文章编号:1004-0609(2007)04-0525-05

AM60变形镁合金薄板激光焊接接头的组织与性能

全亚杰, 陈振华, 黎 梅, 俞照辉, 龚晓叁

(湖南大学 材料科学与工程学院, 长沙 410082)

摘 要:以AM60变形镁合金薄板为研究对象,分析CO2激光焊后接头的组织和性能,探讨镁合金激光焊接的工艺特点。结果表明:在合适的工艺参数下,能获得表面成型良好、变形小的焊接接头。金相观察分析发现接头中热影响区不明显,焊缝区组织致密,晶粒细小,晶界上均匀分布着脆性相(Mg17Al12),但内部易产生气孔、裂纹等微观缺陷。硬度测试结果显示,焊缝硬度略高,母材和热影响区硬度相当。在本实验条件下采用CO2激光焊能实现AM60镁合金的焊接,抗拉强度可达母材的94%,断口表现为混合断裂。

关键词:变形镁合金AM60;激光焊接;微观组织;力学性能

中图分类号:TG 456.7 文献标识码:A

Microstructure and properties of joints of wrought magnesium alloy AM60 plates welded by laser beam welding

QUAN Ya-jie, CHEN Zhen-hua, LI Mei, YU Zhao-hui, GONG Xiao-san

(School of Materials Science and Engineering, Hunan University, Changsha 410082, China)

Abstract: The CO2 laser beam was used to weld the wrought magnesium alloy AM60 plates, the microstructure and mechanical properties of the joints were studied, and the technical characteristics of magnesium alloy laser welding were discussed. The results show that a favorable weld without obvious distortion can be obtained under the suitable parameters. By metallurgical analysis it is found that the heat affected zone is not distinct, and the microstructure in fusion zone presents compact fine grains with brittle intergranular precipitates (Mg17Al12), which often accompanies with micro defects such as porosity and cracking. The result of hardness test shows that the hardness of the weld is slightly high, while the hardness of the base metal is equivalent to that of the HAZ. Under this experimental condition, the wrought magnesium alloy AM60 can be welded by CO2 laser beam welding, and the joint strength is up to 94% of the base metal. The fracture surface is characterized by mixture fracture.

Key words: wrought magnesium alloy AM60; laser beam welding; microstructure; mechanical property

近年来,随着航空航天、交通运输和信息产业的发展,新型轻合金材料的研究和应用受到了各国的高度重视。镁合金具有密度低、比强度高、可回收性好等优点,已广泛应用于航空航天、汽车、摩托车、电子等领域 [1-2]。随着镁合金结构件应用的逐渐推广,必然会涉及到其焊接问题。由于镁合金熔点低,线膨胀系数和热导率高,与氧、氮的亲和力强,焊后易形成脆性相和夹杂,使接头的力学性能显著下降,所以对焊接工艺的要求较高。郑荣等[3-8]研究了Mg-Al-Zn系合金TIG焊接头的组织性能变化以及焊接过程中存在的关键问题和主要解决措施。但TIG焊热输入大,焊件变形严重,热影响区较宽,晶粒粗大,接头性能不太理想。而激光焊接作为一种先进的连接技术,具有加热速度快、热输入低、焊后变形小、接头强度高等优点,得到了人们的大量关注。宋刚等[9-10]对AZ31镁合金 YAG 激光焊接的工艺特点进行了系统研究,在合适的实验条件下得到了强度达母材95%的接头。另外,王红英等[11-12]对AZ31和AZ61镁合金CO2激光焊工艺进行研究也得到了性能良好的焊接接头。由此可见,激光焊是焊接镁合金的理想方法之一。

