文章编号:1004-0609(2007)11-1744-06

超塑预处理01420铝锂合金层状晶粒组织的形成机制

叶凌英,张新明,刘颖维,杜予晅,罗智辉

(中南大学 材料科学与工程学院,长沙 410083)

摘 要:采用形变热处理法制备01420铝锂合金细晶板材,研究时效第二相对位错分布和层状再结晶组织形成的影响。结果表明:时效第二相沿板材法向呈梯度分布,在表面层分布均匀且含量较大,而在中心层主要沿平行轧制方向分布且含量较小;第二组粒子的这种分布方式导致轧制过程中在其周围形成的高应变区域也呈梯度分布,这是导致层状再结晶组织形成的主要原因;板材表面层为细小等轴的再结晶晶粒,平均粒径约为10 μm;板材中心层再结晶晶粒呈长条状,平均尺寸约为30 ?m×12 ?m;各层约占板材总厚度的1/3。

关键词:01420 铝锂合金;层状晶粒组织;晶粒细化;形变热处理;粒子激发形核

中图分类号:TG 166.3 文献标识码:A

Formation mechanism of layered grain structure during

superplastic pre-treatment in 01420 Al-Li alloy

YE Ling-ying, ZHANG Xin-ming, LIU Ying-wei, DU Yu-xuan, LUO Zhi-hui

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: Fine grained 01420 Al-Li alloy sheet was produced by thermo-mechanical processing. The precipitation behavior of the second phase particles and their effects on the distribution of dislocations and gradient recrystallized grains were investigated. The results show that after aging, a gradient distribution of the large particles through the thickness occurs. The particles in the surface layer (SL) distribute homogeneously with larger content whereas the particles in the center layer (CL) mainly distribute parallel to the rolling direction with smaller content. The subsequent rolling results in a corresponding gradient distribution of high strained regions around these particles, which is the main reason for the formation of the gradient grain structure. The SL contains a fine, equiaxed grain structure with an average grain diameter of 10 μm whereas CL contains coarse elongated dimension with average grain size of 30 ?m ×12 ?m, each layer accounts for about 1/3 of the whole thickness.

Key words: 01420 Al-Li alloy; layered grain structure; grain refinement; thermo-mechanical processing; particle stimulated nucleation (PSN)

基于粒子激发再结晶形核机制的形变热处理方法已经成功应用在7×××[1]、Al-Mg-X[2]、Al-Li-X[3?5]的细晶超塑预处理中,并可实现工业化生产。该类方法的基本工艺路线为:固溶处理→过时效→大压下率轧制变形→静态再结晶。通过对过时效后的样品进行大压下率轧制变形,从而在大尺寸第二相粒子(一般粒径大于1 μm)周围形成强烈的变形区,在其后的再结晶退火过程中这些强应变区域便可能成为再结晶的形核位置,这个过程便是粒子激发再结晶形核(Particle stimulated nucleation of recrystallization, PSN)[6?9]。基 于PSN机制的晶粒细化法在01420铝锂合金的超塑 预处理中已有应用,获得的最细晶粒尺寸约为8~10 μm[10?12],但采用该方法细化铝锂合金晶粒时所获得的晶粒组织通常很不均匀,往往会获得粗大的长条状晶粒或沿板材的法向呈层状分布的晶粒组织[13],这种组织使板材具有各向异性并且影响超塑变形行 为[14?15]。现有的研究报道主要集中在研究这种组织不均匀性对超塑变形行为的影响[16?18],关于这种不均匀组织形成的原因及其影响因素的研究报道很少。过时效是PSN机制细化晶粒工艺中的核心工序,因此,本文作者通过观察01420铝锂合金第二相粒子的析出行为及其对位错分布、再结晶组织的影响,以探寻这种不均匀晶粒组织的形成机制。

1 实验

实验用材料为01420铝锂合金热轧板,板厚8.5 mm,化学成分(质量分数,%)为:5.2 Mg, 2.1 Li, 0.12 Zr, 0.06 Fe, 0.04 Si, 0.002 Ti, 余量为Al。合金在空气炉中经470 ℃固溶处理2 h后,分别在120、200和300 ℃温度下进行12~48 h不同保温时间的时效处理,然后将样品在400 ℃保温4 h后立即进行轧制,轧辊直径350 mm,得到厚度约1.6 mm的板材,轧制时通过控制道次变形量以保证变形区几何形状系数在2~3之间,使板材变形均匀。最后将轧制得到的样品在盐浴炉内进行510 ℃,30 min再结晶退火。

