文章编号:1004-0609(2008)12-0222-06

工艺参数对AZ31镁合金激光?MIG复合焊缝成形的影响

高 明1,谭 兵2,冯杰才2,曾晓雁1,严 军1

(1. 华中科技大学 光电子科学与工程学院 武汉光电国家实验室,武汉 430074;

2. 中国兵器科学研究院 宁波分院,宁波 315103)

摘 要:系统研究激光功率、电弧电流和热源间距对10 mm厚AZ31镁合金激光?MIG (Metal inert gas) 复合焊接工艺稳定性和焊缝成形的影响规律。结果表明:实现最大激光?电弧协同效应的最优热源间距为3 mm;复合焊接熔深决定于激光功率;MIG电弧电流对焊缝宽度有显著影响,但是对焊接熔深影响有限;在优化的工艺参数下,激光?MIG复合焊接能够有效消除镁合金激光焊缝中存在的表面成形缺陷,焊接速度提高50%;与MIG焊接相比,复合焊接熔深提高近10倍,电弧燃烧和熔滴过渡稳定性大幅度提高;因而激光?MIG复合焊接是镁合金焊接的一种有效方法。

关键词:镁合金;复合焊接;激光焊接;电弧焊接;焊缝成形

中图分类号:TG 456.9 文献标识码: A

Effects of welding parameters on weld shape of laser-MIG hybrid welding of AZ31 magnesium alloy

GAO Ming1, TAN Bing2, FENG Jie-cai2, ZENG Xiao-yan1, YAN Jun1

(1. School of Optoelectronics Science and Engineering, Wuhan National Laboratory for Optoelectronics,

Huazhong University of Science and Technology, Wuhan 430074, China;

2. Ningbo Branch of China Academy of Ordnance Science, Ningbo 315103, China)

Abstract:Laser-MIG (Metal inert gas) hybrid welding with 10 mm thick AZ31 magnesium alloy was carried out and the effects of laser power, arc current and laser-arc distance on the weld shape were studied. The results show that the optimal laser-arc distance that has the maximum laser-arc synergic effect is 3 mm and the penetration depth of hybrid weld depends on the laser power. The arc current has an evident effect on the bead width but only a little influence on weld penetration depth. Under the optimal welding parameters, the laser-MIG hybrid welding can obtain good welds without morphological defect and the welding speed increases to 1.5 times as that of laser welding. Compared with MIG welding, the droplet transfer of hybrid welding is more stable and the weld penetration depth increases to nearly 10 times. The study demonstrates that the laser-MIG hybrid welding is an effective welding process for magnesium alloy.

Key words: magnesium alloy; hybrid welding; laser welding; arc welding; weld shape

镁合金是最轻的结构金属材料,具有高比强度、比刚度、减震性好等优异性能,在航空航天、汽车、电子等领域具有广阔的应用空间。但是,镁合金的一些特殊物理化学特性如表面张力低、沸点低、化学活泼性强,使其焊接存在一定困难,主要表现为焊接稳定性差,容易产生气孔、热裂纹、表面凹陷等冶金缺陷[1?3]。激光焊接因为速度快、效率高、精度高等优点,成为近年来镁合金焊接关注的焦点,并在薄板焊接上取得了较理想的焊接效果[4?6]。刘黎明等[7?8]将激光?TIG (Tungsten inert gas)电弧复合焊接技术应用于1~3 mm厚AZ31B镁合金薄板,也取得了显著成效。相比较于激光焊接,复合焊接能够获得更好的工艺稳定性、焊缝成形及力学性能。只是激光?TIG复合焊接工艺存在难以填充辅助材料的缺点,无法从根本上解决镁合金焊接,尤其是厚板焊接中极易出现的合金元素烧损、气孔、表面凹陷等冶金缺陷。

