文章编号:1004-0609(2015)-01-0001-08

TC11高强钛合金激光焊接接头的显微组织与力学性能

虞鸿江1,范如意2,黄 坚1,潘丽华2,王 勇2

(1. 上海交通大学 上海市激光制造与材料改性重点实验室,上海 200240;

2. 上海新力动力设备研究所,上海 201109)

摘 要:采用光纤激光进行TC11钛合金对接焊接,分析焊接接头的显微组织和力学性能。结果表明,TC11钛合金焊缝为α′马氏体组织,从母材至熔合线组织由α+β逐渐向α′ 转变;随着热输入量的增加,焊缝柱状晶尺寸变大,马氏体分布更加密集交错,同时热影响区宽度增加,粗晶区晶粒尺寸变大;2 mm厚TC11钛合金在焊接速度2.0 m/min、激光功率2.8 ~3.2 kW的工艺参数下得到的焊缝成形良好;焊缝硬度高于母材硬度,并随热输入量的增加而增大;焊接接头抗拉强度达到母材的97 %以上,塑性明显下降,低于母材的50%,焊缝断口形貌为低塑性沿晶断裂特征。

关键词:TC11钛合金;激光焊接;显微组织;力学性能

中图分类号:TG456.7 文献标志码:A

Microstructure and mechanical properties of high-strength TC11 titanium alloy joints welded by laser beam

YU Hong-jiang1, FAN Ru-yi2, HUANG Jian1, PAN Li-hua2, WANG Yong2

(1. Shanghai Key Laboratory of Materials Laser Processing and Modification,

Shanghai Jiao Tong University, Shanghai 200240, China;

2. Shanghai Xin Li Institute of Power Equipment, Shanghai 201109, China)

Abstract: The titanium alloy TC11 was welded by fiber laser beam, the microstructure and mechanical properties of the laser welded TC11 joints with different welding parameters were studied. The results show that the microstructure of weld metal consists of α′ martensite. From the base metal to fusion line, the microstructure evolves from α+β phase to α′ phase. With increasing the heat input, the size of columnar dendrites increases, the distribution of α′ martensite becomes more dispersive, the width of HAZ and grain size in coarse grain zone increase. Under the welding speed of 2.0 m/min and laser power of 2.8-3.2 kW, the sound welds of 2 mm thick TC11 alloy were obtained. The hardness of the weld increases with increasing the heat input. The tensile strength of welded joints reaches at least 97% of that of the base metal, while the plasticity decreases significantly. The fracture topography of welded joints shows brittle fracture character.

Key words: TC11 titanium alloy; laser beam welding; microstructure; mechanical property

钛及钛合金是极其重要的轻质合金材料,具有比强度高,抗腐蚀能力强,耐高温、低温性能好,无磁性等优良的性能,在航空、航天、车辆工程、石油、化工、冶金、机械和生物医学等方面得到了广泛的应用。

TC11是一种马氏体型α+β双相热强型钛合金,合金成分为Ti-6.5Al-3.5Mo-1.5Zr-0.3Si,在500 ℃仍然可以保持较高的性能,已广泛用于航空关键构件,主要用于制造航空器发动机的压气机盘、叶片、环形件、鼓筒和紧固件等零件[3-4]。随着TC11钛合金的广泛使用,对其焊接性的研究也显得日益重要。目前,针对TC11钛合金焊接的研究已有报道,采用钨极氩弧焊[5]获得了成形良好的焊缝,使用TC11同质焊丝可获得与母材抗拉强度相当的焊接接头,略高于使用TA2纯钛焊丝的接头,但使用TA2焊丝时的塑性接近母材的塑性;采用电子束焊[6-8]方法得到的焊接接头冲击韧性优于母材的,同时得出焊缝气孔的产生与增氢有关;采用摩擦焊[9-11]方法得到焊接接头的拉伸强度超过母材的,塑性接近母材的。但针对TC11钛合金,目前国内外均未有激光焊接方面的研究,相似的热强型钛合金如Ti6Al2Sn4Zr2Mo(Ti6242)[12-13]在激光焊接方面有一定的研究,得到质量可靠的接头,但关于焊缝组织以及焊接工艺参数对焊缝微观组织影响的研究甚少。激光焊接具有能量密度高、焊接线能量小、焊接速度高、焊缝深宽比大、热影响区(HAZ)窄、焊件变形极小、非接触和无需真空等特点,相较于以上方法具有独特的优势[14]。目前,高强钛合金激光焊接方面以Ti6Al4V的研究为主,研究表明激光束很适合钛合金的焊接,尤其在薄板和精密零件的焊接上有很大的应用前景[15-19]。