固溶处理后及再结晶退火后的样品经抛光和Keller试剂腐蚀后,在XJP?6A型光学显微镜下观察分析。采用截距法测量晶粒度,测量时每条直线所截的晶粒数不少于50个。再结晶晶粒的平均尺寸按照国家标准GB/T 3246.1—2000进行分析计算。过时效后的样品经机械抛光和Keller试剂腐蚀后,在KYKY?2800型扫描电镜下利用二次电子像观察样品中的第二相粒子。用于透射电镜观察的试样取自时效后样品的板平面,在TECNAI G220型透射电境下观察第二相粒子的形貌及分布。过时效后样品的定性物相分析在D/max 2550 X射线衍射仪上进行。

2 实验结果

2.1 显微组织观察

8.5 mm厚的01420铝锂合金原始热轧板经470 ℃固溶处理2 h后的三维金相组织如图1(a)所示。根据组织特征可将其沿板材法向划分为3层,各层约占板材总厚度的1/3。固溶处理过程中合金未发生明显再结晶,两个表面层仍为典型的轧制变形过程中产生的纤维状组织,腐蚀后晶粒沿轧制方向呈细长条状,晶粒尺寸沿板法向约为5 μm;而板材的中心层变形组织较粗,可清楚地观察到该层由一些平行轧制方向的粗长条状的晶粒组成,沿板法向晶粒尺寸约为10~30 μm,沿轧制方向和横向约为几百个微米。图1(b)所示为固溶处理后的样品经300 ℃时效48 h后,81%轧制变形得到1.6 mm厚的板材,再经过510 ℃,30 min盐浴再结晶退火后得到的晶粒组织。观察发现,晶粒组织与样品固溶后的组织有类似的层状分布现象,两个表面层的晶粒细小且趋近等轴,晶粒度在10 ?m左右;中心层晶粒组织相对粗大呈长条状,长度方向晶粒平均尺寸约30 ?m,板法向方向晶粒尺寸约为12 ?m;各层所占厚度约为板材总厚度的1/3(见图1(b))。

图1 01420铝锂合金的典型微观组织

Fig.1 Typical microstructures of 01420 Al-Li alloy: (a) Original 8.5 mm thick plate after solution treated at 470 ℃ for 2 h; (b) Thermo-mechanical processed to 1.6 mm thick sheet

2.2 第二相观察

图2(a)~(c)所示为不同时效工艺下01420铝锂合金板平面的典型析出相,样品取自表面层。合金经120 ℃时效12 h后,析出直径10~30 nm的球形δ′(Al3Li)强化相(见图2(a))。提高时效温度可以获得明显粗大的析出相,如图2(b)和(c)所示,合金在200 ℃时效48 h,第二相粒子尺寸在0.1~0.5 μm,而在300 ℃时效48 h,析出大量尺寸接近1 μm的第二相粒子。

图2 01420铝锂合金第二相的TEM形貌

Fig.2 TEM morphologies of second phase particles in surface layer: (a) Aged at 120 ℃, 12 h; (b) Aged at 200 ℃, 48 h; (c) Aged at 300 ℃, 48 h

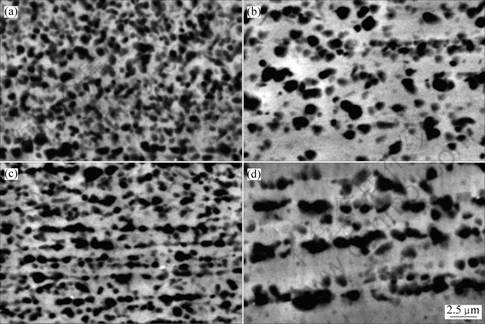

图3所示为合金经300 ℃时效48 h以及轧制前对其进行400 ℃保温4 h后纵截面第二相的二次电子像,图3(a)和(b)所示形貌取自原始板材的表面层,图3(c)和(d)所示形貌取自中心层,对比图3(a)和(c)可以看出,合金经300 ℃时效48 h,第二相在样品的表面层和中心层的析出行为区别较大。在样品表面层,第二相均匀地分布于基体中,而样品中心层中的第二相则主要在平行于轧制方向上呈条带状分布。由于本实验采用的原始板坯为01420铝锂合金热轧板,由图1(a)可见,固溶后的晶粒组织是典型轧制后的纤维组织,晶粒沿轧制方向呈细长条状分布,且可能在先前的热轧过程中由于板材表面与轧辊接触而温度下降较大,表面层的温度要低于中心层的,致使变形后板材的表面层与中心层相比,由于变形温度低而具有更高的储能。固溶处理并没有使这些储能全部释放出来,那么时效过程中表面层这些平行于轧制方向的晶界以及残留的变形组织由于具有较高的储能是第二相易于形核和长大的位置。300 ℃时效时,如图3(a)所示,在样品的表面层第二相可以均匀地形核,粒子分布比较均匀。而在样品的中心层,固溶后的组织主要由一些长条状的晶粒组成,不像表面层那样保留了较大程度的变形组织,那么在时效的过程中,如图3(c)所示,第二相主要沿着这些晶粒的晶界析出,而在晶粒内部析出比较少,所以第二相主要呈条带状平行轧制方向分布。

