自由锻Ti-Ni形状记忆合金的显微组织和超弹性

来源期刊:中国有色金属学报(英文版)2018年第3期

论文作者:Abdollah BAHADOR Esah HAMZAH Katsuyoshi KONDOH Tuty ASMA ABUBAKAR Farazila YUSOF Junko UMEDA Safaa N. SAUD Mustafa K. IBRAHIM

文章页码:502 - 514

关键词:形状记忆合金;超弹性;放电等离子烧结;自由锻

Key words:shape-memory alloy; superelasticity; spark-plasma sintering; free forging

摘 要:采用放电等离子烧结(SPS)法将元素钛粉和镍粉制备成Ti-51%Ni 形状记忆合金(SMAs)。研究目的是采用自由锻二次加工以提高SPS合金的性能。对自由锻前后合金的显微组织、相变温度和超弹性进行比较。结果表明,自由锻可以显著提高Ti-Ni 形状记忆合金的拉伸强度和形状记忆性能,自由锻后合金的韧性从6.8% 提高到了9.2%,超弹性的应变范围从5%增加到7.5%,应变恢复速率从72%提高到92%。Ti-51%Ni合金显微组织中含有立方奥氏体相(B2)基体、单斜马氏体相 (B19′)、第二相(Ti3Ni4,Ti2Ni 和TiNi3) 和氧化物相(Ti4Ni2O,Ti3O5)。自由锻后再经500 °C时效处理的最终样品的马氏体相变温度向高温方向偏移,这是由于Ti3Ni4相(透射电镜下可以观察到)的析出而导致基体中Ni含量的减少。总之,自由锻可以提高Ti-51%Ni形状记忆合金的超弹性和力学性能。

Abstract: Elemental titanium (Ti) and nickel (Ni) powders were consolidated by spark plasma sintering (SPS) to fabricate Ti-51%Ni (mole fraction) shape-memory alloys (SMAs). The objective of this study is to enhance the superelasticity of SPS produced Ti-Ni alloy using free forging as a secondary process. Products from two processes (with and without free forging) were compared in terms of microstructure, transformation temperature and superelasticity. The results showed that, free forging effectively improved the tensile and shape-memory properties. Ductility increased from 6.8% to 9.2% after forging. The maximum strain during superelasticity increased from 5% to 7.5% and the strain recovery rate increased from 72% to 92%. The microstructure of produced Ti-51%Ni SMA consists of the cubic austenite (B2) matrix, monoclinic martensite (B19′), secondary phases (Ti3Ni4, Ti2Ni and TiNi3) and oxides (Ti4Ni2O and Ti3O5). There was a shift towards higher temperatures in the martensitic transformation of free forged specimen (aged at 500 °C) due to the decrease in Ni content of B2 matrix. This is related to the presence of Ti3Ni4 precipitates, which were observed using transmission electron microscope (TEM). In conclusion, free forging could improve superelasticity and mechanical properties of Ti-51%Ni SMA.

Trans. Nonferrous Met. Soc. China 28(2018) 502-514

Abdollah BAHADOR1, Esah HAMZAH1, Katsuyoshi KONDOH2, Tuty ASMA ABUBAKAR1, Farazila YUSOF3, Junko UMEDA2, Safaa N. SAUD4, Mustafa K. IBRAHIM1

1. Faculty of Mechanical Engineering, Universiti Teknologi Malaysia, 81310 UTM Johor Bahru, Johor, Malaysia;

2. JWRI, Osaka University, 11-1 Mihogaoka, Ibaraki, 567-0047 Osaka, Japan;

3. Department of Mechanical Engineering, Faculty of Engineering, University of Malaya, 50603 Kuala Lumpur, Malaysia;

4. Faculty of Information Science and Engineering, Management and Science University, 40100 Shah Alam, Malaysia

Received 14 February 2017; accepted 14 May 2017

Abstract: Elemental titanium (Ti) and nickel (Ni) powders were consolidated by spark plasma sintering (SPS) to fabricate Ti-51%Ni (mole fraction) shape-memory alloys (SMAs). The objective of this study is to enhance the superelasticity of SPS produced Ti-Ni alloy using free forging as a secondary process. Products from two processes (with and without free forging) were compared in terms of microstructure, transformation temperature and superelasticity. The results showed that, free forging effectively improved the tensile and shape-memory properties. Ductility increased from 6.8% to 9.2% after forging. The maximum strain during superelasticity increased from 5% to 7.5% and the strain recovery rate increased from 72% to 92%. The microstructure of produced Ti-51%Ni SMA consists of the cubic austenite (B2) matrix, monoclinic martensite (B19′), secondary phases (Ti3Ni4, Ti2Ni and TiNi3) and oxides (Ti4Ni2O and Ti3O5). There was a shift towards higher temperatures in the martensitic transformation of free forged specimen (aged at 500 °C) due to the decrease in Ni content of B2 matrix. This is related to the presence of Ti3Ni4 precipitates, which were observed using transmission electron microscope (TEM). In conclusion, free forging could improve superelasticity and mechanical properties of Ti-51%Ni SMA.

Key words: shape-memory alloy; superelasticity; spark-plasma sintering; free forging

1 Introduction

Shape-memory alloys (SMAs) exhibit two structures of austenite and martensite depending on temperature and applied load. The unique properties of shape-memory effect and superelasticity correspond to reversible transformation between these two phases. The critical temperatures at which each phase begins and finishes rely on the composition of the alloy, thermomechanical history and applied load [1,2].

Among SMAs, Ni-Ti SMA is the most widely used due to excellent shape-memory properties. Moreover, high strength and ductility along with high corrosion resistance and good biocompatibility make it promising for many applications in the automotive, aircraft and biomedical industries as well as micro electromechanical systems and micro actuations [3-5]. However, cytotoxicity concern about the Ni in these alloys has presented a challenge for biomedical applications [6].