AM系镁合金由于含铝量较低,使合金中含铝的二次化合物相的析出量减少,虽然强度有所降低,但具有优良的塑性和韧性。常用的合金有AM50和AM60,代替AZ91合金用于要求较高塑性、韧性和耐蚀性的场合,制作经受冲击载荷、安全性能要求较高的零部件。目前,其应用主要集中在汽车仪表板、转向操纵系统部件、汽车座架等方面[13-14]。随着AM系列镁合金在零部件中应用范围的扩大,解决其焊接问题变得日趋重要。本文作者主要针对AM60变形镁合金,研究CO2激光焊的工艺特点,分析其焊接接头的微观组织及力学性能。

1 实验

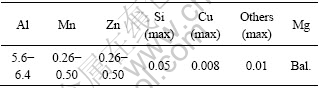

实验采用经挤压、轧制加工而成的AM60镁合金薄板,厚度为1.6 mm,其化学成分见表1,抗拉强度为330 MPa。采用线切割技术将板材加工成50 mm×30 mm的长方形片状试件。焊前采用丙酮去除油脂,干燥后分别用砂纸和钢丝刷去除氧化膜。保护气体用纯度为99.99%的高纯氩气。

表1 AM60镁合金化学成分

Table 1 Chemical composition of magnesium alloy AM60 (mass fraction, %)

焊接设备采用武汉金石凯公司生产的GS-TFL- 6000W高功率横流CO2激光器。焊接时采用对接方式,不加填充焊丝,单面焊双面成型。为防止焊件变形,焊件两端采用夹具固定。将焊后的试样按图1所示的方向和尺寸截取拉伸试样,然后在WDW-E200微机控制电子万能实验机上进行拉伸,取各参数条件下3个试样的测试平均值作为该状态下的强度值,再在KYKY-Amray2800扫描电镜下观察其断口形貌。制备的金相试样采用5 g苦味酸+5 g冰醋酸+10 mL水+100 mL酒精配成的溶液进行腐蚀,时间为20~60 s,然后到Leitz MM-6型卧式金相显微镜上进行微观组织观察及接头硬度分布分析。

图1 拉伸试样的截取位置(a)及尺寸(b)示意图

Fig.1 Schematic diagram of position (a) and dimensions (b) of tensile specimens(unit: mm)

2 结果与分析

2.1 焊缝成型特点

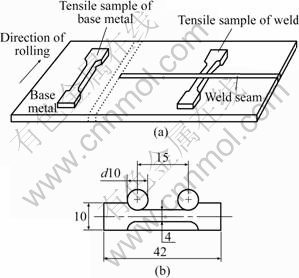

图2(a)所示为典型的激光焊AM60镁合金焊缝上、下表面的宏观形貌。由图可见,焊缝上下表面均连续、平整,鱼鳞状波纹均匀,表面无明显的气孔、裂纹等缺陷存在,接头变形小。图2(b)所示为接头横截面的宏观形貌,焊缝狭窄,深宽比大,顶部与根部成形良好,形状呈典型的“手指”状,这是由于激光束能量密度高,焊接过程中热输入小,对材料的加热比较集中造成的。

图2 焊接接头的形貌

Fig.2 Photographs of welded joints: (a) Weld appearance; (b) Cross-section geometry

