℃在700 ℃退火态合金中取得。650 ℃和700 ℃退火态合金分别在60 ℃和40 ℃以上温度变形时SE消失。由图8还可看出,SME→SE转变温度和退火温度的关系与DSC加热曲线上马氏体逆相变峰温度tMr和退火温度的关系类似,二者变化趋势基本平行,平均相差约16 ℃,亦即SME→SE转变温度为tMr+16℃。因此,Ti-50.8Ni-0.5V形状记忆合金的SME→SE转变温度可用tMr+16 ℃近似估算。

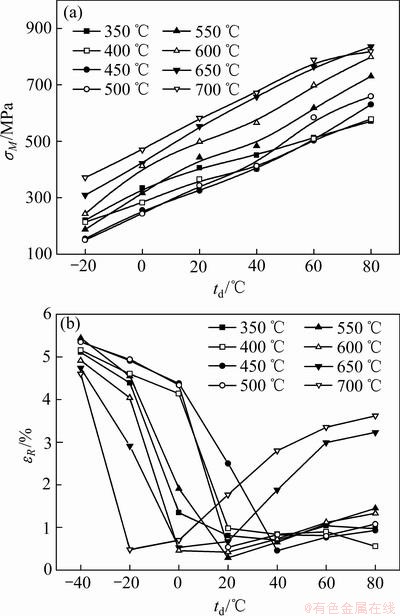

td对350~700 ℃退火态Ti-50.8Ni-0.5V合金σM、εR的影响如图9所示。由图9可以看出,随td升高,不同退火态合金的σM线性增加(见图9(a)),原因是随td增加,强度较高的母相的体积分数比强度较低的M的体积分数增加的快,使合金的σM线性增加。350~600 ℃退火态合金的εR先减小后趋于稳定,而650 ℃和700 ℃退火态合金的εR先减小后增大(见图9(b))。

2.5.3 应力-应变循环对形状记忆行为的影响

图7 不同形变温度时Ti-50.8Ni-0.5V合金加载/卸载应力-应变曲线

Fig. 7 Loading/unloading stress-strain curves of Ti-50.8Ni-0.5V alloy at different deforming temperatures

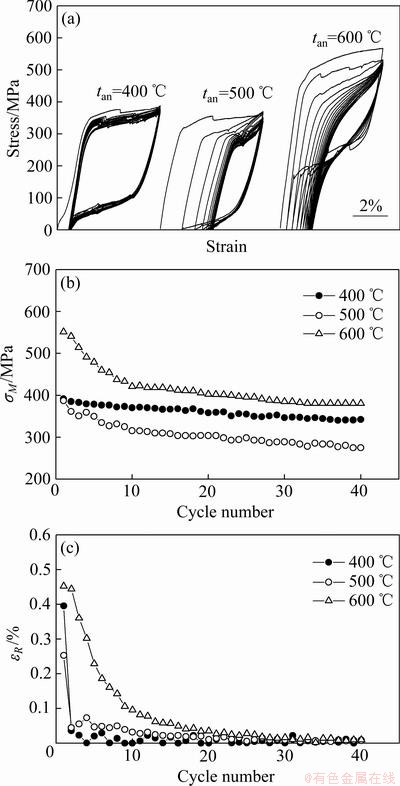

应力-应变循环对400、500和600 ℃退火态Ti-50.8Ni-0.5V合金超弹性曲线和σM、εR的影响如图10所示。由图10(a)可以看出,400~600 ℃退火态Ti-50.8Ni-0.5V合金室温下呈SE,tan和应力-应变循环次数(N)对合金的SE有显著影响。1) 400 ℃退火态合金的循环稳定性较好,经过一次循环即可呈现完全非线性SE,随N增加,应力-应变回滞曲线形态比较稳定,σM略有降低,εR较小(约0.82%),SE稳定性良好。2) 500 ℃退火态合金的循环稳定性较差,随N增加,应力-应变回滞曲线形态变化较大,由部分非线性SE转变为近似平行四边形SE;σM先减小后趋于稳定,εR较大(约3.1%);应力诱发M相变平台长度减小。3) 600 ℃退火态合金的σM高于400和500 ℃退火态合金。随N增加,合金的循环稳定性亦较差,应力-应变曲线形状变化显著,由非线性SE转变为近似线性SE。