在此,本文作者采用光纤激光对TC11钛合金薄板进行焊接,对不同激光功率下焊接接头的组织进行观察,研究焊接热输入对接头显微组织的影响,同时对不同焊接热输入下接头的力学性能进行评价,分析接头组织对力学性能的影响,为TC11钛合金激光焊接的实际应用提供理论依据。

1 实验

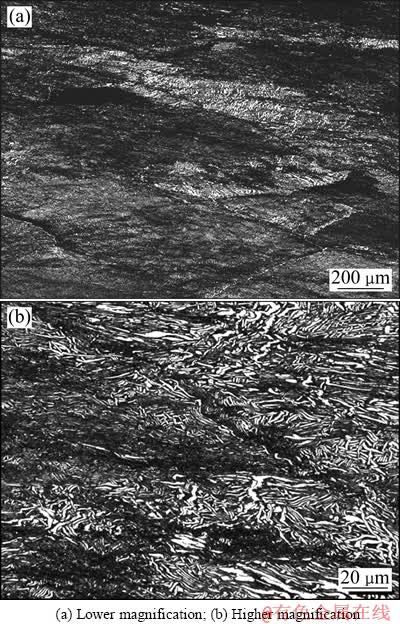

试验材料为经旋压加工后的退火态TC11钛合金薄板,厚度为2 mm,其组织形貌如图1所示。母材组织特征为粗大的原始β晶粒,冷却过程中粗大β晶粒发生组织转变,形成层片状转变组织,图1中白色α相由β中间相分开,沿原始β晶粒有α镶边[20]。经热旋压变形后粗大的β原始晶粒沿金属流动方向变扁、拉长(见图1(a))。层片组织沿变形方向被拉长,垂直于变形方向发生弯折(见图1(b))。

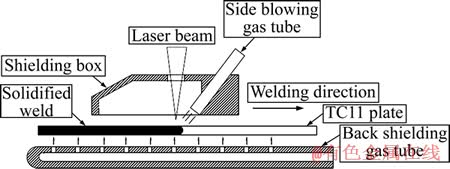

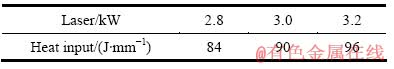

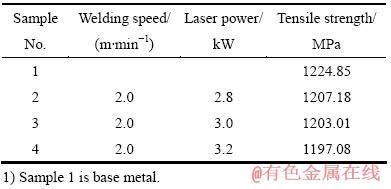

焊接试验所用设备为IPG公司生产的光纤激光器YLS 10000,额定最大输出激光功率为10kW,激光工作头的焦距为300 mm,聚焦后焦斑直径为0.6 mm。焊接前对焊接件进行酸洗去除表面氧化膜,酸洗液配方为5%HF+15%HNO3+80%H2O(体积分数)。焊接采用激光自熔工艺,因为钛合金在高温下吸收氢、氧及氮的能力很强,会引起塑性下降,焊接过程中对焊缝上下表面都使用保护气体进行保护,为了扩大焊缝上方的保护范围,在上方吹气管上增加尾拖,使正反面焊接区域温度超过400 ℃的区域均能得到保护,以达到防止大气污染和抑制等离子体的效果,装置示意图见图2。试验中焊接速度为2 m/min,离焦量为-3 mm,激光功率分别取为2.8、3.0和3.2 kW,以获得不同的焊接热输入(即焊接线能量),激光功率与名义焊接热输入量对应关系,结果如表1所列。

图1 TC11钛合金母材微观组织

Fig. 1 Microstructures of base metal (TC11 titanium alloy)

图2 TC11钛合金板焊接装置示意图

Fig. 2 Sketch of experiment set for laser welding of TC11 titanium alloy plate with gas shielding

表1 TC11钛合金激光焊接时与激池功率对应的名义焊接热输入值

Table 1 Nominal welding heat input values corresponding to laser power at TC11 titanium alloy laser beam welding

