文章编号:1004-0609(2011)04-0701-07

ZK40高强镁合金CO2激光焊接接头的组织与力学性能

俞照辉,严红革,陈 琼,苏 斌

(湖南大学 材料科学与工程学院,长沙 410082)

摘 要:采用CO2激光对轧制态ZK40镁合金板材进行焊接,并研究焊接工艺参数对接头显微组织及力学性能的影响规律。结果表明:在合理的工艺条件下,可以获得成型良好的焊接接头,其抗拉强度可达到315MPa,为母材的91.3%;熔池边界无外延生长的柱状晶,整个熔池完全由细小均匀的等轴树枝晶组成;分布于晶界及枝晶臂间的第二相粒子主要是Mg51Zn20;随着焊接热输入的增大,枝晶臂生长更为发达,晶粒粗化。

关键词:ZK40镁合金;激光焊接;显微组织;力学性能

中图分类号:TG456.7 文献标志码:A

Microstructures and mechanical properties of ZK40 high strength magnesium alloy joints by CO2 laser beam welding

YU Zhao-hui, YAN Hong-ge, CHEN Qiong, SU Bin

(School of Materials Science and Engineering, Hunan University, Changsha 410082, China)

Abstract: The as-rolled ZK40 magnesium alloy sheets were joined by laser beam welding. The effects of welding parameters on the microstructures and mechanical properties of the joints were studied. The results show that a sound bead, with the ultimate tensile strength of 315 MPa, up to 91.3% of that of base metal, can be obtained with the optimized welding parameters. No columnar grains can be found at the fusion boundary, and the fusion zone (FZ) is characteristic of equiaxed dendritic grains and fine Mg51Zn20 precipitates disperse along the grain boundaries and among the dendritic arms. With the heat input increasing, the grains in FZ get coarser and more dendritic.

Key words: ZK40 magnesium alloy; laser beam welding; microstructure; mechanical property

镁合金具有密度低、比强度和比刚度高、导热性好、电磁屏蔽性佳、对振动和冲击能量吸收性能优异及可回收等优点,是目前非常重要的轻量化结构用绿色工程材料,被广泛应用于航空、汽车、电子和通讯等领域[1-3]。随着镁合金结构件应用范围的不断扩大,其连接问题的解决也变得日益迫切,焊接由于具备其他连接方法所不能比拟的优点受到了极大的关注和重视。可用于镁合金焊接的方法有很多,如:钨极氩弧焊(TIG)、电子束焊(EBW)、激光焊(LBW)、搅拌摩擦焊(FSW)及激光-电弧复合焊等[4-9]。但当前工业生产中对于镁合金的焊接主要还是采用传统的TIG,这种焊接方法由于热输入大、焊接速度低等缺点将导致焊缝和热影响区较宽,晶粒粗大,焊件残余应力大,变形严重,接头性能不理想[4]。而与传统电弧焊不同的是,激光焊接具有较低的热输入、较高的焊接速度及控制精度等优点,可以克服传统电弧焊工艺在焊接镁合金过程中所产生的缺点,是镁合金焊接的优选方法之一[10]。