图8 Ti-50.8Ni-0.5V合金SME→SE转变温度与DSC曲线上马氏体逆转变峰温度tMr的比较

Fig. 8 Comparison of SME→SE transformation temperature and reverse martensitic transformation temperature tMr in DSC curve of Ti-50.8Ni-0.5V alloy

图9 形变温度对350~700 ℃退火态Ti-50.8Ni-0.5V合金σM和εR的影响

Fig. 9 Effect of deforming temperature on σM (a) and εR (b) of Ti-50.8Ni-0.5V alloy annealed at 350-700 ℃

应力-应变循环对该合金σM和εR的影响如图10(b)和(c)所示。由图10(b)知,随N增加,400、500和600 ℃退火态合金的σM均呈下降趋势,且σM600>σM400>σM500。其中,600 ℃退火态合金的σM下降最快,由第1次循环时的551 MPa下降到第40次时的380 MPa,下降幅度为171 MPa;500 ℃退火态合金的σM下降幅度低于600 ℃退火态合金的,其数值由第1次循环时的387 MPa下降到第40次时的275 MPa,下降幅度为112 MPa;而400 ℃退火态合金的σM则变化不大,由第1次循环时的391 MPa下降到第40次时的342 MPa,下降幅度仅为49 MPa,说明400 ℃退火态合金的应力-应变循环稳定性好。由图10(c)可以看出,随N增加,400、500和600 ℃退火态合金的εR均先快速减小后趋于稳定,表明SMA使用前进行一定次数预循环可稳定形状记忆性能。此外,由图10(c)还可以看出,400 ℃退火态合金εR趋于稳定的速率最快,600 ℃退火态合金的最慢。

图10 应力-应变循环对400、500和600 ℃退火态Ti-50.8Ni-0.5V合金超弹性曲线、σM和εR的影响

Fig. 10 Effect of stress-strain cycle on superelasticity curves (a), σM (b) and εR (c) of Ti-50.8Ni-0.5V alloy annealed at 400, 500 and 600 ℃

3 分析与讨论

3.1 退火温度对相变行为的影响

退火温度tan显著影响冷拉态Ti-50.8Ni-0.5V合金的相变类型。随tan升高,合金的马氏体相变温度tM升高,R相变温度tR降低。该现象与合金冷却转变产物引起的应力场与合金中残留的冷变形结构缺陷的相互作用有关[22]。B2→R属母相→M型相变,为对称性较高的CsCl型有序结构向对称性较低的菱方结构的转变过程;R→B19′属M→M型相变,为对称性较低的菱方结构向对称性更低的单斜结构的转变过程,故M相变引起的应力场高于R相变,前者约为后者的10倍[23]。当退火温度较低时,冷拉合金丝中残留的位错密度较高,残余应力较大,残留织构较多,这些结构缺陷与M相变应力场相互作用后会阻碍马氏体相变进行,使M相变推迟,故tM较低;而冷变形缺陷对R相变的阻碍作用较小,故tR较高。随tan升高,合金丝中冷变形组织逐渐回复,形变内应力释放,位错密度降低,对M相变阻抑作用减弱,故tM升高;R相变温度降低与R相形核阻力增大有关,随tan升高,合金中残留位错密度降低,组织均匀,R相有效形核位置减少,故tR降低。当温度达到600 ℃时,R和M相变峰部分重合,形成了一个温度范围宽、形状不规则的大相变峰。随tan进一步升高,冷变形缺陷消除,组织均匀性提高,合金的相变温度和相变峰的形状稳定。