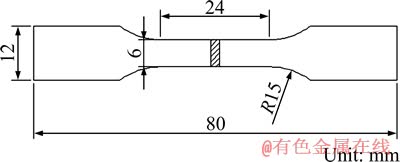

采用金相显微镜和扫描电子显微镜对焊接接头不同区域进行微观组织观察,金相试样所用侵蚀液为Kroll试剂,即3%HF+7%HNO3+90%H2O混合液(体积分数)。拉伸试验采用SANS微机控制电子万能试验机进行,最大试验力100 kN,加载速率为1 mm/min。母材以及焊接接头的室温拉伸试验试样形状尺寸根据GB/T228-2002和GB/T2651-2008设计,其尺寸示意图如图3所示。焊接接头显微硬度的测定采用HVS-10型SCTMC数显维氏硬度计,测试载荷为9.8 N,保持时间为15 s。

图3 拉伸试样尺寸示意图

Fig. 3 Sketch of tensile sample size

2 结果与分析

2.1 焊接接头组织分析

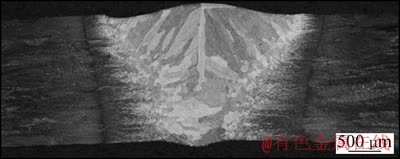

图4所示为焊接速度2 m/min和激光功率3.0 kW条件下得到的TC11钛合金焊接接头宏观金相照片。焊接接头中母材、热影响区和焊缝的界限清晰,焊缝区为粗大的柱状晶组织。焊接过程中,焊缝金属联生结晶于熔合线位置处的半熔化母材晶粒表面,以柱状晶的形式由母材晶粒向焊缝中心生长。钛合金导热性能较差,热导率仅为15.24 W/(m×K),焊接时容易在熔池产生过热,利于粗大柱状晶的生长。

图4 焊接速度2 m/min和激光功率3.0 kW下得到的TC11钛合金焊接接头形貌

Fig. 4 Macrograph of TC11 titanium alloy joint welded at welding speed of 2 m/min and laser power of 3.0 kW

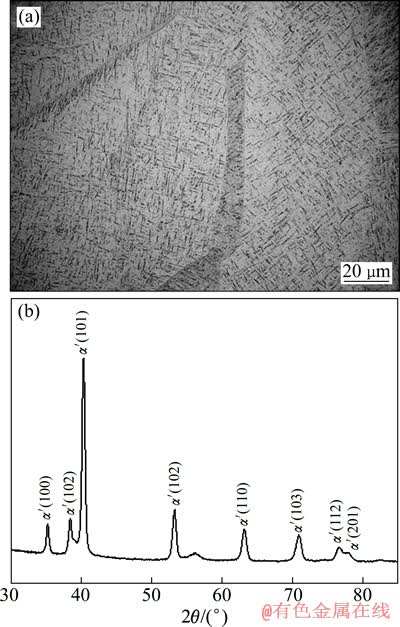

图5(a)所示为焊缝中部柱状晶的微观组织形貌,可以清晰地观察到灰黑色位置的柱状晶晶界及其内部交错分布的针状组织。焊缝XRD分析结果如图5(b)所示,焊缝内部为α′马氏体组织。激光焊接因能量密度高、作用范围小,热量可以更快地向母材传输而具有很大的冷却速度,焊缝金属在凝固生成β柱状晶之后,由于冷却很快,因此,β相来不及通过合金元素的充分扩散而转变成α相,而是发生无扩散转变,生成α′马氏体相。α′马氏体在原始柱状晶内部形核长大,先形成一根或若干相互平行的一次针状马氏体,然后再形成一系列相对细小的二次针状马氏体,遇晶界或一次马氏体而停止,导致焊缝中形成了典型的交错分布的针状组织[21]。

图5 焊接速度2 m/min和激光功率3.0 kW下TC11焊缝显微组织和XRD谱

Fig. 5 Microstructure (a) and XRD patterns (b) of TC11 weld metal welded at welding speed of 2 m/min and laser power of 3.0 kW