2.2 焊缝金相组织

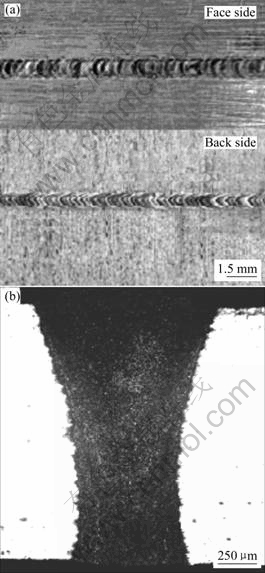

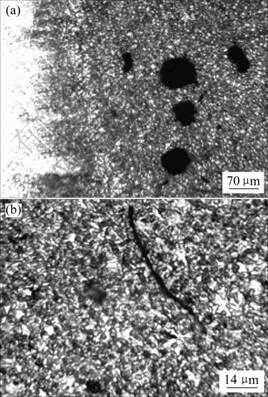

图3所示为AM60镁合金激光焊的典型接头中各区域的显微组织形貌。图3(a)所示的母材为典型的轧制态组织,晶粒不均匀,在较大的条带状组织周围往往分布着细小的再结晶组织。从图3(b)可以看出,焊接接头中的热影响区不明显,几乎看不到近缝区组织的变化。这是因为在焊接过程中激光能量高度集中,焊接时所需要的热输入小;同时,由于焊接过程中激光与材料的作用时间极短,使得近缝区的热影响明显减小。图3(c)所示的焊缝区为细小的等轴晶,晶界上均匀分布着颗粒状的析出相。这主要是因为激光焊接速度快,镁合金热导率大,熔化后的焊缝金属冷却速度快,使晶粒得到了细化,再加上晶粒细化元素铝等的存在也会限制晶粒长大。因此,AM60镁合金激光焊能获得质量较好的焊接接头。

图3 焊接接头的显微组织

Fig.3 Microstructures of welded joint: (a) Base metal; (b) Transition zone; (c) Weld zone

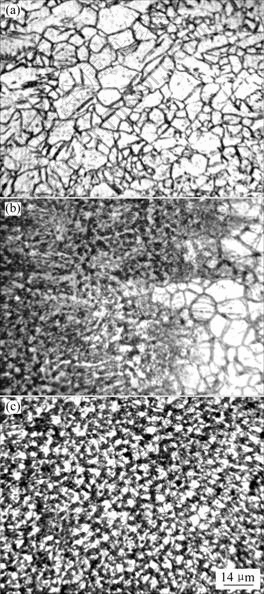

图4所示为金相实验中观察到的焊缝缺陷。由图4(a)可见,焊缝中存在较多的气孔,目前普遍认为其形成与焊缝中的氢有关[15]。因为高温时氢在镁中的溶解度很高,镁熔液可以吸收大量的氢。在焊后的冷却过程中,随着温度的降低,氢在熔池中的溶解度急剧下降。并且镁的密度比铝小,析出的气体不易逸出,因而容易在焊缝中形成气孔。图4(b)所示为焊缝中产生的结晶裂纹。这主要是由于一方面激光焊接速度快,焊缝内部的应力增加;另一方面AM60属共晶型合金,在焊接条件下的非平衡凝固过程中晶界存在易熔共 晶体。

图4 焊缝中的缺陷

Fig.4 Defects in weld metal: (a) Porosity; (b) Cracking

2.3 接头拉伸实验

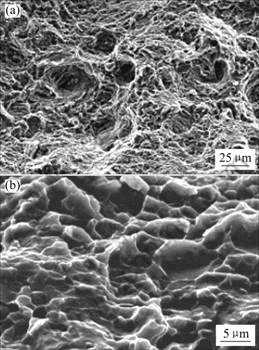

将焊后的试样上下表面磨平去除焊缝余高,进行常温拉伸实验。结果表明:在激光输出功率为0.8 kW,保护气体氩气流量为15 L/min,焊接速度为3 m/min的条件下,接头抗拉强度可达310 MPa,为母材的94%。接头拉伸断口的SEM形貌如图5所示。断裂发生在焊缝区,显示为混合断口形式,表面呈现出一定的脆性,局部存在韧窝形貌。这主要与激光焊接头的微观结构有关。对比母材,虽然焊缝区的晶粒得到了明显细化,但由于脆性相在晶界的析出,容易造成连续分布,同时焊缝中还常常存在如上所述的缺陷,而接头中不存在明显的晶粒粗化的热影响区,所以焊缝区成了接头强度的薄弱地带,拉伸断裂容易发生在此位置。