3.2 退火温度对拉伸性能和形状记忆行为的影响

tan对Ti-50.8Ni-0.5V合金的拉伸性能和形状记忆行为影响较大。当tan低于合金的再结晶温度时,合金在冷拉拔过程中引入的位错、形变织构及各种应力场得以保留,这些结构缺陷可以对合金基体起到强化作用,从而使低温退火态Ti-50.8Ni-0.5V合金具有较高的抗拉强度和较低的伸长率。随tan升高,合金中的冷形变组织结构及内应力逐渐消除,位错密度降低,对合金的强化作用减小,因而高温退火态合金的抗拉强度降低,塑性提高。

应力诱发M临界应力σM取决于合金的M相变开始温度Ms和晶粒取向,随Ms升高σM降低,母相晶粒取向越有利,σM越低[24]。当tan低于合金的再结晶温度时,合金的显微组织保持纤维状,晶粒取向对σM的影响较小,此时σM降低主要由合金的Ms随tan升高而升高引起。随tan升高,合金中的纤维状组织逐渐被等轴晶粒取代,有利于应力诱发M取向的晶粒减少,σM升高,故随tan升高,σM先降低后升高,600~700 ℃退火态合金的σM高于350~500 ℃退火态合金的。εR取决于母相的屈服强度,如果母相的屈服强度低,则在应力诱发M相变前母相会发生塑性变形,卸载后,形变不能完全恢复,会产生较大的εR。合金在650 ℃以上温度退火后,晶粒迅速长大,屈服强度降低,应力诱发M相变前合金中产生了不可恢复的塑性变形和永久残留应变,故εR增加。

3.3 形变温度对形状记忆行为的影响

形变温度td对Ti-50.8Ni-0.5V合金的形变特性有显著影响。当td低于合金的M逆相变开始温度tAs时,合金表现为以马氏体为其存在条件的SME行为;当td高于tAs时,合金表现为以母相为其存在条件的SE行为[25]。随td升高,不同温度退火态合金的应力-应变曲线均呈现出由SME到SE的转变。由图2和图7~9知,由于tan显著影响合金的相变温度,故不同温度退火态合金由SME到SE的转变温度不同,可用马氏体逆相变峰温度tMr+16 ℃近似估算。随td升高,合金的σM呈线性增加,这是由于随td升高,合金发生了由M到母相的转变,对Ti-Ni基SMA来说母相的强度高于M相,随td升高,合金中母相份额逐渐增加,故随td升高,Ti-50.8Ni-0.5V SMA的σM线性增加。

3.4 应力-应变循环对形状记忆行为的影响

400 ℃退火态Ti-50.8Ni-0.5V合金经过一次循环后即可呈现良好的SE,且在多次循环后合金的应力-应变曲线形态变化不大,这是由于在该温度退火时,退火温度较低,合金的显微组织呈纤维状,组织中仍残留有大量因冷拉拔而引入的形变织构和内应力,这些结构缺陷钉扎位错,使之不易滑移[19],故只需一次加载/卸载循环即可获得形态稳定的应力-应变回滞曲线和超弹性。随循环次数增加,500 ℃退火态合金的σM降低。这是由于此时合金的退火温度较高,显微组织中纤维连续性变差,纤维密度降低,形变织构减少,形变应力消除,组织结构缺陷对位错的钉扎作用减弱,故σM降低。随循环次数增加,600 ℃退火态合金的滞后面积较快衰减,应力-应变平台斜率增大。这是由于600 ℃退火后,合金处于再结晶状态,位错密度显著降低,在开始几次循环过程中,母相界面的可动性较高;随应力-应变循环次数增加,母相界面的可动性变差,通过母相界面运动产生的耗能逐渐消失[15],超弹性滞回面积减小并渐趋于稳定。

4 结论

1) 400~700 ℃退火态Ti-50.8Ni-0.5V合金室温组成相为母相B2和马氏体B19′。350~400 ℃退火态Ti-50.8Ni-0.5V合金冷却/加热时发生B2→R/R→ B2一阶段可逆相变;450~500 ℃退火态合金发生B2→R→B19′/B19′→R→B2二阶段可逆相变;550 ℃退火态合金发生B2→R→B19′/B19′→B2型相变;600 ℃以上温度退火态合金发生B2→B19′/B19′→ B2一阶段可逆相变。350~800 ℃退火后,随tan升高,合金的tR、tRr先升高后降低,400 ℃退火态合金的tR、tRr分别达到极大值28.1 ℃、31.7 ℃;tM、tMr亦先升高后降低,极大值为-58.5 ℃、8.7 ℃在500 ℃退火态合金中取得。