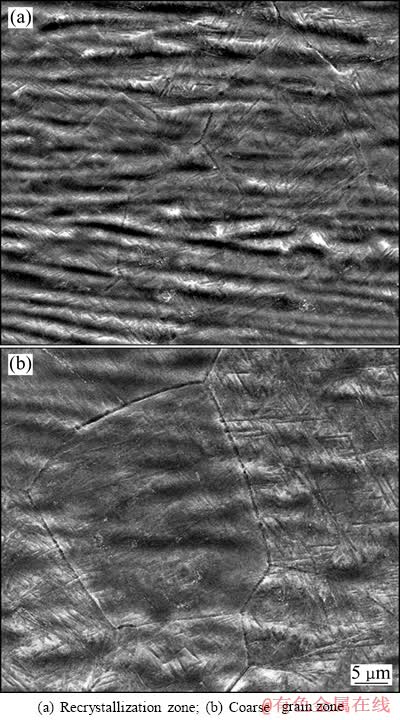

图6所示为焊接速度2 m/min和激光功率3.0 kW下得到的TC11钛合金焊接接头热影响区微观组织。图6(a)所示为再结晶区显微组织,此区域靠近母材,与母材有明显的分界线(见图4),这是因为组织的转变是一个热激活过程,只有达到一定温度后,母材才能发生组织转变。在此区域原始粗大β晶粒组织特征逐渐消失,α+β层片组织层片长大。在层片组织长大的同时发生再结晶,得到细小的再结晶晶粒,此区域为α+β组织。图6(b)所示为粗晶区显微组织,此区域靠近焊缝,再结晶晶粒在过热后进一步长大,得到较大的等轴晶粒组织。因靠近焊缝,此区域在焊接过程中热量输入很高,发生快速冷却,晶粒内为淬火形成的细小马氏体组织,此区域是α+α′组织,至熔合线部分可形成全α′组织。

图6 焊接速度2 m/min和激光功率3.0 kW下TC11钛合金焊接接头热影响区的显微组织

Fig. 6 Microstructures of heat-affected zone (HAZ) of TC11 titanium alloy joint welded at welding speed of 2 m/min and laser power of 3.0 kW