图3 01420铝锂合金的第二相SEM二次电子像

Fig.3 SEM secondary electron images of second phase particles in 01420 Al-Li alloy: (a) Aged at 300 ℃ for 48 h in surface layer; (b) Aged at 300 ℃ for 48 h+400 ℃ for 4 h in surface layer; (c) Aged at 300 ℃ for 48 h in center layer; (d) Aged at 300 ℃ for 48 h+400 ℃ for 4 h in center layer

图3(b)和(d)所示为合金经300 ℃时效48 h后,又经400 ℃保温4 h后的第二相形貌像。可见轧制前炉中保温对第二相大小及分布有较大的影响,大粒子进一步粗化,尺寸由0.8~1.0 μm长大到1.0~1.2 μm;有一些小粒子则被熔化,尤其是在样品的中心层,晶内的粒子熔化而晶界的粒子则显著粗化,加剧了中心层第二相的条带状分布趋势(图3(d))。其实这一过程可以视为一个双级时效过程,这表明后一级较高温度的保温过程可以促进大粒子进一步的粗化。针对本实验中01420铝锂合金,前期的研究结果表明第二相至少在0.8 ?m以上才能起到激发形核作用[20]。图4给出不同时效状态下表面层与中心层直径大于0.8 μm的第二相粒子体积分数,合金经300 ℃时效48 h后,表面层和中心层的大尺寸第二相(>0.8 μm)的体积分数分别为4.1%和2.9%,再经400 ℃保温4 h后,所对应的体积分数分别增加至4.8%和3.7%。

图4 不同时效状态下表面层与中心层直径大于0.8 μm的第二相体积分数

Fig.4 Volume fraction of second phase particles larger than 0.8 μm in surface and center layer produced by various aging treatment

图5所示为01420铝锂合金在不同时效状态下的XRD衍射分析结果。合金经300 ℃时效48 h与经300 ℃,48 h+400 ℃,4 h双级时效所得到的衍射谱线基本一致,结合文献[11?12]对该合金在300 ℃过时效状态粒子相组成的分析结果,可以判定两种时效状态下的大尺寸的第二相主要为S(Al2MgLi)相和β(Mg2Al3)相,小颗粒的为Al3Zr相,其中还有少量的大粒子是在固溶处理过程中没有溶解的富Fe、Si杂质相。对比上下两条谱线也可以看出,后一级较高温度的保温并未引起合金相组成的改变,导致第二相大小和分布产生变化的主要原因是第二相的粗化与溶解。

图5 01420铝锂合金不同时效状态下的X射线衍射谱

Fig.5 XRD patterns of 01420 Al-Li alloy produced by different treatments: (a) Aged at 300 ℃ for 48 h; (b) Aged at 300 ℃ for 48 h+400 ℃ for 4 h

3 讨论

人们对第二相粒子对再结晶行为的影响进行较为深入和广泛的研究。一般认为,大粒子(直径大于1 μm)、间距较大的粒子可以促进再结晶,因为变形过程中在这些大粒子周围形成的强变形区可以为再结晶提供形核点和驱动力;空间紧密分布的小粒子(沉淀或弥散粒子)对大、小角度晶界的移动都有钉扎作用(Zener阻力),从而抑制再结晶过程,阻止再结晶晶粒长大[6?9]。根据第二相对再结晶的影响规律,人们便可以通过合金化或热处理工艺来控制第二相的大小及分布,从而控制合金再结晶晶粒大小及织构[6, 9]。采用粒子激发再结晶形核机制细化晶粒的方法中,时效的主要目的是析出大尺寸第二相粒子。如前所述,合金在低温(<200 ℃)时效时,析出的第二相粒子尺寸小于0.5 ?m(见图1(a)和(b)),难以起到激发再结晶形核作用,而当高温(300 ℃)时效处理后合金析出大量尺寸大于0.8 ?m的第二相(见图1(c))。Humphreys等[6]认为,假设大于临界尺寸dg(本实验中为0.8 ?m)的每个第二相粒子都可以成功激发一个再结晶形核,那么最终的再结晶晶粒尺寸(DN)可以近似表示为