2) 当tan低于550 ℃时,冷变形态Ti-50.8Ni- 0.5V合金的显微组织呈纤维状;当tan高于600 ℃时,显微组织呈等轴晶粒;合金的再结晶温度在550~600 ℃之间。

3) 350~550 ℃退火态Ti-50.8Ni-0.5V合金的抗拉强度高于600~700 ℃退火态合金的,塑性则低于后者。室温下,Ti-50.8Ni-0.5V合金呈超弹性。随着tan升高,合金的σM先降低后升高,极小值(325 MPa)和极大值(582 MPa)分别在450 ℃和700 ℃退火态合金中取得;εR先升高后降低再升高,450 ℃和700 ℃退火态合金中取得极大值(2.55%和1.84%),500~650 ℃退火态合金中取得极小值(0.65%)。

4) 随形变温度升高,不同温度退火态Ti-50.8Ni-0.5V合金均发生由SME向SE转变,SME→SE转变温度可用DSC加热曲线上马氏体逆相变峰温度tMr+16 ℃近似估算。

5) 400 ℃退火态Ti-50.8Ni-0.5V合金的应力-应变循环特性和σM稳定,超弹性特性良好,经一次循环后合金即可呈现完全非线性超弹性;500和600 ℃退火态合金的循环稳定性较差,随循环次数的增加,合金的σM先降低后趋于稳定。

REFERENCES

[1] SHARIAT B S, MENG Qing-lin, MAHMUD A S, et al. Functionally graded shape memory alloys: Design, fabrication and experimental evaluation[J]. Materials and Design, 2017, 124: 225-237.

[2] YI Xiao-yang, SUN Kui-shan, GAO Wei-hong, et al. The precipitation behaviors, martensite transformation and superelasticity in the aged Ni-rich Ti-Ni alloy with the assist of super-high stress[J]. Intermetallics, 2019, 104: 8-15.

[3] MANCHURAJU S, KROEGER A, SOMSEN C, et al. Pseudoelastic deformation and size effects during in situ transmission electron microscopy tensile testing of NiTi[J]. Acta Mater, 2012, 60: 2770-2777.

[4] JANI J M, LEARY M, SUBIC A, et al. A review of shape memory alloy research, applications and opportunities[J]. Materials & Design, 2014, 56: 1078-1113.

[5] HORNBOGEN E, MERTINGER V, WURZEL D. Microstructure and tensile properties of two binary NiTi alloys[J]. Scripta Mater, 2001, 44: 171-178.

[6] DONG Y S, XIONG J L, LI A Q, et al. A passive damping device with TiNi shape memory alloy rings and its properties[J]. Mater Sci Eng A, 2006, 416: 92-97.

[7] ZHANG S, LIANG S X, YIN Y X, et al. Martensitic transition and shape memory effect of Ti-Zr-Mo series alloys[J]. Intermetallics, 2017, 88: 55-60.

[8] 贺志荣, 王 启, 邵大伟. 时效对Ti-50.8Ni-0.3Cr形状记忆合金组织和超弹性的影响[J]. 金属学报, 2012, 48: 56-62.

HE Zhi-rong, WANG Qi, SHAO Da-wei. Effect of aging on microstructure and superelasticity in Ti-50.8Ni-0.3Cr shape memory alloy[J]. Acta Metall Sin, 2012, 48: 56-62.

[9] 贺志荣, 蔡继峰, 杨 军, 等. Co对Ti-Ni形状记忆合金相变和形变特性的影响[J]. 稀有金属材料与工程, 2010, 39 (4): 633-637.

