文章编号:1004-0609(2009)07-1203-06

Be/AlSi/Be激光焊接接头的显微组织

李玉斌,蒙大桥,刘柯钊,谢志强,李盛和

(中国工程物理研究院,绵阳 621900)

摘 要: 以AlSi合金为过渡材料,运用激光焊接技术实现Be与Be的连接;采用扫描电镜、纳米压痕仪及透射电镜对焊接接头的显微组织、剪切断口形貌及性能进行研究。结果表明:熔合区和焊缝区组织由Be与AlSi合金形成的复合相构成,焊缝区显微硬度和弹性模量分别为2 GPa和140 GPa,熔合区宽度约10 μm;焊接接头剪切强度约为283 MPa,剪切断口具有以准解理为主并伴有塑性的混合型断口特征,熔合区附近热应力诱发的微裂纹、焊缝中的金属间化合物和气孔是导致焊接接头失效的主要原因。

关键词:铍;铝硅合金;激光焊接;微观组织

中图分类号:TG 146.2+4 文献标识码:A

Microstructure of Be/AlSi/Be welding joint by laser

LI Yu-bin, MENG Da-qiao, LIU Ke-zhao, XIE Zhi-qiang, LI Sheng-he

(China Academy of Engineering Physics, Mianyang 621900, China)

Abstract: Using AlSi alloy as transition material, beryllium with beryllium was welded by laser. The microstructure and performance of the welding joint were studied by means of nanoindentation apparatus, scanning electron microscope (SEM), electron probe microanalysis (EPMA) and transmission electron microscope (TEM). The results indicate that the microstructure of weld and fusion zone for the Be/AlSi/Be laser welding joint is composed of compound phase formed by beryllium and AlSi alloy, and the microhardness and elastic modulus of welding zone are 2 GPa and 140 GPa. The concentration distributions of Al and Si show that the width of fusion zone is about 10 μm. The shear strength of Be/AlSi/Be welding joint is 283 MPa. The characteristic of shear fractographs is quasi-cleavage with local ductile dimples. According to the analysis for shear fractographs, the micro-crack made by welding thermal stress, intermetallic compounds and gas porosities formed in welding zone are the main cause leading to brittle rupture for welding joint.

Key words: beryllium; AlSi alloy; laser welding; microstructure

铍是低原子序数材料,具有一系列优越特性,在核工业和航空航天领域有广泛的需求背景[1?3],BRUNDIGE[4]在20世纪50年代就开始采用碳弧焊、气体保护焊等来研究铍与铍的焊接,然而铍焊接性较差,焊接过程中容易产生各种焊接缺陷,阻碍了铍的工程化应用。到目前为止,电子束焊、钎焊和扩散 焊[5?8]被公认为较好的铍焊接方法。由于铍与铍直接焊 接难度很大,研究者[9?13]大多采用在铍焊缝中添加过渡材料(Al-Si、Al-Cu或Al-Mg),使铍与铍的连接转化为铍与过渡材料间的连接,以改善铍的工艺焊接性。在中国,铍焊接研究起步较晚,涉及铍熔化焊接技术的文献不多,李盛和等[14]研究了激光焊接工艺参数对铍裂纹敏感性的影响,获得了激光输入功率与裂纹出现概率间的一些关系。

本文作者采用连续Nd?YAG激光焊机,研究以AlSi合金作为过渡材料的Be/AlSi/Be激光焊接工艺,利用扫描电镜(SEM)、纳米压痕仪、电子探针(EMPA)、透射电镜(TEM)详细分析焊接接头的显微组织与性能。该研究工作对于深入研究铍的激光焊接性,拓展铍材应用范围,具有重要的理论及现实意义。

1 实验

实验材料为热等静压铍(HIP)和AlSi合金,其主要化学成分如表1所列。铍环加工成外径30 mm、内径26 mm,并开止口,AlSi合金过渡环尺寸为外径30 mm,内径27 mm,厚度0.4 mm,AlSi环镶嵌在被焊两铍环间。典型的Be/AlSi/Be激光焊接工艺为:试件预热 100 ℃、激光功率1 500 W、焊接速度600 mm/min。