激光?MIG (Metal inert gas,熔化极惰性气体保护焊)复合焊接能够在实现激光?电弧协同效应的同时添加填充材料,消除上述缺陷。它既能够实现镁合金薄板的高速焊接又能够实现厚板的可靠焊接,其缝隙桥接能力更强,适用范围更广,工艺控制相对于郝新锋等[9]提出的激光?TIG复合冷填丝焊接技术来说也更简单直接,是目前最受关注、研究最广泛的激光?电弧复合焊接技术。研究镁合金激光?MIG复合焊接对提高镁合金焊接质量、焊接效率和扩大其应用范围具有重要意义。但是,镁合金的低沸点和高蒸汽压使其MIG焊接中的熔滴过渡相当困难:熔滴稍有过热就会产生爆炸,造成大量飞溅,工艺稳定性很差,无法形成稳定连续的焊缝。目前仅有WOHLFAHRT等[10]利用可控电流波形使熔滴既能过渡,又不过热并获得理想的工艺稳定性和焊缝成形。但是该工艺的核心技术并没有向公众透露,商用MIG焊机焊接镁合金仍然存在相当困难。这导致目前镁合金的MIG焊接研究非常缺乏。基于这一原因,迄今为止,未见关于镁合金激光?MIG复合焊接的报道。

本文作者采用10 mm厚AZ31镁合金开展CO2激光?MIG复合焊接研究,在实现稳定焊接的基础上研究焊缝成形变化规律,并对相关机理进行探讨。

1 实验

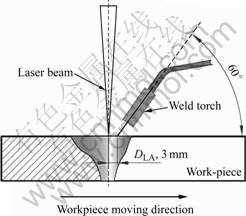

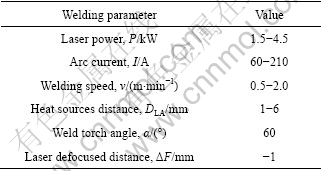

实验采用Rofin TR050 5 kW CO2激光器和Panasonic 350AG2型脉冲MIG焊机。激光束模式为TEM01,采用反射聚焦,焦距为286 mm,聚焦直径为0.6 mm。实验材料为10 mm厚AZ31镁合金板,尺寸为100 mm×50 mm,成分(质量分数)为:Al 3.95%-Zn 1.0%-Mn0.40%-Mg94.65%。实验装置示意图及相关参数标识如图1所示,采用激光引导方式,即激光作用在熔池前方。激光束中心和焊丝尖端的距离定义为热源间距,用DLA表示。实验所采用的工艺参数及变化范围如表1所列。电流和电压的对应关系如表2所列。焊炬用保护气体为He-Ar混合气体,流量15 L/min。沿激光束入射方向有同轴保护Ar气,流量为7.5 L/min。试验采用平板堆焊。焊接完成后,试样都从焊道中间切断并采用标准程序制作金相试样,采用10%硝酸酒精溶液腐蚀。随后采用金相显微镜观测焊缝形貌并测量相关参数。

图1 CO2激光?MIG复合焊接示意图

Fig.1 Schematic diagram of CO2 laser-MIG hybrid welding

表1 实验采用的工艺参数

Table 1 Welding parameters used in experiment

表2 电弧电流及其对应的电压

Table 2 MIG arc voltage corresponding to arc current

2 结果与讨论

2.1 焊缝成形特征及热源协同效应

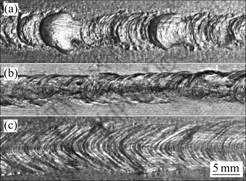

图2所示为镁合金MIG电弧、激光及复合焊缝表面形貌。对于单独MIG焊接来说,因为镁合金的低蒸汽压和低熔点,熔滴容易过热爆炸,其焊接过程不连续,工艺稳定性不高(见图2(a)),即使焊接速度只有0.5 m/min,MIG焊缝表面仍然凸凹不平,焊道边缘弯曲。如图2(b)所示,激光焊缝表面平整度得到提高。但是,因为缺乏添加材料的补充,镁合金蒸发烧损及焊缝根部下垂将消耗部分焊缝金属,激光焊缝表面有下凹现象出现,焊道边缘有明显咬边缺陷。如图2(c)所示,复合焊缝表面更平整,而且有余高出现,无咬边缺陷。这说明在镁合金激光?MIG复合焊接中,热源协同效应对MIG电弧燃烧和熔滴过渡,即电弧稳定性有显著增强作用,保证了复合焊接的稳定进行,焊丝材料的填充则对消除焊缝冶金缺陷有积极作用。