目前,有关镁合金激光焊接的研究主要集中在Mg-Al-Zn(AZ)、Mg-Al-Mn(AM)等系列合金。宋刚 等[11-12]对AZ31镁合金激光焊接的工艺及显微组织进行了系统的研究,在合适的工艺条件下接头的抗拉强度最高可达96%,焊缝显微组织主要由细小的等轴晶组成。单际国等[13]则对AZ31镁合金焊缝的成形做了详细的研究,结果表明,低功率、高速焊有助于获得深而窄的焊缝。全亚杰等[14]在研究AM60镁合金激光焊接过程中发现,在最优化的焊接工艺条件下,接头成形美观,无明显的缺陷,其抗拉强度可达母材的94%。与常用AZ系、AM系合金相比,Mg-Zn-Zr(ZK)系变形镁合金具有更高的强度、优异的抗应力腐蚀开裂性能及可热处理强化等优点,是目前综合性能最为优异的商用变形镁合金体系之一,并通常以铸造或挤压的方法用于制造轻量化、高强度的航空零部件,如飞机的翼肋、直升飞机的齿轮箱等[3]。但是,此类合金随着Zn含量的增加结晶温度区间迅速宽化、凝固过程中成分偏析加重,在焊接过程中热裂纹倾向变大,从而难以获得性能优异的焊接接头[15]。这极大地限制了ZK镁合金在轻量化结构件中的应用,因此,有必要对激光焊接条件下这类合金的冶金行为及接头性能进行研究。到目前为止,少量关于ZK系列镁合金焊接的研究主要集中在高Zn含量的ZK60和低Zn含量的ZK21[16-17],尚未有关于中等Zn含量ZK系变形镁合金焊接研究的报道。因此,为了研究中等Zn含量ZK镁合金的焊接性能,本文作者采用CO2激光束对ZK40合金进行焊接,分析焊接工艺参数对接头组织和性能的影响,并选择出合理的激光焊接工艺,旨在为中高Zn含量的难焊镁合金在焊接构件中的应用提供技术支持。

1 实验

本实验采用规格为120 mm×50 mm×2 mm的轧制态ZK40镁合金薄板试样,其名义化学成分为Mg-4.0%Zn-0.45%Zr(质量分数)。焊前采用丙酮去除油脂后进行干燥,然后分别用砂纸和钢刷去除氧化膜。为防止焊件变形,焊件两端采用夹具固定。保护气体采用纯度为99.99%的高纯氩气;焊接设备采用GS-TFL-6000W高功率横流CO2激光器及西门子802D自动焊系统。焊接时,试样采用对接接头形式进行拼焊,单面焊双面成型及双面气体保护,不添加任何填充材料,焊接工艺参数设置如表1所示。焊后截取小块接头试样,在5%酒石酸溶液侵蚀5 s,并进行金相观察。采用扫描电镜(JSM-6700F)、具有EDS功能的透射电镜(JEM-3010)及X射线衍射仪(Siemens D5000)对焊缝区的析出相进行观察并分析。另外,将焊件按图1所示的方向和尺寸截取拉伸试样,在WDW-E200微机控制电子万能实验机上进行室温拉伸试验,并在扫描电镜上观察其断口形貌。

表1 焊接参数变化范围

Table 1 Variety of welding parameters

2 结果与分析

2.1 焊缝成型特点

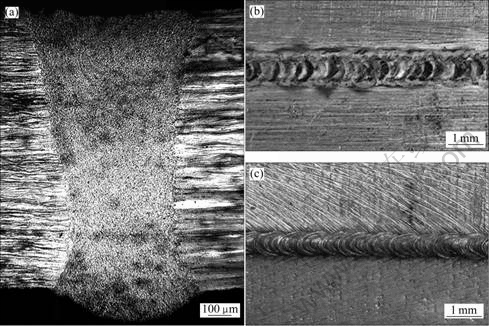

图2(a)所示为ZK40镁合金激光焊接接头的横截面形状。从图2(a)可以看出,焊缝较为狭窄,顶部及根部宽度均小于1 mm,深宽比大于2,为典型的深熔焊接头;除顶部出现微略的凹陷之外,焊缝成型良好,无明显的宏观缺陷。图2(b)和(c)所示分别为焊缝上表面和下表面的宏观形貌。从图2(b)和(c)可以看出,焊缝上下表面均较为连续、平整,成型性较好。

2.2 接头的显微组织

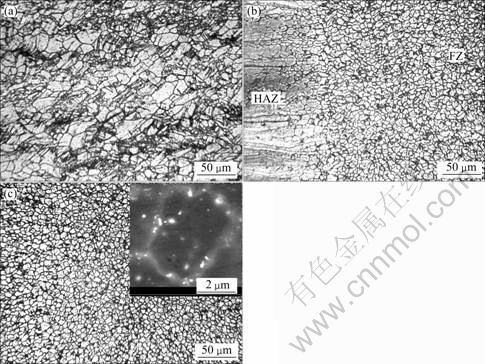

图3所示为ZK40镁合金CO2激光焊接接头各区域的显微组织。从图3(a)中可以看出:母材呈典型的轧制态组织,晶粒大小不均匀,在大晶粒周围分布着由于轧制过程中的动态再结晶作用而形成的细小晶粒。图3(b)所示为熔合线附近的显微组织。由图3(b)