2.2 焊接热输入对接头组织的影响

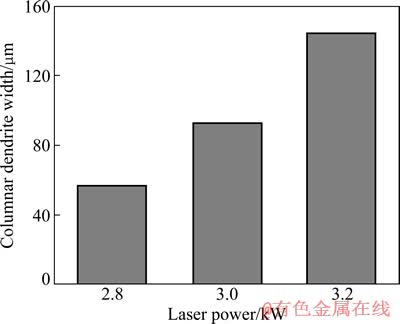

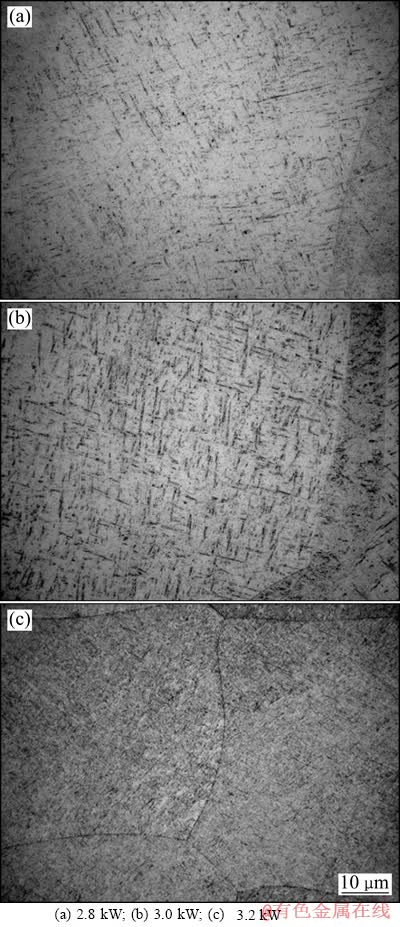

TC11钛合金激光焊接焊缝组织与激光功率即焊接热输入有密切的关系,随着焊接热输入量的增加,焊缝柱状晶尺寸增大,结果如图7所示。

在焊接速度2 m/min、不同激光功率下得到的焊缝显微组织如图8所示。由图8可以看出,柱状晶内部马氏体的形态与焊接热输入密切相关。在较低的热输入量下,焊缝内马氏体密集程度较低,如图8(a)所示。随着热输入的增大,马氏体分布更加密集杂乱,相互之间交错呈网状,如图8(b)和(c)所示。本试验中所采用工艺在焊缝处的热输入均能实现很大的冷却速度,以保证马氏体的转变,马氏体形态的不同主要受马氏体形核影响,这一因素与熔池搅拌有关[22]。马氏体的形核与母相中预先存在的缺陷有紧密联系,预先存在的缺陷可成为马氏体形核的核胚,在较高热输入量下,熔池金属蒸发和等离子体喷射作用加强,焊接熔池受其搅拌作用同时加强,这一过程中焊缝内部容易产生马氏体形核所依赖的缺陷,造成更多的形核核心,马氏体一旦形核立即快速完成生长,从而生长成更加散乱交错的组织。同时伴随着热输入量的增加,焊接过程中合金元素的烧蚀程度加剧,Mo等合金元素含量的降低将引起马氏体转变温度(Ms)升高[23],使马氏体的转变更早开始,但热输入的增加也造成焊接速度减小,抑制了马氏体单向生长,使马氏体分布变得更加密集。

图7 TC11钛合金激光焊接焊缝中柱状晶宽度与激光功率对应关系

Fig. 7 Relationship between columnar dendrite width and laser power in weld metal of TC11 titanium alloy weld by laser beam

图8 焊接速度2 m/min、不同激光功率下焊缝的显微组织

Fig. 8 Microstructures of weld metal at welding speed of 2 m/min and different laser powers

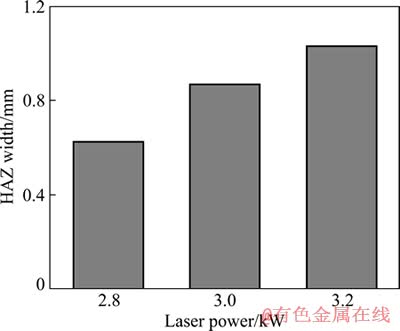

焊接热输入的改变对焊接接头热影响区的影响主要体现在热影响区的宽度和粗晶区的晶粒尺寸上。在焊接过程中,随着焊接热输入的增加,由焊缝向母材方向传递的热量增大,在更远的地方原子被激活发生组织转变,导致热影响区的宽度增加,热影响区宽度与激光功率的关系如图9所示。

图9 热影响区宽度与激光功率对应关系

Fig. 9 Relationship between HAZ width and laser power

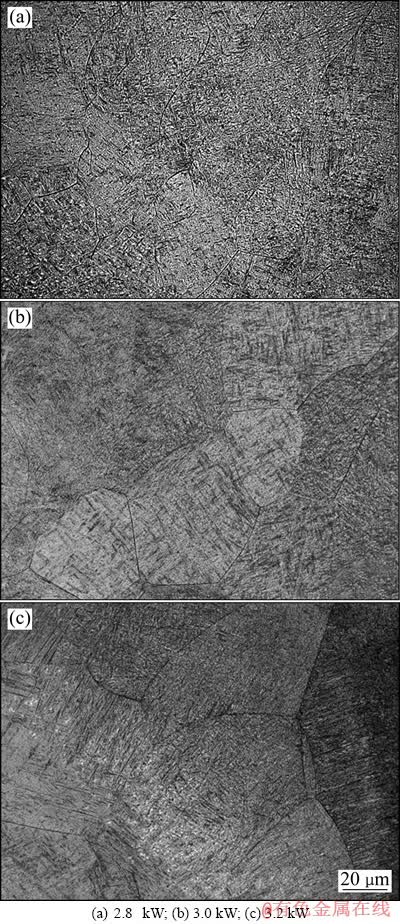

图10所示为TC11钛合金焊接接头在不同热输入量下粗晶区的显微组织。由于热量的增加,高热输入量时的能量更大,可以满足晶粒晶界迁移和原子扩散通过晶界,再结晶晶粒在形核后更容易长大,形成粗大的晶粒,导致粗晶区晶粒尺寸显著增加。