图2 镁合金MIG电弧、激光及复合焊缝的表面形貌

Fig.2 Weld surface morphologies of MIG arc welded, laser welded and hybrid welded magnesium alloys: (a) Arc weld, I=120 A, v=0.5 m/min; (b) Laser weld, P=3.5 kW, v=1.0 m/min; (c) Hybrid weld, P=3.5 kW, I=120 A, v=0.5 m/min;

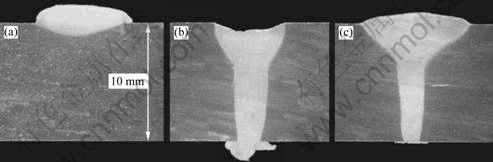

图3所示为单独MIG电弧、激光及复合焊缝的横截面形貌对比。从中可以看到,2.64 kW(120 A,22 V)MIG电弧即使在0.5 m/min低速下,焊接熔深也仅为1.1 mm;3.5 kW激光能在1.0 m/min的焊速下得到全熔透焊缝,但焊缝表面存在下凹缺陷。两者复合后,实现10 mm镁板完全熔透的复合焊接速度达到1.5 m/min,焊缝表面有过渡平滑的余高出现。相比较于MIG焊接,复合焊接熔深提高近10倍;相比较于激光焊接,其焊接速度增加50%,焊缝冶金缺陷也得到有效消除。这表明激光?MIG复合焊接能够通过激光?电弧协同效应改善镁合金MIG电弧燃烧和熔滴过渡的稳定性,实现稳定焊接,获得更好的焊缝成形和更高的焊接效率,是一种有效的镁合金焊接工艺。

图3 镁合金MIG电弧、激光及复合焊缝横截面形貌

Fig.3 Weld cross section morphologies of MIG arc, laser and hybrid welds magnesium alloys: (a) Arc weld, I=120 A, v=0.5 m/min; (b) Laser weld, P=3.5 kW, v=1.0 m/min; (c) Hybrid weld, P=3.5 kW, I=120 A, v=0.5 m/min;

通常认为,在激光?电弧复合焊接中,电弧稳定性的增强来自于两种作用:首先,激光光致等离子体中的高温带电粒子通过两热源相互作用中形成的导电通道进入电弧,提高电弧温度和电离度[11]。根据最小电压原理,电弧弧柱体积必然收缩以减少热量损耗,这使得电弧能量更集中,有助于其稳定性的提高。其次,高温激光小孔为电弧提供了稳定的阴极斑点,可以阻止电弧弧根漂移、避免电弧中断并提高熔滴过渡的指向性和电弧燃烧的稳定性[12]。激光功率越高,其对电弧的稳定作用越强[13]。对于镁合金激光?MIG复合焊接来说,热源协同效应对电弧稳定性的提高能够缓解镁合金熔滴过渡中的局部过热,抑制因熔滴过热爆炸而导致的电弧断弧及弧根漂移现象,提高熔滴过渡进入熔池的指向性,最终获得较稳定的焊接工艺并得到如图2(c)和图3(c)所示的良好焊缝形貌。另一方面,稳定燃烧的电弧能够通过预热工件来辅助增强激光,提高复合焊接效率。