可知,热影响区(HAZ)的晶粒明显发生了再结晶,晶

图1 焊接接头拉伸试样的取样位置及尺寸

Fig.1 Position(a) and geometry((b), (c)) of tensile specimens of welded joint (mm)

图2 焊接接头形貌

Fig.2 Cross-section geometry of welded joint(a) and macrostructures of face(b) and back(c) of weld

粒呈典型的六角晶形状,但没有发生粗化现象,其平均晶粒尺寸约为10 μm。在焊接过程中,位于HAZ区域的轧制态晶粒由于储能较高,在焊接热源的作用下将发生再结晶。再结晶晶粒首先形核再长大,这个过程需要一定的时间周期。但是,由于激光焊接速度快、能量集中,使得热源对HAZ的作用时间短,范围小,导致再结晶晶粒来不及充分长大而保持一个较小的晶粒尺寸范围,这将有助于HAZ保持较优的力学性能。值得注意的是,ZK40镁合金激光焊接接头的熔池边界并不存在外延生长的柱状晶,整个熔池区(FZ)完全由细小的等轴树枝晶组成,如图3(b)和(c)所示。均匀细小的晶粒有助于提高焊缝的力学性能。一般来说,从熔池边界到中心晶粒的凝固方式会随着G/R(G为温度梯度;R为生长速率)值的减小而变化,依次为平面→胞状→柱状树枝→等轴树枝[18]。但这一凝固方式的变化同时也受到焊缝合金成分和含量的影响。ZK40镁合金由于Zn含量较高,则在一定的G/R比值范围内,整个熔池区范围的金属熔体将以等轴树枝晶形式凝固,而不像常见焊缝组织有一定的凝固组织变化梯度[18]。再者由于ZK40合金中存在强形核元素Zr,为焊缝金属形核提供了大量的异质形核质点,有利于等轴树枝晶的形成。与母材相比,熔池区的晶粒组织明

图3 焊接接头不同区域的显微组织

Fig.3 Microstructures of welded joints: (a) Base metal; (b) Fusion boundary; (c)FZ

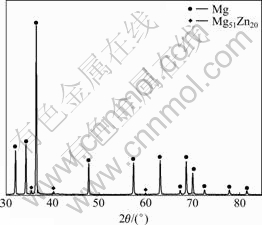

显细化,其平均晶粒尺寸仅为5 μm,如图3(c)所示。一方面,这主要是由于激光焊接过程中焊件的冷却速度很快,熔池很快凝固,使得焊缝组织得到细化;另一方面由于晶粒细化剂Zr元素的异质形核作用,以及熔池中溶质原子Zn的浓度较高而产生了过冷,从而促进了液态金属的形核率[1],细化焊缝晶粒。此外,从图3(c)中还可以发现,在熔池区晶粒的内部及晶界处分布着许多粒度不均的第二相颗粒。通过对焊缝金属的XRD分析(见图4)及对颗粒较大的第二粒子的能谱分析(见图5)显示,第二相主要为Mg51Zn20。Mg51Zn20是Mg-Zn合金的共晶,其熔点仅为341 ℃[1]。这种相的出现对ZK40合金焊接接头的高温性能是不利的。