The binary system of Ti-Ni SMAs usually shows intermetallic phases such as Ti3Ni4, Ti2Ni and TiNi3. Among them, Ti3Ni4 precipitates are known to enhance shape memory properties depending on their size, morphology and distributions [7]. SHAHMIR and NAGHDI [8] reported that Ti3Ni4 precipitates and the dislocation network, which are introduced by aging and thermomechanical treatment, improve the superelastic properties of Ti-Ni SMAs.

Spark plasma sintering (SPS) is a novel sintering technique in which pressure and pulsed continuous current are applied simultaneously to consolidate powders [9]. It is believed that the role of the pulsed current is to generate plasma and the Joule heating effect, which can promote bonding and consolidating of the powders during sintering. Therefore, SPS has the advantage of the rapid fabrication of materials that are difficult to produce by other conventional sintering processes [10,11]. However, there is no general agreement regarding the presence of plasma sparks and the mechanism of sintering during powder consolidation by the SPS process. Nevertheless, the effect of Joule heating on initiating localized heating in the powders’ contact regions and causing solid state diffusion is widely accepted by researchers [12]. In 2009, ANDERSSON and HULBERT [13] challenged the generation of spark plasma with an experimental demonstration during the sintering process. In 2014, ZHANG et al [14] reported the occurrence of high- temperature spark plasma. They suggested that the spark plasma can be generated in gaps due to the electrical discharge effect between powder particles at the beginning of on-off DC pulse energizing. In addition, for effective sintering in a short period, a combination of the following is necessary: spark discharge, Joule heating, electrical diffusion and plastic deformation [14].

SPS has been used in the powder metallurgy of many metal powders, including the fabrication of Ti-Ni based SMAs [15-17], but there is limited research [18] on the effect of secondary processes on the shape- memory properties of Ti-Ni SMAs. Therefore, in this study, secondary process known as free forging (open die forging) was used to deform spark plasma sintered Ti-51%Ni SMA and the result was compared with specimen processed without free forging (unforged specimen) in terms of microstructure and superelasticity.

2 Experimental

2.1 Materials preparation

Commercially pure powders of Ti (<45 μm, CP-450, 99.5% purity, supplied by Toho Tec.) and Ni (<5 μm, T123, 99.8% purity, supplied by Vale, Japan) were mixed by cylindrical table mixer for 6 h using zirconia balls. A 1:5 mass ratio for ball to powder was selected. To consolidate the mixed powders, spark plasma sintering (SPS-1030S, SPS Syntex) system was used. The sintering was performed at 1000 °C for 60 min, with pressure of 30 MPa under a vacuum of 5 Pa. The sintered specimen was homogenized at 1000 °C for 12 h. The process included two methods: with and without using free forging. The free forging process was carried out by preheating the billet samples to 1100 °C for 5 min under an argon atmosphere, followed by immediate forging using 300 MPa pressure from a hydraulic pressing machine (SHP-200-450, Shibayama). A height reduction of 50% was obtained after free forging. The specimen before and after deformation is shown in Fig. 1. Both forged and unforged specimens were solution treated at 1000 °C for 1 h and then quenched with water. Finally, specimens underwent aging at 500 °C for 1 h and followed by water quenching to introduce the desired lenticular Ti3Ni4 precipitates in order to improve shape-memory properties [19].

Fig. 1 Ti-51%Ni specimen before (a) and after (b) free forging

2.2 Materials characterization

Specimens were cut and then ground using abrasive papers, followed by polishing using a suspension with 0.5 μm alumina particles to obtain mirror-polished surfaces.

The polished samples were etched in H2O+HNO3+ HF 100:5:1 (volume fraction) solution [20]. A field emission scanning electron microscope (JEM-6500F, JEOL), an energy dispersive spectrometer (EDS) and an X-ray diffractometer (XRD-6100, Shimadzu) were used for microstructure and phase composition identification and analysis. Transmission electron microscopy (JEM-2010, JEOL) was used to detect Ti3Ni4 precipitates. An electron backscatter diffractometer (EBSD, TSL Digi View IV; EDAX) with a scanning step size of 0.2 μm was used to obtain elemental mapping and texture investigations. Differential scanning calorimetry (DSC-60, Shimadzu, Japan) was performed to determine the phase transformation temperatures at a controlled heating and cooling rate of 10 °C/min.

2.3 Tensile and superelasticity tests

A universal testing machine (Autograph AG-X 50 kN, Shimadzu) was used to perform tensile and superelasticity tests. The strain rate was set at 1.67×10-4 s-1, and the test was conducted at room temperature. Figure 2 presents the dimensions of test specimens with 1 mm in thickness. In this experiment, to record the applied load and gauge length extension and recovery, the tensile machine was connected to the CCD camera. Microhardness tests were conducted in each step of fabrication for both processing methods using a Shimadzu microhardness tester. The test force and dwell time were 1.961 N and 15 s, respectively.

Fig. 2 Tensile and superelasticity test sample design (unit: mm)

3 Results and discussion

3.1 Microstructural observations

Figure 3 presents the morphologies of received Ti and Ni powders. The initial Ti (Fig. 3(a)) is irregularly shaped whereas carbonyl gas refinery-produced Ni (Fig. 3(b)) powders are spiky, spherical particles [21].

Fig. 3 Morphologies of Ti (a) and Ni (b) as-received powders

The needle-like dendrites on the surface of the Ni particles help for mixing and bonding with other large-size Ti powders. The particle size of Ti varied from 7 to 46 μm with a mean particle size of about 18 μm. The particle size of Ni varied from 2 to 8.5 μm with a mean particle size of about 4 μm. Figure 4 shows EDS mapping of the mixed particles to reveal their distribution pattern. The figure indicates that mixing time is suitable to obtain a homogeneous distribution of the mixed powders. The distribution of the particles plays an important role in improving the diffusion during sintering. Therefore, homogeneous distribution of the mixed powders directly affects the metallurgical structure and desired properties of sintered alloy [22,23].