图5 断口表面的扫描电镜照片

Fig.5 SEM images of fracture surface

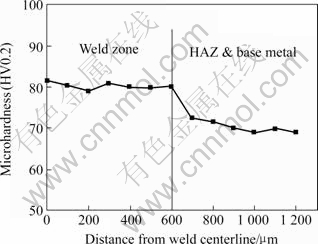

2.4 接头硬度分布

AM60变形镁合金焊接接头的硬度分布如图6所示。由图6可见,接头中焊缝的硬度较高,由焊缝到母材的硬度逐渐降低,说明焊缝区域的硬度优于母材。这与焊接接头的组织特征有关。与母材组织相比,焊缝晶粒显著细化,同时在晶界有颗粒状的析出相析出,从而起到了明显的强化作用,而近缝区组织无明显变化。

图6 焊接接头显微硬度分布

Fig.6 Microhardness distribution of welded joint

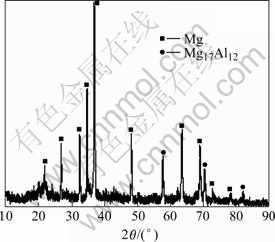

2.5 焊缝区物相分析

对焊缝区进行X射线衍射分析,其结果如图7所示。可见焊缝区存在α-Mg和Mg17Al12 2种衍射峰,由于AM60合金中铝元素含量较少,相应生成的Mg17Al12化合物较少,导致Mg17Al12衍射峰较弱。从理论上来说,在平衡凝固过程中,温度为710 K时铝在镁固溶体中的最大固溶度为12.6%,如铝含量较低则不会结晶出化合物相Mg17Al12。但在焊接过程中,冷却速度快,呈现非平衡凝固,即使是少量的铝元素存在也会结晶出Mg17Al12[16]。由于Mg17Al12熔点较低,在冷却过程中往往以颗粒状的形式偏析于晶界,如图3(c)所示。

图7 焊缝区的X射线衍射谱

Fig.7 X-ray diffraction pattern of weld zone

3 结论

1) 采用CO2激光焊能实现AM60镁合金的焊接,得到的接头变形小,焊缝上下表面均连续、平整,鱼鳞状波纹均匀。

2) 接头热影响区不明显,焊缝区组织均匀细小,晶界上均匀分布着颗粒状的析出相;焊缝中容易产生气孔、裂纹等微观缺陷,导致接头质量下降。

3) 采用合适的工艺参数可获得高强度的接头,抗拉强度为310 MPa,达到了母材强度的94%,断口表现为混合断裂;硬度测试表明,焊缝硬度略高,母材及热影响区硬度相当。

REFERENCES

[1] Mordike B L, Ebert T. Magnesium properties applications potential[J]. Materials Science and Engineering, 2001, A302(1): 37-45.

[2] 曾荣昌, 柯 伟, 徐永波, 韩恩厚,朱自勇. Mg合金的最新发展及应用前景[J]. 金属学报, 2001, 37(7): 673-685.

ZENG Rong-chang, KE Wei, XU Yong-bo, HAN En-hou, ZHU Zi-yong. Recent development and application of magnesium alloys[J]. Acta Metall Sin, 2001, 37(7): 673-685.

[3] 郑 荣, 林 然. AZ31B镁合金薄板TIG焊接[J]. 焊接, 2003(4): 43-44.

ZHENG Rong, LIN Ran. TIG welding of AZ31B Mg alloy[J]. Welding & Joining, 2003(4): 43-44.

[4] 苗玉刚, 刘黎明, 赵 杰, 于德凯. 变形镁合金熔焊接头组织特征分析[J]. 焊接学报, 2003, 24(2): 63-66.

MIAO Yu-gang, LIU Li-ming, ZHAO Jie, YU De-kai. Microstructure feature analysis of fusion welded joint of wrought Mg-alloy[J]. Transactions of the China Welding Institution, 2003, 24(2): 63-66.

[5] Munitz A, Cotler C, Stern A, Kohn G. Mechanical properties and microstructure of gas tungsten arc welded magnesium AZ91D plates[J]. Materials Science and Engineering, 2001, A302(1): 68-73.