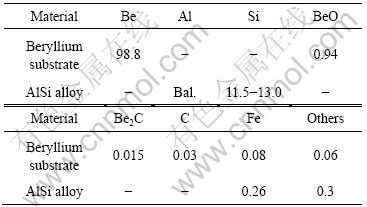

表1 Be和AlSi合金的化学成分

Table 1 Chemical composition of Be and AlSi alloy (mass fraction)

切取焊接接头试样并用氢氟酸、硝酸和盐酸混合溶液蚀刻。利用TriBolndenter纳米压痕仪测量焊接接头各区域的显微硬度和弹性模量,采用IXA?80扫描电镜(SEM)、电子探针(EPMA)观察和分析焊接接头显微组织形貌和剪切断口特征,采用H800透射电镜(TEM)和选区电子衍射技术分析焊接接头熔合区形成相微观形貌和分布形态。

2 结果与分析

2.1 焊接接头显微组织

2.1.1 组织形貌

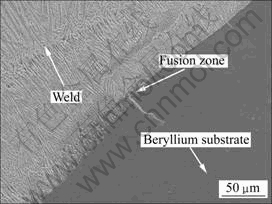

采用扫描电镜观察Be/AlSi/Be焊接接头显微组织,图1所示为焊接接头的微观形貌。

由图1中可看出,焊接接头主要由焊缝区构成,熔合区和焊接热影响区很窄,出现这种现象的原因应该与正确选取AlSi合金作为过渡材料和制订适当的激光焊接工艺有关。因为添加过渡材料方法实现铍与铍熔焊连接,熔合区和热影响区是容易产生焊接缺陷的区域,在保证焊接接头有效连接情况下,应该尽量缩小这两个区的范围,以降低焊接接头出现缺陷的几率。

图1 激光焊接接头微观组织

Fig.1 Microstructure of laser welding joint

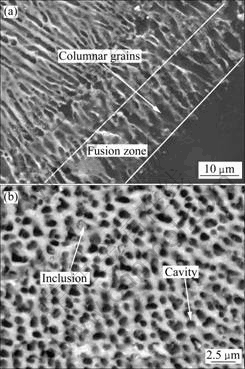

对熔合区进一步扫描电镜观察,发现热影响区与熔合区之间存在明显的界线(图2(a))。熔合线上,铍晶粒以非自发结晶的柱状晶形态,垂直于基体向熔合区延伸生长,AlSi合金(图2(a)中白色组织)在熔合区内以枝晶形式与铍晶粒相互啮合,随着晶粒向焊缝区生长,铍晶粒形貌由柱状晶逐步向等轴晶转变。由图2(b)可以看出,AlSi合金等轴晶组织和分布在等轴晶上的

图2 熔合区与焊缝中心的微观组织

Fig.2 Microstructure of center on fusion(a) and weld(b) zone

微小孔洞构成了焊缝中心形貌。采用EPMA对孔洞元素表征,发现多数孔洞所含元素为Be、Al、Si,根据Be-Al、Be-Si、Al-Si二元相图和激光焊接热循环特点,Be与Al、Si不会形成金属间化合物和新相。因此,本文作者认为焊缝中心出现孔洞的原因是熔池凝固时,由熔池金属流动而带入到焊缝中心的液态铍首先结晶,在快速冷却条件下铍来不及长大,以细小颗粒形式弥散分布在随后凝固的AlSi合金基体上,这些铍颗粒在金相蚀刻时被腐蚀脱落,最终在照片上显示焊缝中心出现了孔洞。基于上述分析可以判定Be/AlSi/ Be焊接接头熔合区和焊缝区是由Be与AlSi合金的复合相组织构成。

2.1.2 元素成分分析

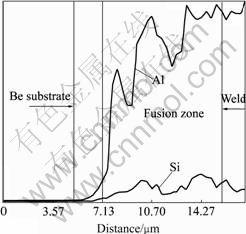

图3所示为焊接接头熔合区附近Al、Si元素分布。

图3 激光焊接接头熔合区附近的元素分布

Fig.3 Element distribution near fusion zone

从热影响区向焊缝区EPMA线扫描,由图3可知,在5~15 μm范围,Al、Si元素计数点呈现逐渐上升趋势,其余区域计数则没有明显的起伏与波动,这说明在本文中所采用焊接工艺条件下形成的Be/AlSi/Be焊接接头熔合区宽度约为10 μm。