2.2 焊缝形貌特征

研究表明[14?16],典型的激光?电弧复合焊接焊缝呈明显的“葡萄酒杯”状。根据激光焊接和常规电弧焊接的焊缝形貌特征,可以将其分为两个区域:电弧区和激光区。镁合金激光?MIG复合焊缝同样具备这种形貌,如图4所示。分析认为[14?15],激光和电弧在工件熔池内的能量分布和受力状况是决定这种焊缝成形的原因。焊缝上半部分宽大且较浅的电弧区表明电弧主要作用在焊接熔池上半部分,复合焊缝宽度主要取决于电弧的作用范围和强度;而焊缝下半部分明显的激光深熔焊特征则说明复合焊接熔深主要决定于激光小孔效应的强弱。

图4 激光?MIG复合焊缝区域划分

Fig.4 Nomination for different zones of laser-arc hybrid welded magnesium alloy (P=3.5 kW, I=120 A, v=1.2 m/min)

2.3 工艺参数对焊缝成形的影响

2.3.1 激光功率的影响

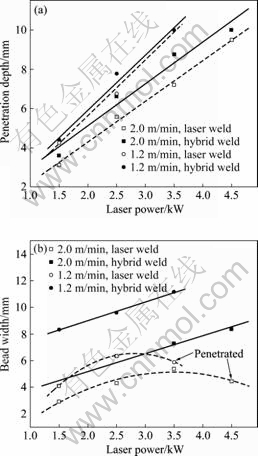

如图5所示,随着激光功率的增加,复合焊接熔深和焊缝宽度呈线性增加。这是因为在既定焊接速度下,激光功率的增加直接提高了激光小孔效应,进而提高复合焊接熔深;同时增加了焊接热输入并扩大了工件表面的受热范围,使复合焊缝变宽。

从图5(a)还可以看到,复合焊接熔深相对于激光焊接只有微弱增加。这可以通过镁合金的MIG电弧特性来进行解释。对钢铁、铝合金来说,现有商用MIG焊机能够获得非常稳定的熔滴喷射过渡。此时,电弧具有较大的熔滴冲击力和电弧压力。在激光?MIG复合焊接中,通过这些力和电弧热量的作用,电弧会在激光束作用区域形成一个凹陷熔池。激光束直接作用于该凹陷熔池内相当于其在工件上的作用平面下降,间接提高了激光小孔穿透深度。同时,激光直接作用于熔融的金属材料上,减少了其熔化金属所需的能量消耗,提高了激光束形成小孔的有效能量,增强了激光小孔效应。这两种机制的共同作用使得复合焊接熔深在钢铁和铝合金中相对于激光焊接有很大幅度的增加。但是,如前所述,镁合金MIG电弧燃烧及熔滴过渡极不稳定,因此,难以实现稳定的喷射过渡,只能形成凹陷深度很小的熔池及较浅的焊接熔深(见图2(a))。在本次复合焊接实验中,镁合金MIG电弧虽然能够通过激光?电弧协同效应得到提高,但仍然无法获得稳定的喷射过渡,只是其熔滴过渡的指向性得到改善,使熔滴和电弧热量能更稳定的进入熔池。这样,镁合金复合焊接中通过电弧作用形成凹陷熔池来提升焊接熔深的作用相对微弱,电弧辅助作用主要表现为预热工件来增强激光小孔效应。但是,不稳定电弧在通过热源协同效应实现稳定的过程中会消耗部分激光能量,一定程度上减弱了激光小孔效应[13]。总体上看,电弧对激光的辅助作用相对微弱,这导致镁合金复合焊接熔深只是略高于激光焊接。

图5 电弧电流120 A时激光功率对复合焊接熔深和焊缝宽度的影响

Fig.5 Effects of laser power on penetration depth (a) and bead width (b) by hybrid weld at arc current of 120 A

通常来说,因为能量密度高,激光焊接通常形成深宽比很大的细窄焊缝。但在复合焊接中,电弧和激光同时作用于工件表面,电弧宽大的热作用范围使得工件表面的熔化面积显著增加,最终形成明显变宽的复合焊缝。