2.3 接头力学性能分析

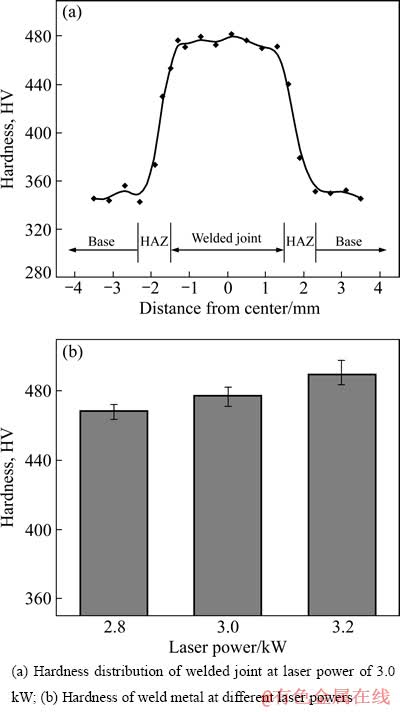

图11(a)所示为焊接速度2 m/min激光功率3.0 kW下TC11钛合金焊接接头维氏硬度曲线。TC11钛合金母材组织硬度值为350 HV,从母材到焊缝硬度值不断增加。热影响区靠近母材区域为不完全的再结晶区,再结晶生成的细小晶粒使硬度值增加。随着吸收热量的增加,热影响区也发生马氏体转变,并且α′转变量随靠近焊缝增加,至熔合线完全转变为α′组织,引起硬度值继续增大。伴随着热输入量的增加,焊缝硬度呈现增加的趋势,如图11(b)所示。这是由于随着热输入量的增加,焊缝马氏体更加密集杂乱,提高焊缝硬度。

图10 焊接速度2 m/min、不同激光功率下热影响区粗晶区的显微组织

Fig. 10 Microstructures of coarse grain zone in HAZ at welding speed of 2 m/min and different laser powers

表2所列为焊接速度2 m/min下不同激光功率焊接试样的拉伸力学性能。焊接试样的抗拉强度略低于母材的,达到母材强度97 %以上,焊接接头断裂位置均为热影响区,原因是焊接热影响区不同部位所受热作用不一致,造成内部组织分布不均匀,靠近母材部分为α+β组织,随靠近焊缝组织向α+α′转变,至熔合线完全转变为α′组织,虽然硬脆的α′马氏体提高晶内强度,但此时因组织的不均匀,晶间变得更加薄弱,导致裂纹提前萌生。同时接头在焊缝与热影响区交汇区域出现微小的下凹,如图4所示,造成承载面积降低,对于薄板试样易由于此位置应力增加而引起断裂。母材伸长率7%,为低塑性材料;焊接试样伸长率为3%,其塑性较母材的显著下降,焊接接头热影响区的粗晶区晶粒粗大,对该区域的塑性产生不利影响。

图11 2 m/min焊接速度下焊接接头硬度

Fig. 11 Hardness of welded joints at weld speed of 2 m/min

表2 焊接接头的拉伸性能

Table 2 Tensile strength of welded joints

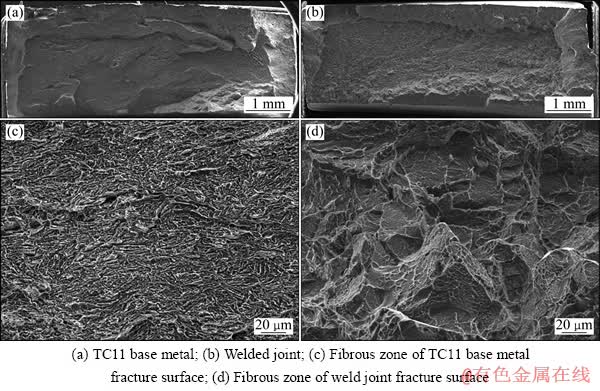

图12(a)和(b)所示分别为母材和焊接速度2 m/min激光功率3.0 kW下焊接接头室温拉伸断口整体形貌。两者均表现出低塑性材料的断裂特征,断口仅由纤维区和剪切唇构成。二者区别为母材断口纤维区表现为韧窝断口特征,如图12(c)所示;焊接试样断口为沿晶断口,断口表面呈冰糖状,同时带有低程度的韧窝特征,如图12(d)所示。改变激光功率得到的焊接接头断口整体相貌相同,试样断裂位置为均热影响区粗晶区,此区域发生马氏体转变,硬脆马氏体相引起晶内强度显著提高,高于晶界强度,使材料发生沿晶脆性断裂。