2.2 焊接接头显微硬度

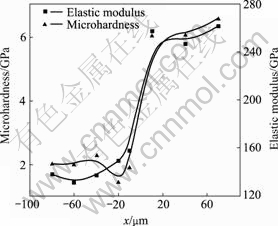

对焊接接头进行了显微硬度和弹性模量测定,结果如图4所示。试验载荷为焊缝和熔合区15 μN、热影响区30 μN,加载时间15 s。

图4 焊接接头熔合区附近的显微硬度和弹性模量

Fig.4 Microhardness and elastic modulus of laser welded joint near fusion zone

实验测得焊缝区的显微硬度和弹性模量分别为 2 GPa和140 GPa,略大于AlSi合金的相应值0.9 GPa和120 GPa(其原因应该与焊缝金属中含有铍颗粒有关),但远小于Be基体的显微硬度和弹性模量(Be的显微硬度为7 GPa,弹性模量为250 GPa)。从图4可知,熔合区内显微硬度和弹性模量平滑地从热影响区向焊缝区过渡,这种硬度和模量过渡形式使接头熔合区在受力状态下不会因为出现明显应力集中而导致过早失效,为焊接接头获得良好的力学性提供了保证。

2.3 接头剪切断口形貌及断裂分析

2.3.1 焊接接头剪切断口SEM分析

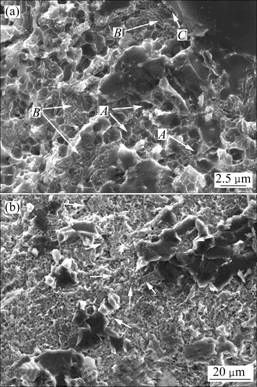

剪切实验结果显示典型工艺条件下的Be/AlSi/Be焊接接头平均剪切强度为283 MPa。从剪切断口的扫描电镜照片(见图5)来看,断口表面形貌具有以准解理断裂为主,伴有局部塑性断裂的混合断口特征。

图5 激光焊接接头剪切断口形貌(SEM)

Fig.5 Morphologies of shear fracture surface for laser welded joint: (a) Center of weld zone; (b) Near fusion zone

从图5(a)中A箭头所指可以发现,接头剪切断口表面具有韧窝,但是韧窝比较浅和小。在图5(a)中B箭头处发现其断口表面有很多较为平坦的准解离面,这些准解理面上可以清楚地看到河流状花纹,在一些准解理面边缘还可以发现细小的裂纹(如图中箭头C所示)。图5(b)中箭头所指处显示断口表面存在沿晶裂纹,是剪切断面沿晶界开裂后留下的痕迹,同时断口表面出现大量散乱的金属间化合物凸起,这些凸起物呈现一定的层状或阶梯状准解理形貌。由此可知,Be/AlSi/Be激光焊接接头在剪切试验中属于脆性断裂失效。

2.3.2 焊接接头断裂分析

Be/AlSi/Be激光焊接接头的剪切断裂机制十分复杂,过渡材料与铍物理性能的差异、焊接过程中形成的氧化物夹杂和气孔等,都是导致接头失效的原因。

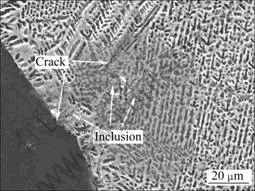

1) 焊接材料的影响

Be与AlSi合金的热传导系数和线膨胀系数不同,焊后必定在熔合区附近产生较大残余热应力,如果在焊接过程中侵入了有害元素生成金属或非金属化合物,在二者共同作用下,容易诱发在熔合区附近产生微裂纹。图6所示为熔合区附近的显微组织。由图6可知,在焊接接头熔合区杂质相附近存在龟裂状细小裂纹,在应力作用下,这将是焊接接头断裂的起点之一。

图6 熔合区附近显微组织

Fig.6 Microstructure near fusion zone

2) 脆性相的影响

焊缝中的脆性化合物对接头的断裂形式有重要的影响。Be、Al化学性质都很活泼,容易与进入焊缝中的氧结合生成氧化物,继而形成复杂的金属间化合物相。由于脆性化合物相与Be基体和焊缝金属的力学性能及晶体结构存在明显差异,在应力作用下,脆性化合物附近容易产生裂纹,并最终导致焊接接头断裂。