Fig. 4 EDS mapping of elemental distribution of mixed powders

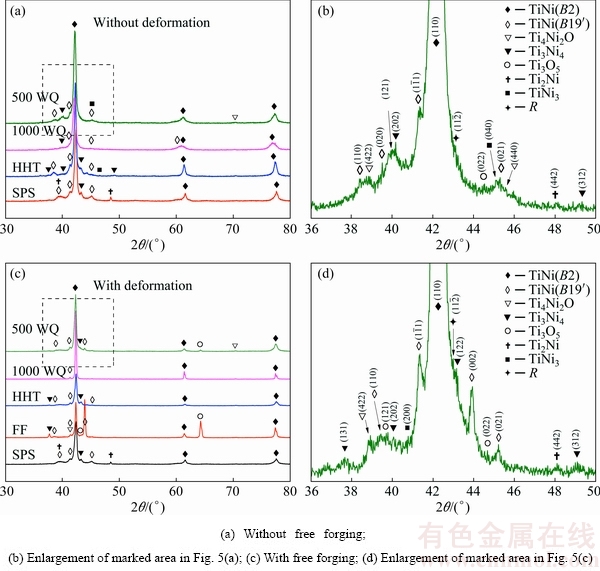

The XRD patterns of Ti-51%Ni specimens produced with and without forging are illustrated in Fig. 5. It can be seen that the sintered specimens contain austenite (B2), martensite (monoclinic B19′) and secondary phases (Ti2Ni and Ti3Ni4). Martensite B19′ is an important phase in Ti-Ni SMAs because shape recovery and superelasticity are related to a reversible B19′→B2 transformation in this alloy [24]. The diffraction patterns of B19′ martensite are (101), (110), (020),  , (002) and (021).

, (002) and (021).

Fig. 5 XRD patterns of specimens (HHT: Homogenization heat treatment; FF: Free forging)

Chemical composition and thermomechanical processing history affect the formation of secondary phases such as Ti3Ni4, Ti2Ni and TiNi3 in the alloy [25,26]. Gibbs free energy studies indicate that the formation of Ti2Ni and TiNi3 is unavoidable due to the higher driving force during formation compared to austenite Ti-Ni [27]. The formation secondary phase depends on chemical composition, processing method and thermomechanical conditions. It has been reported that Ti2Ni was formed during casting and forging of Ti-rich [28], equatomic SMAs [29] and Ni-rich Ti-Ni SMAs [30].

BHAGYARAJ et al [25] showed that during deformation of Ti-Ni alloy, Ti2Ni precipitate has a significant effect on the grain refinement and severe plastic deformation of the matrix in the vicinity, resulting in localized amorphization and structure recovery. Ti-rich Ti2Ni formation results in Ni enrichment of the matrix. Increasing the Ni content in the Ni-rich matrix can easily induce the formation of Ni-rich secondary phases of Ti3Ni4 and TiNi3 [31,32]. The corresponding peaks of Ti3Ni4 are (131), (202), (122) and (312), whereas (200) and (004) are related to TiNi3. Many researchers [33,34] have reported that the Ti3Ni4 phase has a significant effect on R phase transformation. Moreover, depending on size and density, the strength and shape-memory characteristics of Ti3Ni4 were improved due to a pinning effect on the inhibition of the dislocation movement [35]. It is known that Ti3Ni4 is stable below 600 °C and thus aging temperature and time play a critical role in obtaining fine precipitates. OTSUKA and REN [26] and RADEV [36] reported that Ti3Ni4 is an intermediate phase and can decompose to TiNi3 based on the diffusional transformation, which depends on aging time and temperature: Ti3Ni4→Ti2Ni3→TiNi3.

The XRD pattern of the forged sample shows considerable differences compared to other fabrication steps. There is a significant increase in the B19′ peak pattern on (002), which indicates the presence of stress-induced martensite. The  peak indicates the presence of Ti3O5. It is apparent that this peak was eliminated in the subsequent steps of the process because only a low-intensity peak can be seen in the final product. MIZUNO et al [37] reported that Ti3O5 was stable below 400 °C and, when the temperature was increased, it decomposed and defused into a bulk Ti matrix. In addition, the intensity of the peak related to Ti3Ni4 emitted from the (131) plane at 2θ of 37.74° increased after forging.

peak indicates the presence of Ti3O5. It is apparent that this peak was eliminated in the subsequent steps of the process because only a low-intensity peak can be seen in the final product. MIZUNO et al [37] reported that Ti3O5 was stable below 400 °C and, when the temperature was increased, it decomposed and defused into a bulk Ti matrix. In addition, the intensity of the peak related to Ti3Ni4 emitted from the (131) plane at 2θ of 37.74° increased after forging.

The austenite (B2) and martensite (B19′) phases were observed as main phases of the solution treatment in both processes, with and without deformation. After the homogenization step, Ti2Ni was absent (the peak of (442) at 2θ of 48.39°) in both processes. However, the unforged sample exhibits a TiNi3 secondary phase emitted from the (202) plane at 2θ of 46.59°.

Forged and unforged samples after aging at 500 °C show that the dominant phase is cubic B2 (austenite) for both products. The corresponding peaks of the B2 phase are (110), (200) and (211). In addition, the peaks exhibit other compounds and phases such as monoclinic B19′ (martensite), secondary phases (Ti3Ni4, Ti2Ni and TiNi3) and oxides (Ti4Ni2O and Ti3O5). The Ti oxides (Ti3O5) form after aging of the deformed specimen. The presence of Ti3O5 results in a decrease of Ti content in the matrix. In other words, the Ti-Ni matrix becomes rich in Ni, which affects the transformation temperature. Moreover, secondary-phase precipitates in the final products after deformation process may be broken off into smaller particles and distributed homogenously throughout the matrix [25].

In this study, the relative density of the SPS specimen was about 98.5%. This was calculated based on Archimedes’ principle. Figure 6 shows EDS mapping of the specimens after SPS, which clearly shows a homogenous distribution of the Ti and Ni elements after consolidation of the powders.