HE Zhi-rong, CAI Ji-feng, YANG Jun, et al. Effect of Co on transition and deformation characteristics of Ti-Ni shape memory alloy[J]. Rare Met Mater Eng, 2010, 39(4): 633.

[10] 黄兵民, 蔡 伟, 赵 蔚, 等. 热处理和冷变形对Ti-Ni合金非线性超弹性的影响[J]. 宇航材料工艺, 1997(5): 24-28.

HUANG Bing-min, CAI Wei, ZHAO Wei, et al. The effect of heat-treatment and cold deformation on non-linear superelasticity of Ti-Ni alloy[J]. Aerospace Materials & Technology, 1997(5): 24-28.

[11] 司乃潮, 赵培根, 司松海, 等. 预变形对TiNiCr形状记忆合金超弹性及显微组织的影响[J]. 中国有色金属学报, 2009, 19(4): 695-700.

SI Nai-chao, ZHAO Pei-gen, SI Song-hai, et al. Effect of pre-deformation on superelasticity and microstructure of TiNiCr shape memory alloy[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(4): 695-700.

[12] 王 启, 贺志荣, 王永善, 等. 退火温度和应力-应变循环对TI-Ni-Cr形状记忆合金超弹性的影响[J]. 金属学报, 2010, 46(7): 800-804.

WANG Qi, HE Zhi-rong, WANG Yong-shan, et al. Effect of annealing temperature and stress-strain cycle on superelasticity of Ti-Ni-Cr shape memory alloy[J]. Acta Metall Sin, 2010, 46(7): 800-804.

[13] COLUZZI B, BISCARINI A, CAMPANELLA R, et al. Effect of thermal cycling through the martensitic transition on the internal friction and Young’s modulus of a Ni50.8Ti49.2alloy[J]. J Alloys Compd, 2000, 310: 300-305.

[14] HOSODA H, WAKASHIMA K, MIYAZAKI S, et al. Factors for controlling martensitic transformation temperature of TiNi shape memory alloy by addition of ternary elements[J]. Mater Res Soc Symp Proc, 2005, 842: 353-358.

[15] SOGA Y, DOI H, YONEYAMA T. Tensile properties and transformation temperatures of Pd added Ti-Ni alloy dental castings[J]. Mater in Medicine, 2000, 11(11): 695-700.

[16] KAYA I, TOBE H, KARACA H E, et al. Effects of aging on the shape memory and superelasticity behavior of ultrahigh strength Ni54Ti46 alloys under compression[J]. Mater Sci Eng A, 2016, 678: 93-100.

[17] CHROBAK D, STROZ D. Two-stage R phase transformation in a cold-rolled and annealed Ti-50.6at%Ni alloy[J]. Scripta Mater, 2005, 52(8): 575-760.

[18] SABURI T, TATSUMI T, NENNO S. Effect of heat treatment on mechanical behavior of TiNi alloy[J]. J Phys Colloques, 1982, 43: 04-261-04-266.

[19] ADHARAPURAPU R R, VECCHIO K S. Superelasticity in a new Bioimplant material: Ni-rich 55NiTi alloy[J]. Experimental Mechanics, 2007, 47(3): 365-371.

[20] 贺志荣, 王 芳, 王永善, 等. V和Cr对Ti-Ni超弹性合金相变和形变特性的影响[J]. 金属学报, 2007, 43(12): 1293-1296.

HE Zhi-rong, WANG Fang, WANG Yong-shan, et al. Effects of V and Cr on transformation and deformation characteristics of Ti-Ni superelastic alloy[J]. Acta Metall Sin, 2007, 43(12): 1293-1296.

[21] 贺志荣, 刘曼倩, 王 芳, 等. 时效工艺对Ti-Ni-V形状记忆合金显微组织和超弹性的影响[J]. 中国有色金属学报, 2013, 23(5): 1301-1306.

HE Zhi-rong, LIU Man-qian, WANG Fang, et al. Effect of aging process on microstructure and superelasticity of TiNiV shape memory alloy[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(5): 1301-1306.