2.3.2 电弧电流的影响

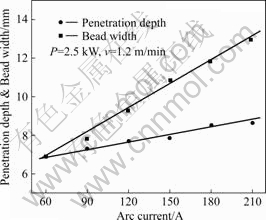

如图6所示,随着电弧电流的增加,焊接熔深和焊缝宽度呈线性增加。但是,焊缝宽度的增加幅度高于焊接熔深。

图6 电弧电流对复合焊缝成形的影响

Fig.6 Effects of arc current on weld shape of hybrid weld

对于电弧焊接来说,增加电流会提高电弧在工件表面的热作用面积,对焊缝宽度的增加有直接影响:电弧电流越大,工件表面受热熔化范围越大,焊缝宽度越大。因为复合焊缝宽度主要受到电弧的影响,因此,增加电弧电流会显著增加复合焊缝宽度。如2.3.1节所述,在镁合金复合焊接中,电弧对激光的辅助作用主要表现为预热作用。随着电弧电流的增加,热输入增加,电弧对激光的辅助作用增强,有利于激光小孔效应的增强和复合焊接熔深的增加。但是,增加电弧电流会提高电弧弧柱温度及电离度,缩小电弧和激光光致等离子体之间的差距。这导致从激光光致等离子内迁移进入电弧的带电粒子数量降低,即激光?电弧协同效应减弱,削弱了电弧通过带电粒子迁移“稀释”激光光致等离子体、降低了激光光致等离子体对激光束散焦效应并提高激光能量传输效率的积极作 用[13]。最终,在这两种影响的综合作用下,复合焊接熔深随电弧电流增加的幅度小于焊缝宽度。

由于复合焊接熔深主要决定于激光功率,而电弧电流对其影响并不显著,因此,在镁合金激光?MIG复合焊接中,电弧电流的作用更多的表现在控制焊缝宽度和材料填充量上。

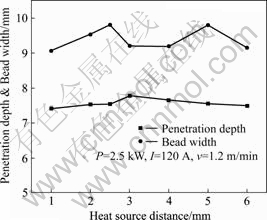

2.3.3 热源间距的影响

如图7所示,存在一个获得最大复合焊接熔深,较窄焊缝宽度的最佳热源间距DLA(3 mm)。从整体上看,热源间距对复合焊接熔深的影响并不显著。这是因为,在镁合金激光?MIG复合焊接中,热源协同效应主要体现为激光对电弧稳定性的提高,激光被电弧辅助增强的作用相对较小。因此,决定于激光小孔效应的复合焊接熔深相对于激光焊接的提升幅度不大。在最佳间距DLA=3 mm处,复合焊接熔深相对于激光焊接仅增加0.97 mm(见图5(a)和图7)。最终,随着热源间距的变化,复合焊接熔深仅在此很窄的范围内变化,总体变化并不明显。

图7 热源间距对复合焊缝成形的影响

Fig.7 Effects of heat sources distance on weld shape of hybrid weld

热源间距对复合焊缝成形的影响主要取决于热源协同效应,但也受到其他因素的影响。随着DLA的增加,激光和电弧等离子体逐步分离[13],这导致两等离子体通过两者之间的导电通道进行粒子迁移的难度逐渐增加,即激光?电弧协同效应逐步减弱。这样,激光小孔效应被电弧增强的作用逐渐减弱,复合焊接熔深下降;同时,电弧被激光压缩的程度逐渐变小,电弧在工件表面的热作用范围增加,复合焊缝宽度逐步增加。当热源间距增至一定程度,如DLA=6 mm时,激光?电弧协同效应消失,电弧对激光的辅助作用消失,复合焊接熔深下降至和激光焊接相同。同时,激光对电弧的稳定作用消失,电弧稳定性急剧下降,其作用于工件表面的有效热量降低,因此,决定于电弧的复合焊缝宽度反而降低。