图12 TC11钛合金断口形貌

Fig. 12 Fracture morphologies of TC11 titanium alloy

3 结论

1) TC11钛合金纯激光焊接焊缝为粗大柱状晶组织,晶粒内部在冷却过程中形成交错的α′马氏体组织。热影响区由母材至熔合线发生α+β到α+α′再到α′相的转变。

2) 焊接热输入对焊接接头组织有显著影响,随热输入量的增加,焊缝柱状晶的尺寸变大,内部马氏体分布更加密集杂乱;热影响区宽度增加,粗晶区晶粒尺寸显著变大。

3) 焊接接头硬度从母材到焊缝呈现增加趋势,至焊缝处达到最高;焊缝硬度随热输入量的增加而增大;钛合金激光焊接接头抗拉强最低达到母材的97%,拉伸试样均断裂于热影响区,接头的微观断口形貌表现为沿晶断裂特征,塑性明显下降,低于母材的50%。

REFERECES

[1] L tjering G, Williams J C. Titanium[M]. Berlin: Springer, 2007: 1-12.

tjering G, Williams J C. Titanium[M]. Berlin: Springer, 2007: 1-12.

[2] TAN Li-jun, YAO Ze-kun, ZHOU Wei, GUO Hong-zhen, ZHAO Yan. Microstructure and properties of electron beam welded joint of Ti-22Al-25Nb/TC11[J]. Aerospace Science and Technology, 2010, 14: 302-306.

[3] 古 一, 戚延龄, 夏长清, 李学雄, 王志辉. 热暴露对TC11钛合金组织和力学性能的影响[J]. 中国有色金属学报, 2013, 23(4): 997-1004.

GU Yi, QI Yan-ling, XIA Chang-qing,LI Xue-xiong,WANG Zhi-hui. Effects of thermal exposure on microstructure and mechanical properties of TC11 titanium alloy[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(4): 997-1004.

[4] 王鼎春. 高强钛合金的发展与应用[J]. 中国有色金属学报, 2010, 20(S1): s958-s963.

WANG Ding-chun. Development and application of high-strength titanium alloys[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s958-s963.

[5] 万晓慧, 杜欲晓. TC11钛合金钨极氩弧焊工艺试验研究[J]. 航空制造技术, 2011, 16: 78-80.

WANG Xiao-hui, DU Yu-xiao. Argon tungsten-arc welding process research on TC11 titanium alloy[J]. Aeronautical Manufacturing Technology, 2011, 16: 78-80.

[6] YANG Hang-hang, YAO Ze-kun, GAO Jun, GUO Hong-zhen, LIU Ying-ying, WANG Min. Influence of gradient heat treatment on microstructure and microhardness in weld seam of Ti3Al/TC11 dual alloys[J]. Rare Metal Materials and Engineering, 2010, 39(1): 22-26.

[7] 康文军. TC11材料的电子束焊接[D]. 西安: 西北工业大学, 2005: 27-53.

KAN Wen-jun. Electron beam welding of TC11 alloy[D]. Xi’an: Northwestern Polytechnical University, 2005: 27-53.

[8] 王世清, 刘金合, 温国栋, 姜玉恒, 马正斌. 10 mm厚TC11钛合金电子束焊接组织性能和残余应力[J]. 稀有金属材料与工程, 2013, 42(6): 1150-1153.

WANG Shi-qing, LIU Jin-he, WEN Guo-dong,JIANG Yu-heng, MA Zheng-bing. Microstructure, mechanical properties and residual stress of electron beam welded TC11 alloy joint of 10 mm thickness[J]. Rare Metal Materials and Engineering, 2013, 42(6): 1150-1153.

[9] 陈 涛, 马铁军, 康文军, 阮成勇, 杨思乾. TC11线性摩擦焊接头的组织特征及力学性能[J]. 材料科学与工艺, 2009, 17(1): 191-195.

CHEN Tao, MA Tiej-un, KANG Wen-jun,RUAN Cheng-yong,YANG Si-qian. Mechanical properties and microstructure features of linear friction welded TCll joint[J]. Materials Science and Technology, 2009, 17(1): 191-195.

[10] LANG B, ZHANG T C, LI X H, GUO D L. Microstructural evolution of a TC11 titanium alloy during linear friction welding[J]. J Mater Sci, 2010, 45: 6218-6224.