图4 熔池区的XRD谱

Fig.4 XRD pattern of FZ

图5 焊缝中第二相粒子的形貌及能谱图

Fig.5 SEM image(a) and EDS analysis(b) of precipitated particles in FZ

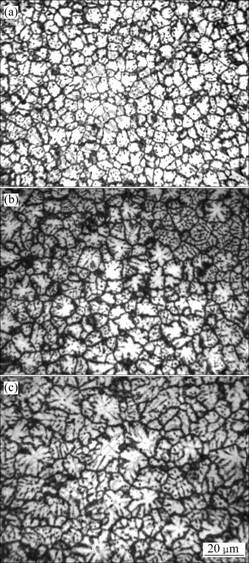

尽管激光焊接过程中热输入很低,但是工艺参数的改变也会造成熔池区凝固组织的不同。图6所示为焊接速度为3 m/min时不同功率条件下ZK40镁合金接头熔池区的凝固组织。对比图6(a)、(b)和(c)可以明显地看出,在焊接速度一定的条件下,随着激光功率的降低,熔池区的晶粒尺寸变小,其形貌由原来的等轴树枝晶转变为等轴晶。据报道,提高焊接速度或者降低激光功率,会减少焊接热输入并引起焊接熔池区体积变小,因此,可以提高熔池区中熔体在凝固过程中的冷却速率[18]。凝固时,提高冷却速率有助于促进熔池区熔体的结晶形核,并缩短晶粒的生长时间,从

图6 焊接速度为3 m/min时不同激光功率条件下熔池区的显微组织

Fig.6 Microstructures of FZ under constant welding speed of 3 m/min with different laser powers: (a) 1 000 W; (b) 1 200 W; (c) 1 400 W

而可以细化熔池区的晶粒尺寸,并抑制其枝晶臂的长大[19]。由此可知,降低焊接热输入有利于获得晶粒细小的焊缝组织。

2.3 接头的力学性能

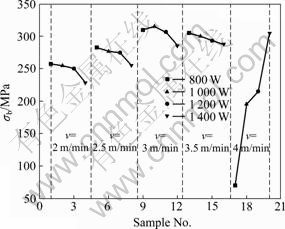

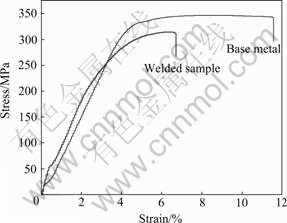

图7所示为不同焊接工艺参数条件下接头的抗拉强度。由图7可以看出,激光功率和焊接速度对焊接接头的拉伸性能以及焊缝熔深均有很大的影响。当焊接速度较大而焊接功率较低时,将会得到未焊透的接头,如焊接速度为4 m/min、激光功率低于1 400 W的焊接试样(见表1)。相反地,焊接接头则会宽化,随着焊缝的宽化,其中存在的焊接缺陷特别是热裂纹也会相应增加[18],这将严重恶化焊接接头的力学性能;同时当焊接速度较低时,其焊接热输入则增大,接头组织相应粗化,这也会降低焊接接头的力学性能。由图7可知,当焊接速度为2 m/min时,接头的抗拉性能较差。因此,为了获得组织和性能良好的焊接接头,要选择合适的焊接工艺参数。对于ZK40镁合金的激光焊接,当焊接速度为3 m/min、激光功率为1 000 W时,所得到的接头抗拉性能最好,其抗拉强度高达 315 MPa,为母材的91.3%,其拉伸曲线如图8所示。

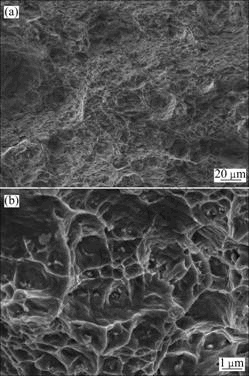

拉伸试验表明,接头的断裂均发生于焊缝区,其典型断口形貌如图9所示。从图9(a)可以看出,解理台阶与韧窝在断面上并存,但韧窝尺寸较小、深度较浅。这说明,断裂的脆性较大,呈混合型断裂特征。对断口进一步放大观察可以发现,韧窝的底部有尺寸较大的第二相粒子存在(见图9(b))。这说明,在拉伸试验过程中,断裂首先在这些大尺寸第二相粒子的表面与基体界面处脱开而开始。因此,大颗粒第二相的