当热源间距减小至一定范围时,激光束会直接作用在焊丝或熔滴上。这会消耗部分激光能量,造成激光小孔效应和光致等离子体强度减弱,并降低复合焊接熔深。光致等离子体强度的减弱会降低激光?电弧协同效应及激光束对电弧的压缩和稳定作用。电弧弧柱体积的增加将增大复合焊缝宽度。本实验条件下,DLA≤2.5 mm时,即出现激光束和熔滴或焊丝直接作用的情况:DLA越小,两者间距越近,该情形越严重。但是,当热源间距很小时,如DLA=1 mm时,激光束直接熔化焊丝或熔滴消耗的能量过大,在激光小孔效应减弱并降低复合焊接熔深的同时,激光束和熔滴作用瞬间产生的高温会使熔滴爆炸并造成电弧稳定性急剧下降。这同样致使电弧作用于工件表面用于熔化金属的有效热量降低,并降低复合焊缝宽度。

在上述影响因素的共同作用下,存在获得最大热源协同效应的最佳间距。在此最佳间距下,激光小孔效应得到最大程度的增强,电弧被压缩的程度较大。此外,在DLA=4 mm时,复合焊缝成形和最佳间距差距很小。之所以没有选择该间距为最佳间距是因为随着热源间距的增加,保护气体由焊炬喷嘴至熔池的距离增加,对熔池的保护效果变差,不利于复合焊接接头质量的提高。

3 结论

1) 在优化的工艺参数下,镁合金激光?MIG复合焊接能够得到稳定工艺和成形良好的焊缝,有效消除镁合金激光焊缝中容易形成的冶金缺陷。在给定参数下,相比较于单纯MIG焊接,其焊接熔深提高近10倍;相比较于激光焊接,其焊接速度提高50%。

2) 镁合金激光?MIG复合焊接熔深主要决定于激光功率,基本随激光功率的增加而线性增加。但是,复合焊接熔深相对于激光焊接只有微弱增加。

3) 在镁合金激光?MIG复合焊接中,焊接熔深和焊缝宽度都随着电弧电流的增加而线性增加。电弧电流的作用更多的体现在控制焊缝宽度和材料填充量上,对复合焊接熔深影响相对较小。

4) 镁合金激光?MIG复合焊接的最优热源间距为3 mm,此时激光?电弧协同效应最大,复合焊接熔深最大。

REFERENCES

[1] 冯吉才, 王亚荣, 张忠典. 镁合金焊接技术的研究现状及应用[J]. 中国有色金属学报, 2005, 15(2): 165?178.

FENG Jie-cai, WANG Ya-rong, ZHANG Zhong-dian. Status and expectation of research on welding of magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(2): 165?178.

[2] Zhao H, Debroy T. Pore formation during laser beam welding of die-cast magnesium alloy AM60—Mechanism and remedy[J]. Weld Journal, 2001, 80(8): 204?210.

[3] 全亚杰, 陈振华, 俞照辉, 龚晓叁. AZ31镁合金激光焊接头中的缺陷分析[J]. 热加工工艺, 2007, 36(3): 33?36.

Quan Ya-jie, Chen Zhen-hua, Yu Zhao-hui, GONG Xiao-san. Defects analysis of AZ31 magnesium alloy joints by laser beam welding[J]. Hot Working Technology, 2007, 36(3): 33?36.

[4] Cao X, Jahazi M, Immarigeon J P, WALLACE W. A review of laser welding techniques for magnesium alloy[J]. J Mater Process Technol, 2006, 171(2): 188?203.

[5] 全亚杰, 陈振华, 黎 梅, 俞照辉, 龚晓叁. AM60变形镁合金薄板激光焊接接头的组织与性能 [J]. 中国有色金属学报, 2007, 17(4): 525?529.

Quan Ya-jie, Chen Zhen-hua, LI Mei, YU Zhao-hui, GONG Xiao-san. Microstructure and properties of joints of wrought magnesium alloy AM60 plates welded by laser beam welding[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(4): 525?529.