[11] 季亚娟, 张田仓, 李晓红. TC11/TC17钛合金线性摩擦焊接头组织与性能[J]. 航空制造技术, 2011(8): 66-69.

JI Ya-juan, ZHANG Tian-cang, LI Xiao-hong. Structure and mechanical property of TC11/TCl7 linear friction[J]. Aeronautical Manufacturing Technology, 2011(8): 66-69.

[12] ZHANG Li, GOBBI S L, NORRIS I, ZOLOTOVSKR S, RICHTER K H. Laser welding techniques for titanium alloy sheet[J]. Journal of Materials Processing Technology, 1997, 65: 203-208.

[13] ZHANG Li, GOBBI S L. Laser welding for lightweight structures[J]. Journal of Materials Processing Technology, 1997, 70: 137-144.

[14] AKMAN E, DEMIR A, CANEL T, SINMAZCELIK T. Laser welding of Ti6Al4V titanium alloys[J]. Journal of Materials Processing Technology, 2009, 209: 3705-3713.

[15] CHEN Hui-chi, ANDREW J, PINKERTON, LI Lin. Fibre laser welding of dissimilar alloys of Ti-6Al-4V and Inconel 718 for aerospace applications[J]. Journal of Materials Processing Technology, 2009, 209: 3705-3713.

[16] BLACKNURN J E, ALLEN C M, HILTON P A, LI L, HOQUE M I, KHAN A H. Modulated Nd:YAG laser welding of Ti-6Al-4V[J]. Science and Technology of Welding and Joining, 2010, 15(5): 433-439.

[17] 赵锡龙, 宋 旭, 张建勋. TC4钛合金激光焊接接头组织与性能[J]. 中国有色金属学报, 2012, 22(2): 388-393.

ZHAO Xi-long, SONG Xu, ZHANG Jian-xun. In-situ investigation on mechanical behavior of laser-welded joint for TC4 titanium alloy [J]. The Chinese Journal of Nonferrous Metals, 2012, 22(2): 388-393.

[18] LIU J, WATABABE I, YOSHIDA K, ATSUTA M. Joint strength of laser-welded titanium[J]. Dental Materials, 2002, 18: 143-148.

[19] QI Yun-lian, DENG Ju, HONG Quan, ZENG Li-ying. Electron beam welding, laser beam welding and gas tungsten arc welding of titanium sheet[J]. Materials Science and Engineering A, 2000, 280: 177-181.

[20] E.A.鲍利索娃. 钛合金金相学[M]. 陈时卿, 译. 北京: 国防工业出版社, 1986: 206-224.

BORISOVA Е А. Titanium alloy metallography[M]. CHEN Shi-qin, transl. Beijing: National Defence Industry Press, 1986: 206-224.

[21] 程东海, 黄继华, 林海凡, 张 华. TC4钛合金激光拼焊接头显微组织及力学性能分析[J]. 焊接学报, 2009, 30(2): 103-106.

CHEN Dong-hai, HUANG Ji-hua, LIN Hai-fan, ZHANG Hua. Microstructure and mechanical analysis of Ti26Al24V laser butt weld joint[J]. Transactions of the China Welding Institution, 2009, 30(2): 103-106.

[22] 杨 静, 程东海, 黄继华, 张 华, 赵兴科, 郭和平. TC4钛合金激光焊接接头组织与性能[J]. 稀有金属材料与工程, 2009, 38(2): 259-262.

YANG Jing, CHENG Dong-hai, HUANG Ji-hua, ZHANG Hua, ZHAO Ke-xing, Guo He-ping. Microstructure and mechanical properties of Ti-6Al-4V joints by laser beam welding[J]. Rare Metal Materials and Engineering, 2009, 38(2): 259-262.

[23] 邓安华. 钛合金的马氏体相变[J]. 上海有色金属, 1999, 20(4): 193-199.

DENG An-hua. Martensitic transformation of titanium alloys[J]. Shanghai Nonferrous Metals, 1999, 20(4): 193-199.

(编辑 龙怀中)

基金项目:上海航天技术研究院-上海交大航天先进技术联合研究中心项目(USCAST2012-18)

收稿日期:2014-04-20;修订日期:2014-10-13

通信作者:黄 坚,副教授,博士;电话:021-54748940-8020;E-mail:jhuang@sjtu.edu.cn