[6] 徐锦锋, 翟秋亚. AZ91B镁合金TIG焊接头组织与性能[J]. 特种铸造和有色合金, 2004, 24(4): 23-25.

XU Jin-feng, ZHAI Qiu-ya. Microstructure and properties of TIG welding joint for AZ91B Mg alloy[J]. Special Casting &

Nonferrous Alloys, 2004, 24(4): 23-25.

[7] Marya M, Edwards G R, Liu S. An investigation on the effects of gases in GTA welding of a wrought AZ80 magnesium alloy[J]. Welding Journal, 2004, 83(7): 203-212.

[8] 张兆栋, 刘黎明, 王 来. 镁合金活性TIG焊焊接接头组织特征分析[J]. 焊接学报, 2004, 25(4): 55-58.

ZHANG Zhao-dong, LIU Li-ming, WANG Lai. Microstructure feature analysis of activating TIG welded joint of magnesium alloy[J]. Transactions of the China Welding Institution, 2004, 25(4): 55-58.

[9] 宋 刚, 刘黎明, 王继锋, 许德胜. 变形镁合金AZ31B的激光焊接工艺研究[J]. 应用激光, 2003, 23(6): 327-329.

SONG Gang, LIU Li-ming, WANG Ji-feng, XU De-sheng. Study of YAG laser welding process on wrought magnesium[J]. Applied Laser, 2003, 23(6): 327-329.

[10] 王继锋, 刘黎明, 宋 刚. 激光焊接AZ31B镁合金接头微观组织特征[J]. 焊接学报, 2004, 25(3): 15-18.

WANG Ji-feng, LIU Li-ming, Song Gang. Microstructure character of YAG laser welding AZ31B Mg alloy[J]. Transactions of the China Welding Institution, 2004, 25(3): 15-18.

[11] 王红英, 李志军, 陈斐明. AZ31镁合金薄板的CO2激光焊接接头性能[J]. 焊接, 2006(3): 47-50.

WANG Hong-ying, LI Zhi-jun, CHEN Fei-ming. Properties of the CO2 laser welded joint of AZ31B magnesium alloy sheet[J]. Welding & Joining, 2006(3): 47-50.

[12] 王红英, 李志军. AZ61镁合金CO2激光焊接工艺[J]. 焊接, 2006(1): 46-48.

WANG Hong-ying, LI Zhi-jun. CO2 laser beam welding of AZ61 magnesium-based alloys[J]. Welding & Joining, 2006(1): 46-48.

[13] Siederslebnen M. Vacuum die-casting of magnesium parts with high pressure[A]. Kainer K U, Kaiser F. Magnesium Alloys and Technology[C]. Weinheim: Wiley-Vch Verlag GmbH & Co. KG aA, 2003: 45-51.

[14] Fink R. Die-casting magnesium[A]. Kainer K U, Kaiser F. Magnesium Alloys and Technology[C]. Weinheim: Wiley-Vch Verlag GmbH & Co. KG aA, 2003: 23-30.

[15] Zhao H, Debroy T. Pore formation during laser beam welding of die-casting magnesium alloy AM60B—mechanism and remedy[J]. Welding Journal, 2001, 80(8): 204-210.

[16] 陈振华, 严红革, 陈吉华, 全亚杰,王慧敏,陈 鼎. 镁合金[M]. 北京: 化学工业出版社, 2004: 325-384.

CHEN Zhen-hua, YAN Hong-ge, CHEN Ji-hua, QUAN Ya-jie, WANG Hui-min, CHEN Ding. Magnesium Alloy[M]. Beijing: Chemical Industry Press, 2004: 325-384.

收稿日期:2006-09-20;修订日期:2006-12-15

通讯作者:陈振华,教授;电话:0731-8821648; E-mail:chenzhenhua45@hotmail.com

(编辑 杨幼平)