[6] Sun Z, Pan D, Wei J. Comparative evaluation of tungsten inert gas and laser welding of AZ31 magnesium alloy[J]. Science and Technology of Welding and Joining, 2002, 7(6): 343?351.

[7] Liu Li-ming, Wang Ji-feng, Song Gang. Hybrid laser-TIG welding, laser beam welding and gas tungsten arc welding of AZ31B magnesium alloy[J]. Materials Science and Engineering A, 2004, 381(1/2): 129?133.

[8] 宋 刚, 刘黎明, 王继锋, 周继扬. 激光-TIG复合焊接镁合金AZ31B焊接工艺[J]. 焊接学报, 2004, 25(3): 31?34.

SONG Gang, LIU Li-ming, WANG Ji-feng, ZHOU Ji-yang. Laser tungsten inert gas arc hybrid welding process on wrought magnesium alloy AZ31B[J]. Transactions of the China Welding Institution, 2004, 25(3): 31?34.

[9] 郝新锋, 刘黎明, 李长茂. 镁合金激光氩弧复合热源冷填丝焊接工艺[J]. 焊接学报, 2007, 28(5): 77?81.

HAO Xin-feng, LIU Li-ming, LI Chang-mao. Low powered laser-arc hybrid welding of magnesium alloy with cold filler wire[J]. Transactions of the China Welding Institution, 2007, 28(5): 77?81.

[10] Wohlfahrt H, Rethmeier M, Brunswick, BOUAIFI B, SCHUTZ M. Metal-inert gas welding of magnesium alloy[J]. Welding and Cutting, 2003, 55(2): 80?84.

[11] 高 明, 曾晓雁, 严 军, 胡乾午, 王福德. 激光?电弧复合焊接的热源相互作用[J]. 激光技术, 2007, 31(5): 465?468.

GAO Ming, ZENG Xiao-yan, YAN Jun, HU Qian-wu, WANG Fu-de. Heat sources interaction of laser-arc hybrid welding[J]. Laser Technology, 2007, 31(5): 465?468.

[12] 刘黎明, 王继锋, 宋 刚. 激光电弧复合焊接AZ31B镁合金 [J]. 中国激光, 2004, 31(12): 1523?1526.

LIU Li-ming, WANG Ji-feng, SONG gang. Hybrid laser-arc welding of AZ31B Mg alloy[J]. Chinese Journal of Lasers, 2004, 31(12): 1523?1526.

[13] Gao M, Zeng X Y, Hu Q W. Effects of welding parameters on melting energy of CO2 laser-GMA hybrid welding[J]. Science and Technology of Welding and Joining, 2006, 11(5): 517?522.

[14] 高 明, 曾晓雁, 胡乾午, 严 军. 热源空间位置对激光电弧复合焊接焊缝成形的影响[J]. 中国激光, 2007, 34(s1): 279?283.

GAO Ming, ZENG Xiao-yan, HU Qian-wu, YAN Jun. Effects of heat sources arrangement on weld shape of laser-arc hybrid welding[J]. Chinese Journal of Lasers, 2007, 34(s1): 279?283.

[15] Gao Ming, Zeng Xiao-yan, Yan Jun, HU Qian-wu. Microstructure characteristics of laser-MIG hybrid welded mild steel[J]. Applied Surface Science, 2008, 254(18): 5715?5721.

[16] Rayes M EL, Walz C, Sepold G. The influence of various hybrid welding parameters on bead geometry[J]. Welding Journal, 2004, 83(5): 147s?153s.

基金项目:中国博士后科学基金资助项目(20070420897);中国博士后科学基金特别资助项目(200801309)

收稿日期:2008-04-29;修订日期:2008-09-10

通讯作者:曾晓雁,教授;电话:027-87792457;传真:027-87541423;E-mail: xyzeng@mail.hust.edu.cn

(编辑 陈爱华)