Figure 7 shows a comparison of the inverse pole figures (IPFs) and {001} pole figures of SPS, free forged (FF) and final products (aged at 500 °C) for each process, obtained with the EBSD technique. The mapping reveals the random texture and equiaxed grains formed in both processes. Moreover, the grains have an irregular shape and bulge at the grain boundary, which results in dynamic recrystallization. In general, strain- induced grain-boundary migration causes grain-boundary bulging. Different levels of stored energies in adjacent grains result in boundary movement. This movement of boundaries is the mechanism of strain-induced grain-boundary migration [38].

Fig. 6 EDS mapping of element distribution of Ti-51%Ni alloy after SPS process

As illustrated in Fig. 7, there is an increase in texture from 2.418 to 3.596 times random after forging in the {001} pole figure between the SPS and free forged samples. The forged specimen after aging showed no significant change in texture (changing from 3.596 to 3.751), but there was an increase in peak intensity from 2.418 to 4.681 for the unforged sample aged at 500 °C.

Figure 8 presents grain size and misorientation distribution for forged and unforged specimens after aging at 500 °C. The grain boundary is defined by a misorientaion angle higher than 4° [39]. Figures 8(a) and (b) show that the fraction of fine grains (2.5 μm) was reduced after forging. Figures 8(c) and (d) exhibit misorientation angle distribution of the specimens. In the unforged specimen, significant misorientation angles were observed at 5° and in the range of 30°-60°, whereas in the forged specimen, the considerable misorientation angle was formed between 30° and 50°. Moreover, misorientation angles near 30° and 45° in the unforged and free forged specimens, respectively, indicate the maximum number of fractions.

Fig. 7 EBSD inverse pole figure orientation maps and {001} pole figures of SPS (a) and free forged (b) specimens and those of unforged (c) and free forged (d) specimens aged at 500 °C

Fig. 8 Grain size distribution of SPS (a) and free forged (b) specimens and misorientation angles of unforged (c) and forged (d) specimens aged at 500 °C

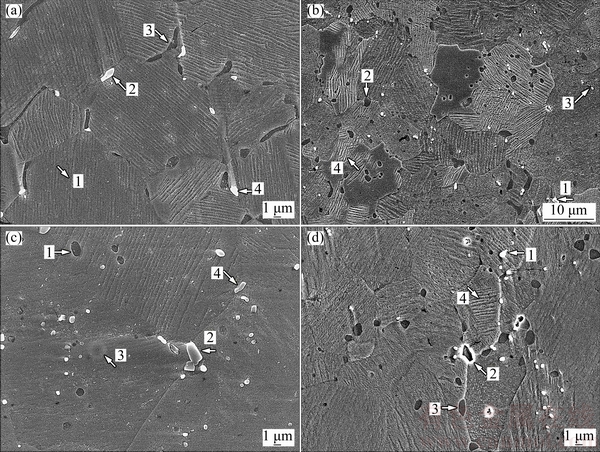

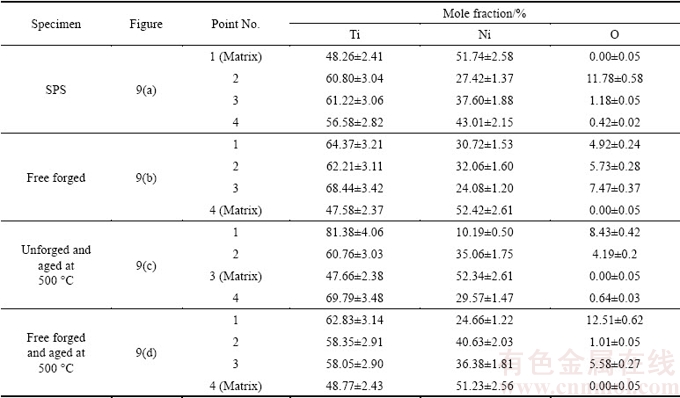

Figure 9 shows FESEM high magnification images of the microstructures corresponding to SPS and free forged, unforged and final products (aged at 500 °C). Martensite plates were clearly distinguished in all specimens. However, after forging, the volume fraction of needle-like martensite increased significantly, which indicated the development of stress-induced martensite. Moreover, a variety of different phases were clearly seen in all the specimens. The compositions of these phases, determined semi-quantitatively by energy dispersive X-ray spectrometer (EDS) attached to FESEM, are listed in Table 1. Ni content of the matrix in the free forged sample was higher than that in the SPS specimen. But this amount decreased after thermomechanical and aging treatment due to an increase in the Ni content of the precipitates. Many literatures [40-43] have indicated that aging has an important influence on transformation and shape memory properties of Ni-rich Ni-Ti shape- memory alloys due to the formation of Ti3Ni4 precipitates. Figure 10 shows TEM observation of Ti3Ni4 precipitates of free forged specimen after aging at 500 °C.

Fig. 9 FESEM images of elemental distribution of SPS (a) and free forged (b) specimens, and those of unforged (c) and free forged (d) specimens aged at 500 °C

Table 1 EDS point analysis results of Ti-51%Ni alloys in Fig. 9

Fig. 10 TEM micrograph of Ti3Ni4 precipitates after free forging process

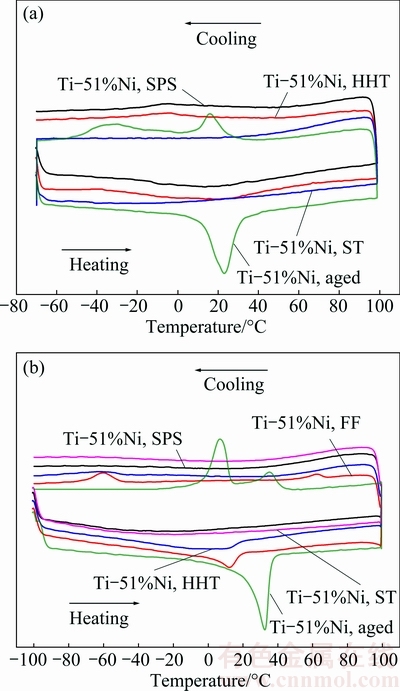

3.2 Transformation temperatures

Figure 11 shows the DSC curves of all fabrication steps for Ti-51%Ni SMAs produced by two processing methods: with and without deformation. As shown in Fig. 11(a), in the process without free forging, there is no obvious peak for the SPS, homogenization or solution treatment steps. The free forged sample shows one endothermic peak while heating and two exothermic peaks while cooling, as seen in Fig. 11(b). The heating peak indicates the B19′→B2 transformation and the two-step transformation with cooling as B2→R and R→B19′ for the first and second steps, respectively. Phase transformations and the consequent shape-memory properties after free forging are related to the introduction of a dislocation network during plastic deformation [8]. Austenitic transformation was observable during heating of the free forged specimen after homogenization, but martensitic transformation was detected only slightly during cooling. No phase change occurred during solution treatment of the forged specimen. Disappearance of the transformation peaks should be related to the elimination of the dislocation networks during homogenization and solution treatment.