采用EMPA分析焊接接头剪切断口表面凸起物主要由Be、Al、O等元素组成,根据元素含量(摩尔分数)和这3种元素间有可能形成的化合物的生成吉布斯自由能高低[15],推测凸起物可能为BeO?xAl2O3金属间化合物,在应力作用下,此处容易成为断裂源。

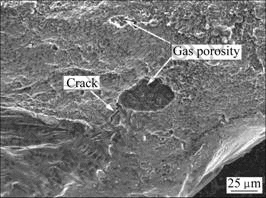

3) 焊接气孔的影响

图7所示为剪切断口表面气孔和裂纹形貌。由图6可知,剪切断口表面存在少量气孔,而且一些气孔附近出现了微裂纹。

图7 剪切断口表面气孔和裂纹形貌

Fig.7 Morphology of gas porosity and crack on shear fracture surface

气孔是以铝基合金为过渡材料的铍激光焊接中常见的缺陷,形成气孔的原因是焊接保护气氛或被焊部位氧化膜中含有H2O,高温下H2O分解产生H溶解于熔池,当焊缝凝固时,H来不及逸出而残留在焊缝中形成气孔。气孔不仅会削弱焊缝的有效工件断面,同时也会使焊接接头产生应力集中,显著降低焊缝金属的强度和韧性,因而气孔也有可能是Be/AlSi/Be激光焊接头的断裂源。

2.4 激光焊焊接接头熔合区TEM分析

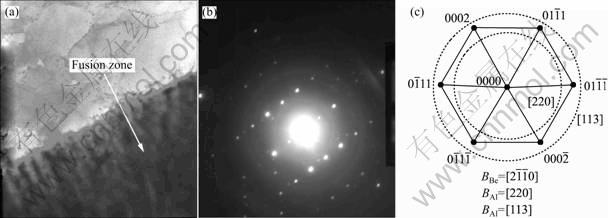

一般而言,熔合区是焊接接头的薄弱部位,因此实验采用透射电镜(TEM)对Be激光焊接接头熔合区附近的精细结构进行了深入分析。图8所示为接头熔合区的TEM形貌、选区电子衍射图及指数标定结果。

图8(a)所示为熔合区附近TEM像,由图8(a)可看出,熔合区由两相组成,铍晶粒沿熔合线以非自发形核柱状晶模式向焊缝生长,随着铍在熔合区内含量的降低,晶粒尺寸也逐步减小,而铝硅合金则间隔在相邻铍晶粒间以枝晶形式向焊缝生长,二者结合十分紧密。图8(b)所示为熔合区内铍晶界处选区电子衍射 谱,其特征是强衍射斑点伴随弱多晶环。经标定,衍射花样中的强衍射斑点对应密排六方结构(HCP)的Be,BBe=[ ];弱衍射环表征面心立方(FCC) 结构Al相的BAl=[220]和BAl=[113]。虽然限于试样制备的精度,只在熔合线附近发现了Al和Be相,未发现Si相,但分析认为此时的Si应该和Al形成共晶相或亚共晶。因此,研究认为熔合区铍和铝硅合金结合处没有除上述两种材料的新相生成,铍材与过渡材料AlSi合金在熔合区的结合方式有助于提高焊接接头的力学性能。

];弱衍射环表征面心立方(FCC) 结构Al相的BAl=[220]和BAl=[113]。虽然限于试样制备的精度,只在熔合线附近发现了Al和Be相,未发现Si相,但分析认为此时的Si应该和Al形成共晶相或亚共晶。因此,研究认为熔合区铍和铝硅合金结合处没有除上述两种材料的新相生成,铍材与过渡材料AlSi合金在熔合区的结合方式有助于提高焊接接头的力学性能。

图8 熔合区的TEM分析

Fig.8 TEM analysis near fusion zone: (a) TEM morphology; (b) Electron diffraction pattern; (c) Schematic index diagram of panel(b)

3 结论

1) 焊接接头焊缝区和熔合区组织由Be与Al形成的复合相构成,有利于焊接接头的塑性变形,提高接头的综合力学性能。

2) 焊接接头主要由焊缝区构成,熔合区的宽度大约为10 μm,焊缝区显微硬度和弹性模量分别为2 GPa和140 GPa,熔合区内显微硬度和弹性模量过渡平滑,使熔合区在受力状态下不会因为产生明显应力集中而导致过早失效,为焊接接头获得良好的力学性提供了保证。

3) 焊接接头剪切强度为283 MPa,剪切断口呈现以准解理为主并伴有塑性的混合型断口特征,熔合区附近热应力诱发的微裂纹、焊缝中的金属间化合物和气孔是导致焊接接头失效的裂纹源。

致谢:

本研究内容受中国工程物理研究院重点基金支持,姜云波、何建军协助完成激光焊接工艺实验,在此一并表示感谢。

REFERENCES

[1] 孙本双. 铍的应用进展[J]. 稀有金属, 1995, 19: 127?131.