可见第二相的大小及分布将直接决定最终再结晶晶粒的大小。本实验中,由于第二相在原始板坯的表面层及中心层的体积分数及分布形式不同导致了最终的再结晶晶粒组织呈层状分布。第二相的不均匀分布对位错分布及最终的再结晶组织的影响如图6所示,在样品的表面层,大尺寸第二相均匀分布于基体中,这些大粒子主要由S(Al2MgLi)相和β(Mg2Al3)相组成,而S相在轧制过程中往往会破碎成微小的粒子[12, 20]。因此在大尺寸粒子周围形成的高位错密度区域也会均匀地分布于基体中,这样与样品的中心层相比,表面层在再结晶过程中可以提供均匀的新晶粒的形核位置,且破碎的S相也相对均匀的分布于基体中,可以阻碍晶界的迁移,所以表面层的晶粒组织与中心层相比要细小、等轴化。而在样品的中心层,大尺寸的第二相主要沿与轧制方向平行的晶界析出(见图3(c)、(d)),这样分布的粒子容易导致扁平状晶粒的形成[19]。因为轧制过程中在这些大尺寸粒子周围形成的高位错密度区域易沿着轧制方向呈条带状分布,而破碎的S相大部分也会沿轧制方向分布于基体内,形成如图6中轧制环节中所示的小粒子带。在接下来的再结晶退火过程中,这些呈条带分布的高位错密度区域便成为再结晶新晶粒的形核位置,而破碎的S相粒子将阻碍晶界在板法向方向上的移动,于是形成粗大的长条状晶粒。

图6 表面层与中间层晶粒组织形成示意图

Fig. 6 Schematic evolution of grain structures in surface and center layer

由于并不是每一个大于临界尺寸的第二相都可以成功激发一个再结晶晶粒形核,前期研究表明粒子激发再结晶形核的效率较低,在1/20左右[20]。由图6可知,在样品的表面层可以激发再结晶形核的第二相的含量为4.8%(体积分数),明显大于中心层的3.7%,这样在变形过程中,在板材的表面层可以获得更多的具有高位错密度的区域,在再结晶的过程中可以提供更多的形核位置,细化最终的再结晶晶粒组织。

另外,由于样品的表面层与轧辊接触,轧制过程中温降会比中心层大,所以在样品的表面层由于变形温度低可以获得更高的储能。再加上轧辊对合金表面也存在剪切变形作用可以使晶粒趋近等轴化[13],这加剧了表面层与中心层晶粒组织的梯度分布。

4 结论

1) 01420铝锂合金经300 ℃时效48 h后,析出的大尺寸第二相沿板材的法向呈梯度分布,第二相在板材的表面层分布均匀且含量较大,而在板材的中心层则主要沿原始晶界分布且含量较小。

2) 轧制前对已进行300 ℃时效48 h后的样品再经400 ℃保温4 h,可以使已析出的大尺寸第二相显著粗化,表面层和中心层的含量分别由4.1%和2.9%增加至4.8%和3.7%(体积分数),而一些小粒子则被回熔。

3) 第二相沿板材的板法向呈梯度分布,导致轧制变形后在这些粒子周围形成的高位错密度区域也呈梯度分布,这是最终形成层状再结晶组织的主要原因。板材两个表面层的再结晶组织细小等轴,晶粒度约为10 μm,中心层是长条状晶粒其长度方向平均尺寸30 ?m左右,板法向方向尺寸约为12 ?m,各层约占板材总厚度的1/3。

REFERENCES

[1] Smolej A, Gnamu? M, Sla?ek E. The influence of the thermomechanical processing and forming parameters on superplastic behaviour of the 7475 aluminium alloy[J]. Journal of Materials Processing Technology, 2001, 118: 397?402

[2] Troeger L P, Starke Jr E A. Particle-stimulated nucleation of recrystallization for grain-size control and superplasticity in an Al-Mg-Si-Cu alloy[J]. Mater Sci Eng A, 2000, 293(1): 19?29

[3] Wadsworth J, Henshall C A, Nieh T G. Superplastic aluminum-lithium alloys[C]//Baker C, Gregson P J, Harris S J. Aluminum-Lithium Alloys III. Oxford: Oxford University Press, 1985: 199?212

[4] Nieh T G, Wadsworth J, Sherby O D. Superplasticity in metals and ceramics[M]. Cambridge: Cambridge University Press, 1997

[5] DU Yu-xuan, ZHANG Xin-ming, YE Ling-ying, LUO Zhi-hui. Superplastic behavior of Al-Cu-Li based alloy[J]. Trans Nonferrous Met Soc China, 2006, 16(Special 3): s1379?s1382

[6] Humphreys F J, Hatherly M. Recrystallization and related annealing phenomena[M]. 2nd ed. Oxford: Pergamon Press, 2004.