Both the deformed and undeformed samples after aging showed one-way transformation during heating and two-way transformation during cooling. Figure 11(b) shows that the martensitic transformation peak shifted towards higher temperatures for the free forged specimen after aging. This may result from a decrease in Ni content in the B2 matrix due to higher Ni content of the precipitates formed in the specimen. It is believed that decreasing Ni content significantly increases the B19′ transformation temperature for Ti-Ni binary alloys [44]. Similarly, aging of the unforged specimen resulted in a B19′→B2 transformation during heating and B2→R and R→B19′ transformations during cooling. Martensitic transformation occurred at lower temperatures in the unforged sample. This may also result from lower Ni content of precipitates along with lower volume fraction of Ti3Ni4, as shown in the XRD pattern of the unforged specimen after aging. This indicates that the B2 matrix has higher Ni content, which leads to martensite transformation temperature.

Fig. 11 DSC curves of Ti-51%Ni SMAs produced without (a) and with (b) forging processes

Recorded data of reversible austenite martensite transformation temperatures related to As, Af, Ms and Mf for both processes are shown in Table 2.

It is believed that R phase transformation appears in Ni-rich (x(Ni)>50.5%) binary Ti-Ni SMAs due to fine Ti3Ni4 precipitate and introduction of dislocation in the matrix [44,45]. Recently, however, WANG et al [46] discussed the effect of fine grain size in provoking R phase transformation under aging conditions.

KIM et al [47] reported that a B2→R transformation occurs in the vicinity of Ni-rich Ti3Ni4 precipitates. These precipitates are coherent with a matrix that can induce coherency stress fields, and these external stresses may favor the occurrence of certain precipitate variants [48]. Therefore, it can be concluded that multiple-stage transformation caused by Ti3Ni4 precipitates is related to the structural inhomogeneity of the matrix, results from composition change and local stress fields.

Table 2 Transformation temperatures of Ti-51%Ni SMAs with and without free forging

The B2→B19′ transformation produces much greater transformation strain than the B2→R transformation. Therefore, local stress has a stronger influence on martensitic transformation temperatures. Moreover, displacive transformations have multiple choices of variants and hence a simple stress field causes an increase of martensitic transformation temperatures [47]. However, in this study, dominant external stress imposed by forging may have a reverse effect, with the R→B19′ transformation occurring at lower temperatures. When this external stress is removed after aging, only local stress exists, which can increase R→B19′ transformation temperatures.

3.3 Mechanical properties

3.3.1 Tensile and fracture properties

The tensile behavior of Ti-Ni SMAs differs from that of other alloys because they exhibit three regions: an elastic deformation region, a plateau region related to detwinning of martensite and, finally, an elastic and plastic mixed deformation region of martensite [49]. The room temperature stress-strain curves of both the unforged and forged specimens are shown in Figs. 12(a) and (b), respectively. These figures clearly show a significant increase in mechanical strength after forging. The unforged specimen showed the tensile strength of about 850 MPa with a maximum strain to fracture of 6.8%, whereas the forged specimen exhibited tensile strength of about 1300 MPa and a maximum strain of 9.2%. The ductility improvement may be related to microstructural evolution due to dynamic recry- stallization after forging of the specimen and the low volume fraction of the TiNi3 intermetallic phase [38,50].

Moreover, the tensile behavior of the specimens was investigated by fracture surface observations. Figure 13(a1) shows river marks related to the brittle fracture surface of the unforged specimen. In addition, cleavage facets and dimples at high magnification indicate ductile and brittle mixed modes of fracture. In contrast, after forging, the fracture surface displays smaller and narrower river marks, which are shown in Fig. 13(b1). However, high magnification of the fracture surface shows dimples, indicating a dominant ductile fracture mode.

Fig. 12 Stress-strain curves of Ti-51%Ni SMAs produced without (a) and with (b) forging process

3.3.2 Superelastic properties

Figures 14(a) and (b) respectively show the results of cyclic stress-strain hysteresis at room temperature for both unforged and forged Ti-51%Ni by mechanical loading and unloading. The free forged specimen exhibited better superrelasticity (four cycles) compared with specimen produced without free forging (three cycles). The tensile load was released from the sample after the initial stain of 1.5% was achieved. Subsequently, the strain was increased to 1.5% for each consecutive stress cycle. Both specimens showed a strain recovery of 100% for the first, second and third cycles up to a strain of 4%. Interestingly, however, the unforged sample failed in the fourth cycle whereas the forged specimen underwent the fourth cycle at a strain of 6% and exhibited a strain recovery of 90%. To observe the maximum superelasticity, single-cycle test was carried out by loading-unloading of the specimens at room temperature. As seen in Figs. 14(c) and (d), unforged specimen showed the strain recovery of 72% at the maximum strain of 5%. In contrast, the forged specimen exhibited a strain recovery of 92% at higher strain of 7.5%. It is known that the magnitude of the tensile strain recovery in a Ti–Ni polycrystal is between 5% and 8% in low-cycle limits [51]. Therefore, the obtained results are satisfactory and indicate that the deformation process (free forging) is effective in improving superelastic properties.