SUN Ben-shuang. Advanced in beryllium application[J]. Chinese Journal of Rare Metals, 1995, 19: 127?131.

[2] KLEYKAMP H. Thermal properties of beryllium[J]. Thermochimica Acta, 2000, 345: 179?184.

[3] ASSMORE E M. Fusion welding of beryllium[J]. Welding Journal Research Supplement, 1964, 43(3): 116?119.

[4] BRUNDIGE E L. Welding of beryllium[J]. Welding Journal Research Supplement, 1959, 38(10): 410?414.

[5] HAUSER D. Electron beam welding of beryllium[J]. Welding Journal Research Supplement, 1967, 46: 525?529.

[6] 张鹏程, 王庆富, 伍绍萍. 铍与HR-1不锈钢感应钎焊界面特性研究[J]. 稀有金属, 2001, 25(6): 419?422.

ZHANG Peng-cheng, WANG Qing-fu, WU Shao-ping. Characteristics of interface between beryllium and HR-1 stainless steel by induction brazing[J].Chinese Journal of Rare Metals, 2001, 25(6): 419?422.

[7] KALIN B, FEDOTOV V, SEVRYUKOV O, PLYUSCHEV A, MAZUL I, GERVASH A, GINIATULIN R. Be-Cu joints based on amorphous alloy brazing for divertor and first wall application[J]. Journal of Nuclear Materials, 1999, 212?271: 410?414.

[8] KHOMU TOV A, BARABASH V. Beryllium for fusion application-recent results[J]. Journal of Nuclear Materials, 2002, 307?311: 630?637.

[9] HICKEN G K. Joining beryllium by electron beam braze welding technique[J]. Welding Journal Research Supplement, 1967, 46(12): 541?558.

[10] SCAFFIDI-ARGENTINA F, LONGHURST G R, SHESTAKOV V, KAWAMURA H. The status of beryllium technology for fusion[J]. Journal of Nuclear Materials, 2000, 283?287: 43?51.

[11] WATSON R D, YOUCHISON D L, DOMBROWSKI D E, GUINIATOULINE R N, KUPRIYNOV I B. Low cycle thermal fatigue testing of beryllium[J]. Fusion Engineering and Design, 1997, 37: 553?579.

[12] COTTON J D, FIELD R D. Microstructural Features of cracking in autogenous beryllium weldments[J]. Metallurgical and Materials Transactions, 1997, 28A(3): 673?680.

[13] BONFIELD W, LI C H. The Microstrain characteristics of beryllium[M]. Philadelphia: Gordon and Breach Science Publishers, Inc, 1966: 539?567.

[14] 李盛和, 谢志强, 姜云波, 吴东周, 张友寿. 铍的YAG激光焊接裂纹敏感性研究宇[J]. 航材料工艺, 2005, 35(3): 43?47.

LI Sheng-he, XI Zhi-qiang, JIANG Yun-bo, WU Dong-zhou, ZHANG You-shou. Sensitivity to cracking of beryllium by YAG laser welding[J]. Aerospace Materials & Technology, 2005, 35(3): 43?47.

[15] 梁英教, 车荫昌, 刘小霞. 无机物热力学数据手册[M]. 沈阳: 东北大学出版社, 1994: 449?473.

LIANG Ying-jiao, CHE Yin-chang, LIU Xiao-xia. Manual of the thermo-physical data on mineral material[M]. Shengyang: Northeastern University Press, 1994: 449?473.

基金项目:中国工程物理研究院重大基金资助项目(2005Z0302)

收稿日期:2008-12-17;修订日期:2009-03-13

通讯作者:李玉斌,博士;电话:0816-3626940; E-mail: zaoxiao496@sohu.com

(编辑 李向群)