[7] Humphreys F J. Particle stimulated nucleation of recrystallization at silica particles in nickel[J]. Scripta Materials, 2000, 43(7): 591?596

[8] Humphreys F J. Nucleation in recrystallization[J]. Materials Science Forum, 2004, 467/470(1): 107?116.

[9] Doherty R D, Hughes D A, Humphreys F J, Jonas J J, Juul Jensen D, Kassner M E, King W E, McNelley T R, McQueen H J, Rollett A D. Current Issues in recrystallization: a review[J]. Mater Sci Eng A, 1997, 238(2): 219?274

[10] 李献民, 崔建忠, 胡忠式, 徐祝萍, 周清燕. 01420合金的超塑变形行为[J]. 材料研究学报, 2000(6): 318?320.

LI Xian-min, CUI Jian-zhong HU Zhong-shi, XU Zhu-ping, ZHOU Qing-yan. Superplastic deformation behavior of 01420 alloy[J]. Chinese Journal of Materials Research, 2000(6): 318?320.

[11] 王淑云, 张晓博, 崔建忠, 张彩培. 两种Al-Mg合金超塑性能的对比研究[J]. 热加工工艺, 1997(1): 20?22.

WANG Shu-yun, ZHANG Xiao-bo, CUI Jian-zhong, ZHANG Cai-pei. Comparison on the superplasticity of two Al-Mg alloys[J]. Hot Working Technology, 1997(1): 20?22.

[12] 王淑云, 张晓博, 崔建忠, 张彩培. Al-Mg-Li-Zr合金超塑性能的研究[J]. 轻金属, 1997(5): 50?52.

WANG Shu-yun, ZHANG Xiao-bo, CUI Jian-zhong, ZHANG Cai-pei. Studies of superplasticity in an Al-Mg-Li-Zr alloy[J]. Light Metal, 1997(5): 50?52.

[13] 杜予晅. 铝锂合金超塑性板材的制备原理与技术[D]. 长沙: 中南大学, 2006.

DU Yu-xuan. Principles and techniques in preparation of superplastic Al-Li sheets[D]. Changsha: Central South University, 2007.

[14] Chaturvedi M C, Kashyap B P, Fan W. Microtextural evolution during superplastic deformation of AA 8090 Al-Li alloy[J]. Mater Sci Technol, 2001, 17( 3): 237?248.

[15] Fan W, Kashyap B P, Chaturvedi M C. Anisotropy in flow and microstructural evolution during superplastic deformation of a layered-microstructured AA 8090 Al-Li alloy[J]. Mater Sci Eng A, 2003, 349(2): 166?182.

[16] Fan W, Kashyap B P, Chaturvedi M C. Effect of composite-like microstructure on superplastic flow and concurrent microstructural evolution in AA8090 Al-Li alloy[J]. Canadian Metallurgical Quarterly, 2003, 42(2): 219?230.

[17] Fan W, Kashyap B P, Chaturvedi M C. Effect of layered microstructure and its evolution on superplastic behaviour of AA 8090 Al-Li alloy[J]. Mater Sci Technol, 2001, 17(4): 439?445.

[18] Fan W, Kashyap B P, Chaturvedi M C. Effects of strain rate and test temperature on flow behaviour and microstructural evolution in AA 8090 Al-Li alloy[J]. Mater Sci Technol, 2001, 17(4): 431?438.

[19] DU Yu-xuan, ZHANG Xin-ming, YE Ling-ying, LUO Zhi-hui. Evolution of grain structure in AA2195 Al-Li alloy plate during recrystallization[J]. Trans Nonferrous Met Soc China, 2006, 16(2): 321?326.

[20] 张新明, 叶凌英, 杜予晅, 罗智辉. 01420铝锂合金的粒子激发再结晶形核[J]. 中南大学学报(自然科学板), 2007, 38(1): 19?23.

ZHANG Xin-ming, YE Ling-ying, DU Yu-xuan, LUO Zhi-hui. Particle stimulated nucleation of recrystallization in 01420 Al-Li alloy[J]. Journal of Central South University (Science and Technology), 2007, 38(1): 19?23.

基金项目:国际科技合作重点资助项目(2006DFA53250);国家重大基础研究发展规划资助项目(2005CB623706)

收稿日期:2007-03-06;修订日期:2007-07-03

通讯作者:叶凌英,博士研究生;电话:0731-8830265;传真:0731-8830265;E-mail: yelingying_1981@163.com

(编辑 龙怀中)