Fig. 13 Morphologies of tensile fracture surface of Ti-51%Ni specimens produced without (a1, a2) and with (b1, b2) forging process

Fig. 14 Cyclic superelastic curves of unforged (a) and forged (b) Ti-51%Ni specimens, and single cycle curves of unforged (c) and forged (d) specimens

It is believed that recovery from strain is orientation-dependent in Ti-Ni SMAs. Strain recovery increases when the crystals are aligned along [111] and [011] directions but decreases when the crystals are oriented along [001] direction [18]. Therefore, crystal orientation during deformation along with the influence of Ti3Ni4 should be considered for superelasticity improvement. As shown in the XRD pattern, the free forged specimen showed a higher amount of Ti3Ni4 precipitates. Moreover, increase in superelastic properties may be related to the dynamic recrystallization occurring during free forging [50].

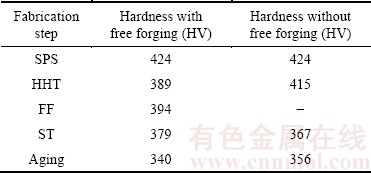

3.3.3 Hardness test

The microhardness values related to all steps of fabrication in both processes with and without deformation are presented in Table 3. The SPS sample showed the highest microhardness value of HV 424, which is related to the presence of a higher amount of Ti2Ni [52], as shown in the XRD pattern. This is because FCC-structured Ti2Ni with hardness of HV 700 [53] acts as a reinforcing phase. Therefore, due to the low volume fraction of Ti2Ni (as shown in the XRD pattern), the microhardness values decreased in the homogenized and solution-treated specimens.

Table 3 Microhardness values obtained for all steps of fabrication processes

Moreover, free forging also reduces hardness, which may be related to dynamic recrystallization and secondary particle refinement, such as TiNi3 and Ti2Ni and the homogenous distribution of these after free forging. In both processes, the aged specimens exhibited the lowest hardness. In addition, among all the samples, the deformed sample had the lowest hardness after aging.

4 Conclusions

1) Tensile test results revealed that ductility increased from 6.8% to 9.2% using free forging process, which may be due to dynamic recrystallization and low volume fraction of TiNi3 intermetallic phases.

2) Free forging has a significant effect on improving superelasticity of powder metallurgy-processed Ti- 51%Ni SMAs. The maximum strain increased from 5% to 7.5% during superelasticity test and the strain recovery rate increased from 72% to 92%.

3) The powder metallurgy produced Ti-51%Ni SMAs showed one-way transformation during heating and two-way transformation during cooling, but there was a shift in the transformation peaks towards higher temperatures in the final product of the free forging process due to increased Ni content in the matrix.

4) The free forged SPS specimen showed a texture increase from 2.418 to 3.596 times random. However, after aging, the forged specimen showed no significant change in texture (with a change in intensity from 3.596 to 3.751). Peak intensity increased from 2.418 to 4.681 after the unforged sample was aged at 500 °C.

Acknowledgments

The authors would like to thank the Ministry of Higher Education of Malaysia for the Malaysian International Scholarship and research funding under FRGS vote No. R.J13000.7824.4F810 as well as Universiti Teknologi Malaysia and Joining & Welding Research Institute (JWRI), Osaka University, Japan for providing the research facilities.

References

[1] RAGHAVAN J, BARTKIEWICZ T, BOYKO S, KUPRIYANOV M, RAJAPAKSE N, YU B. Damping, tensile, and impact properties of superelastic shape memory alloy (SMA) fiber-reinforced polymer composites [J]. Compos: Part B, 2010, 41: 214-222.

[2] NESPOLI A, BESSEGHINI S. A complete thermo-mechanical study of a NiTiCu shape memory alloy wire [J]. J Therm Anal Calorim, 2011, 103: 821-826.

[3] BALAK Z, ABBASI S M. Influence of the Ti content, training cycles and pre-strain on the two-way shape memory effect in NiTi alloys [J]. Mater Des, 2011, 32: 3992-3996.

[4] NAWRAT G, MARCINIAK J, ZAK J. Electropolishing and passivation of NiTi shape memory alloy [J]. Electrochimica Acta, 2010, 55: 2437-2441.

[5]  Surface science surface structure and corrosion resistance of short-time heat-treated NiTi shape memory alloy [J]. Applied Surface Science, 2010, 257: 1573-1582.

Surface science surface structure and corrosion resistance of short-time heat-treated NiTi shape memory alloy [J]. Applied Surface Science, 2010, 257: 1573-1582.

[6] BAHADOR A, SAUD S N, HAMZAH E, ABUBAKAR T, YUSOF F, IBRAHIM M K. Nd:YAG laser welding of Ti-27at%Nb shape memory alloys [J]. Weld World, 2016, 60: 1133–1139.

[7] CAO S, SCHRYVERS D. Quantitative 3-D morphologic and distributional study of Ni4Ti3 precipitates in a Ni51Ti49 single crystal alloy [J]. Scr Mater, 2012, 66: 650-653.

[8] SHAHMIR H, NAGHDI F. Superelastic behavior of aged and thermomechanical treated NiTi alloy at Af+10 °C [J]. Mater Des, 2011, 32: 365-370.

[9] MUNIR ZA,ANSELMI-TAMBURINI U,OHYANAGI M. The effect of electric field and pressure on the synthesis and consolidation of materials: A review of the spark plasma sintering method [J]. J Mater Sci, 2006, 41: 763-777.

[10] PELLIZZARI M, FEDRIZZI A, ZADRA M. Spark plasma co-sintering of hot work and high speed steel powders for fabrication of a novel tool steel with composite microstructure [J]. Powder Technol, 2011, 214: 292-299.

[11] DOBEDOE R S, WEST G D, LEWIS M H, DOBEDOE R S, WEST G D, LEWIS M H. Spark plasma sintering of ceramics: Understanding temperature distribution enables more realistic comparison with conventional processing [J]. Advances in Applied Ceramics, 2005, 104: 110-116.

[12] YADHUKULAKRISHNAN G B, KARUMURI S, RAHMAN A, SINGH R P, KALKAN A K, S. P. Spark plasma sintering of graphene reinforced zirconium diboride ultra-high temperature ceramic composites [J]. Ceram Int, 2013, 39: 6637-6646.