图7 不同焊接工艺参数条件下焊接接头的抗拉强度

Fig.7 Ultimate tensile strength (UTS) of laser welded ZK40 magnesium alloy samples under different welding conditions

图8 ZK40母材和CO2激光焊接试样的应力—应变曲线

Fig.8 Stress—strain curves for ZK40 base metal and CO2 laser beam welded sample

图9 ZK40镁合金CO2激光焊接试样断口的SEM像

Fig.9 SEM image of tensile fracture at room temperature

存在对焊缝的强度是不利的。此外,由于焊缝组织为完全铸态,焊缝中存在裂纹、气孔和夹杂等缺陷要比母材的多,同时激光焊接头的HAZ组织并没有粗化,所以,焊缝区则成了焊接接头的薄弱区域,拉伸断裂常发生在此区域,并且接头的断口伸长率明显降低,即使最优试样的伸长率也仅为母材的56%。

3 结论

1) 采用CO2激光束能对ZK40高强镁合金板材进行了焊接。在焊接速度为3 m/min,激光功率为1 000 W的条件下,接头成型良好,无明显的缺陷,其抗拉强度可达到315 MPa,为母材的91.3%。

2) 在最优的工艺条件下,熔池边界无外延生长的柱状晶,整个熔池区均由细小的等轴树枝晶组成;分布于枝晶间及晶界处的第二相粒子主要为Mg51Zn20。随着焊接热输入的增大,晶粒的枝晶臂生长更为发达,晶粒尺寸增大。

3) 由于激光焊接较低的热输入,ZK40镁合金焊接接头的热影响没有发生明显的晶粒长大,因而拉伸断裂均发生在较弱的熔池区;断裂模式为混合型断裂。

REFERENCES

[1] 陈振华, 严红革, 陈吉华, 全亚杰, 王慧敏, 陈 鼎. 镁合金[M]. 北京: 化学工业出版社, 2004: 325-384.

CHEN Zhen-hua, YAN Hong-ge, CHEN Ji-hua, QUAN Ya-jie, WANG Hui-min, CHEN Ding. Magnesium alloy[M]. Beijing: Chemical Industry Press, 2004: 325-384

[2] 曾荣昌, 柯 伟, 徐永波, 韩恩厚, 朱自勇. Mg合金的最新发展及应用前景[J]. 金属学报, 2001, 37(7): 673-685.

ZENG Rong-chang, KE Wei, XU Yong-bo, HAN En-hou, ZHU Zi-yong. Recent development and application of magnesium alloys[J]. Acta Metall Sin, 2001, 37(7): 673-685.

[3] AVEDESIAN M M, BAKER H. ASM specialty handbook: Magnesium and magnesium alloys[M]. Materials Park: ASM International, 1999: 16-19.

[4] 苗玉刚, 刘黎明, 赵 杰, 于德凯. 变形镁合金熔焊接头组织特征分析[J]. 焊接学报, 2003, 24(2): 63-66.

MIAO Yu-gang, LIU Li-ming, ZHAO Jie, YU De-kai. Microstructure feature analysis of fusion welded joint of wrought Mg-alloy[J]. Transactions of the China Welding Institution, 2003, 24(2): 63-66.

[5] MARYA M, EDWARDS G R, LIU S. An investigation on the effects of gases in GTA welding of a wrought AZ80 magnesium alloy[J]. Welding Journal, 2004, 83(7): 203-212.

[6] 王红英, 李志军, 陈斐明. AZ31镁合金薄板的CO2激光焊接接头性能[J]. 焊接, 2006(3): 47-50.

WANG Hong-ying, LI Zhi-jun, CHEN Fei-ming. Properties of the CO2 laser welded joint of AZ31 magnesium alloy sheet[J]. Welding, 2006(3): 47-50.

[7] 王红英, 李志军. AZ61镁合金激光焊接接头的组织与性能[J]. 中国有色金属学报, 2006, 16(8): 1388-1393.

WANG Hong-ying, LI Zhi-jun. Microstructure and properties of AZ61 magnesium alloy joints produced by laser welding method[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(8): 1388-1393.