[22] VAIDYNATHAN R, BOURKE M A M, et al. Texture, strain, and phase-fraction measurements during mechanical cycling in superelastic NiTi[J]. Metall Mater Trans A, 2001, 32A: 777-786.

[23] MIYAZAKI S, OTSUKA K. Deformation and transition behavior associated with the R-phase in Ti-Ni alloys[J]. Metall Trans, 1986, 17A: 53-59.

[24] CHANG B C, SHAW J A, IADICOLA M A. Thermodynamics of shape memory alloy wire: Modeling, experiments, and application[J]. Continuum Mech Thermodyn, 2006; 18(1/2): 83-118.

[25] 贺志荣, 张永宏, 王永善, 等. Ti49.4Ni50.6超弹性弹簧的相变和形变特性[J]. 金属学报, 2004, 40(1): 46-50.

HE Zhi-rong, ZHANG Yong-hong, WANG Yong-shan, et al. Transformation and deformation characteristics of Ti49.4Ni50.6 superelastic spring[J]. Acta Metall Sin, 2004, 40(1): 46-50.

Phase transformation, microstructure and properties of Ti-50.8Ni-0.5V shape memory alloy

HE Zhi-rong1, WANG Fang2, YE Jun-jie1, ZHANG Kun-gang1, DU Yu-qing1

(1. School of Materials Science and Engineering, Shaanxi University of Technology, Hanzhong 723001, China;

2. Library, Shaanxi University of Technology, Hanzhong 723003, China)

Abstract: The phase transformation behaviors, microstructure characteristics and mechanical properties of Ti-50.8Ni-0.5V (mole fraction, %) shape memory alloy were studied by XRD, differential scanning calorimetry (DSC), optical microscope and tensile test. The results show that the constituent phases at room temperature of Ti-50.8Ni-0.5V alloys annealed at 400-700 ℃ are parent phase B2 and martensite B19′. With the increase of the annealing temperature, the phase transformation type of the alloy changes from B2→R/R→B2 to B2→R→B19′/B19′→R→B2 to B2→R→ B19′/B19′→B2 to B2→B19′/B19′→B2 upon cooling/heating. The R, martensitic transformation temperatures of the alloy increase first and then decrease, and the maximum 28.1 ℃, -58.5 ℃ are obtained in the alloys annealed at 400 ℃ and 500 ℃, respectively. The microstructure of the alloy changes from fibrous to equiaxed, and the recrystallization temperature of the is among 550-600 ℃. The strength of extension decreases and the plasticity increases in the alloy. The critical stress for inducing martensitic transformation (σM) of the alloy decreases first and then increases, and the minimum 325 MPa of σM is obtained in the alloy annealed at 450 ℃. The residual strain increases first and then decreases and then increases, the maximum 2.55% and 1.84% are obtained in the alloys annealed at 450 ℃ and 700 ℃, respectively, and the minimum 0.65% is acquired in the alloys annealed at 500-650 ℃. With the increase of the deforming temperature, a transformation of shape memory effect (SME)→ superelasticity (SE) occurs in annealed Ti-50.8Ni-0.5V alloy, and the SME→SE transformation temperature can be approximately estimated by tMr+16 ℃ (tMr is the peak temperature of the martensitic reverse transformation in DSC curve). With the increase of the cyclic number, the σM of the alloy annealed at 400℃ is stable, and the σM of the alloys annealed at 500 and 600 ℃ decreases first and then tend to be stable.

Key words: Ti-Ni-V alloy; shape memory alloy; phase transformation; shape memory effect; superelasticity

Foundation item: Project(2016YFE0111400) supported by the National Key Research and Development Program of China

Received date: 2020-03-02; Accepted date: 2020-07-12

Corresponding author: HE Zhi-rong; Tel: +86-13892611307; E-mail: hezhirong01@163.com

(编辑 李艳红)

基金项目:国家重点研发计划资助项目(2016YFE0111400)

收稿日期:2020-03-02;修订日期:2020-07-12

通信作者:贺志荣,教授,博士;电话:13892611307;E-mail:hezhirong01@163.com