[13] ANDERSSON J, HULBERT D M. A discussion on the absence of plasma in spark plasma sintering [J]. Scr Mater, 2009, 60: 835-838.

[14] ZHANG Z, LIU Z, LU J, SHEN X, SCIENCE F. Direct the sintering mechanism in spark plasma sintering—Proof of the occurrence of spark discharge [J]. Scr Mater, 2014, 81: 56-59.

[15] ZHANG L, ZHANG Y Q, JIANG Y H, ZHOU R. Superelastic behaviors of biomedical porous NiTi alloy with high porosity and large pore size prepared by spark plasma sintering [J]. J Alloys Compd, 2015, 644: 513-522.

[16] KIM Y, LEE Y, NAM T. Shape memory characteristics of Ti-Ni-Mo alloys sintered by sparks plasma sintering [J]. J Alloys Compd, 2013, 577: s205-s209.

[17] LI D S, ZHANG Y P, EGGELER G, ZHANG X P. High porosity and high-strength porous NiTi shape memory alloys with controllable pore characteristics [J]. J Alloys Compd, 2009, 470: L7-L5.

[18] YIN X, MI X, LI Y, GAO B. Microstructure and properties of deformation processed polycrystalline Ni47Ti44Nb9 shape memory alloy [J]. J Mater Eng Perform, 2012, 21: 2684-2690.

[19] KHALIL-ALLAFI J, DLOUHY A, EGGELER G. Ni4Ti3 precipitation during aging of NiTi shape memory alloys and its influence on martensitic phase transformations [J]. Acta Meterialia, 2002, 50: 4255-4274.

[20] PRIPANAPONG P, LI S, UMEDA J, KONDOH K. Effect of textures on tensile properties of extruded Ti64/VGCF composite by powder metallurgy route [J]. Mechanics, Materials Science and Engineering Journal, 2018, 5: 22-32.

[21] CLUFF D, CORBIN S F. The influence of Ni powder size, compact composition and sintering profile on the shape memory transformation and tensile behaviour of NiTi [J]. Intermetallics, 2010, 18: 1480-1490.

[22] DIOUF S, MOLINARI A. Densification mechanisms in spark plasma sintering: Effect of particle size and pressure [J]. Powder Technol, 2012, 221: 220-227.

[23] SABIROV I, KOLEDNIK O, VALIEV R Z, PIPPAN R. Equal channel angular pressing of metal matrix composites?: Effect on particle distribution and fracture toughness [J]. Acta Materialia, 2005, 53: 4919-4930.

[24] CHU C L, CHUNG C Y, LIN P H. DSC study of the effect of aging temperature on the reverse martensitic transformation in porous Ni-rich NiTi shape memory alloy fabricated by combustion synthesis [J]. Materials Letters, 2005, 59: 404-407.

[25] BHAGYARAJ J, RAMAIAH K V, SAIKRISHNA C N, BHAUMIK S K, GOUTHAMA. Behavior and effect of Ti2Ni phase during pocessing of NiTi shape memory alloy wire from cast ingot [J]. J Alloys Compd, 2013, 581: 344-351.

[26] OTSUKA K, REN X. Physical metallurgy of Ti-Ni-based shape memory alloys [J]. Prog Mater Sci, 2005, 50: 511-678.

[27] LI H, YUAN B, GAO Y, CHUNG C Y, ZHU M. High-porosity NiTi superelastic alloys fabricated by low-pressure sintering using titanium hydride as pore-forming agent [J]. J Mater Sci, 2009, 44: 875-881.

[28] ZHENG H X, YU J K, XUE S C, WANG W, ZHENG H X, YU J K, XUE S C, WANG W. On formation mechanism of Ti2Ni particles in melt-spun TiNi shape memory ribbons [J]. Material Research Innovations, 2016, 18(S4): 574-577.

[29] NEVES F, MARTINS I, CORREIA J B, OLIVEIRA M, GAFFET E. Mechanically activated reactive forging synthesis (MARFOS) of NiTi [J]. Intermetallics, 2008, 16: 889-895.

[30] BALAGNA C, FAIS A, BRUNELLI K, PERUZZO L, CELKO L, HORYNOV M. Electro-sinter-forged Ni-Ti alloy [J]. Intermetallics, 2016, 68: 31-41.

[31] CHU C L, CHUNG C Y, LIN P H, WANG S D. Fabrication of porous NiTi shape memory alloy for hard tissue implants by combustion synthesis [J]. Mater Sci Eng A, 2004, 366: 114-119.

[32] CHU C L, CHUNG J C, CHU P K. Effects of heat treatment on characteristics of porous Ni-rich NiTi SMA prepared by SHS technique [J]. Transactions of Nonferrous Metals Society of China, 2006, 16: 49-53.

[33] BRAM M, AHMAD-KHANLOU A, HECKMANN A, FUCHS B, BUCHKREMER H P, ST VER D. Powder metallurgical fabrication processes for NiTi shape memory alloy parts [J]. Mater Sci Eng A, 2002, 337: 254-263.

VER D. Powder metallurgical fabrication processes for NiTi shape memory alloy parts [J]. Mater Sci Eng A, 2002, 337: 254-263.

[34] FAN G, ZHOU Y, CHEN W, YANG S, REN X, OTSUKA K. Precipitation kinetics of Ti3Ni4 in polycrystalline Ni-rich TiNi alloys and its relation to abnormal multi-stage transformation behavior [J]. Mater Sci Eng A, 2006, 438-440: 622-626.

[35] KIM J I, MIYAZAKI S. Effect of nano-scaled precipitates on shape memory behavior of Ti-50.9 at% Ni alloy [J]. Acta Materialia, 2005, 53: 4545-4554.

[36] RADEV D D. Mechanical synthesis of nanostructured titanium- nickel alloys [J]. Adv Powder Technol, 2010, 21: 477-482.

[37] MIZUNO A, KING Y, YAMAUCHI F K, HOMMA Y, TANAKA T. Temperature dependence of oxide decomposition on titanium surfaces in ultrahigh vacuum [J]. J Vac Sci Technol, 2002, 20: 1716-1721.