[8] COMMIN L, DUMONT M, MASSE J E, BARRALLIER L. Friction stir welding of AZ31 magnesium alloy rolled sheet: Influence of processing parameters[J]. Acta Materialia, 2009, 57(8): 326-334.

[9] LIU Li-ming, SONG Gang, WANG Ji-feng, et al. Microstructure and mechanical properties of wrought magnesium alloy AZ31B welded by laser-TIG hybrid[J]. Trans Nonferrous Met Soc China, 2004, 14(3): 550-555.

[10] 冯吉才, 王亚荣, 张忠典. 镁合金焊接技术的研究现状及应用[J]. 中国有色金属学报, 2005, 15(2): 165-178.

FENG Ji-cai, WANG Ya-rong, ZHANG Zhong-dian. Status and expectation of research on welding of magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(2): 165-178.

[11] 宋 刚, 刘黎明, 王继锋, 许德胜. 变形镁合金AZ31B的激光焊接工艺研究[J]. 应用激光, 2003, 23(6): 327-329.

SONG Gang, LIU Li-ming, WANG Ji-feng, XU De-sheng. Study of YAG laser welding process on wrought magnesium[J]. Applied Laser, 2003, 23(6): 327-329.

[12] 王继锋, 刘黎明, 宋 刚. 激光焊接AZ31B镁合金接头微观组织特征[J]. 焊接学报, 2004, 25(3): 15-18.

WANG Ji-feng, LIU Li-ming, SONG Gang. Microstructure character of YAG laser welding AZ31B Mg alloy[J]. Transactions of the China Welding Institution, 2004, 25(3): 15-18.

[13] 单际国, 雷 祥, 谭稳达, 张红军, 陈武柱, 任家烈. AZ31B变形镁合金CO2激光焊接模式及焊缝成形特点[J]. 焊接学报, 2008, 29(4): 9-12.

SHAN Ji-guo, LEI Xiang, TAN Wen-da, ZHANG Hong-jun, CHEN Wu-zhu, REN Jia-lie. Welding modes and weld formation characteristics of CO2 laser welding of wrought magnesium alloy AZ31B[J]. Transactions of the China Welding Institution, 2008, 29(4): 9-12.

[14] 全亚杰, 陈振华, 黎 梅, 俞照辉, 龚晓叁. AM60 变形镁合金薄板激光焊接接头的组织与性能[J]. 中国有色金属学报, 2007, 17(4): 525-529.

QUAN Ya-jie, CHEN Zhen-hua, LI Mei, YU Zhao-hui, GONG Xiao-san. Microstructure and properties of joints of wrought magnesium alloy AM60 plates welded by laser beam welding[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(4): 525-529.

[15] KEARNS W H. Welding handbook[M]. Miami: American Welding Society, 1982: 396.

[16] VILUKIN, DOBRYNINA I S. Weldability of cast magnesium alloys of the Mg-Zn-Zr system[J]. Welding International, 1998, 12(10): 801-803.

[17] YU Z H, YAN H G, GONG X S, QUAN Y J, CHEN J H, CHEN Q. Microstructure and mechanical properties of laser welded wrought ZK21 magnesium alloy[J]. Materials Science and Engineering A, 2009, 523(1/2): 220-225.

[18] KOU S. Welding metallurgy[M]. Hoboken: Wliley-Interscience, 2002: 196-197.

[19] 胡赓祥, 蔡 珣. 材料科学基础[M]. 上海: 上海交通大学出版社, 2000: 217-218.

HU Gen-xiang, CAI Xun. Scientific foundation of materials[M]. Shanghai: Shanghai Jiao Tong University Press, 2000: 217-218.

(编辑 龙怀中)

基金项目:高等学校博士学科点专项科研基金资助项目(20070532087)

收稿日期:2010-03-18;修订日期:2010-06-18

通信作者:严红革,教授,博士;电话:0731-88664005;传真:0731-88821611;E-mail: yanhg68@163.com