[38] KHAMEI A, DEHGHANI K. Microstructural evolution during the hot deformation of Ti-55Ni (at. pct) intermetallic alloy [J]. Metallurgical and Materials Transactions A, 2010, 41: 2595-2605.

[39] TERAYAMA A, FUYAMA N, YAMASHITA Y, ISHIZAKI I, KYOGOKU H. Fabrication of Ti-Nb alloys by powder metallurgy process and their shape memory characteristics [J]. J Alloys Compd, 2013, 577: s408-s412.

[40] JIANG S R, ZHANG Y Q, ZHAO Y N, LIU S W, HU L, ZHAO C Z. Influence of Ni4Ti3 precipitates on phase transformation of NiTi shape memory alloy [J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 4063-4071.

[41] JIANG S Y, ZHAO Y N, ZHANG Y Q, HU L, LIANG Y L. Effect of solution treatment and aging on microstructural evolution and mechanical behavior of NiTi shape memory alloy [J]. Transactions of Nonferrous Metals Society of China, 2013, 23: 3658-3667.

[42] ZHANG Y Q, JIANG S Y, ZHAO Y N, TANG M. Influence of cooling rate on phase transformation and microstructure of Ti-50.9%Ni shape memory alloy [J]. Transactions of Nonferrous Metals Society of China, 2012, 22: 2685-2690.

[43] JIANG S, ZHANG Y, ZHAO L, ZHENG Y. Influence of annealing on NiTi shape memory alloy subjected to severe plastic deformation [J]. Intermetallics, 2013, 32: 344-351.

[44] REN X, MIURA N, ZHANG J, OTSUKA K, TANAKA K, KOIWA M, SUZUKI T. A comparative study of elastic constants of Ti- Ni-based alloys prior to martensitic transformation [J]. Mater Sci Eng A, 2001, 312: 196-206.

[45] XUE D, ZHOU Y, REN X. The effect of aging on the B2-R transformation behaviors in Ti-51at%Ni alloy [J]. Intermetallics, 2011, 19: 1752-1758.

[46] WANG X, KUSTOV S, VERLINDEN B, van HUMBEECK J. Fundamental development on utilizing the R-phase transformation in NiTi shape memory alloys [J]. Shape Mem Superelasticity, 2015, 1: 231-239.

[47] KIM J I, LIU Y, MIYAZAKI S. Ageing-induced two-stage R-phase transformation in Ti-50.9at%Ni [J]. Acta Materialia, 2004, 52: 487-499.

[48] GUO W, STEINBACH I, SOMSEN C, EGGELER G. On the effect of superimposed external stresses on the nucleation and growth of Ni4Ti3 particles: A parametric phase field study [J]. Acta Materialia, 2011, 59: 3287-3296.

[49] JONES N G, DYE D. Influence of applied stress on the transformation behaviour and martensite evolution of a Ti-Ni-Cu shape memory alloy [J]. Intermetallics, 2013, 32: 239-249.

[50] ZHU R F, TANG G Y, SHI S Q, FU M W. Effect of electroplastic rolling on the ductility and superelasticity of TiNi shape memory alloy [J]. Mater Des, 2013, 44: 606-611.

[51] SHEARWOOD C, FU Y Q, YU L, KHOR K A. Spark plasma sintering of TiNi nano-powder [J]. Scr Mater, 2005, 52: 455-460.

[52] ZHANG B, CHEN J, CODDET C, LYON I. Microstructure and transformation behavior of in-situ shape memory alloys by selective laser melting Ti-Ni mixed powder [J]. J Mater Sci Technol, 2013, 29: 863-867.

[53] GAO F, WANG H M. Dry sliding wear property of a laser melting/ deposited Ti2Ni/TiNi intermetallic alloy [J]. Intermetallics, 2008, 16: 202-208.

Abdollah BAHADOR1, Esah HAMZAH1, Katsuyoshi KONDOH2, Tuty ASMA ABUBAKAR1, Farazila YUSOF3, Junko UMEDA2, Safaa N. SAUD4, Mustafa K. IBRAHIM1

1. Faculty of Mechanical Engineering, Universiti Teknologi Malaysia, 81310 UTM Johor Bahru, Johor, Malaysia;

2. JWRI, Osaka University, 11-1 Mihogaoka, Ibaraki, 567-0047 Osaka, Japan;

3. Department of Mechanical Engineering, Faculty of Engineering, University of Malaya, 50603 Kuala Lumpur, Malaysia;

4. Faculty of Information Science and Engineering, Management and Science University, 40100 Shah Alam, Malaysia

摘 要:采用放电等离子烧结(SPS)法将元素钛粉和镍粉制备成Ti-51%Ni 形状记忆合金(SMAs)。研究目的是采用自由锻二次加工以提高SPS合金的性能。对自由锻前后合金的显微组织、相变温度和超弹性进行比较。结果表明,自由锻可以显著提高Ti-Ni 形状记忆合金的拉伸强度和形状记忆性能,自由锻后合金的韧性从6.8% 提高到了9.2%,超弹性的应变范围从5%增加到7.5%,应变恢复速率从72%提高到92%。Ti-51%Ni合金显微组织中含有立方奥氏体相(B2)基体、单斜马氏体相 (B19′)、第二相(Ti3Ni4,Ti2Ni 和TiNi3) 和氧化物相(Ti4Ni2O,Ti3O5)。自由锻后再经500 °C时效处理的最终样品的马氏体相变温度向高温方向偏移,这是由于Ti3Ni4相(透射电镜下可以观察到)的析出而导致基体中Ni含量的减少。总之,自由锻可以提高Ti-51%Ni形状记忆合金的超弹性和力学性能。

关键词:形状记忆合金;超弹性;放电等离子烧结;自由锻

(Edited by Wei-ping CHEN)

Corresponding author: Esah HAMZAH; E-mail: esah@fkm.utm.my; Abdollah BAHADOR; E-mail: a79bahador@gmail.com

DOI: 10.1016/S1003-6326(18)64683-7